HRSG Circulation System Design

In the design of Babcock & Wilcox

Power Generation Group, Inc’s

(B&W PGG) heat recovery steam

generator (HRSG), the evaporator

circulation system is an important

aspect that must be considered

for successful operation. An

improperly or inadequately

designed circulation system can

limit the HRSG’s availability during

rapid startup and shutdown

conditions, and during extreme

rates of load change; result in drum

level excursions or persistent water

level trips; and contribute to flowassisted corrosion. To compensate

for an undersized or improper

circulation system design, many

OEM suppliers require a circulation

system that includes a larger-thannormal steam drum with a large

water-holding capacity.

B&W PGG’s design philosophy is

to provide the proper circulation

system for the design conditions

the boiler is expected to experience

during typical operation. Through

circulation design analysis, the boiler

components can be sized properly

and more economically for the

expected operational conditions.

unit through the use of larger

steam drums. Analyzing for flow

excursions during load changes

and transient operation can be

beneficial by eliminating larger

and/or additional supply and riser

connections to the heat generating

surface. An optimized circulation

system design provides a reliable

HRSG, which will eliminate most of

the operational issues that result

from an improperly designed unit.

B&W PGG has developed an

extensive set of design requirements

for HRSGs to meet the demanding

conditions required for today’s

combined cycle power generation

operation. Our circulation analysis

goes beyond the typical steadystate circulation analysis and

investigates the transient operation

of the boiler. This type of analysis

reduces the need for special and

costly features, like additional

water holding capacity for the

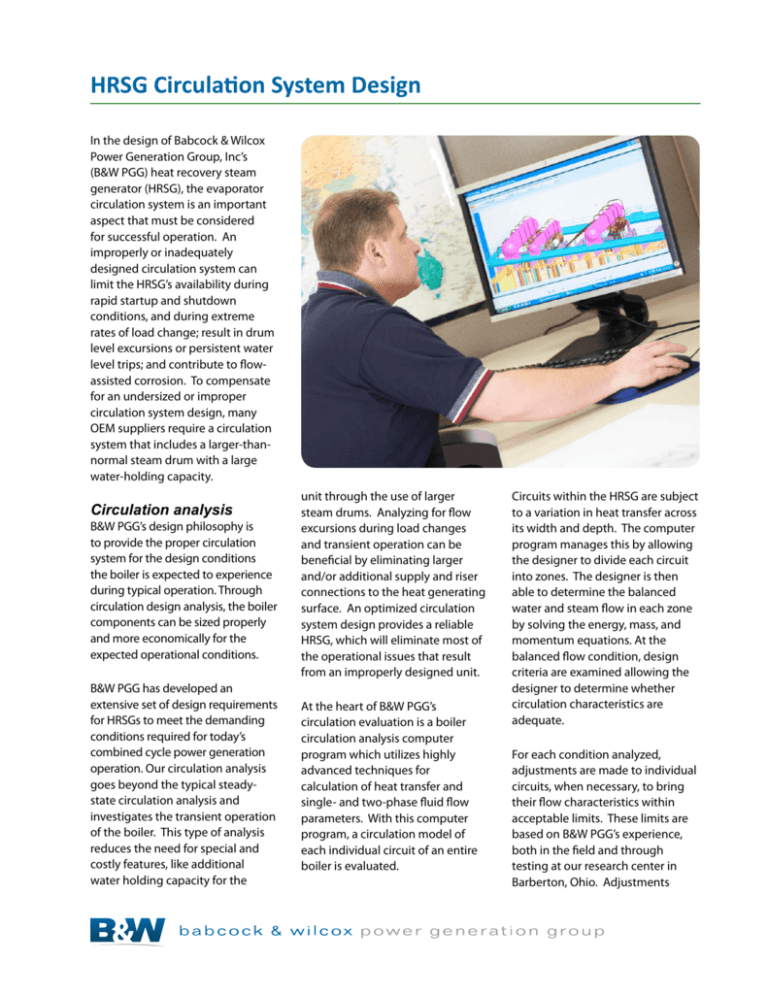

At the heart of B&W PGG’s

circulation evaluation is a boiler

circulation analysis computer

program which utilizes highly

advanced techniques for

calculation of heat transfer and

single- and two-phase fluid flow

parameters. With this computer

program, a circulation model of

each individual circuit of an entire

boiler is evaluated.

Circulation analysis

Circuits within the HRSG are subject

to a variation in heat transfer across

its width and depth. The computer

program manages this by allowing

the designer to divide each circuit

into zones. The designer is then

able to determine the balanced

water and steam flow in each zone

by solving the energy, mass, and

momentum equations. At the

balanced flow condition, design

criteria are examined allowing the

designer to determine whether

circulation characteristics are

adequate.

For each condition analyzed,

adjustments are made to individual

circuits, when necessary, to bring

their flow characteristics within

acceptable limits. These limits are

based on B&W PGG’s experience,

both in the field and through

testing at our research center in

Barberton, Ohio. Adjustments

to improve circuit circulation

can include, but are not limited

to, determining the appropriate

number of steam separators in the

steam drum or incorporating a

vertical separator; adding orifices

at the entrance or within individual

circuits; altering the number of

supplies and/or risers; and lowering

feedwater temperature entering

the steam drum. Each circulation

analysis is unique and the

requirements to achieve acceptable

circulation characteristics are casespecific to the boiler and operating

conditions being examined.

Details that B&W PGG considers

when it designs and analyzes an

HRSG include exit quality, saturated

water head, saturated velocity,

sensitivity, stability, departure from

nucleate boiling (DNB) and drum

internals.

Exit quality

Maximum exit quality from a circuit

is a function of the drum operating

pressure. Keeping a circuit’s exit

quality below the maximum exit

quality assures that boiling in

the circuit will be restricted to

nucleate boiling, and that the tube

metal temperature will be close to

saturation temperature.

Saturated velocity

Adherence to the required

minimum circuit saturated velocity

helps assure that steam blanketing

does not occur and reduces the

possibility of solids deposition.

Both steam blanketing and solids

deposition can cause tube failure.

B&W PGG limits on saturated

velocity are a function of tube

orientation, tube location and type

of firing. Circuit velocities must also

be below the maximum limit to

avoid flow-assisted corrosion.

Sensitivity

In a correctly designed natural

circulation system, steam-water

mixture flow increases with

increased heat input, until a point

where maximum flow is reached. If

more heat is added, mixture flow

then begins to decrease as specific

volume and frictional pressure

losses offset the pumping head

due to increased heat absorption.

Beyond the maximum circuit

flow point at a specific load, heat

input, and quality, circuits become

unstable and may flow upward,

stagnate, or flow backward. For a

range of heat inputs, sensitivity is

the steam-water mixture flow trend

(i.e., increasing or decreasing) of

circulation capability relative to

the maximum continuous steam

flow rating. B&W PGG carefully

evaluates both steady state and

transient operation to assure

reliable circulation.

Stability

Stability is based on the pressure

drop in a circuit between common

pressure points. B&W PGG has

established limits of circuit pressure

drop allowed at a given steam flow

and pressure. Circuits with heat

absorption rates that vary across

the different tube rows are most

susceptible to instability.

The stability analysis is a measure

of the tendency of a circuit to flow

in the desired direction. Figure 1

shows possible pressure differential

characteristics for a furnace circuit.

Line dP2 is the maximum attainable

pressure differential for downflow.

By forcing the pressure differential

to be greater than line dP2, the

circuit will flow upward. The

graph indicates that for pressure

differentials less than line dP2,

there are three different flows

that may yield the same pressure

differential: two downflow and one

upflow. In practice, the flow can

also oscillate or stall. Therefore,

Saturated water head

The saturated water head criterion

is the relationship between (a) the

actual density and pressure drop

characteristics of the steam and

water mixture, and (b) those of a

static column of saturated water of

the same vertical height between

common pressure points. Circuits

operating at a lower percentage

saturated water head could have

problems with recirculation

between parallel paths within

the same circuit. B&W PGG has

established limits for percentage

saturated water head preventing

this problem from occurring.

Fig. 1 Relationship between boiler tube pressure loss and direction of flow.

a circuit operating along line dP1,

which does not meet the stability

criteria, may operate at point C

indefinitely and would be an upflow

case. Unfortunately, the inherent

nature of an unstable system means

that it is sensitive to boundary

conditions. The result is that

system disturbances or changes,

sometimes even small ones, may

cause the operating point to be

moved from one upflow solution

to the potential for either upflow

or downflow. Therefore, it is always

desirable to operate above line dP2,

the stability limit.

of cooling liquid near the heated

surface of the tube, causing the

temperature of the tube to increase

rapidly, as seen between points

D and S in Figure 2. The point at

which the boiling mechanism is

interrupted (point D) is called the

DNB point. DNB must be avoided

in circulation design because it

produces serious overheating and/

or rapid corrosion of boiler tubes,

which leads to subsequent tube

failures. In general, higher boiler

tube absorption rates at higher

loads and/or higher circulating

(drum) pressures tend to cause DNB

problems.

Departure from nucleate

boiling

Drum internals

HRSG evaporator tubes are cooled

by nucleate boiling, which is

characterized by a very high heat

transfer coefficient. At certain

conditions, the boiling mechanism

is suddenly impaired, due to a lack

Steam and water flow rates to

each cyclone separator, as well

as the pressure drop through

each separator, are checked

against B&W PGG-established

limits. Conformance with B&W

PGG standards reduces the risk of

unacceptable carryunder levels of

steam into the downcomers and

carryover of water out of the drum.

B&W PGG’s patented low-pressuredrop cyclone separators improve

flow stability, increase drum water

level control range, and minimize

water carryover and steam

carryunder for the highest possible

steam purity.

What separates B&W PGG

from others?

Boiler circulation design is one of

many technical capabilities B&W

PGG offers that separates us from

the competition. We have more

than 145 years of experience in the

boiler industry. This experience,

combined with the company’s

state-of-the-art technology,

have allowed us to offer superior

products and services to customers.

B&W PGG is considered a leader

in the boiler circulation thermal

hydraulics field because of our:

• Boiler circulation analysis

computer program, which was

developed and benchmarked

using laboratory field data, and

features:

-- Benchmarking across a

wide pressure range

(15 - 4000 psig)

-- Easy evaluation of gas-side

unbalances

• Proprietary two-phase flow

correlations

• Accurate flow stability

predictions

• Flow sensitivity analyses at

steady-state and transient

conditions

• Technical knowledge of steam

separation equipment and its

performance

• Low-pressure-drop drum internals

and economizer cyclones

Fig. 2 Boiling conditions in evaporator tubes.

www.babcock.com

Babcock & Wilcox Power Generation Group, Inc.

20 S. Van Buren Avenue

Barberton, Ohio 44203 USA

Phone: 330.753.4511

Fax: 330.860.1886

Babcock & Wilcox Power Generation Group, Inc. is a subsidiary of

The Babcock & Wilcox Company (B&W). Established in 1867, B&W is

a world leader in providing steam generating and emissions control

equipment, nuclear operations and components, and defense program

management services.

The information contained herein is provided for general information

purposes only and is not intended nor to be construed as a warranty, an

offer, or any representation of contractual or other legal responsibility.

For more information, or a complete listing of our sales and service

offices, call 1-800-BABCOCK (222-2625), send an e-mail to

info@babcock.com, or access our website at www.babcock.com.

© 2012 Babcock & Wilcox Power Generation Group, Inc.

All rights reserved.

SP-588500PS2B