CHEM 36 – Spring 2006 Experiment 1: Synthesis and

advertisement

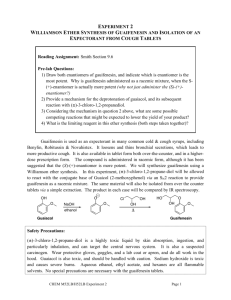

CHEM 36 – Spring 2006 Experiment 1: Synthesis and Simultaneous Extraction of Guaifenesin from Cough Tablets Objectives: In this experiment you will be using a simultaneous Williamson ether synthesis of guaifenesin, a potent anti-tussive (cough), and its extraction from an over-the-counter cough tablet to illustrate the equivalence between a “natural” and “synthetically” derived material. The experiment will further reinforce the concepts of the SN2 reaction in practice through the Williamson ether synthesis as well as solid-liquid and liquid-liquid extraction techniques we have covered last semester. Reading: Natural vs. Synthetic One of the major misconceptions in modern life is the difference between a “natural” product and a “synthetic” one. In an effort to return to more environmental and health-conscious lifestyle many would have the average lay-person believe there is a different chemistry in the natural world than that used in modern industry. Products deemed natural are labeled “healthy”, “safe” and “green”, while those from industry are labeled in less complimentary ways. The truth is far more complex. Nature, through billions of years of chemical experimentation (mostly through living things) has economized the production of hundreds of thousands of compounds from simple compounds in the environment for use by life. Further more, once these compounds are “used” they are degraded into molecules that are readily used by other living things, often forming closed cycles. With a heritage of only a mere 150 years, it is difficult to expect modern synthetic chemistry to be as efficient or economical. In many cases the urgent need for a particular chemical compound may preclude any thought given to by-products. The final step of any human made chemical process is to “close the loop” and optimize the process. The ultimate truth in comparing something natural to that which is synthetic is that there is NO difference in the pure molecules created by either process. What may differ is the side products contained in each or the by-products produced in the process of achieving them. In this experiment you will demonstrate the identical nature of the guaifensin, an effective over the counter (OTC) cough suppressant, found in cough tablets to that prepared in a bench-top procedure via the Williamson ether synthesis. Guaifenesin Guaifenesin is natural substance that was first isolated in the sixteenth century for its believed effectiveness in the treatment of rheumatism (fibromyalgia). Modern clinical studies have disproved this use and applied CH3 OH O the compound as an effective expectorant in nearly every cough, cold, flu, and allergy medication on the market. The extraction from the natural HO O creosote or turpentine is involves a steam distillation process (from our distillation lecture) followed by a series of acid-base extractions (from our Guaifenesin extractions lecture) to remove the guaifenesin from the other substituents in the distillate. Typical dosages of guaifenesin are 100, 200 and up to 600 mg every 4-6 hours. Various preparations containing this compound include Tylenol Cold®, Robitussin® and Guai-Aid® as either tablet or syrup form. Guai-Aid® tablets are the best source for the laboratory extraction as they include the highest concentration of our target with the fewest interferences. A typical table includes: the active ingredient, guaifenesin, 100-600 mg (Expectorant) and inactive ingredients: Carbomer 934P (a muco-adhesive polymer), dyes (to make the pill look unique and attractive) and the water-soluble binding agents hydroxypropyl methylcellulose, magnesium stearate, microcrystalline cellulose, sodium starch glycolate (these agents tune the “solubility” of the active compounds in vivo, i.e. “time release”). Synthetic Preparation As with many natural ingredients, the natural extraction processes are not efficient enough, or the compound simply isn’t abundant enough from its natural sources for a large-scale distribution. Thus, synthetic processes must be designed to obtain the needed compound. You will be performing the laboratory synthesis of guaifenesin by means of the Williamson ether synthesis an example of the SN2 chemistry you have covered in lecture class. SN2, as you recall is the reaction nomenclature for substitution, nucleophilic, bimolecular. In these reactions a suitable nucleophile collides with an unhindered sp3 carbon center bearing a good leaving group. Through the collision a bond between the nucleophile and the carbon is formed with the simultaneous cleavage of the bond between the carbon and the leaving group. For this reaction to proceed several factors must be considered: 1.) The nucleophile must be reasonably small and have a high density of negative charge in the electron pair that is donated to the carbon center. 2.) The carbon center must be unhindered for the collision to occur (1o or 2o) and to lower the energy of the transition state (where 5 entities are attached to carbon). 3.) The leaving group with its departing pair of electrons must be a weaker nucleophile (poor e– pair donor) than the incoming nucleophile, or the reverse reaction will occur. 4.) The solvent should support the charged species involved but not over-stabilize them (polar aprotic solvent). Williamson Ether Synthesis base R OH R O + R O H2 R' C X R O H2 C R' + X X = Cl, Br or I The Williamson ether synthesis features these conditions and therefore can be used to illustrate this important reaction type. Generally the Williamson synthesis utilizes a phenoxide or alkoxide nucleophile (oxygen is small, and has a full negative charge) acting on a (usually) primary alkyl halide (Cl, Br or I leaving groups) substrate. Although SN2 reactions are promoted by polar aprotic solvents, the high nucleophilicity of the oxygen nucleophile and primary substrate allow the reaction to occur in protic solvents at higher temperatures (i.e. greater number of collisions per unit time). For our synthesis of guaifenesin the most convenient route would be to use the phenoxide (from 2methoxyphenol) nucleophile as it is the most easily generated by deprotonation (remember phenols are more acidic than alcohols). In addition, this end of the final ether could not be used as a substrate for SN2 as a sp2 carbon would bear the leaving group. The substrate will be the primary alkyl halide 3-chloro-1,2propanediol. In the pre-lab preparation you should endeavor to show the main chemical reaction, and study the procedure to see where the deprotonation reaction and actual SN2 reaction are occurring. Procedure: Williamson Ether Synthesis of (±)-Guaifenesin Guaiacol (2-methoxyphenol, 1.1 mL is dissolved in 6 mL 95% ethanol in a fumehood, and a solution of 0.5 g of crushed NaOH pellets in 2 mL water is added. The mixture is heated under reflux for 10 min. Then, a mixture of 1.0 mL of (±)-3-chloro-1,2-propanediol in 1.0 mL 95% ethanol is added dropwise to the phenoxide anion and the reflux is continued for 1 h (Perform the “Isolation of (±)-Guaifenesin from Guai-Aid Tablets” during this time!) The ethanol is removed by evaporation on a sand bath, and 6 mL water is added to dissolve precipitated NaCl. The aqueous solution is extracted twice with 10 mL ethyl acetate, and the organic layer is dried using MgSO4. Removal of the drying agent and evaporation of the solvent affords a pale yellow oil which is solidified by the addition of 10-20 mL hexanes with cooling and stirring in an ice-bath. This crude solid is collected by vacuum filtration and is recrystallized from ethyl acetate-hexanes. Weigh and obtain the % yield. Isolation of (±)-Guaifenesin from Guai-Aid Tablets During the 1-h reflux time discussed above, a single Guai-Aid® or Mucinex® tablet (containing 200-600 mg (±)-guaifenesin) is crushed to powder and added to 5 mL ethyl acetate. The suspension is stirred at room temperature for 10 min and any insoluble material removed by gravity filtration. Addition of 10 mL hexanes to the filtrate in 2-mL portions causes white crystals to form on standing for a few min. After cooling in an ice-bath the precipitate is collected by vacuum filtration and washed with 5 mL cold hexanes. Calculate the percent of the material recovered from the tablet vs. the reported amount. Perform a melting point on the synthesized material, the extracted material as well as a mixture of the two. Compare. What is the purpose of taking a melting point of the mixture? Procedure adapted from: Journal of Chemical Education, Vol. 80 No. 3 March 2003