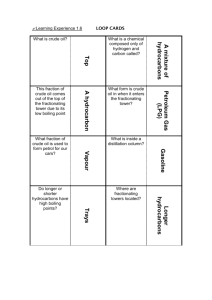

Chap 2

advertisement