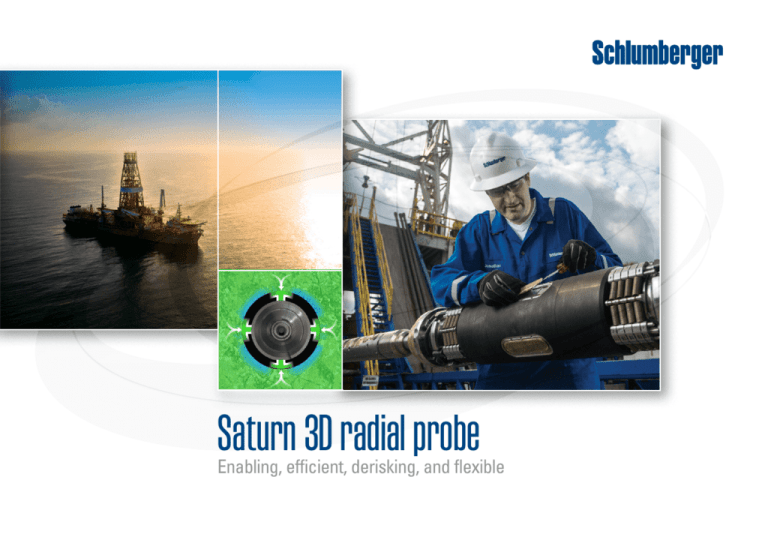

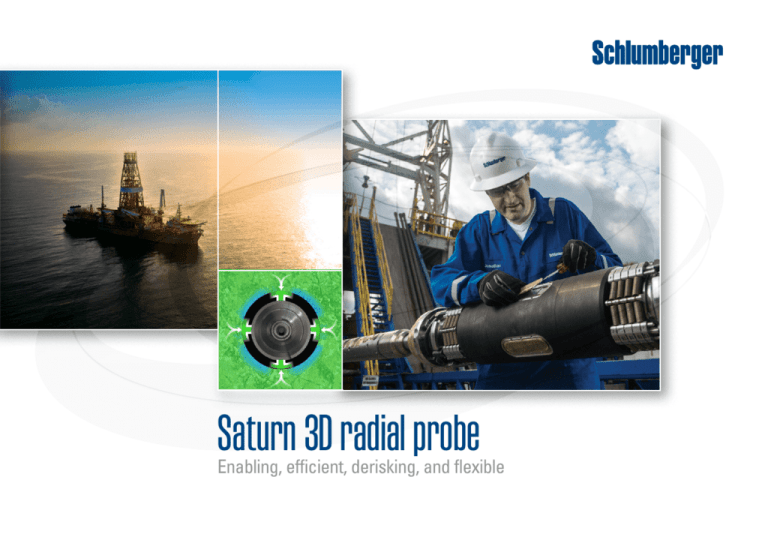

Saturn 3D radial probe

Enabling, efficient, derisking, and flexible

Saturn

Formation

testing where

not previously

possible

Applications

■

Formation pressure measurement

■

■

Downhole fluid analysis (DFA)

■

■

Formation fluid sampling

■

Fluid-gradient determination

■

Far-field permeability measurement

and anisotropy determination

Well testing design optimization

Enabling: pressure measurement,

DFA, and fluid sampling

– Wide permeability range, extending

down to 0.01 mD

– Heavy oil

– Near-critical fluids

– Unconsolidated formations

– Thinly laminated formations

– Rugose and unstable boreholes

■

■

01

Benefits

■

Efficient: significant rig-time savings

Derisking: reduced station time and

assured retraction

Flexible: deployable across a wide

range of hole sizes, temperatures, and

pressures on all conveyance options,

from wireline to TLC* tough logging

conditions system to openhole tractors

Features

■

■

■

■

■

■

■

The industry’s largest total surface

flow area: 79.44 in2

8,000-psi differential pressure rating

qualified between flowline and

hydrostatic pressures

■

■

Fast setting and retracting time

No sump and low storage effect

to eliminate mixing of fluids with

stationary mud

Quantified contamination monitoring

algorithm for ensuring representative

sampling in oil-base mud

4-ft spacing from monitoring probe

above for vertical interference testing

■

■

Self-sealing drain assembly for excellent

seal maintenance during sampling in anyquality borehole

Improved mud bypass system to provide

superior pressure maintenance

in unstable wellbores

Combinable with all MDT Forte*,

MDT Forte-HT*, MDT* tester modules,

and the InSitu Fluid Analyzer* real-time

downhole fluid analysis system

Conveyance on wireline cable, TLC tough

logging conditions system, and UltraTRAC*

all-terrain wireline tractor

Four elliptical ports with fieldreplaceable, customizable filters

to prevent flowline plugging

02

Setting a new standard in downhole formation testing

The Saturn* 3D radial probe establishes

and maintains true 3D circumferential

flow in the formation around the borehole, enabling highly accurate pressure

measurement, downhole fluid analysis

(DFA), sampling, and permeability estimation in what were previously challenging

conditions for conventional wireline

formation testing:

Reducing stationary time and assuring

retraction every time significantly derisks

operations. Flexible deployment is supported

by wide borehole-size coverage, HPHT rating,

and qualification for up to 20 sequential

operational cycles in a single descent.

- rugose or unstable boreholes

- extremely low-permeability

or unconsolidated formations

- heavy oil or near-critical fluid types.

The Saturn probe’s fast setting and

retracting times, zero sump for a low

storage effect and elimination of

stationary mud mixing, and largest

flow area in the industry of 79.44 in2

facilitate efficient operations across

a wide permeability range in a single trip.

q

k A dP

uL

Flow from the formation to a conventional formation

tester is narrowed to the intake of the single probe,

not from the entire circumference of the borehole wall.

03

Back to basics

Successful wireline fluid sampling and

DFA begin with accessing a representative

sample of the virgin reservoir fluid, ideally in a

minimum amount of time. Formation pressure

testing similarly requires fluid withdrawal.

The fluid extraction is typically conducted

with a probe module that includes a packer,

telescoping backup pistons, and a flowline.

The pistons extend the probe and packer

assembly against the borehole wall to

provide a sealed fluid path from the reservoir

to the flowline. The governing principle

behind flowing any fluid from a reservoir for

formation testing is Darcy’s law, in which

flow (q) is a function of permeability (k),

drawdown pressure (dP), surface area open

to flow (A), fluid viscosity (u), and the length

(L) over which the drawdown is applied.

Different probe surface flow areas and

the maximum pressure drawdowns that

the formation tester can manage are used

depending on the formation permeability

and fluid viscosity. Typically, the larger the

surface area and the higher the maximum

drawdown pressure, the higher the flow rate

of fluid from the formation that can be

achieved for a formation testing operation.

Over the years, Schlumberger innovation

has increased the maximum allowable

differential pressure from 4,596 psi with

the standard pumpout displacement unit to

11,760 psi with a high-pressure displacement

unit. Concurrently, the available surface area

of the probes has increased by nearly 40 times,

from the standard probe’s 0.15 in2 to the 6.03-in2

elliptical probe. This technical progression

enables successfully performing formation

testing in a wider range of environments.

However, as operators attempt to tap

into hydrocarbons previously thought

to be unproducible—low-permeability

or unconsolidated reservoirs, highviscosity formation fluids—or where

reduced drawdown is necessary to

test reservoirs in which the saturation

pressure of the fluid is close to the

reservoir pressure, formation testing

is technologically challenged.

The Saturn 3D radial probe meets

these challenges with a radical

redesign of the fluid-extraction module

to deploy multiple self-sealing ports

around the borehole. With a total

surface flow area of 79.44 in2, Saturn

probe technology expands the operating

envelope of formation testing for both

fluid flow and reservoir environments.

The self-sealing drain assembly

incorporating the four ports

circumferentially extracts fluid from

the formation instead localizing

flow at a single probe.

04

x4

The Saturn 3D radial probe

increases the probe surface area by more than 500 times.

Probes not to scale.

79.44

6.03

Surface flow

area, in2

Surface flow

area, in2

Saturn 3D

radial probe

Eliptical

probe

Extralargediameter probe

Surface flow

area, in2

05

2.01

1.01

0.85

0.15

Surface flow

area, in2

Surface flow

area, in2

Surface flow

area, in2

Quicksilver Probe*

focused extraction

Large-diameter

probe

Standard

probe

Unlike the packer incorporated in a

conventional probe assembly or operations

using a dual straddle packer in the testing

string, the four ports of the Saturn probe

self-seal with suction to the borehole wall

to receive direct flow from the formation

with faster cleanup.

Complete pressure surveys

in low-mobility formations

The technology that makes the Saturn 3D

radial probe excel at fluid extraction also

delivers a step change in formation pressure

testing. Conventional formation tester probes

with the largest surface flow area currently

available are limited to pressure testing formations with mobilities no lower than about

1 mD/cP. Pretesting-only service is the current

benchmark for excellent performance in lowpermeability formations, but the mobility limit

for those pressure tests is about 0.1 mD/cP.

Direct rig-time savings in lowpermeability formations

As the permeability of a formation decreases,

the performance improvement of the Saturn 3D

radial probe over conventional probes

widens significantly.

As shown in comparison with the extralargediameter probe for achieving 5% contamination,

the Saturn 3D radial probe improves sampling

efficiency beginning at formation mobilities of

500 mD/cP, with the performance gap greatly

expanding as the mobility decreases.

Once mobility approaches 10 mD/cP, the

extralarge-diameter probe cannot move the

formation fluid, whereas the Saturn 3D radial

probe is an enabling technology.

4-in invasion, 300-psi drawdown, kv/kh = 1

25

Sample enabling in low mobility

Time to reach 5% contamination, h

Sealing with confidence

Sample efficiency

20

15

Saturn 3D radial probe

Extralarge-diameter probe

10

5

0

1

10

100

Mobility, mD/cP

Modeled cleanup times for the Saturn 3D radial probe and a conventional extralarge-diameter probe

show the increase in sampling efficiency possible. The Saturn 3D radial probe is an enabling technology

for sampling at mobilities less than 10 mD/cP, at which the conventional probe cannot perform.

06

Flow fluid in three dimensions

The Saturn 3D radial probe comprises

four elliptical suction ports, distributed

at 90° intervals around the circumference

of the tool. This placement pulls fluid

circumferentially from around the borehole,

instead of the conventional probe

arrangement of one port as the sole fluid

access point. Each of the four Saturn ports

has a surface flow area of 19.86 in2, which

is more than 3 times larger than the surface

area of an elliptical probe, which is the

largest conventional probe. Together, the

four Saturn ports total 79.44 in2 of surface

flow area, an increase of more than

500 times over the area of the standard

conventional probe.

Flow from the formation to a conventional formation tester is narrowed to the intake of the single probe, not from

the entire circumference of the borehole wall.

07

Circumferential flow around the wellbore

has significant benefits for both sampling

cleanup and interval pressure transient

testing (IPTT). The Saturn 3D radial probe

quickly removes the filtrate from the entire

circumference of the wellbore to draw in

uncontaminated formation fluid. In addition,

the significantly larger flow area of the 3D

radial probe can induce and sustain flow in

low-mobility formations, formations in which

the matrix is uncemented, and the viscous

fluid content of heavy oil reservoirs.

The four Saturn ports efficiently establish circumferential flow from the formation to quickly remove filtratecontaminated fluid and flow uncontaminated, representative fluid for DFA, sampling, and pressure measurements.

08

Circumferential support for

unconsolidated formations

The circumferential self-sealing technology

of the Saturn 3D radial probe mechanically

supports the borehole with the compliant rubber

seal of its drain assembly throughout the sampling

operation. Pressure drawdown is localized to

the four elliptical suction ports, which minimizes

the matrix stress while flowing fluid. If any matrix

disengages while flowing fluid, the Saturn 3D

radial probe is equipped with sandface filtering

mechanisms on each of the ports to prevent

plugging of the system.

Accurate permeability and permeability

anisotropy measurement

The Saturn 3D radial probe is designed with zero

sump, which significantly minimizes wellbore

storage. This storage reduction coupled with

spacing of the monitoring probe just 1.23 m

from the Saturn probe’s pressure gauge makes

it possible to derive formation permeability

and permeability anisotropy across a wide

permeability range in a single trip.

09

The mechanical retract mechanism of the Saturn 3D radial

probe employs heavy-duty springs to secure the drain

assembly when not deployed.

Extending sampling to large-diameter

wellbores, HPHT conditions, and

lengthy programs

Available in both 7-in and 9-in tool diameters,

the Saturn probe brings the efficiency of radial

fluid flow to boreholes sized up to 14½ in.

The high temperature rating of the 7-in Saturn

probe at 400 degF and high pressure rating

for both Saturn probe sizes at 30,000 psi

extends coverage across practically all

downhole environments.

Qualified for 20 sequential sealings of the drain

assembly at maximum differential pressure

in a single descent, the Saturn 3D radial probe

has achieved up to 60 settings in the field,

depending on environmental conditions. This

reliable downhole flexibility enables achieving

ambitious formation testing objectives.

Combinability and conveyance

flexibility

Full compatibility with the MDT Forte,

MDT Forte-HT, and MDT tester modules

along with the InSitu Fluid Analyzer realtime downhole fluid analysis system family

maximizes configuring the formation testing

string to match the wellbore and formation

conditions and the test objectives. Deployment

capabilities are similarly flexible—from

wireline to the TLC tough logging conditions

system to the UltraTRAC all-terrain tractor—

for accessing wells at any angle: vertical

to highly deviated and horizontal.

Reliably out of the hole, every time

Sixty-four individual heavy-duty springs

mounted around the edges of the Saturn probe

assembly and two large-diameter heavy-duty

springs around the mandrel ensure reliable,

consistent retraction of the elliptical suction

ports after every station. The large cumulative

closing force of the mechanical spring system

keeps operational risk to a bare minimum.

10

Case Study

High-quality samples in OBM and tests across wide

permeability range, Norwegian Sea

Benefits:

Enabling

Efficient

Derisking

Flexible

When a potential Lower Jurassic reservoir

was found to consist of unexpectedly poorer

quality, low-permeability rock in comparison

with the over- and underlying producing

beds in a deepwater field, Statoil wanted

to conduct a thorough evaluation by measuring

pressure data, collecting fluid samples, and

conducting pressure transient and vertical

interference tests. However, an initial run of

the MDT tester employing conventional single

probes could not answer these data needs in

the low-permeability zones. For example,

a hydrocarbon sample collected in 2.4-mD/cP

mobility after 5 h of pumping contained 17-wt%

oil-base mud (OBM) filtrate.

Sampling efficiency was greatly improved

by incorporating the Saturn 3D radial probe

in the tester toolstring. Three oil samples

and six water samples at mobilities as low

as 0.3 mD/cP were collected, including

11

fluid extracted from 5 m lower in the same

formation as a sample collected with a

conventional probe at 17-wt% contamination.

However, the Saturn probe reduced the

drawdown by half in a 0.6-mD/cP zone

to deliver only 5-wt% contamination after

6 h of pumping.

The toolstring also incorporated an

observation probe at a 1.23-m interval

from the Saturn probe for conducting

vertical interference tests (VITs) to evaluate

permeability and permeability anisotropy

and to estimate the flow potential. All four

VITs returned valid, interpretable reservoir

responses at the probes, with particularly

good data acquired in a zone with

120-mD/cP mobility. High-quality pretest

pressure measurements were made at all

Saturn probe stations, in mobility as low

as 0.3 mD/cP.

Water

1.0

0.5

0

Oil

Highly absorbing fluid flag

Pumped volume

440

420

9-bar drawdown

at 3 cm3/s

400

380

360

340

320

X Saturn probe

Three samples

at only 5 wt%

contamination

460

Pressure, bar

Volume, L

Quartz gauge

240

220

200

180

160

140

120

100

80

60

40

20

0

High quality

X Observation probe

Saturn probe derivative

Pressure and pressure derivative, psi

Gas/oil ratio,

m3/m3

Low quality

300

200

100

Observation probe derivative

10 –1

10 –2

10 –3

35-bar drawdown at 12 cm3/s

300

0

1

2

3

4

Elapsed time, h

5

6

The Saturn 3D radial probe sampled a zone at 0.6-mD/cP mobility with contamination

reduced to 5 wt% after only 6 h of pumping. Drawdown was 35 bar during cleanup

at 12 cm3/s and 9 bar during sampling at 3 cm3/s. A conventional probe used in a

zone 5 m higher in the same formation with 4 times the mobility required almost

twice the drawdown and still had 17-wt% OBM filtrate contamination.

10 –3

10 –2

10 –1

Elapsed time, h

A pressure transient test with vertical interference monitoring shows

well-developed pressure transient responses at both the Saturn probe

and the observation probe. The buildup interpretation yields a mobility of

120 mD/cP, for which a dual-packer configuration would be challenged

to create sufficient drawdown for conducting a valid test.

12

Case Study

Oil/water contact delineated in 12¼-in wellbore

in low-permeability presalt carbonate

An operator needed to accurately define the oil/water contact in a low-permeability

zone of a 12¼-in deepwater well offshore Brazil where conventional single probes had

returned only tight tests. The low mobility also implied longer pumping times on station,

which would increase operational risk.

Benefits:

Enabling

Efficient

Derisking

Flexible

13

The 9-in version of the Saturn 3D radial probe extends the efficiency of four-port fluid

extraction with the industry’s largest surface flow area to large-diameter wellbores.

Where a conventional probe had previously failed to define the pressure gradient in the

transition and water zones, the 9-in Saturn probe reliably sealed in the 12¼-in wellbore.

Fluid was extracted at stations with estimated mobilities of 0.03 and 0.06 mD/cP in only

3.5 and 6.5 h, respectively, to both save rig time and reduce risk. The purity of the collected

samples was confirmed with real-time downhole fluid analysis.

Free-Fluid

Volume

Capillary-Bound

Water

Tight Test

Dry Test

Dry Test

Tight Test

8,100

Washout

psi

NMR Porosity

9,100

0.3

Gamma Ray

0

gAPI

150

Bit Size

10

in

Water

20 0

in

V/V

0.2

Mud After

8,800

psi

10,000

Mud Before

Oil

1 8,800

psi

0.3

Depth,

m

Cable Tension

10,000 15,000 lbf

Dry test

X,550

Dry test

V/V

Permeability

0

Drawdown Mobility

Free-Fluid

0.01

mD/cP

1,000

Volume Using

NMR Permeability

3-ms Cutoff

0 0.3

V/V

0 0.01

mD

ohm.m 2,000

Density Standoff Correction

g/cm3

0.2

ohm.m 2,000

Array Induction 2

2-ft

Resistivity A10

1,000 0.2

0.25

Standard-Resolution Formation

Photoelectric Factor

Array Induction

20

2-ft

Resistivity A90

0

Free-Fluid

Volume

InSitu Fluid

Analyzer

Fluid Fractions

20

Caliper

10

Array Induction

2-ft

-1

Resistivity A30

Clay-Bound

Water

Formation pressure

ohm.m 2,000 0.45

0

Standard-Resolution

Formation Density

g/cm3

3

Near/Array-Corrected

Limestone Porosity

V/V

–0.15

The tight, low-quality pressure points (red) returned by

a conventional probe were so scattered that pressure gradients

and contacts across the low-permeability water zone could not

be determined. The Saturn 3D radial probe acquired multiple valid

pressure measurements (yellow) and low-contamination samples

from the zone that confirmed the presence of water and delineated

the contact to the overlying oil zone.

X,560

Dry test

Tight test

X,570

Lost seal

X,580

Dry test

Tight test

Lost seal

No seal

No seal

Lost seal

X,590

14

Case Studies

Saturn probe retrieves uncontaminated 7.5-API oil

from friable sandstone

Benefits:

Enabling

Efficient

Derisking

Flexible

Accurate fluid description and determination

of pressure differentials were needed to guide

well placement and completion in an onshore

Mexico field to avoid the development

of preferential flow along higher-mobility

intervals. However, the combination of a poorly

consolidated formation, with unconfined

compressive strength (UCS) values ranging

from 100 to 800 psi, and high-viscosity fluid

content meant that the pressure differential

generated by conventional formation testing

inevitably caused collapse of the wellbore wall and failure of the seal or sanding out of the tool.

The operator had to resort to temporarily

perforating, completing, and flowing each

sand separately to collect samples in coiled

tubing–deployed bottles on a DST string.

The complicated logistics and high costs

of this approach were not sustainable.

15

Unlike single-probe conventional formation

testers, the Saturn 3D radial probe is ideal for

flowing fluid in these challenging conditions

of an unconsolidated reservoir with low

mobility. The four self-sealing elliptical ports,

with the industry’s largest surface flow area

of more than 79 in2, quickly establish and

maintain flow from the entire circumference

of the wellbore instead of funneling fluid from

the reservoir to a single access point. The

result is quicker cleanup and the efficient

performance of pressure measurements.

In unconsolidated formations, the compliant

rubber surface of the Saturn probe’s drain

assembly mechanically supports the borehole

throughout the sampling operation. Pressure

drawdown is localized to the four elliptical

ports, which minimizes matrix stress while

fluid is flowing. If sand grains were drawn in with

the flowing fluid, the drain assembly incorporates individual port filters

to prevent flowline plugging.

The Saturn 3D radial probe was deployed

in the field to test and sample at multiple

stations in several wells, which have up

to 12% ovalization. Whereas conventional

probes commonly experienced lost seals

in the rugose holes, the Saturn probe’s selfsealing ports maintained seal integrity to

support the borehole in the unconsolidated

sandstone reservoirs. There was no

evidence of sand grains reaching the pumps.

Each self-sealing port incorporates a filter to capture

any dislodged matrix and prevent plugging.

Full pressure surveys were conducted in

both water- and oil-base mud environments

with only minor storage effects observed

in the pressure responses. The pressure

surveys in combination with the mobilities

determined from every pretest are being

used to design completions that will evenly

distribute injected steam among designated

intervals and avoid channeling.

Fluid sampling successfully captured

an uncontaminated sample of 7.5-API oil;

subsequent laboratory analysis reported

a viscosity of approximately 1,030 cP at

downhole conditions. Being able to use the

Saturn 3D radial probe to collect what were

previously unobtainable high-quality samples

and pressure data is providing a wealth

of information for the operator.

The Saturn 3D radial probe collected an uncontaminated

sample of 7.5-API oil from an unconsolidated sandstone

reservoir without sanding or seal failure.

16

Case Study

Saturn probe proves low-permeability laminated

pay, offshore northwest Australia

Benefits:

Enabling

Efficient

Derisking

Flexible

17

An operator identified an interval for further investigation from borehole images obtained with

the OBMI* oil-base microimager. However, a wireline formation tester with a conventional probe

was unsuccessful at evaluating the thinly laminated sands in the deepwater exploration well.

The probe’s pressure measurements were ineffective, indicating very low permeabilities, and

flow could not be established for fluid sampling.

The Saturn 3D radial probe performed well in the low-permeability laminated sands, obtaining

valid pressure measurements in submillidarcy formations for pressure transient analysis to

accurately determine the permeability. Fluid samples were collected for identification, including

a gas sample from a zone with 0.36-mD permeability. The operator’s reservoir evaluation was

greatly improved by the Saturn probe’s results to significantly increase the net pay for the well.

X,X13

X,X14

Formation contact area

of Saturn 3D probe

X,X15

X,X16

X,X17

Formation contact area

of conventional probe

Pressure measurements and fluid samples were acquired

by the Saturn radial probe with its large 79-in2 contact area

in the interval identified from images obtained by the OBMI

oil-base microimager. A conventional single probe, with its

much smaller contact area, was not able to perform in the

very low-permeability laminated sands.

18

Case Study

650% faster flow rate efficiently acquires fluids from dolomite

Benefits:

Enabling

Efficient

Derisking

Flexible

The openhole logs from a dolomitic limestone

interval drilled with saline water-base mud

in the Middle East did not indicate the

presence of hydrocarbon, but the analysis was

ambiguous because some zones had resistivity

values as low as 0.7 ohm.m. The operator

wanted to conduct DFA and collect samples to resolve the identity of the reservoir fluids,

but the time allowed at each sampling station

was limited to 4 h in consideration of mud

losses during the job.

Schlumberger deployed an advanced wireline

formation tester toolstring that included both

the Saturn 3D radial probe and an extralargediameter conventional probe to acquire fluid at multiple stations in a single trip.

19

After DFA at Station I clearly identified

60%–70% oil, Station II was selected for

determining the lowest mobile oil. The initial

sampling attempt with the extralarge-diameter

probe experienced a significant pressure drop,

with 2,000-psi drawdown and a low flow rate

of 5.2 L/h. The resulting pretest mobility was

1.5 mD/cP. After 1.5 h of pumping out, flow

was switched to the Saturn 3D radial probe,

and the rate increased 650% with only 680-psi

drawdown. The performance of the Saturn 3D

radial probe for the ratio of rate to pressure

drop was a 19-times improvement over that of

the extralarge-diameter probe for the 1.5-mD/cP

mobility. Flowline resistivity stabilization was

achieved with water identification at Station II

within the 4-h limit for the well, and the water

collected in the sample bottle confirmed the

DFA results.

Thermal Neutron Porosity

V/V

Formation Density

g/cm3

530

Pretest

Mobility

mD/cP

Formation Pressure

psi

930 0.01 1,000

46

Delta-T

Compressional Slowness

us/ft

Bulk Density Correction

g/cm3

Photoelectric Factor

Resistivity

Array Induction 4-ft A60

ohm.m

Array Induction 4-ft A30

ohm.m

Array Induction 4-ft A20

ohm.m

Array Induction 4-ft A10

ohm.m

Invaded Zone Resistivity Core

Interval

ohm.m

MDT

Station

Drillstem

Test

Interval

MDT

Quality

Station III

46

30%

oil

70%

water

0.367 psi/ft (oil)

48

48

Station I

40%

water

60%

oil

49

Station II

Water

50

0.477 psi/ft (water)

± 0.021 psi/ft

50

51

51

52

52

The extralarge-diameter probe was able to collect reservoir fluid at Station I, but after 1.5 h of pumping out at Station II, flow was switched to the

Saturn 3D radial probe, which increased the flow rate by 650%.

20

Time, s

ExtralargeDiameter

Probe

16,200

7,200

5,400

6

5

4

Pressure

X,000

W,000

9,000

Flow rate,

cm3/s

3

2

Rate

W,500

1

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

0

Time, s

35 L

5,400

3,600

20

Inflation, 7 L

Y, 800

18

Y, 600

16

Y,400

3,600

Y, 200

1,800

Pressure, Y, 000

psi

X, 800

1,800

No oil was observed by the optical analyzers for the

34 L of fluid extracted at Station II by the extralargediameter probe (left) at a large drawdown and low

rate. Once flow was switched to the Saturn 3D radial

probe (right), cleanup was achieved at a rate that

was about 3.5 times faster. The insets show how the

fluid flow in the reservoir is to a single point for the

conventional probe but circumferentially for the four

self-sealing ports.

21

7

Pressure,

psi

X,500

10,800

7,200

8

Y,000

12,600

34 L

9

Z,000

Y,500

14,400

12,600

9,000

10

16,200

14,400

10,800

Time, s

Saturn 3D

Radial

Probe

14

Formation pressure

12

10 Flow rate,

8

Flow rate

X, 600

6

X,400

4

X, 200

2

0

2,000

4,000

6,000

8,000

10,000

12,000

cm3 /s

14,000

0

16,000

Time, s

Comparison of pressure and rate of the extralarge-diameter probe (left) and Saturn 3D radial probe (right) at

Station II shows that the Saturn probe increased the flow rate 650% with only 680-psi drawdown, which is

one-third of the conventional single probe’s drawdown. The resulting ratio of rate to pressure drop delivered an improvement of 19 times over the single probe’s performance.

Saturn

Specifications

Saturn 3D Radial Probe

Measurement

Output

Logging speed

Mud type or weight limitations

Combinability

Special applications

Mechanical

Temperature rating

Pressure rating

Borehole size—min.

Borehole size—max.

Max. hole ovality

Outside diameter

Length

Weight (in air)

Ultralow-contamination formation fluids, formation pressure, fluid mobility,

downhole fluid analysis, permeability anisotropy

Stationary

None

Fully integrates with MDT modular formation dynamics tester and

InSitu Family* sensors

Low-permeability formations, heavy oil, near-critical fluids, unconsolidated

formations, rugose boreholes, large-diameter boreholes, high temperatures

7- and 9-in versions: 350 degF [177 degC]

High-temperature 7-in version: 400 degF [204 degC]

20,000 psi [138 MPa]

High-pressure version: 30,000 psi [207 MPa]

7-in version: 7.875 in [20.0 cm]

9-in version: 9.875 in [25.08 cm]

7-in version: 9.5 in [24.13 cm]

9-in version: 14.5 in [36.83 cm]

20%

Tool body: 4.75 in [12.06 cm]

7-in version drain assembly: 7 in [17.78 cm]

9-in version drain assembly: 8.75 in [22.23 cm]

5.7 ft [1.74 m]

With Modular Reservoir Sonde and Electronics

(MRSE): 12.4 ft [3.78 m]

7-in version: 385 lbm [175 kg]

9-in version: 485 lbm [220 kg]

22

Saturn

slb.com/saturn

*Mark of Schlumberger

Other company, product, and service names are the properties of their respective owners.

Copyright © 2014 Schlumberger. All rights reserved. 14-FE-0050