Fabrication of Structured Polymer Films Using Vapor Deposition

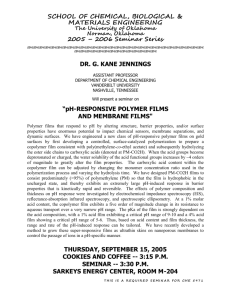

advertisement