A Clean Way to Plate

advertisement

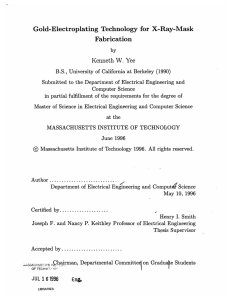

I. This cabinet is used lor neutral salt spray testing at Tan"?. Emphasis ispiacedoo developing finishes that are attractive and long-lasting. A Clean Way to Plate Precious Metals Plater Finds Practical Solutions for Pollution Control Plating companies are finding it necessary to make major changes i n their processes so they can eliminate the use of chemical solvents and freon in cleaning technology and continue to manufacture without risking damage to the environment. Family-owned Tanury Industries, Lincoln, RI, began making changes in plating processes years before the changes were required. The company i s now solvent-free with its plating processes. Here i s how Tanury found practical solutions to environmental problems while continuing to grow and diversify in the plating business. anury Industries is one of New England's largest independent gold electroplaters. Founded in 1948 as Tanury Brothers, the company is now in its second generation of family leadership. Starting out in a 3,000-sq-ft facility in Providence, the company now operates from a 25,000-sq-ftfacility in Lincolnwith annual sales of $10 million. lnordertosefvean increasing need for all types of plating, the company has installednewtechnologyandequipment, suchasgoldunitsformicrongold plating, new processes for palladium, light and darkruthenium, platinum, nickel-free,and electrophoretic(E-coat)plating.Thecompany has also invested heavily in research and development of new technologies to keep itsprocessespollution free and in compliance with EPA requirements. T Eliminating Solvents Jim DiNunzio.vice presidentof salesand marketing, saysTanury'sdecisionto eliminate solvents was difficult because solvent cleaners are proven to be effective in the electroplatingprocess. The use of chlorinated solvents (such as trichlorethylene) are among the most efficient 36 methodsof cleaning and degreasingpa& before plating. Freon is also an effective drying agent in the process. DiNunzio says the greatest challenge was evaluating the large number of systems on the market and finding the right process for Tanury. "We found that a lot of companies offered products in this market, but some just wouldn't work for us,"hesaid. Forexample,oneair-sprayer device that the company tested would actually blowsmall parts, such as jewelry pieces, off the plating rack. Tanury's method of eliminating solvents was a combination of traditional and new technology. In place of chlorinated cleaning solvents, the company has gone to an aqueous-basedsolution. The solution is incorporated into the existing solvent tanks. A few minor equipment changes (including the removal of some filters) made the process possible at a cost of about $2,000. The new process accomplishes the desired cleaning effect through a series of aqueous soaks and ultrasonics. The process has more steps than the chlorinated solvent process and the action of the aqueous-based solution is slower, requiring a longerprocessingtime. In the end, however, it is just as effective. Plating and Surface Finishing L ~ ~ , ~ and marketing. The change-over from solvents to the new process took more than a year becausethecompany tookthe time toevaluate a large number systems before making the change. ::iiminating Freon Tanury installed a hot-air oven to replace its freon dryer. The oven Tanury selected is acustomizedcombination blow-offwith dryer. There are two steps in the drying process. A conveyor carries the racked parts past a chamber where fluid is literallyblownfromthepart.Allresidualmoisture is removed by convection dryer. Tanury builta5,OOO-sq-ftadditionto its facilitytoaccommodatethe conveyorized unit. Because much of the conveyor is ceiling-hung, extra storage space was created in the addition. Thedryerwaspurchasedfor$lOO,OOO. With the cost of freon approaching $200,00O/year, however, the company Taysthedryerpaidforitself in six months. Other Changes Coming Tanury is turning its attention to other safety and environmentalconcernsthese days, It plans to eliminate the use of cyanide within the next two to three years. One source of cyanide is in copper plating chemistry used for adhesion. The process is easy to plate and easy to plate on. Tanury officials say the greatest challenge in eliminating the use of cyanide will probably not involve much money, but will involve time. Alkaline-copper solutions are now available and Tanury is already installingits first alkaline-copper bath. The companysays evaluatingproduct performance with this technology is expected to take several months. Diverse Products Tanury's growth can be attributed in Part to its diversification beyond the tradiIionaljewelry market, says DiNunzio. The company has expanded into writing instruments, giftware, eyewear. and automotive ornaments. October 1993 Writing Instruments When A.T. Cross launched its Signature Series, the company had an unusual plating requirement. They wanted more than 5 microns of gold on their writing Instruments. Most decorative plating is 1 micron of gold or less because as the thickness of the precious metal increases so do the problems associated with the process. Automotive Trim When the automotive industry became For example, in order for a company to interested in offering an exterior gold plate 5 microns (200 mil) of gold, the trim package, Tanury developed an in- product must stay in a regular plating terest in plating for the automotive in- bath for about two hours. The longer the dustry. The problem was that most plat- product stays in the gold bath, the higher ing companies were not able to pro- becomes the potential for stress fracduce a product that could meet the tures, discoloration and hazing. Working closely with A.T. Cross engirequirements for holding up in the constant exposure of extreme weather and neers, Tanury developed a specialized plating process that plates the product adverse road conditions. 200 microinches of gold without with According to DiNunzio,Tanuryworked with GM senior product engineers to de- stress while achieving a desired uniform velop GM Specification 6270M, "which color on the entire gold deposit. The dictated environmentaltesting specifica- Signature series was successfully tions for exterior gold ornamentation to launched by A.T. Cross in early 1991. meet or exceed five-year durability requirements." The company invested in Anticipating Needs an environmental testing laboratory that A spin-off of Tanury's successful diversiwas subsequently GM approved.Tanury fication is its reputation among customalso co-developed a proprietary protec- ers for being more than just an elective coating'capable of withstanding ex- troplater, says DiNunzio. "The combined knowledgeandexperienceineach areatreme weather conditions. It worked. In 1988. GM approved Tanury as an jewelry, writing instrument, eyewear and OEM supplier. Cadillac, a product of GM, automotive-helps the company to recbegan offering the OEM gold ornamen- ognize and anticipate the needs of inditation option that same year. These vidual customers," he said. Techniques developed for one market developments have enabled Tanury to are found useful in other markets. For move forward with the gold ornamentaexample, environmental laboratory testtion program. ing developed for the automotive market is now used by most of Tanury'scustomers. Eyeware Another example is the concern of the Randolph Engineering, a manufacturer jewelry industry with export issues over of eyeware, is known for diligently monitoring the field performance of the eye- nickel content. Many users of jewelry glass frames produced by the firm. The have developed an allergy to jewelry company also evaluates every product products that contain nickel. DiNunzio says Tanury anticipates that the issue that is returned by customers. Randolph began working with Tanury could affect other industries, or could in 1989 in an effort to improve the corro- even become a domestic issue in the sion resistanceand wearabilityoftheeye jewelry industry. The company now Offrames the company manufactures. To fers nickel-free processes and has even accomplish this, Tanury started a testing launched an educational campaign to and evaluation program in its in-house inform its customers about the issue. DiNunzio says there is no doubt that laboratories. The program lasted for Tanury will continue the same way in the three months. Microscopic testing of future. Eliminating pollution and toxics, Randolph's base metals indicated that certain prefinishingoperationscouldmini- and supplying customers with a safe, mize corrosive attack on the base-metal. dependable product, will continue to be Neutral salt spray (100-500 hours) and prioritiesfor the company. 0 oermiration (48-96 hours) test results , . helped TanuG to "fine tune Randolph's plating specification and to produce a product with improved wearability and 'DuraClear' was ca-developed by Tanury lndus performance. mes and Quality Spraying and Stencilling Co Whendiversifying,thecompanylooked formarketsthatneededspecification plating. Markets that were targeted included the writing instrument, eyewear and automotive industries because those markets were moving into an era of highquality, decorativefinishessuch asthose found on high-quality jewelry. 37 .