Sustainability Report 2012

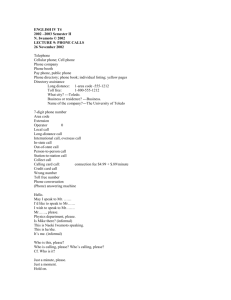

advertisement