Rotational Dynamics, Moment of Inertia, Torque and

advertisement

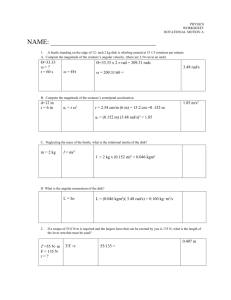

Rotational Dynamics, Moment of Inertia, Torque and Rotational Friction Junaid Alam, Waqas Mahmood, Sohaib Shamim, Wasif Zia, Muhammad Sabieh Anwar LUMS School of Science and Engineering August 7, 2011 When you push the throttle to accelerate a moving car, all you are doing is using the engine to apply more force. But why is there no acceleration after a certain speed is reached, even when the engine is still applying the force? Why do you nd it dicult to stop a rotating wheel even if there is no translational motion? Why are the brake linings of formula 1 cars made dierently from ordinary cars? Why is it easy to accelerate a bicycle having smaller wheels but hard when it has large wheels? How are the rotations of a wheel of a car translated into the linear speed of the car? Why is the lower gear capable of imparting more acceleration than the higher ones? Study of the quantities like moment of inertia, torque, angular speed and speed dependent friction may help us nd the answers to these questions. This is what we will be dealing with in this experiment. The design of very fundamental mechanical devices, such as gears, ywheels and mechanical centrifuges, requires a clear understanding of the concepts of rotational mechanics and mechanical friction that depends on angular speed. The relationship between linear and rotational motion has to be dealt with in many situations. This experiment will help grasp these concepts. KEYWORDS Rigid Body Angular Momentum Angular Velocity Moment of Inertia Torque 1 Angular Acceleration 1 Conceptual Objectives In this experiment, we will, 1. appreciate the similarities, dierences and relationship between rotational and translational motion; 2. investigate energy loss through friction; 3. appreciate that there exist dierent ways of measuring a physical quantity with dierent accuracy and precision; 4. t experimentally observed curves with mathematically modeled solutions; and 5. see how errors propagate from measured to inferred quantities. 2 Experimental Objectives The experiment is divided into two sections: determining the frictional losses and measuring the moment of inertia of a circular disc. In the rst section, height loss measurements will be done by correlating the rotation of a disc with the loss in the height of a mass attached to a thread wound over a pulley on the disc. After having established the nature of the relationship between angular speed and frictional losses taking place in the system, a value of the moment of inertia of the disc will be determined. 3 Theoretical Introduction This experiment introduces you to the concepts of rotational motion. We shall touch upon a number of topics and discuss how a large complex object can be considered to be composed of a large assemblage of ideal particles. We will elaborate that a full description of a body's motion must include linear as well as rotational motion. Furthermore, we will discuss torque as it applies to our experiment. 2 3.1 Angular Momentum We can consider the provided circular disks (rigid bodies) to be made up of small m1 ; m2 ; m3 ; : : : mi ; : : :. Their placement may be dened with the position vectors r1 ; r2 ; r3 ; : : : ri ; : : : and when rotating, their instantaneous velocities may be dened as v1 ; v2 ; v3 ; : : : vi ; : : :. The index i shows innitesimal particles of masses one of the many particles. Figure 1 illustrates the i th particle rotating about the z axis. z mi vi ri J = mi vi ri Figure 1: A representative particle rotating about the z-axis; mi vi is the linear momentum and J is the angular momentum. The angular momentum of the particle about z axis is given by, Ji = mi vi ri ; (1) where denotes the vector or cross product. For a particle rotating with an angular velocity ! about z axis, we can say that, vi = ri !: (2) Consider a circular disk rotating about the z axis. The disk itself can be considered to be composed of with all its innitesimal elements in the xy plane. Using Equation (1) and Equation (2) we can write for the i th particle, Ji = mi ri2 !: (3) The total angular momentum of a disk about an axis is simply the sum of all the angular momentums for the innitesimal particles, 3 z J2= m2v2 r2 R J1= m1v1 r1 J3= m3v3 r3 Figure 2: Disk can be considered to comprise particles. The individual angular momentums of these particles will all add up resulting in the total angular momentum. J= N ∑ mi vi ri : i =1 (4) 3.2 Moment of Inertia The cross product for a disk rotating about the z axis with its components in the xy plane can be expanded as, Jz = N ∑ i =1 (mi ri 2 )!: (5) ∑ Here I = mi ri 2 is a constant (irrespective of the angular velocity of the disk) and is known as the moment of inertia of the disk. Therefore Equation (5) becomes, Jz = I!: (6) In the present experiment, we will investigate the rotational kinematics of a disk. It will also be helpful to know the moment of inertia for a circular disk, which is, 1 I = 2 MR2 (7) where M is the mass and R is the radius of the disk. Q 1. Show that the kinetic energy of a rotating disk is given by, 1 KE = 2 I!2 : (HINT: Kinetic energy for a particle is given by, K = particles and use the fact, I = ∑ mi ri 2 .) 4 (8) 1 2 mv . Sum for all the 2 Moment of inertia is analogous to inertia in linear kinematics. However, since in rotational motion, we always nd ourselves dealing with moments, we call the inertia in circular motion as moment of inertia. Moment of inertia of a particular body is dened with respect to a particular rotation axis and is dierent for a body when it is rotating about x , y or z axes. Table 1 provides a brief comparison of linear and rotational motions and their characteristics. Table 1: Comparison between Linear and Rotational Motion. Concepts and quantities Linear Motion Rotational Motion Position Velocity Acceleration Motion Equations Newton's 2nd Law Momentum Work Kinetic Energy Q x v v a =t x = vt F = ma p = mv Fx 1 2 mv 2 ! ! = t = !t = I J = I! 1 2 I! 2 2. A circular disk of mass 0:2 kg and radius 0:1 m is rotating at 10 revolu- tions per second. Calculate the angular frequency, moment of inertia and kinetic energy of this disk. 3.3 Turning Eect Q 3. Dene torque. Mathematically, torque ( ) is, = r F; (9) where r is the displacement between the line of action of force and the particle and F is the force applied. Expanding the cross-product we get, = rF sin(): (10) where is the angle between F and r. In a gravity driven system, we may replace express the equation as, 5 F using Newton's second law and = mgr sin(); where (11) m is the mass used to drive the mechanism and g is the acceleration due to gravity. 3.4 Angular Acceleration Q 4. Dene angular acceleration. Mathematically, angular acceleration is given by d! = dt : (12) You may want to refer to Table 1 to become more comfortable with this seemingly new term which is just an equivalent of linear acceleration adapted for rotational motion. In other words it is the gradient of angular velocity versus time graph. Newton's second law for rotational motion states that, = I where (13) is the applied torque, is the angular acceleration and I is the moment of inertia|the rotational equivalent of mass. Note its similarity to Newton's law for linear motion F = ma, establishing the moment of inertia as the analogue of mass and torque as the analogue of force. If we substitute Equation (11) and Equation (12) in Equation (13) we get, d! mgr sin() = I dt : (14) 4 Introduction to the Apparatus The apparatus (Figure 4) consists of the following components: 1. Rotational Motion Apparatus This apparatus, ME-9341 was procured from PASCO Scientic. The contents of the apparatus are in Figure 3. 6 Spindle Bushing of the bearing assembly Screw Rod Base Leveling Support Bubble Level Main Platter Auxiliary Platter Super Pulley (SP) Step Pulley Smart Timer (ST) Holder Photogate Figure 3: The components of the rotational motion apparatus. Note the arrows showing the particulars of the components. 2. Smart timer, photogate and super pulley: The photogate sends a narrow beam of infra-red radiation from one arm which is detected by a detector in the opposite arm. When the beam is blocked, the LED at the back of the photogate lights and a signal is sent to the smart timer (ST ). A super pulley is placed such as its spokes block the photogate beam. As the super pulley has 10 spokes, in one revolution, it blocks the photogate beam 10times. Using these devices, we will measure the speed as well as the number of rotations of the platter. We use the smart timer in the fence mode to record the time between ten successive interruptions of the photogate. The timing begins when the photogate beam is rst blocked and stops when it has been blocked ten times. Using the Select Measurement key, user can recall the cumulative readings of the durations for 10 consecutive interruptions of the beam. 7 Base Step pulleys Main platter Photogate To photogate Holder super pulley 1 super pulley 2 levelling screws Figure 4: Arrangement of the experimental set up (side view). 5 Experimental Method 5.1 Preparation : Record every measurement and the associated uncertainty in your lab NOTE notebook with suitable commentary wherever required. 1 Place the bubble level on the base. See if the bubble is in the inner ring. If not, screw or unscrew the three adjustable supports underneath, to bring the bubble in the inner most ring. 2 Find the outer diameter of the main platter (Cd ) and the supper pulley (Cp ), and the inner diameter of the pulleys on the main platter using vernier callipers. 3 Find the mass of the main platter using a mass balance. Note the uncertainty in your reading and comment about your choice of a particular value for it. 4 Slide the spindle into the bushing of the bearing assembly. Then slide the main platter atop with the step pulleys facing up. Main platter Spindle Base Base 8 5 Clamp the rst super pulley with a clamping screw to the base. super pulley 1 6 Attach the screw rod to the second super pulley and fasten it into the holder. Then slide the holder into one of the holes on the sides of the base and use a rubber band to keep the rim of the super pulley touching that of the main platter. super pulley 2 screw rod Holder Holder super pulley 1 7 Place the photogate such that the spokes of the horizontal super pulley block its beam. Check the connections of the photogate (P1 ) with the smart timer (ST ). Photogate Smart Timer (ST) Holder 8 Check if ST beeps when you switch it ON using the power switch on the side. Press 1 to select the quantity to be measured and then 2 to choose the measurement mode. Try taking a reading in the GATE timing mode. 9 Give a push to the main platter and press 3 from ST. 10 Explain the value that has been returned by ST . 9 11 What is the uncertainty in your measurement? 5.2 Frictional Losses In every real life situation, a mechanical system involves losses due to friction. In order to measure the moment of inertia of the disc accurately, we have to quantify the losses, so that a balanced energy transfer equation can be written and solved. In this section you will measure the frictional losses by relating friction to the speed of rotation of the disc. Besides nding out the qualitative dependence of frictional loss on angular speed, you will be able to establish a quantitative relationship as well. 1 Press 1 on the smart timer to go to the count mode. In this mode, the device acts as a counter, incrementing its reading by when every time the beam of the PASCO SMART TIMER Count: Manual photogate is interrupted. By pressing 2 , you can go to the Manual mode, so that you can start and stop the counter whenever you like. 2 Take a thread of suitable length e.g. 100 cm. Tie one end of the thread to the screw protruding from 1 2 3 the smallest pulley on the main platter. Then pass the thread from the holes right beside the screw. Pass it through only as many holes as suitable for the pulley that you choose for this part of the experiment. Screw Holes To hanger Fasten the free end of the thread to the hanger and put two 100 g masses in it. 3 Position the super pulley (1) such that it is exactly in front of the axle of the disc. Pass the thread over the pulley and wind the thread on the chosen step pulley until the mass hanger is at a suitable height, e.g. 65 cm above the oor. 4 Press the start ( 3 ) button on the smart timer (counter) and release the 10 Photogate Smart Timer (ST) Holder Mass hanger mass-hanger. Note down the counts that are displayed by the counter when the mass-hanger returns to the subsequent maxima (positions 1, 2, 3 and so on). You will have to carry out the measurements 3 times in order to have an average value of the counts. 1 a b ∆h 2 3 c Remember, however, that counts measured from the counter are cumulative and for individual cycles, they can be calculated as the dierence of two consecutive readings. After having recorded the measured counts for 10 subsequent maxima, change the measurement quantity to Time and measure the time elapsed between the two spokes of the horizontal super pulley at every minima of the mass-hanger (positions a, b, c and so on in the gure above). Take three readings of time for every minimum. 5 From the measured diameters of the super pulley and the main platter and the ratio of their revolutions, derive a quantitative relationship between the measured time and the time that will be taken by the main platter to complete one revolution if the changes in speed are ignored. HINT: As the number of spokes of the super pulley is 10, time measured between two spokes represents the time it takes for the super pulley to rotate by 1=10th of a revolution. The ratio of the circumference of the super pulley to that of the 11 main platter may help in determining a relationship. Using that relationship, calculate the Nc instantaneous speed of the main plat- Cd ter. This value represents the maximum speed achieved by the main platter in the respective cycle. To cal- Np culate the average speed of the main platter during the whole cycle of the Cp mass-hanger, the following formula is Cd = x Cp Np = x Nc used: !avg = 0 + !max !max = : 2 2 (15) 6 Once you have measured the counts for every cycle and the average angular speed, you can construct a table that looks as below. Cycle `n' 0 1 2 3 4 5 6 7 8 9 C C 564 483 416 359 312 271 238 209 183 162 81 67 57 47 41 33 29 26 21 1 h (m) EB (J) N ER (J) !avg (rad/s) Table 2: Sample data table for calculating frictional loss. h, EB , N and ER represent respectively the corresponding height loss, energy loss of the cycle (= mg h), number of rotations of the main platter that occurred during a cycle of the mass hanger and the energy loss per rotation. 7 Plot the energy loss per rotation against the average angular speed, with !avg on the x -axis. You should get a straight line, as shown in gure (5), that shows a linear proportion between the two quantities. Q What does the relationship between ER and !avg signify? 12 ∆ER ωavg Figure 5: Average angular speed vs. energy loss per rotation. 5.3 Determination of Moment of Inertia I As frictional losses can be calculated for a range of angular speeds, we are now in a position to measure the moment of inertia of the main platter. Using a reasonable mass in the hanger, you will drive the main platter to a certain speed and nd out the corresponding energy loss per rotation due to friction from the graph you have plotted in the previous section. Once you can write a complete energy equation, the value of the moment of inertia can be calculated. 1 Unfasten the thread from the step pulleys and the mass-hanger. Take a new thread of a suitable length, e.g. 120 cm approximately, and attach it to the mass-hanger. Load a mass of 150 g in the hanger. Wind the free end of the thread around the pulley that you have been using. Make sure that the vertical super pulley is in line with the thread. Photogate Smart Timer (ST) Holder Mass hanger 2 Measure the height of the mass-hanger using a meter rule. Try to make a relevant judgment about the uncertainty, which can be far greater than the least 13 count of the meter rule in this case. 3 Set the smart timer to measure time in the ONE GATE mode. 4 Release the mass and let it drive the main platter. As soon as the mass hits the ground, press the START button on the smart timer. Using this measurement, determine the instantaneous and average angular speed of the main platter during the period when the mass-hanger was descending towards the ground. 5 To determine the energy losses, refer to the graph you plotted in the previous section and nd out the energy loss per rotation that corresponds to now measured value of average angular speed. 6 From the height of release of the mass-hanger and the circumference of the step pulley used, calculate the number of revolutions of the main platter that occurred during the time of the mass-hanger's descent. Total frictional loss will be the product of energy loss per rotation and the number of rotations of the main platter. 7 Write down an energy equation for the experiment that includes the energy lost and retained by the mass-hanger as well as the frictional losses. 8 Solve the equation to nd out a value of the moment of inertia. You are expected to give a reasonable estimate of uncertainty in the calculated value. 9 Discuss the main sources of error in your measurement. 6 Experience Questions 1. Why do we feel vertigo after a spin on a merry-go-round? 2. Does the inertia of our body increase in a swimming pool? m is right on top of center of gravity, does that mean there is no value of I for that mass? 3. If mass 4. In an accident, the body may be stopped by the seat belt and air bags. Where does all the momentum go? Can this cause bodily injury? 5. Why do cats always fall feet rst on the ground? 14 7 Idea Experiments 1. Find your body's moment of inertia. 2. Use dierent masses to check if the relationship between the frictional losses and energy delivered is linear. 3. Drop the auxiliary platter on the main platter when rotating to verify the conservation of momentum. 15