Sommaire Addition sur un alcène 1,2

advertisement

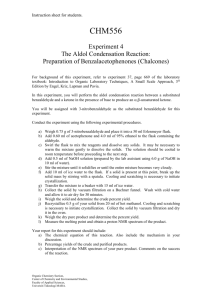

Sommaire Addition ionique sur un alcène ............................................................................................................................................... 1 Friedel et Crafts ...................................................................................................................................................................... 4 Grignard .................................................................................................................................................................................. 5 Déshydratation d’alcool.......................................................................................................................................................... 2 Source : http://www.orgsyn.org/ Addition sur un alcène Organic Syntheses, Coll. Vol. 2, p.171 (1943); Vol. 12, p.26 (1932). 1,2-DIBROMOCYCLOHEXANE [Cyclohexane, 1,2-dibromo-] Submitted by H. R. Snyder and L. A. Brooks. Checked by Lee Irvin Smith, R. T. Arnold, and John Ryan. 1. Procedure In a 2-l. three-necked, round-bottomed flask, fitted with a 500-cc. separatory funnel, a mechanical stirrer, and a thermometer, is placed a solution of 123 g. (1.5 moles) of cyclohexene (Note 1) in a mixture of 300 cc. of carbon tetrachloride and 15 cc. of absolute alcohol. The flask is surrounded by an ice-salt bath. The stirrer is started, and, when the temperature has reached −5°, a solution of 210 g. (67 cc., 1.3 moles) of bromine in 145 cc. of carbon tetrachloride is added from the separatory funnel at such a rate that the temperature of the reaction mixture does not exceed −1° (Note 2). The addition requires about three hours. When the bromine has been added the contents of the flask are transferred directly to a 1-l. modified Claisen flask and the carbon tetrachloride and excess cyclohexene are distilled from a water bath (Note 3), (Note 4), and (Note 5). The water bath is replaced by an oil bath and the product distilled under reduced pressure. There is a small low-boiling fraction, and then pure dibromocyclohexane distils at 99– 103°/16 mm. (108–112°/25 mm.). The yield is 303 g. (95 per cent of the theoretical amount) (Note 6) and (Note 7). References and Notes 1. Baeyer, Ann. 278, 108 (1894); Hofmann and Damm, Mitt. schlesischen Kohlenforsch. Kaiser Wilhelm Ges. 2, 97 (1925) [C. A. 22, 1249 (1928)]; Rothstein, Ann. chim. (10) 14, 542 (1930). 2. Coffey, Rec. trav. chim. 42, 398 (1923); Greengard, Org. Syn. 12, 27. 3. Fortey, J. Chem. Soc. 73, 948 (1898). 4. Harries and Splawa-Neyman, Ber. 42, 695 (1909). 5. Markownikoff, Ann. 302, 29 (1898); Swarts, Bull. soc. chim. Belg. 46, 13 (1937): 6. Truffault, Bull. soc. chim. (5) 1, 398 (1934). Partie II - Objectif 2 Introduction Déshydratation d’alcool Organic Syntheses, Coll. Vol. 1, p.183 (1941); Vol. 5, p.33 (1925). CYCLOHEXENE Submitted by G. H. Coleman and H. F. Johnstone. Checked by C. S. Marvel and A. B. Adams. 1. Procedure In a 500-cc. modified Claisen flask (p. 130) are placed 400 g. (4 moles) of cyclohexanol (Note 1) and 12 cc. of concentrated sulfuric acid, and the flask is connected to a condenser and receiver surrounded by an ice bath. It is then placed in an oil bath which is heated to a temperature of 130–140°. The distillation is continued until only a small residue remains and the odor of sulfur dioxide is apparent. Toward the end of the distillation the temperature of the bath may be raised to 150°. The receiver is kept cold (Note 2) during the entire distillation, which requires from five to six hours (Note 3). The distillate is saturated with salt, and the cyclohexene is separated from the water layer. It is dried with calcium chloride and fractionated through an efficient column (Note 4). The fraction boiling at 80– 82° (uncorr.) is collected separately. It may be necessary to refractionate the low- and high-boiling portions once or twice (Note 5). The high-boiling fraction is finally added to the next run. The yield ofcyclohexene is 260–285 g. (79–87 per cent of the theoretical amount) (Note 6). References and Notes 1. 2. 3. 4. 5. 6. Kistiakowsky, Ruhoff, Smith, and Vaughan, J. Am. Chem. Soc. 58, 140 (1936). Hahn, Ber. 43, 419 (1910). Waterman and van Westen, Rec. trav. chim. 48, 637 (1929). Bartlett and Berry, J. Am. Chem. Soc. 56, 2684 (1934). Brunel, Bull. soc. chim. (3) 33, 270 (1905); Willstätter and Hatt, Ber. 45, 1466 (1912). Zelinsky and Zelikov, Ber. 34, 3252 (1901); Willstätter and Hatt, Ber. 45, 1466 (1912); Zelinsky, J. Russ. Phys. Chem. Soc. 43, 1222 (1911) [Chem. Zentr. I, 139 (1912)]; Juery, Bull. soc. chim. (4) 17, 174 (1915). 7. Senderens, Compt. rend. 154, 1169 (1912); 177, 1183 (1923); Osterberg and Kendall, J. Am. Chem. Soc. 42, 2620 (1920). 8. Evans and Witzemann, Bull. soc. chim. Belg. 26, 304 (1912) [Chem. Zentr. II, 1006 (1912)]. 9. Dehn and Jackson, J. Am. Chem. Soc. 55, 4285 (1933). 10. Hibbert, J. Am. Chem. Soc. 37, 1754 (1915). 11. Ipatiev, Ber. 43, 3385 (1910); Friedr. Bayer and Co., Ger. pat. 241,895 [Frdl. 10, 1032 (1910–12)]; Senderens, Ann. chim. phys. (8) 25, 461, 500 (1912). 12. Zal'kind and Markov, Narodnyi Komissariat Tyazheloi Prom. S. S. S. R. Nauch.-Issledovatel. Inst. Plasticheskikh Mass., Plasticheskie Massy. Sbornik, 2, 331 (1937) [C. A. 31, 3875 (1937)]. 13. Kazanskii and Glushnev, J. Gen. Chem. (U.S.S.R.) 8, 642 (1938) [C. A. 33, 1279 (1939)]. Partie II - Objectif 2 Introduction Organic Syntheses, Vol. 48, p. 68 (1968); Coll. Vol. 5, p.424 (1973). 7,7-DIMETHOXYBICYCLO[2.2.1]HEPTENE [2-Norbornen-7-one dimethyl acetal] Submitted by P. G. Gassman and J. L. Marshall1. Checked by William G. Dauben and James L. Chitwood. 1. Procedure Caution! Most polychlorinated compounds show some toxicity. These compounds should be handled in a hood. A. 5,5-Dimethoxy-1,2,3,4tetrachlorocyclopentadiene. In a 3-l. threenecked flask fitted with a condenser (Note 1), an addition funnel, and a mechanical stirrer (Note 2) are placed 254 g. (0.93 mole) of hexachlorocyclopentadiene (Note 3) and 800 ml. of methanol (Note 4). The stirrer is started, and a solution of 120 g. (2.14 moles) of potassium hydroxide in 600 ml. of methanol is added dropwise over a period of 2 hours (Note 5). The reaction mixture is stirred for an additional 2 hours and then poured over 3 l. of chopped ice. After the ice has melted, the mixture is extracted with three 250-ml. portions of dichloromethane. The combined extracts are dried over anhydrous magnesium sulfateand concentrated to a yellow syrup on a rotary evaporator (Note 6). The residue is distilled through a 12-in. vacuum-jacketed Vigreux columnto yield 187–189 g. (76–77%) of 5,5-dimethoxy-1,2,3,4tetrachlorocyclopentadiene as a viscous, yellow-tinted oil, b.p. 79–84° (0.6 mm.)(Note 7). B. 7,7-Dimethoxy-1,2,3,4-tetrachlorobicyclo[2.2.1]hept-2-ene. A large Pyrex gas washing bottle with fritted-glass inlet (Note 8) is fitted with a condenser and a drying tube. In the bottle is placed 189 g. (0.72 mole) of 5,5dimethoxy-1,2,3,4-tetrachlorocyclopentadiene, and a slow stream of nitrogen and ethylene is passed through the fritted-glass inlet (Note 9). The bottle is heated to 180–190° by means of an oil bath. The color of the liquid changes from yellow to reddish brown as ethylene is bubbled through the reaction mixture at this temperature for 6 hours (Note 10). The reaction mixture is cooled and distilled through a 12-in. vacuum-jacketed Vigreux column to yield 155–165 g. (73–78%) of a yellow syrup, b.p. 70–75° (0.15 mm.) (Note 11). C. 7,7-Dimethoxybicyclo[2.2.1]heptene. A 3-l. three-necked flask is equipped with a sealed Hershberg stirrer,2 a condenser fitted with anitrogen inlet to maintain a slight positive pressure, and a pressure-equalizing dropping funnel. The flask is placed in a heating mantle, and into it are placed 1.5 l. of tetrahydrofuran, 130 g. (5.7 g. atoms) of sodium chopped into 5-mm. cubes, and 190 ml. (150 g., 2.0 moles) of t-butyl alcohol. This mixture is stirred vigorously and brought to gentle reflux (Note 12). As soon as refluxing occurs, 106 g. (0.36 mole) of 7,7-dimethoxy1,2,3,4-tetrachlorobicyclo[2.2.1]hept-2-ene is added dropwise over a 2-hour period (Note 13). The mixture is heated under reflux for 38 hours, cooled to room temperature, and filtered through a wire screen to remove the unreacted sodium. The dark filtrate is refiltered by suction through Celite in a Buchner funnel (Note 14). The filtrate is mixed with 2 l. of chopped ice and 500 ml. of ether. The aqueous phase is separated (Note 15), and the organic phase is washed with 500-ml. portions of saturated aqueous sodium chloride until the washings are clear. The ethereal solution is dried over anhydrous magnesium sulfate and concentrated to a dark oil by removal of the ether by fractional distillation. The oil is fractionally distilled through a 6-in. Vigreux column to yield 17–24 g. (31– 43%) of colorless liquid, b.p. 58–68° (17 mm.),n25D 1.4598 (Note 16) and (Note 17). References and Notes 1. 2. 3. 4. 5. 6. Department of Chemistry, The Ohio State University, Columbus, Ohio 43210. P. S. Pinkney, Org. Syntheses, Coll. Vol. 2, 116 (1943). P. Bruck, D. Thompson, and S. Winstein, Chem. Ind. (London), 405 (1960). J. S. Newcomer and E. T. McBee, J. Am. Chem. Soc., 71, 946 (1949). P. E. Hoch, J. Org. Chem., 26, 2066 (1961). P. G. Gassman and P. G. Pape, J. Org. Chem., 29, 160 (1964). Partie II - Objectif 2 Introduction Friedel et Crafts Organic Syntheses, Vol. 12, p. 16 (1932); Coll. Vol. 2, p.156 (1943). DESOXYBENZOIN Submitted by C. F. H. Allen and W. E. Barker. Checked by C. S. Marvel and Tse-Tsing Chu. 1. Procedure To 68 g. (0.5 mole) of phenylacetic acid (Note 1) in a 1-l. flask fitted with a reflux condenser and a system for absorbing hydrogen chloride, is added 35 g. (0.25 mole) of phosphorus trichloride. The mixture is heated on a steam bath for one hour. While the contents of the flask are still warm, 400 cc. of dry benzene is added. The benzene solution of phenylacetyl chloride is decanted from the residue ofphosphorous acid onto 75 g. (0.56 mole) of anhydrous aluminum chloride in a dry, 1-l. flask which can be fitted to the same condenser. The reaction is vigorous at first and cooling is necessary. The mixture is refluxed for one hour on a steam bath, then cooled and poured into a mixture of 500 g. of cracked ice and 200 g. of concentrated hydrochloric acid. The benzene layer is separated, and the aqueous layer is extracted once with a mixture of 100 cc. of benzene and 100 cc. of ether (Note 2). The etherbenzene solution is washed once with 100 cc. of water (Note 3), and then dried over 40–50 g. of calcium chloride. The solution is filtered (Note 4) with suction into a 1-l. Claisen flask, and the solvent is removed by distillation under reduced pressure (Note 5); the residue consists of a brown oil which solidifies on cooling. The crude material (91–92 g.) is purified by distillation under reduced pressure from a 250-cc. Claisen flask (Note 6). The product distils at160°/5 mm. (172°/15 mm.; 200°/30 mm.) as a colorless oil which solidifies on cooling. The yield is 81–82 g. (82–83 per cent of the theoretical amount based on the phenylacetic acid used) of a product which melts at 53–54°. The product is recrystallized from methyl alcohol, using 4 cc. of solvent for each gram of product (Note 7); the yield is 55–56 g. of crystals melting at 55–56°. An additional 7 g. of crystals melting at55–56° is obtained by cooling the filtrate in an ice-salt bath. On further cooling of the mother liquors, about 5 g. of crystals melting at 54–55°is obtained. The total yield of purified product is 67–70 g. (Note 8). Further recrystallization of the product from methyl alcohol does not raise the melting point above 55–56°. References and Notes 1. Graebe and Bungener, Ber. 12, 1080 (1879). 2. Kohler, Am. Chem. J. 36, 182 (1906); Irvine and Weir, J. Chem. Soc. 91, 1388 (1907); Kohler and Nygaard, J. Am. Chem. Soc. 52, 4133 (1930); Ballard and Dehn, ibid. 54, 3970 (1932). 3. Limpricht and Schwanert, Ann. 155, 60 (1870). 4. Japp and Klingemann, J. Chem. Soc. 63, 770 (1893). 5. Thiele and Straus, Ann. 319, 163 (1901). 6. Zincke, Ber. 9, 1771 (1876). 7. Ivanoff and Nicoloff, Bull. soc. chim. (4) 51, 1331 (1932). 8. Jenkins, J. Am. Chem. Soc. 55, 704 (1933). 9. Behaghel and Schneider, Ber. 68, 1588 (1935). Partie II - Objectif 2 Introduction Grignard Organic Syntheses, Vol. 5, p. 75 (1925); Coll. Vol. 1, p.361 (1941). dl-METHYLETHYLACETIC ACID [Butyric acid, α-methyl-] Submitted by Henry Gilman and R. H. Kirby. Checked by H. T. Clarke and L. L. Engel. 1. Procedure In a 1-l. three-necked flask, fitted with a mechanical stirrer, condenser, and 500-cc. separatory funnel, is placed 13.4 g. (0.55 atom) ofmagnesium shavings (Note 1). The shavings are then covered with 50 cc. of anhydrous ether. A crystal or two of iodine and 3 g. of sec.-butyl chloride (Note 2) are added. The reaction is started by warming the flask with a microburner and is then allowed to proceed by its own heat for twenty minutes. A second addition of 50 cc. of anhydrous ether is made. A solution of 43 g. (the remainder of 0.5 mole) of sec.-butyl chloride in 300 cc. anhydrous ether is added over a period of twenty minutes. Vigorous refluxing is avoided by externally cooling the flask with water. The heat from the reaction causes refluxing to continue for twenty minutes after the addition of the halide solution. The reaction mixture is then gently refluxed for one hour with a microburner. The reaction flask is surrounded by an ice and salt mixture and the solution cooled to − 12° in an atmosphere of nitrogen (Note 3). The nitrogen gas, obtained directly from a cylinder, is dried by passing through two wash bottles containing concentrated sulfuric acid and a phosphorus pentoxide tower. It is admitted to the flask through anentry tube 10 mm. in diameter at a height of about 60 mm. above the surface of the ether solution. An additional 100 cc. of ether is added, and the separatory funnel is replaced by a thermometer. The cylinder of nitrogen is then replaced by a cylinder of carbon dioxide. The gas after passing through the drying train enters the reaction flask through the entry tube (Note 4). The rate of flow is regulated so that the temperature of the reaction mixture does not rise above − 5° when rapid stirring is in progress. After one and one-half hours (Note 5) the temperature drops to − 12° and does not rise on increasing the rate of flow of carbon dioxide. The drop in temperature is taken as an end-point for the carbonation. The reaction mixture is then hydrolyzed in the flask with about 500 cc. of 25 per cent sulfuric acid (Note 6). Cooling the solution with ice and water permits of rapid hydrolysis without danger of loss of material through too vigorous refluxing. The mixture is transferred to a 1-l. separatory funnel and the ether layer separated. The water layer is extracted with three 50-cc. portions of ether. The combined ether extracts are washed with about 150 cc. of 25 per cent sodium hydroxide solution until all the organic acid is converted to the salt and thus removed (Note 7) and (Note 8). The alkaline extract is boiled in a distillation apparatus, to remove ether and other volatile impurities, until its volume is decreased by 10 per cent. It is then acidified with concentrated hydrochloric acid and the acid layer separated. The water layer is then distilled from a 1-l. flask until no more oily acid comes over (Note 9). The distillate is saturated with salt and the acid layer separated. This water layer, together with the low-boiling fraction from the acid distillation, is distilled, and the distillate salted out as before. The combined acid layers are distilled from a 75-cc. flask connected to an air condenser. The product is collected at 173–174°. The yield of acid is 39–44 g. (76–86 per cent of the theoretical amount based on the quantity of sec.-butyl chloride used) (Note 10). References and Notes 1. 2. 3. 4. 5. Gilman and Zoellner, J. Am. Chem. Soc. 53, 1945 (1931). Auwers, Ann. 298, 167 (1897). Saur, Ann. 188, 257 (1877). Lieben and Zeisel, Monatsh. 7, 56 (1886). Gilman and Parker, Org. Syn. 5, 75. Marvel, Blomquist, and Vaughn, J. Am. Chem. Soc. 50, 2810 (1928). Partie II - Objectif 2 Introduction