Solution to chapter 9

advertisement

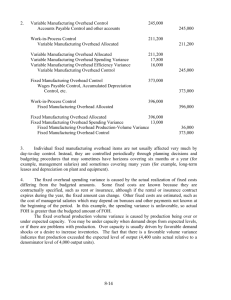

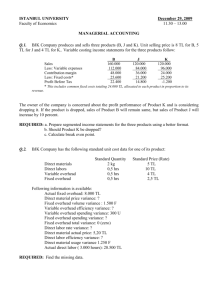

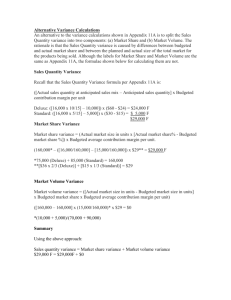

Solution to chapter 9 1. Standard costs are essentially budgeted amounts on a per-unit basis. Unit standards serve as inputs in building budgets. 2. Unit standards are used to build flexible budgets. Unit standards for variable costs are the variable cost component of a flexible budgeting formula. 3. The quantity decision is determining how much input should be used per unit of out- put. The pricing decision determines how much should be paid for the quantity of input used. 4. Historical experience is often a poor choice for establishing standards because the his- torical amounts may include more inefficiency than is desired. 5. Engineering studies can serve as an important input to standard setting. Many feel that this approach by itself may produce standards that are too rigorous. 6. Idealstandards are perfection standards, representing the best possible outcomes. Currently attainable standards are standards that are challenging but allow some waste. Currently attainable standards are often chosen because many feel they tend to motivate rather than frustrate. 7. Standard costing systems improve planning and control and facilitate product costing. 8. By identifying standards and assessing deviations from the standards, managers can locate areas where change or corrective behavior is needed. 9. Actual costing assigns actual manufacturing costs to products. Normal costing assigns actual prime costs and estimated overhead costs to products. Standard costing assigns estimated manufacturing costs to products. 10. A standard cost sheet presents the standard amount of inputs and the price for each in- put and uses this information to calculate the unit standard cost. 11. Managers generally tend to have more control over the quantity of an input used rather than the price paid per unit of input. 12. A standard cost variance should be investigated if the variance is material and if the benefit of investigating and correcting the deviation is greater than the cost. 13. Control limits indicate how large a variance must be before it is judged to be material and the process is out of control. Control limits are usually set by judgment although statistical approaches are occasionally used. 14. The materials price variance is often computed at the point of purchase rather than issuance because it provides control information sooner. When this is done, the variance may be called the materials purchase price variance, and it is the responsibility of the purchasing manager rather than the production manager. 15. Disagree. A materials usage variance can be caused by factors beyond the control of the production manager, e.g., purchase of a lower-quality material than normal. 16. Disagree. Using higher-priced workers to perform lower-skilled tasks is an example of an event that will create a rate variance that is controllable. 17. Some possible causes of an unfavorable labor efficiency variance are inefficient labor, machine downtime, and poor quality materials. 18. Part of a variable overhead spending variance can be caused by inefficient use of overhead resources. 19. Agree. This variance, assuming that variable overhead costs increase as labor usage in- creases, is caused by the efficiency or inefficiency of labor usage. Also labor may not be a good driver for variable overhead 20. Fixed overhead costs are either committed or discretionary. The committed costs will not differ by their very nature. Discretionary costs can vary, but the level the company wants to spend on these items is decided at the beginning and usually will be met unless there is a conscious decision to change the predetermined levels. 21. The volume variance is caused by the actual volume differing from the expected volume used to compute the predetermined standard fixed overhead rate. If the actual volume is different from the expected, then the company has either lost or earned a contribution margin. The volume variance signals this outcome, and if the variance is large, then the loss or gain is large since the volume variance understates the effect. 22. The spending variance is more important. This variance is computed by comparing actual expenditures with budgeted expenditures. The volume variance simply tells whether the actual volume is different from the expected volume 9–3 1. SH = 1.5 × 1,700 = 2,550 hours 2. SQ = 4 × 1,700 = 6,800 components 9–6 1. Cases needing investigation: Week 1: Exceeds the 2,100 rule and the 5% rule. Week 4: Exceeds the $2,100 rule and the 5% rule. 2. The installation and repair manager. If the new workers are now properly trained, no corrective action is required. If they are not, further training will be required to return to the direct labor hours normally used. 9–8 1. MPV = (AP – SP)AQ = ($0.047 – $0.046)6,420,000 = $6,420 U MUV = (AQ – SQ)SP = (6,420,000 – 6,656,000*)$0.046 = $10,856 F * SQ = 52,000 × 128 = 6,656,000 2. LRV = (AR – SR)AH = ($12.50 – $12.00)2,000 = $1,000 U LEV = (AH – SH)SR = (2,000 – 1,976*)$12.00 = $288 U * SH = 52,000 × 0.038 = 1,976 9–9 1. Variable overhead analysis: Actual VOH $160,000 Budgeted VOH $3.00 × 52,000 $4,000 U Spending Applied VOH $3.00 × 54,750* $8,250 F Efficiency * SH for direct labor = 73,000 × 0.75 = 54,750 2. Fixed overhead analysis: Actual FOH $710,000 Budgeted FOH $14 × 50,000 $10,000 U Spending Applied FOH $14 × 54,750 $66,500 U Volume 9–10 1. Materials: $35 × 34,000 = $1,190,000 Labor: $21 × 34,000 = $714,000 2. Materials Labor Actual Cost* $1,183,270 687,150 Budgeted Cost $1,190,000 714,000 Variance $ 6,730 F 26,850 F *$173,500 × $6.82; 50,900 × $13.50 3. MPV = (AP – SP)AQ = ($6.82 – $7.00)173,500 = $31,230 F MUV = (AQ – SQ)SP = (173,500 – 170,000)$7 = $24,500 U AP × AQ $6.82 × 173,500 SP × AQ $7 × 173,500 $31,230 F Price 4. $24,500 U Usage LRV = (AR – SR)AH = ($13.50 – $14.00)50,900 = $25,450 F LEV = (AH – SH)SR = (50,900 – 51,000)$14 = $1,400 F AR × AH $13.50 × 50,900 SP × SQ $7 × 170,000 SR × AH $14 × 50,900 $25,450 F Rate SR × SH $14 × 51,000 $1,400 F Efficiency 9–12 1. Fixed overhead rate = $0.55/(1/2 hr. per unit) = $1.10 per DLH SH = 786,000 × 0.5 = 393,000 Applied FOH = $1.10 × 393,000 = $432,300 2. Fixed overhead analysis: Actual FOH $430,300 Budgeted FOH $1.10 × 400,000* Applied FOH $1.10 × 393,000 $9,700 F Spending $7,700 U Volume *400,000 expected hours = 0.5 hour × 800,000 units) 3. Variable OH rate = ($1,120,000 – $440,000)/400,000 = $1.70 per DLH 4. Variable overhead analysis: Actual VOH $695,000 Budgeted VOH $1.70 × 390,000 $32,000 U Spending Applied VOH $1.70 × 393,000 $5,100 F Efficiency 9–14 1. MPV = (AP – SP)AQ = ($6.60 – $6.40)1,684,700 = $336,940 U MUV = (AQ – SQ)SP = (1,684,000 – 1,680,000)$6.40 = $25,600 U Note: There is no three-pronged analysis for materials because materials purchased is different from the materials used. (MPV uses materials purchased and MUV uses materials used.) 2. LRV = (AR – SR)AH = ($18.10 – $18.00)515,000 = $51,500 U LEV = (AH – SH)SR = [515,000 – (1.8 × 280,000 units)]$18.00 = $198,000 U AR × AH $18.10 × 515,000 SR × AH $18 × 515,000 $51,500 U Rate SR × SH $18 × 504,000 $198,000 U Efficiency 3. Fixed overhead analysis: Actual FOH $4,140,200 Budgeted FOH $8 × 518,400 $7,000 F Spending Applied FOH $8 × 504,000 $115,200 U Volume Note: Practical volume in hours = 1.8 × 288,000 = 518,400 hours 4. Variable overhead analysis: Actual VOH $872,000 Budgeted VOH $1.50 × 515,000 $99,500 U Spending Applied VOH $1.50 × 504,000 $16,500 U Efficiency