green innovation: how firms leverage capabilities, resources

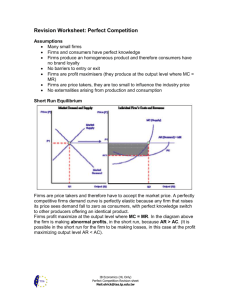

advertisement