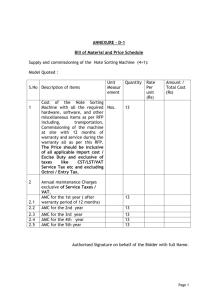

anti-vibration mountings

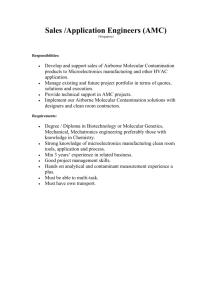

advertisement