The Three-Moment Equation for Continuous-Beam Analysis

advertisement

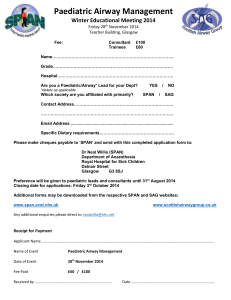

The Three-Moment Equation for Continuous-Beam Analysis CEE 201L. Uncertainty, Design, and Optimization Department of Civil and Environmental Engineering Duke University Henri P. Gavin Spring, 2009 Consider a continuous beam over several supports carrying arbitrary loads, w(x). Using the Moment-Area Theorem, we will analyze two adjoining spans of this beam to find the relationship between the internal moments at each of the supports and the loads applied to the beam. We will label the left, center, and right supports of this two-span segment L, C, and R. The left span has length LL and flexural rigidity EIL ; the right span has length LR and flexural rigidity EIR (see figure (a)). Applying the principle of superposition to this two-span segment, we can separate the moments caused by the applied loads from the internal moments at the supports. The two-span segment can be represented by two simplysupported spans (with zero moment at L, C, and R) carrying the external loads plus two simply-supported spans carrying the internal moments ML , MC , and MR (figures (b), (c), and (d)). The applied loads are illustrated below the beam, so as not to confuse the loads with the moment diagram (shown above the beams). Note that we are being consistent with our sign convention: positive moments create positive curvature in the beam. The internal moments ML , MC , and MR are drawn in the positive directions. The 2 CEE 201L. – Uncertainty, Design, and Optimization – Duke University – Spring 2009 – H.P. Gavin areas under the moment diagrams due to the applied loads on the simplysupported spans (figure (b)) are AL and AR ; x̄L represents the distance from the left support to the centroid of AL , and x̄R represents the distance from the right support to the centroid of AR , as shown. The moment diagrams due to the unknown moments, ML , MC , and MR are triangular, as shown in figures (c) and (d). Examining the elastic curve of the continuous beam (figure (e)), we recognize that the rotation of the beam at the center support, θC , is continuous across support C. In other words, θC just to the left of point C is the same as θC just to the right of point C. This continuity condition may be expressed ∆R tan C ∆L tan C =− , (1) LL LR where ∆L tan C is the distance from the tangent at C to point L, and ∆R tan C is the distance from the tangent at C to point R. Using the second Moment-Area Theorem, and assuming that the flexural rigidity (EI) is constant within each span, we can find the terms ∆L tan C , and ∆R tan C in terms of the unknown moments, ML , MC , and MR and the known applied loads. " # 1 2 1 1 1 ∆L tan C = x̄L AL + LL MC LL + LL ML LL , (2) EIL 3 2 3 2 and # " 1 2 1 1 1 ∆R tan C = x̄R AR + LR MC LR + LR MR LR . (3) EIR 3 2 3 2 Substituting these expressions into equation (1) and re-arranging terms, leads to the three-moment equation. 1 LL LL LR LR 6x̄L AL 6x̄R AR ML + 2 + MC + MR = − − . (4) EIL EIL EIR EIR LL EIL LR EIR Note that if EIL = EIR = EI, the three-moment equation is independent of ! EI. 1 The three-moment equation was derived by Émile Clapeyron in 1857 using the differential equations of beam bending. CC BY-NC-ND H.P. Gavin 3 Strain Energy in Linear Elastic Solids w(x) (a) 111 000 000 111 000 111 111 000 000 111 000 111 EIL L 111 000 000 111 000 111 R EIR C LL = LR xL xR AL (b) 111 000 000 111 000 111 AR w(x) + 111 000 000 111 000 111 111 000 000 111 2 3 LL 2 3 LR (c) 111 000 000 111 000 111 000 M111 000M 111 111 000 000 111 000 111 000 111 C C 1L 3 L + 1L 3 R (d) M111 000 L M 111 000 000 R 111 111 000 000 111 000 111 θC (e) 11 00 00 11 ∆ L tan C θC 111 000 000 111 ∆ R tan C 11 00 00 11 CC BY-NC-ND H.P. Gavin 4 CEE 201L. – Uncertainty, Design, and Optimization – Duke University – Spring 2009 – H.P. Gavin To apply the three-moment equation numerically, the lengths, moments of inertia, and applied loads must be specified for each span. Two commonly applied loads are point loads and uniformly distributed loads. For point loads PL and PR acting a distance xL and xR from the left and right supports, respectively, the right hand side of the three-moment equation becomes − 6x̄R AR xL xR 6x̄L AL − = −PL (L2L − x2L ) − PR (L2R − x2R ) . (5) LL EIL LR EIR LL EIL LR EIR For uniformly distributed loads wL and wR on the left and right spans, 6x̄L AL 6x̄R AR wL L3L wR L3R − − =− − . LL EIL LR EIR 4EIL 4EIR (6) To find the internal moments at the N + 1 supports in a continuous beam with N spans, the three-moment equation is applied to N − 1 adjacent pairs of spans. For example, consider the application of the three-moment equation to a four-span beam. Spans a, b, c, and d carry uniformly distributed loads wa , wb , wc , and wd , and rest on supports 1, 2, 3, 4, and 5. The three-moment equation is applied to spans a − b, spans b − c, and spans c − d. La M1 + 2 EIa Lb M2 + 2 EIb Lc M3 + 2 EIc La Lb Lb wa L3a wb L3b + M2 + M3 = − − EIa EIb EIb 4EIa 4EIb ! Lb Lc Lc wb L3b wc L3c + M4 = − − M3 + EIb EIc EIc 4EIb 4EIc ! Lc Ld Ld wc L3c wd L3d + M4 + M5 = − − EIc EId EId 4EIc 4EId ! CC BY-NC-ND H.P. Gavin 5 Strain Energy in Linear Elastic Solids We know that M1 = 0 and M5 = 0 because they are at the ends of the span. Applying these end-moment conditions to the three three-moment equations and casting the equations into matrix form, 1 La EIa 0 0 0 0 2 La EIa + Lb EIb 0 Lb EIb 0 Lb EIb 2 Lb EIb + 0 Lc EIc 0 0 Lc EIc 2 0 0 0 Lc EIc 0 Lc EIc + Ld EId Ld EId 0 1 M2 M3 M4 M5 M1 = 3 wb L3b 4EIb 3 wc L3c 4EIc 3 wd L3d 4EId a La − w4EI − a b Lb − w4EI − b c Lc − w4EI − c 0 (7) The 5 × 5 matrix on the left hand side of equation (7) is called a flexibility matrix and is tri-diagonal and symmetric. This equation can be written symbolically as F m = d. By examining the general form of this expression, we can write a matrix representation of the three-moment equation for arbitrarily many spans. If a numbering convention is adopted in which support j lies between span j − 1 and span j, the three non-zero elements in row j of matrix F are given by Lj−1 , EIj−1 L L j−1 j , = 2 + EIj−1 EIj Lj = . EIj Fj,j−1 = Fj,j Fj,j+1 (8) (9) (10) For the case of uniformly distributed loads, row j of vector d is wj−1 L3j−1 wj L3j dj = − − . 4EIj−1 4EIj 0 (11) The moments at the supports are computed by solving the system of equations F m = d for the vector m. CC BY-NC-ND H.P. Gavin . 6 CEE 201L. – Uncertainty, Design, and Optimization – Duke University – Spring 2009 – H.P. Gavin Once the internal moments are found, the reactions at the supports can be computed from static equilibrium. "r" "l" j−1 wj−1 j−1 j wj−1Lj−1 /2 xL M j−1 L PR x R /L j−1 j−1 Mj−1 /L j−1 j+1 xR PR M j /L j w j Lj /2 PL P x /L L L w j Mj j M j /L j M j+1 M j+1 /L j L j−1 j xR Mj Mj Mj−1 Mj+1 1 xL 1 +PR − − + + (12) Rj = wj−1 Lj−1 + wj Lj +PL 2 2 Lj−1 Lj Lj−1 Lj Lj−1 Lj where the first two terms on the right hand side correspond to a uniformly distributed load and the next two terms correspond to interior point loads. Having computed the reactions and internal moments, we can find the shear and moment diagrams from equilibrium equations. For example, consider span j between support j and support j + 1. The internal shear force at support j in span j is Vj,j = Mj − Mj+1 1 xk − wj L j − Pk , Lj 2 Lj (13) and the internal shear force at support j + 1 in span j is Vj+1,j Mj − Mj+1 1 xk = + wj Lj + Pk 1 − . Lj 2 Lj (14) CC BY-NC-ND H.P. Gavin 7 Strain Energy in Linear Elastic Solids The term wj Lj /2 in these two equations corresponds to a uniformly distributed load, Pk is a point load within span j, and xk is the distance from the right end of span j to the point load Pk . Beam rotations at the supports may be computed from equations (1), (2), and (3). The slope of the beam at support j is tan θj . From the second Moment-Area Theorem, 1 1 1 xk 1 1 tan θj = − wj L3j + Pk (L2j − x2k ) + Mj Lj + Mj+1 Lj , EIj 24 6 Lj 3 6 (15) where span j lies between support j and support j + 1. The first term inside the brackets corresponds to a uniformly distributed load. The second term inside the brackets corresponds to a point load Pk within span j, located a distance xk from the right end of span j, (support j + 1). CC BY-NC-ND H.P. Gavin 8 CEE 201L. – Uncertainty, Design, and Optimization – Duke University – Spring 2009 – H.P. Gavin These ideas are implemented in the Matlab function three moment.m. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 function [M ,R ,V , xs , M_Diag , V_Diag , d_Diag , D_max ] = three_moment (L ,I ,E ,w ,P , x ) % [M, R, V, xs , M Diag , V Diag , d Diag , D max ] = three moment (L , I , E, w , P, x ) % s o l v e t h e t h r e e −moment e q u a t i o n s f o r a c o n t i n u o u s beam o f N s p a n s . % % INPUT : % L i s a v e c t o r o f l e n g t h N c o n t a i n i n g t h e l e n g t h s o f each span . % I i s a v e c t o r o f l e n g t h N c o n t a i n i n g t h e moments o f i n e r t i a o f each span . % E i s a s c a l a r c o n s t a n t f o r t h e modulus o f e l a s t i c i t y . % w i s a v e c t o r o f l e n g t h N c o n t a i n i n g t h e uniform l o a d s on each span . % P i s a v e c t o r o f p o i n t l o a d s magnitudes % x i s a v e c t o r o f p o i n t l o a d l o c a t i o n s , from t h e s t a r t o f t h e f i r s t span % % OUTPUT: % M i s a v e c t o r o f l e n g t h N+1 c o n t a i n i n g t h e moments a t each s u p p o r t % R i s a v e c t o r o f l e n g t h N+1 c o n t a i n i n g t h e r e a c t i o n s a t each s u p p o r t % V i s a m a t r i x o f s i z e 2xN+1 c o n t a i n i n g end−s h e a r s o f each span % xs i s a v e c t o r o f t h e x−a x i s f o r t h e s h e a r , moment , and d i s p l p l o t s % M Diag i s a v e c t o r o f t h e moment diagram % V Diag i s a v e c t o r o f t h e s h e a r diagram % d D i a g i s a v e c t o r o f t h e d i s p l a c e m e n t diagram % D max i s a v e c t o r o f t h e max a b s o l u t e d i s p l a c e m e n t o f each span % % This program assumes t h a t none o f t h e s u p p o r t s a r e moment r e s i s t i n g , % t h a t t h e r e a r e no h i n g e s i n t h e beam , t h a t a l l t h e s p a n s a r e made o f % t h e same m a t e r i a l , and t h a t each s p a n s i s p r i s m a t i c . 26 27 % H. P . Gavin , C i v i l and Environmental E n g i n e e r i n g , Duke U n i v e r s i t y , 3/24/09 28 29 N = length ( L ); % number o f spans 30 31 32 33 34 35 36 37 38 nP = length ( x ); % number o f c o n c e n t r a t e d p o i n t l o a d s span = zeros (1 , nP ); % spans c o n t a i n i n g the p o i n t l o a d s sumL = cumsum( L ); xL = zeros (1 , nP ); % d i s t a n c e from p o i n t l o a d t o l e f t r c t n xR = zeros (1 , nP ); % d i s t a n c e from p o i n t l o a d t o r i g h t r c t n f o r i =1: length ( x ) span ( i ) = min( find ( x ( i ) < sumL ) ); end 39 40 41 42 43 44 45 46 47 f o r k =1: nP % loop over a l l concentrated point loads i f span ( k ) == 1 % t h e p o i n t l o a d i s i n t h e f i r s t span xL ( k ) = x ( k ); else xL ( k ) = x ( k ) - sumL ( span ( k ) -1); end xR ( k ) = sumL ( span ( k )) - x ( k ); end 48 49 F = zeros ( N +1 , N +1); % i n i t i a l i z e the f l e x i b i l i t y matrix f o r j =2: N % c r e a t e t h e f l e x i b i l i t y m a t r i x (8) −(10) 50 51 52 53 F (j ,j -1) = L (j -1) / I (j -1); 54 55 F (j , j ) = 2 * ( L (j -1) / I (j -1) + L(j) / I(j) ); CC BY-NC-ND H.P. Gavin 9 Strain Energy in Linear Elastic Solids 56 F (j , j +1) = L ( j ) / I ( j ); 57 58 end 59 60 61 F (1 ,1) = 1.0; F ( N +1 , N +1) = 1.0; 62 63 64 d = zeros ( N +1 ,1); f o r j =2: N % c r e a t e t h e r i g h t −hand−s i d e v e c t o r 65 l = j -1; r = j; 66 67 % j −1 % j i s t h e number o f t h e l e f t span i s t h e number o f t h e r i g h t span 68 d ( j ) = -w ( l )* L ( l )ˆ3 / (4* I ( l )) - w ( r )* L ( r )ˆ3 / (4* I ( r )); 69 70 f o r k =1: nP % loop over a l l concentrated point loads i f span ( k ) == l % t h e p o i n t l o a d i s i n t h e l e f t span d ( j ) = d ( j ) - P ( k )* xL ( k )/( L ( l )* I ( l ))*( L ( l )ˆ2 - xL ( k )ˆ2); end i f span ( k ) == r % t h e p o i n t l o a d i s i n t h e r i g h t span d ( j ) = d ( j ) - P ( k )* xR ( k )/( L ( r )* I ( r ))*( L ( r )ˆ2 - xR ( k )ˆ2); end end 71 72 73 74 75 76 77 78 79 end 80 81 M = ( inv ( F ) * d ) ’; % compute t h e i n t e r n a l moments R = zeros (1 , N +1); f o r j =1: N +1 % build the vector of reaction forces % j i s t h e r e a c t i o n number (7) 82 83 84 85 l = j -1; r = j; 86 87 % j −1 % j i s t h e number o f t h e l e f t span i s t h e number o f t h e r i g h t span 88 i f j == 1 R ( j ) = w ( r )* L ( r )/2 - M ( j )/ L ( r ) + M ( j +1)/ L ( r ); end i f j == N +1 R ( j ) = w ( l )* L ( l )/2 - M ( j )/ L ( l ) + M (j -1)/ L ( l ); end i f j > 1 && j < N +1 R ( j ) = w ( l )* L ( l )/2 + w ( r )* L ( r )/2 ... - M ( j )/ L ( l ) - M ( j )/ L ( r ) + M (j -1)/ L ( l ) + M ( j +1)/ L ( r ); end 89 90 91 92 93 94 95 96 97 98 99 f o r k =1: nP % loop over a l l concentrated point loads i f span ( k ) == l % t h e p o i n t l o a d i s i n t h e l e f t span R ( j ) = R ( j ) + P ( k )* xL ( k )/ L ( l ); end i f span ( k ) == r % t h e p o i n t l o a d i s i n t h e r i g h t span R ( j ) = R ( j ) + P ( k )* xR ( k )/ L ( r ); end end 100 101 102 103 104 105 106 107 108 109 end 110 111 112 slope = zeros (1 , N ); f o r j =1: N % compute t h e s l o p e s (15) CC BY-NC-ND H.P. Gavin 10 CEE 201L. – Uncertainty, Design, and Optimization – Duke University – Spring 2009 – H.P. Gavin 113 % j i s t h e span t o t h e r i g h t o f r e a c t i o n j r = j; 114 115 slope ( j ) = 116 w ( r )* L ( r )ˆ3 / 24 + M ( j +1)* L ( r ) / 6 + M ( j )* L ( r ) / 3; 117 f o r k =1: nP % loop over a l l concentrated point loads i f span ( k ) == r % t h e p o i n t l o a d i s i n t h e r i g h t span slope ( j ) = slope ( j )+ P ( k )* xR ( k )/ L ( r )*( L ( r )ˆ2 - xR ( k )ˆ2)/6; end end 118 119 120 121 122 123 slope ( j ) = - slope ( j ) / ( E * I ( r ) ); 124 125 126 end 127 128 if ( 129 130 abs ( sum( R ) - sum ( w .* L ) - sum( P ) ) < 1e -9 ) disp ( ’ yes ! ’) % e q u i l i b r i u m c h e c k . . . s h o u l d be c l o s e t o z e r o end 131 132 % −−−−−−−−−− s h e a r , moment , s l o p e , and d e f l e c t i o n d a t a and p l o t s −−−−−−−−−−− 133 134 135 136 f o r j =1: N % x−a x i s d a t a f o r s h e a r , moment , s l o p e , and d e f l e c t i o n diagrams xs (: , j ) = [ 0: L ( j )/157: L ( j ) ] ’ ; end 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 f o r j =1: N % j i s t h e span number Vo = ( M ( j ) - M ( j +1) ) / L ( j ) - w ( j )* L ( j )/2; % shear at l e f t V_Diag (: , j ) = Vo + w ( j )* xs (: , j ); f o r k =1: nP % loop over a l l concentrated point loads i f span ( k ) == j % t h e p o i n t l o a d i s i n span t o t h e r i g h t i1 = find ( xs (: , j ) < xL ( k )); i2 = find ( xs (: , j ) > xL ( k )); V_Diag ( i1 , j ) = V_Diag ( i1 , j ) - P ( k )* xR ( k )/ L ( j ); V_Diag ( i2 , j ) = V_Diag ( i2 , j ) + P ( k )*(1 - xR ( k )/ L ( j )); end end M_Diag (: , j ) = M ( j ) + cumtrapz ( - V_Diag (: , j ) ) * xs (2 , j ); s_Diag (: , j ) = cumtrapz ( M_Diag (: , j ) ) * xs (2 , j ) / ( E * I ( j )) + slope ( j ) ; d_Diag (: , j ) = cumtrapz ( s_Diag (: , j ) ) * xs (2 , j ) ; end 153 154 155 156 157 158 159 160 161 % −−−−−−−−−−−−− d i s p l a y k e y r e s u l t s t o t h e s c r e e n −−−−−−−−−−−−−− f p r i n t f ( ’ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -\ n ’ ); fprintf (’ Moment Shear Deflection \ n ’ ); fprintf (’ Maximum %12.5 e %12.5 e %12.5 e \ n ’ , ... max(max( M_Diag )) , max(max( - V_Diag )) , max(max( d_Diag )) ); fprintf (’ Minimum %12.5 e %12.5 e %12.5 e \ n ’ , ... min(min( M_Diag )) , min(min( - V_Diag )) , min(min( d_Diag )) ); f p r i n t f ( ’ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -\ n ’ ); 162 163 164 165 166 f o r j =1: N V (1 , j ) = - V_Diag (1 , j ); V (2 , j ) = - V_Diag (158 , j ); end % j i s t h e span number % shear force at l e f t end o f span % s h e a r f o r c e a t r i g h t end o f span 167 168 169 f o r j =2: N % x−a x i s d a t a f o r s h e a r and moment diagram p l o t s xs (: , j ) = xs (: , j ) + sumL (j -1); CC BY-NC-ND H.P. Gavin Strain Energy in Linear Elastic Solids 170 11 end 171 172 % Plotting 173 174 175 176 177 178 179 xs = xs (:); M_Diag = M_Diag (:); V_Diag = - V_Diag (:); s_Diag = s_Diag (:); d_Diag = d_Diag (:); z = zeros (1 , length ( xs )); 180 181 D_max = max(abs( d_Diag )); 182 183 184 185 186 187 f i g u r e (1) clf subplot (411) plot ( xs , z , ’ -k ’ , xs , V_Diag , ’ -b ’ , ’ LineWidth ’ , 2 ) ylabel ( ’ Internal Shear ’) 188 189 190 191 subplot (412) plot ( xs , z , ’ -k ’ , xs , M_Diag , ’ -b ’ , ’ LineWidth ’ , 2 ) ylabel ( ’ Internal Moment ’) 192 193 194 195 subplot (413) plot ( xs , z , ’ -k ’ , xs , s_Diag , ’ -b ’ , ’ LineWidth ’ , 2 ) ylabel ( ’ Slope ’) 196 197 198 199 subplot (414) plot ( xs , z , ’ -k ’ , xs , d_Diag , ’ -b ’ , ’ LineWidth ’ , 2 ) ylabel ( ’ Deflection ’) 200 201 % −−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−−− three moment .m CC BY-NC-ND H.P. Gavin 12 CEE 201L. – Uncertainty, Design, and Optimization – Duke University – Spring 2009 – H.P. Gavin Example L I E w P x = = = = = = [100 150 150 50]; [ 500 1000 2000 100 ]; 1000; [ 0.10 0.20 0.10 0.30 ]; [ 10 20 40 20 5 ]; [ 110 130 300 330 420 ]; % % % % % % lengths of each span bending moment of inertia of each span elastic modulus uniformly distributed load, each span concentrated interior point loads location of point loads from x=0 [M,R,V] = three_moment(L,I,E,w,P,x) yes! -----------------------------------------------------------------Moment Shear Deflection Maximum 1.30355e+03 4.89758e+01 1.73453e-01 Minimum -1.10017e+03 -2.60242e+01 -1.25557e+00 -----------------------------------------------------------------M = 0.0000e+00 -3.0056e+02 -1.1002e+03 -2.7880e+02 0.0000e+00 R = 1.9944 43.0082 73.9732 42.1003 V = 1.9944 -8.0056 35.0026 -24.9974 48.9758 -26.0242 16.0761 -3.9239 3.9239 CC BY-NC-ND H.P. Gavin 13 Internal Moment Internal Shear Strain Energy in Linear Elastic Solids 40 30 20 10 0 -10 -20 0 50 100 150 200 250 300 350 400 450 0 50 100 150 200 250 300 350 400 450 0 50 100 150 200 250 300 350 400 450 0 50 100 150 200 250 300 350 400 450 1000 500 0 -500 -1000 Deflection Slope 0.02 0.015 0.01 0.005 0 -0.005 -0.01 -0.015 -0.02 0.2 0 -0.2 -0.4 -0.6 -0.8 -1 -1.2 CC BY-NC-ND H.P. Gavin