Aggregates

advertisement

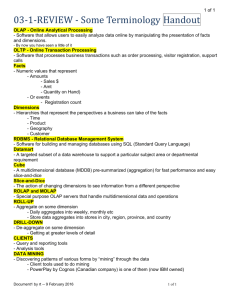

Aggregates INTRODUCTION Mineral aggregates are used in all fields of the construction industry to produce bituminous mixtures, concrete, mortars to be used in structures, fill materials, railway ballast, etc. For this reason we have given particular attention to all testing methods. The new EN standards have grouped all tests on aggregates in five main subjects: - Tests for general properties of aggregates - Tests for geometrical properties of aggregates - Tests for mechanical and physical properties of aggregates - Tests for thermal and weathering properties of aggregates - Tests for chemical properties of aggregate. In the majority of cases the new EN Standards correspond to some existing National Standards and, apart from a few exceptions there is almost no difference in the specifications of test apparatus. 47 48 Contents New EN standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Riffle boxes (sample splitters) . . . . . . . . . . . . . . . . . . . . . . . . Sieving method. Test sieves, nominal size of apertures . . . . Determination of particle shape . . . . . . . . . . . . . . . . . . . . . . . Flakiness and elongation index . . . . . . . . . . . . . . . . . . . . . . . Shape index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Assessment of fines. Sand equivalent test . . . . . . . . . . . . . . Assessment of fines. Methylene blue test . . . . . . . . . . . . . . . Determination of clay, silt, and dust . . . . . . . . . . . . . . . . . . . Determination of the efflux index . . . . . . . . . . . . . . . . . . . . 186 188 188 189 189 189 190 191 191 191 Resistance to fragmentation (Los Angeles) . . . . . . . . . . . . . . Crushing resistance of lightweight aggregate . . . . . . . . . . . Abrasion resistance of natural stones . . . . . . . . . . . . . . . . . Resistance to wear (Micro-Deval) . . . . . . . . . . . . . . . . . . . . . Aggregate crushing value . . . . . . . . . . . . . . . . . . . . . . . . . . . . Deval apparatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Scratch hardness ASTM method . . . . . . . . . . . . . . . . . . . . . . . Aggregate impact value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Determination of the voids of dry compacted filler . . . . . . . Aggregate density by water displacement. BS method . . . . Determination of loose bulk density and voids . . . . . . . . . . . Determination of the particle density . . . . . . . . . . . . . . . . . . Determination of particle density and water absorption . . Determination of Abrasion Value (AAV) . . . . . . . . . . . . . . . . Surface moisture of fine aggregate. ASTM method . . . . . . . Moisture measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Determination of the Polished Stone Value . . . . . . . . . . . . . Skid resistance and friction tester . . . . . . . . . . . . . . . . . . . . . Determination of resistance to freezing and thawing Climatic Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Magnesium sulphate test . . . . . . . . . . . . . . . . . . . . . . . . . . . . Determination of drying shrinkage . . . . . . . . . . . . . . . . . . . . Determination of resistance to thermal shock . . . . . . . . . . . Chloride content BS 812 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Organic impurities in fine aggregates . . . . . . . . . . . . . . . . . . Carbonate content of aggregates . . . . . . . . . . . . . . . . . . . . . Potential reactivity of aggregates . . . . . . . . . . . . . . . . . . . . . Sample reduction. Laboratory crushers . . . . . . . . . . . . . . . . . 192 192 193 193 193 194 194 194 194 195 195 196 196 197 197 197 198 199 200 201 202 202 203 203 203 203 204 185 47 AGGREGATES New EN European Standards. . . . . . . . . . . . . . . . . . . . . . . and relation with the existing National Specifications B y the time this catalogue has been printed a number of new European Standards concerning aggregates will have been published and the correspondent National Standards are automatically superseded. The new EN Standards for aggregates have been grouped in five main subjects: Standards - Tests for general properties of aggregates from EN 932-1 to EN 932-6 - Tests for geometrical properties of aggregates from EN 933-1 to EN 933-10 - Tests for mechanical and physical properties of aggregates from EN 1097-1 to EN 1097-10 - Tests for thermal and weathering properties of aggregates from EN 1367-1 to EN 1367-5 - Tests for chemical properties of aggregates from EN 1744-1 to EN 1744-3 In the majority of cases the new EN Standards correspond to some existing National Standards and, apart from a few exceptions there is almost no difference in the specifications of test apparatus. In order to allow clients the choice to update, if necessary, their laboratory equipment, we list below all the new EN Standards with corresponding National Standard. Considering that in many countries outside Europe the National Standards such as BS and NF will still be adopted, we continue to supply the relative apparatus. EN EN 932-1 EN 932-2 EN 932-5 EN 932-6 EN 933-1 EN 933-2 EN 933-3 EN 933-4 EN 933-5 EN 933-7 EN 933-8 186 Correspondent or comparable National Standards BS 812, 1377, 1924 ISO 4847-78 UNI 8520-3 CNR No. 93 ASTM C702 NF P18-551, 552, 553 UNE 83 109 BS 812, 1377, 1924 ISO 4847-78 UNI 8520-3, CNR No. 93 ASTM C702 NF P18-551, 552, 553 UNE 83 109 BS 812 NF ISO 5725 UNI 8520-5* BS 812 ASTM C136 UNE 7050 NF P18-560 UNI 8520-5* BS 812 ASTM C136 UNE 7050 NF P18-560 NF X11-504 NF P18-561* UNI 8520-18* BS 812, NLT 354 DIN 4226 CNR No. 95 NLT 354 BS 812 ASTM D2419* NF XP18-598, NF P18-597 UNI 8520-15*, CNR No. 27* UNE 83131 Testing equipment for the construction industry Title Tests for general properties of aggregates. Methods for sampling Tests for general properties of aggregates. Methods for reducing laboratory samples Tests for general properties of aggregates. Common equipment and calibration Tests for general properties of aggregates. Definitions of repeatability and reproducibility Tests for geometrical properties of aggregates. Determination of particle size distribution. Sieving method Tests for geometrical properties of aggregates. Determination of particle size distribution. Test sieves, nominal size of apertures Tests for geometrical properties of aggregates. Determination of particle shape. Flakiness index Tests for geometrical properties of aggregates. Determination of particle shape. Shape index Tests for geometrical properties of aggregates. Assessment of surface characteristics. Percentage of crushed and broken surfaces in coarse aggregates Tests for geometrical properties of aggregates. Determ. of shell content. Percentage of shells in coarse aggregates Tests for geometrical properties of aggregates. Assessment of fines. Sand equivalent test AGGREGATES . . . . . . . . . . . . . . . . . . . . . . . New EN European Standards 47 and relation with the existing National Specifications (continued) EN Correspondent or comparable National Standards EN 933-9 NF P94-068 UNI 8520-15*, UNE 83 130 EN 933-10 NF P18-572 CNR No.109, UNE 83 115 EN 1097-2 ASTM C131* NF P18-573* UNI 8520-19*, CNR No. 34* DIN 52115-1(1), UNE 83 114 EN 1097-3 BS 812* ISO 6782*, UNI 8520-6* CNR No. 62*, 63*, 64* NLT 156 EN 1097-4 BS 812, CNR No.123 NF P18-565, NLT 177 EN 1097-5 BS 812 NF P18-554 EN 1097-6 ISO 6783, UNI 8520-13*, 16* NF P18-555, NLT 154 EN 1097-7 BS 812 NF P18-558, NLT 155 EN 1097-8 BS 812, CNR No. 105, 140 NF P18-575, NLT 174 EN 1097-9 EN 1097-10 EN 1367-1 ASTM C682* UNI 8520-20*, CNR No. 80* BS 812 EN 1367-2 UNI 8520-10* ASTM C88, UNE 7136 EN 1097-1 EN 1367-3 EN 1367-4 EN 1367-5 EN 1744-1 EN 1744-3 EN 12620 EN 13043 EN 13055-1 EN 13055-2 EN 13139 EN 13179-1 BS 812 BS 812* UNI 8520-11*, 12*, 14* NF P18-582, 583, 584, 585, 586, 587, 588 NF P18-541, NF P18-101 NF P18-101 EN 13179-2 EN 13242 EN 13383-1 EN 13383-2 EN 13450 Title Tests for geometrical properties of aggregates. Assessment of fines. Methylene blue test Tests for geometrical properties of aggregates. Assessment of fines. Grading of fillers (Air jet sieving) Tests for mechanical and physical properties of aggregates. Determination of the resistance to wear (Micro-Deval) Tests for mechanical and physical properties of aggregates. (1) Impact testing machine only Methods for the determination of resistance to fragmentation Tests for mechanical and physical properties of aggregates. Determination of loose bulk density and voids Tests for mechanical and physical properties of aggregates. Determination of the voids of compacted filler Tests for mechanical and physical properties of aggregates. Det. of the water content by drying in a ventilated oven Tests for mechanical and physical properties of aggregates. Determination of particle density and water absorption Tests for mechanical and physical properties of aggregates. Det. of the particle density of filler. Pyknometer method Tests for mechanical and physical properties of aggregates. Determination of the Polished Stone Value Tests for mechanical and physical properties of aggregates. Method for the determination of the resistance to wear by abrasion from studded tyres: Nordic test Tests for mechanical and physical properties of aggregates. Determination of water suction height Tests for thermal and weathering properties of aggregates. Determination of resistance to freezing and thawing Tests for thermal and weathering properties of aggregates. Magnesium sulphate test Tests for thermal and weathering properties of aggregates. Boiling test for “Sonnenbrandt Basalt” and disintegration of steel slag Tests for thermal and weathering properties of aggregates. Determination of drying shrinkage Tests for thermal and weathering properties of aggregates. Determination of resistance to thermal shock Tests for chemical properties of aggregates. Chemical analysis Tests for chemical properties of aggregates. Preparation of eluates by leaching of aggregates Aggregates for concrete Aggregates for Bituminous mixtures and surface treatments Lightweight Aggregate for concrete Lightweight Aggregate for bound and unbound Aggregates for mortar Tests for filler aggregate used in bituminous mixture. Delta ring and ball test Tests for filler aggregate used in bituminous bound. Bitumen number Aggregates for unbound and hydraulically bound materials for use in civil engineering work and road construction Armour stone – Part 1: Specification Armour stone – Part 2: Test methods Aggregates for railway ballast Legend EN = European Standard (Mandatory); BS = British Standard; ASTM = USA Standard; NF = French Standard; DIN = German Standard; UNE = Spanish Standard; NLT = Spanish “Norma de Laboratorio Transporte”; UNI = Italian Standard; CNR = Italian Road Standard; ISO = International Organization for Standardization Note. The asterisk * after the National Standard means that the testing apparatus does not completely correspond to the EN Standard. Testing equipment for the construction industry 187 47 AGGREGATES General and Geometrical properties . . . . . . . . . . . . . . . . Methods for sampling / Sampling tools Riffle boxes (sample splitters) M 15-D0430 Large capacity sample splitter Riffle boxes (sample splitters) q STANDARD EN 932-1, 932-2 – ASTM C702 To divide aggregates into a representative sample increment for testing. 15-D0438 to 15-D0438/H Riffle boxes sCode Max. size Slot width No. Capacity Weight sample (mm) (mm) of slots approx. (dm3) approx. (kg) 15-D0438 5 712 0.24 1.5 15-D0438/A 10 15 12 2 5 15-D0438/B 20 30 10 4.6 19 15-D0438/C 40 50 8 14 23.5 15-D0438/D 13 19 10 3 5.5 15-D0438/E 20 25 10 3.9 19 15-D0438/F 25 38 8 9.6 19 15-D0438/G 50 64 8 21 27 15-D0438/H 40 45 8 11.3 23.5 Each riffle box is supplied with 3 metal pans Sampling tools M 86-D1645 Shovel A Weight approx.: 1.6 kg Round aluminium scoops sCode Capacity (approx.) 86-D1601 325 ml 86-D1602 1000 ml 86-D1603 2600 ml Size Specifications For aggregate up to 150 mm size Adjustable openings from: 12.5 mm with 12.5 mm increments Clam shell hopper 26 dm3 capacity Complete with two pans B Dimensions: Overall height: 991 mm Hopper size: 737 mm long x 483 mm wide A Weight approx.: 50 kg Spare parts 245x80 mm 335x120 mm 420x160 mm 15-D0430 Woven cloth sieves s15-D0430/1 Spare material pan. Weight 2.3 kg Sieving method. Test sieves, nominal size of apertures q STANDARD EN 933-1, 933-2 Please refer to the Section 15 concerning ISO 3310-1 and 3310-2 test sieves and sieve shakers. Conforming to the above standards the following openings should be used: 86-D1601 to 86-D1603 Woven cloth sieves ISO 3310-1 0.063 – 0.125 – 0.250 – 0.500 – 1 – 2 mm Perforated metal plate sieves ISO 3310-2 4 – 8 – 16 – 31.5 – 63 – 125 mm 86-D1645 188 Testing equipment for the construction industry Perforated metal plate sieves AGGREGATES . . . . . . . . . . . . . . . . General and Geometrical properties 47 Flakiness and elongation index / Shape index / Efflux index Determination of particle shape. Flakiness and elongation index. BS 812 method. Efflux index Flakiness index q STANDARD Also conforming to NF P18561, UNI 8520-18, NLT 354 EN 933-3 / Bar sieves (Grids) Used to determine the flakiness index of the aggregates. Aluminium frame and steel bars. sCode Aperture (mm) 47-D0418/1 47-D0418/2 47-D0418/3 47-D0418/4 47-D0418/5 47-D0418/6 47-D0418/7 47-D0418/8 47-D0418/9 47-D0418/10 47-D0418/11 47-D0418/12 47-D0418/13 2.50 3.15 4.00 5.00 6.30 8.00 10.00 12.50 16.00 20.00 25.00 31.50 40.00 A Weight approx. : 3 kg each Complete set M 47-D0418/A Complete set of 13 aggregate grids including 2.50 - 3.15 - 4.00 - 5.00 - 6.30 - 8.00 - 10.00 - 12.50 16.00 - 20.00 - 25.00 - 31.50 40.00 mm apertures A Weight approx.: 40 kg approx. M 47-D0415 Flakiness sieves test set General description and specifications Used to determine if aggregate particles are to be considered flaky, i.e. their thickness is less than 0.6 of their nominal size. Each sieve is made from heavy gauge steel and each one can also be ordered separately. The set comprises the following sieves: 47-D0415 Flakiness sieve set sCode 47-D0415/1 47-D0415/2 47-D0415/3 47-D0415/4 47-D0415/5 47-D0415/6 47-D0415/7 A Slot width (mm) Slot length (mm) 4.9 7.2 10.2 14.4 19.7 26.3 33.9 30 40 50 60 80 90 100 Passing/Retained (mm) 10/6.3 14/10 20/14 28/20 37.5/28 50/37.5 63/50 Weight approx. : 15 kg (total set) M 47-D0540 Thickness gauge Shape index Description q STANDARD Used to determine if aggregate particles are to be considered flaky, i.e. their thickness is less than 0.6 of their nominal size. A EN 933-4 Also conforming to DIN 4226, CNR No. 95, NLT 354 M 47-D0542 Aggregate shape gauge Weight approx.: 200 g M 47-D0542/A Aggregate shape gauge complete with calibration certificate M 47-D0541 Length gauge Description Aggregate particles are considered elongated when their length is more than 1.8 of their nominal size. A Weight approx.: 1.1 kg 47-D0542 Used to determine the shape factor of aggregates. B Dimensions: 320x160 mm 47-D0418/1 to 47-D0418/13 47-D0541, D0540 A Weight approx.: 450 g Testing equipment for the construction industry 189 47 AGGREGATES Geometrical properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . Assessment of fines. Sand equivalent test Assessment of fines. Sand equivalent shakers Sand equivalent test M 47-T0056/B Motorised sand equivalent shaker. 230 V, 50 Hz, 1 ph. q STANDARD: EN 933-8 Also conforming to NF P18-598, UNI 8520-15, UNE 83131, CNR No. 27 M 47-T0050/B Sand equivalent test set EN 933-8 model The set comprises: four measuring cylinders, two rubber stoppers, measuring can, irrigator tube, siphon assembly with bottle, weighted foot, funnel, graduated rule 1 l bottle of stock solution (packed separately) and plastic carrying case. Each item can be ordered individually. All items are housed in the Plastic carrying case except the Siphon assembly with bottle 47-T0050/5 which is packed separately. A Weight approx.: 12 kg M 47-T0056/BZ Same as above but 110 V, 60 Hz, 1 ph. 47-T0056/B M 47-T0050/C Sand equivalent test set ASTM D2419 - AASHTO T176 model Same as the 47-T0050/B except the four measuring cylinders which are totally graduated. M 47-T0056/BY Same as above but 220 V, 60 Hz, 1 ph. M 47-T0056/C Motorised sand equivalent shaker with safety cover (CE directive). 230 V, 50 Hz, 1 ph. M 47-T0056/CZ Same as above but 110 V, 60 Hz, 1 ph. Accessories for both 47-T0050/B and 47-T0050/C models s47-T0056/B Motorised shaker s47-T0056/C safety cover Motorised shaker with s47-T0050/7 Sand equivalent stock M 47-T0056/CY Same as above but 220 V, 60 Hz, 1 ph. To provide a completely uniform shaking action at the specified rate and also eliminating any operator fatigue. Supplied complete with timer. solution, 1 l bottle s47-T0050/7B Sand equivalent stock solution, 125 cc bottle. Pack of 20 s47-T0050/8 Clamp stand set. Holds syphon assembly in place during the test Stroke: adjustable 200 ± 10 mm Rate: 175 strokes/min B Dimensions: 720x420x450 mm A Weight approx.: 20 kg In the model 47-T0056/C the machine stops automatically when the safety cover is opened. 47-T0050/C with 47-T0050/7 Spare parts for 47-T0050/B and 47-T0050/C apparatus sCode Description 47-T0050/1C Measuring cylinder (ASTM) 47-T0050/1A Measuring cylinder (EN) 47-T0050/2 Rubber stopper 47-T0050/3 Measuring can 47-T0050/4 Irrigator tube 47-T0050/5 Siphon assembly with bottle 47-T0050/6 Weighted foot (ASTM) 47-T0050/61 Weighted foot (EN) 86-D1546 Funnel 82-D1694 Graduated rule, 500 mm 47-T0050/B with 47-T0050/7 190 Testing equipment for the construction industry 47-T0056/C AGGREGATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . Geometrical properties 47 Assessment of fines. Methylene blue test / BS 812 sedimentation method Efflux index Assessment of fines. Methylene blue test q STANDARD EN 933-9 Also conforming or comparable to NF P94068, UNE 83 180, UNI 8520-15 The test is performed for determining the clay content in the fines fraction of the aggregates. 47-D0439/A with 47-D0439/1 Determination of clay, silt, and dust in fine and coarse aggregates. BS 812 sedimentation method M 47-D0439/A Bottle roller. 230 V, 50 Hz, 1 ph. Used for rotating the glass bottle containing samples as described in BS 812 at a speed of 80 ± 20 r.p.m. M 47-D0439/C Methylene blue test set. 230 V, 50 Hz, 1 ph. Comprising: s47-D0439/C1 50 cc burette with stopcock s47-D0439/C2 Support base with clamp 47-D0439/C (Sieves not included) s47-D0439/C3 Determination of the efflux index Filter paper. Pack of 100 discs Power: 90 W B Dimensions: 424x195x275 mm (lxwxh) A Weight approx.: 8.5 kg Accessories s47-D0439/1 Airtight glass container 1 litre capacity of fine aggregates s47-D0439/C4 Glass rod 300x8 mm dia. q STANDARD s47-D0439/C5 EN 933-6 3000 ml cap. plastic beaker NF P18-564, CNR No. 113 s47-D0439/C9 M 47-D0516 Efflux index apparatus Methylene blue. 250 g s47-D0439/C10 Kaolinite. 1000 g s47-D0439/C11 M 47-D0439/B Andreasen pipette 25 ml capacity Used to extract precise quantities of suspension ready for analysis. Made from glass. A Weight approx.: 700 g M 22-T0062/2 Pipette stand Used to precisely adjust the vertical movement of the Andreasen pipette. For full details please refer to the Soil Section 22. Electric agitator, 400 to 700 r.p.m., 75 mm dia. impeller. 230 V, 50 Hz, 1 ph.(1) Complete with support base and double sleeve. Used to obtain information about the shape and the angularity of grains of the 0.075 – 4 mm fraction of aggregates. It consists essentially of a container, which ends in a funnel 12 or 16 mm dia. with 60° opening. Supplied complete with both funnels. Each item can be purchased individually. (1) Other voltages available on request. Accessories B Dimension approx.: 200x200x420 mm A Weight: 9 kg approx. s47-D0439/C13 Automatic bottle top dispenser 0-10 ml, 0.1 ml graduations complete with glass bottle. Note: replaces the 47-D0439/C1 and 47-D0439/C2 burette with support base s47-D0439/C15 Plastic pan 47-D0516 22-T0062/2 with 47-D0439/B Testing equipment for the construction industry 191 48 AGGREGATES Mechanical and physical properties. . . . . . . . . . . . . . . . . Determination of the resistance to fragmentation Determination of resistance Crushing resistance of lightweight aggregates to fragmentation (Los Angeles) q STANDARD q STANDARD EN 13055-1 EN 1097-2 Also conforming to NF P18-573, UNE 83 114, UNI 8520-19, CNR No. 34, ASTM C131 M 48-D0512 Apparatus for the determination of the crushing resistance of lightweight aggregate 113 mm int.dia. Method 1 M 48-D0500/D Los Angeles abrasion machine. 230 V, 50 Hz, 1 ph. M 48-D0512/A M 48-D0500/DZ Same as above but 110 V, 60 Hz, 1 ph. M 48-D0500/DY Same as above but 220 V, 60 Hz, 1 ph. General description and specifications The machine consists of a rolled steel drum having an inside diameter of 711 mm and internal length 508 mm. The drum is rotated by a speed reducer driven by an electric motor at a speed of between 31 and 33 r.p.m. The machine is equipped with an automatic counter, which can be preset to the required number of revolutions of the drum. The unit is supplied without the abrasive charge, which has to be ordered separately depending on the standard in use. Conforming to the CE directive, the machine should be housed in a soundproof and protection cabinet. Our standard model can be upgraded for this requirement by the 48-D0500/XUP Soundproof and protection cabinet, which has to be specified at time of order and factory installed. See Upgrading options. 48-D0500/D with 48-D0505 Upgrading option – Soundproof and security cabinet M 48-D0500/XUP Soundproof and security cabinet General description and specifications This option includes the supply of the cabinet for the Los Angeles machine. The cabinet is manufactured from sheet steel lined internally with soundproofing material to reduce noise and electric safety device, which automatically stops the rotation of the drum when opening the door conforming to the CE directive. The control panel is fitted externally. B Overall dimensions: 933x1052x1250 mm A Weight approx. (less Los Angeles): 180 kg Power: 740 W B Dimensions approx.: - 48-D0500/D: 975x785x937 mm A Weight approx.: 350 kg Abrasive charges s48-D0505 Set of 12 abrasive charges conforming to ASTM/UNI/CNR Standards s48-D0505/A Set of 12 abrasive charges conforming to EN Standards 192 Same as above but 76 mm int. dia. Method 2 Made of steel A Weight approx.: 15 kg (48-D0512) and 7 kg (48-D0512/A) 48-D0500/D upgraded with the 48-D0500/XUP cabinet Testing equipment for the construction industry 48-D0512 48-D0500/XUP Detail of the external control panel AGGREGATES . . . . . . . . . . . . . . . . . Mechanical and physical properties 48 Determination of the resistance to abrasion and wear/Crusting value Abrasion resistance of natural - Stainless steel jars - Preset revolution counter - Safety guard (CE) stones and concrete tiles for external paving q STANDARD EN 1341, 1342, 1338, 1339, 1340, 14157, 12808-2 M 48-D0471 Abrasion testing machine for natural stones and concrete tiles. 230 V, 50 Hz, 1 ph. General description and specifications This machine has been developed for determining the resistance to abrasion/wear of natural stones and concrete products. Easy to use, electronic control of the disc speed with auto shut-off of the machine at the selected number of revolutions. Complete with aspirator to collect powders. The abrasion disc wheel is 70 mm thick. Supplied complete with 5 kg of white corundum FEPA grit size 80 and calibration sample ( Boulonnais Marble). The machine can also be converted for abrasion test on clay pavers conforming to EN 1344 by the conversion kit 48-D0471/K. See accessories. B Overall dimensions: 620x670x850 mm A Weight approx.: 85 kg Accessories and spares s48-D0471/1 Abrasive white corundum sand 80 grade. Pack of 25 kg s48-D0471/K Conversion kit to perform the abrasion test on Clay pavers conforming to EN1344. Comprising counterweight, hopper, abrasion disk dia. 200x10 mm and silica calibration plate Aggregate crushing value. 48-D0524 BS method Determination of the resistance to wear (Micro-Deval) q STANDARD BS 812:110 q STANDARD EN 1097-1, EN 13450 Also conforming to NF P18-572, P18-576, CNR No. 109, UNE 83 115 M 48-D0510 Standard aggregate crushing value apparatus. 150 mm dia. M 48-D0511 Aggregate crushing value apparatus. 75 mm dia. M 48-D0524 Micro-Deval testing machine. 230 V, 50 Hz, 1 ph. General description and specifications General description and specifications Used to determine the resistance to wear of aggregates. The machine consists of a steel frame suitable to house four 154 mm stainless steel cylinders or two 400 mm stainless steel cylinders. The machine stops automatically at the preset number of gyrations. The machine is supplied without stainless steel cylinders and stainless steel spheres. Power: 1100 W B Dimensions: 1000x450x920 mm A Weight approx.: 130 kg The aggregate crushing value provides a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load. Supplied complete with cylinder, plunger, base plate, tamping rod, and measure. Accessories to EN 1097-1 A Weight approx.: 16.5 kg for 48-D0510 and 3.5 kg for 48-D0511 N O T E The ACV test can be performed with our automatic test systems. See page 244-247 s48-D0524/4 Stainless steel cylinder 200 mm dia. x 154 mm length. (Four cylinders required) s48-D0524/7 Steel spheres, 10 mm dia. Pack of 20 kg Accessories to EN 13450 s48-D0524/6 Stailess steel cylinder 200 mm dia. x 400 mm length (Two cylinders required). Abrasive charge not required Other accessories s48-D0524/1 Steel spheres, 30 mm dia. 48-D0471 Pack of 10. Conforming to NF P18-576 s48-D0524/2 Steel spheres, 18 mm dia. Pack of 50. Conforming to NF P18-576 48-D0510, D0511 Testing equipment for the construction industry 193 48 AGGREGATES Mechanical and physical properties. . . . . . . . . . . . . . . . . Determination of the resistance to abrasion (Deval method)/ Impact value Determination of the voids Deval apparatus q STANDARD NF P18-577 M 48-D0523 Deval attrition test machine. 230 V, 50 Hz, 1 ph. General description and specifications Used for testing the abrasion resistance of aggregates. The machine consists of a rotating frame to support two steel cylinders complete with covers and locking device. The rotating frame is driven by a motor/ speed reducer and an automatic counter is included to preset the required number of revolutions. Rotation speed: 33 r.p.m. Motor: 736 W B Dimensions: 1500x500x700 mm A Weight approx.: 190 kg 48-D0523 Aggregate impact value. BS and NF methods q STANDARD BS 812 - NF P18-574 M 48-D0515 Impact testing machine Determination of the voids of dry compacted filler q STANDARD EN 1097-4. Also conforming to BS 812, CNR No. 23, NLT 177 M 48-D0447 Filler compaction apparatus General description and specifications Scratch hardness. ASTM method M 48-D0518 Scratch hardness test apparatus q STANDARD ASTM C235 General description and specifications This apparatus is used in the field to determine the quantity of soft particles in coarse aggregate. Consisting of a metal rod with a rounded point of 1.6 mm diameter, which is mounted in a device so that a load of 8.9 ± 0.4 N is applied to the test specimen. 48-D0518 B Dimensions: 150x200x320 mm A Weight approx.: 8 kg This machine is robustly designed to determine the aggregate impact value of aggregate, which provides a relative measure of the resistance of an aggregate to sudden shock or impact. Manufactured from plated steel for protection against corrosion and provided with an automatic counter to check the number of blows delivered to the sample. Supplied complete with cylindrical measure and tamping rod. B Dimensions: 444x300x879 mm (lxwxh) A Weight approx.: 58 kg 48-D0447 General description and specifications This apparatus is used for the determination of the void content of dry compacted filler. The apparatus essentially consists of three components: - A metal base size 100 mm x 150 mm - A cylinder of 25 mm internal diameter - A plunger of a diameter allowing it to slide freely in the cylinder without lateral play. A 48-D0515 Weight approx.: 3.5 kg Accessories s48-D0447/1 Blow counter kit. To fit the filler compaction apparatus s48-D0447/2 Filter paper 25 mm dia. Pack of 100 194 Testing equipment for the construction industry AGGREGATES . . . . . . . . . . . . . . . . . Mechanical and physical properties 48 Particle density / Loose bulk density and voids Determination of the particle Determination of loose bulk density and voids density and water absorption q STANDARD q STANDARD EN 1097-6, EN 12390-7 EN 1097-3 BS 812:2, 1881:14 - UNI 6394-2 Also conforming as operating principle to BS 812, NLT 156, UNI 8520-6, CNR No. 62-6364, ISO 6872 M 11-D0612/A Specific gravity frame Bulk density measures (Unit weight measures) General description and specifications Used in conjunction with a suitable electronic balance for specific gravity determination of fresh and hardened concrete and aggregates. The lower part of the frame incorporates a moving platform, which carries the water container allowing the test specimens to be weighed in both air and water. The balance is not included in the apparatus and must be ordered separately. Any type of electronic balance fitted with an under-bench weighing facility can be used. B Overall dimensions: 500x500x1200 mm approx. A Weight approx.: 50 kg 11-D612/A with accessories Aggregate density by water displacement. BS method Stainless steel construction with handles. The top rim is smooth and plane and parallel to the bottom conforming to the standards. Four models available: M 48-D0445/5 Bulk density measure 1 litre cap. q STANDARD BS 812 M 48-D0442 Apparatus for measuring coarse aggregate density by water displacement M 48-D0445/6 Bulk density measure 5 litres cap. M 48-D0445/7 Bulk density measure 10 litres cap. M 48-D0445/8 Bulk density measure 20 litres cap. Accessories s11-D0612/A1 Cradle for holding specimens s11-D0630 Digital top pan balance 4500 g x 0.1 g capacity s11-D0631/E Digital top loading balance 15 kg x 1 g capacity s11-D0631/F Digital top pan balance 16 kg x 0.1 g capacity s11-D0631/C Digital top pan balance 48-D0442 30 kg x 1 g capacity The above models incorporate a specialised feature, which allows specific gravity results to be calculated and displayed immediately at the touch of a button. M 11-D0612 Density basket 200 mm dia. x 200 mm high General description and specifications Used to determine the density of coarse aggregate. The apparatus consists of a cylindrical metal container 163 mm dia. and 370 mm high, fitted with a siphon tube at 250 mm from the base. A Weight approx.: 2.5 kg Description Used in specific gravity tests. Made from stainless steel. Complete with handles. Fitted with 3.35 mm mesh size. A Accessories 48-D0445/5 48-D0445/6 48-D0445/7 Accessories s34-T0099 Straight edge s22-T0040/1 Glass plate 300x300 mm s86-D1004 Graduated glass cylinder 250 ml Weight approx.: 1.3 kg Testing equipment for the construction industry 195 48 AGGREGATES Mechanical and physical properties. . . . . . . . . . . . . . . . . Determination of the particle density of filler. Pyknometer method Determination of particle density and water absorption Determination of the particle Determination of relative densities and water absorption for aggregates 10 mm nominal size and smaller. BS 812 method density of filler. Pyknometer method 76-B0066/1 q STANDARD EN 1097-7 Also conforming to BS 812, NF P18-558 Description Note. We propose just the specific apparatus as the test requires much other general laboratory equipment such as balances, oven, sieve, etc. For more information ask for our Buyer’s Guide. Specific gravity bottles (Gay-Lussac type) sCode 86-D1126 86-D1127 Capacity 50 ml 100 ml M 48-D0441 Pyknometer Glass jar supplied complete with cone and rubber seal. 76-B0066/B Capacity: 1 kg A Weight approx.: 500 g Determination of particle density and water absorption q STANDARD EN 1097-6 Also conforming to BS 812, UNI 8520-13-16, NLT 154, ASTM C127-C128, DIN 12039 76-B0066/2 with two 86-D1127 M 76-B0066/B Digital circulating water bath. 230 V, 50-60 Hz, 1 ph. M 76-B0066/BZ Digital circulating water bath. 110 V, 60 Hz, 1 ph. Used for the determination of particle density, small pyknometer method conforming to BS 1377:2 and for general laboratory use Specifications Working capacity (litres): 20 Max. water depth (mm): 150-180 Power (W): 1200 Temperature range (°C): ambient to +60 Digital resolution: 0.1°C Inside dimensions (mm): 500x300 Outside dimensions (mm): 540x340 Weight approx. (kg): 9.5 Accessories s76-B0066/1 Cover with cooling coil. For connection to mains water Note. We propose just the specific apparatus as the test requires much other general laboratory equipment such as balances, oven, sieves, containers, etc. Furthermore the new EN 1097-6 standard groups more than the single methods specified by the National Standards. For more information ask for our Buyer’s Guide which mentions each single standard. Pyknometers. Borosilicate glass, complete with stopper, capillary tube, and funnel These pyknometers are available in two sizes and are used for determining the bulk density and voids of aggregates. M 86-D1037 Pyknometer 500 ml cap. complete with stopper, capillary tube, and funnel. Weight 500 g approx. 86-D1037 M 86-D1038 Same as above but 1000 ml cap. M 48-D0440 Sand absorption cone and tamper Description Cone and tamper manufactured according to the specifications and used in determining the specific gravity and absorption of fine aggregates. A Weight approx.: 250 g s76-B0066/2 Adjustable tray 196 48-D0441 Testing equipment for the construction industry 48-D0440 AGGREGATES . . . . . . . . . . . . . . . . . Mechanical and physical properties 48 Aggregete abrasion value (AAV) / Surface moisture of fine aggregate / Moisture measurement Determination of aggregate Surface moisture abrasion value (AAV) of fine aggregate. ASTM method q STANDARD q STANDARD M 48-D0522 AAV Abrasion machine. 230 V, 50 Hz, 1 ph. M 48-D0460 Chapman flask EN 1097-8, BS 812 ASTM C70, AASHTO T142 General description and specifications General description and specifications The test provides a measure of the resistance of aggregate to surface wear by abrasion. The abrasion machine consists of a flat circular cast iron grinding lap 600 mm dia. which rotates in a horizontal plane at a speed of 28/30 r.p.m. The abrasive sand is fed across the surface of the specimen samples through a special funnel. The machine is supplied complete with two specimen moulds, two trays, two flat plates, weights and clamps. Used for determining the amount of surface moisture in fine aggregate. The flask is graduated to 200 ml between the two bulbs and from 375 ml up to 450 ml above the second bulb. A Weight approx.: 500 g Battery: 4x1.5 V AA cells Typically range: Moisture 0-35%; Temperature -20 to 60°C Resolution: Moisture 0.1%; Temperature 0.1°C Accuracy: Moisture: better than 0.5% over a given range; Temperature: better than 0.5°C Measurement principles: - Moisture: temperature compensated electric field - Temperature: BS 1904 – DIN 751 - Platinum resistance detector Shaft length: 1 or 2 m Total length: 1.2 m approx. A Weight approx.: 2 kg - For sands, aggregates, building materials and mixes - For quick on-site moisture measurement from small batches to hundreds of tons - Ideal in the processes of concrete manufacture, brick making, ceramics etc. A Weight approx.: net 200 kg; shipping 260 kg Accessories s86-D1672 Soft hair brush 3 mm dia. s48-D0522/2 Graded sand. 50 Kg sack 48-D0460 48-D0462 in different working position Moisture measurement M 48-D0462 Microlance, instant moisture and temperature tester General description and specifications 48-D0522 48-D0462 Detail The instrument measures moisture and temperature of building materials at depths up to 1 m approx., simply by insertion. The digital readings are shown instantly. The microlance has a built-in computer, which gives it the flexibility to handle a wide range of materials and water contents. The meter comes with standard calibration for sands and aggregates, but is easily recalibrated in the field for virtually any material or mixture using the built-in “Autocal” facility. Complete with calibration certificate. Testing equipment for the construction industry 197 48 AGGREGATES Mechanical and physical properties . . . . . . . . . . . . . . . Determination of the polished stone value Skid resistance and friction tester Determination of the polished stone value q Accessories and spare parts s48-D0525/12 Corn emery 5 kg pack STANDARD EN 1097-8, EN 1341, 1342, 1343 (paving stones and paving blocks) M 48-D5252 Accelerated polishing machine. 230 V, 50 Hz, 1 ph. s48-D0525/13 Flour emery 5 kg pack s48-D0525/14 Control stone (ungraded) 50 kg bag s48-D0525/15 Friction tester reference stone* (ungraded) 25 kg bag. * Criggion stone Skid resistance and friction tester M 48-B0190 Skid resistance and friction tester (Skid Tester) q STANDARD ASTM, BS 812:144, NLT 174, CNR No. 105, 140, NF P18-578, NF P18-575 EN 1097-8, 1341, 1342, General description and specifications General description and specifications Used to measure the resistance of road stone to the polishing action of vehicle tires on a road surface. This machine provides a method of preparing polished stone specimens for use with the friction tester 48-B0190 when used in a laboratory environment. Used for the measurement of surface friction properties, the apparatus is suitable for both site and laboratory applications and for Polished Stone Value tests using curved specimens from accelerated polishing tests. The test equipment is supplied complete with: - Additional scale for tests on Polished Stone Value specimens. - 3 rubber sliders for site use, complete with conformity certificate. - Thermometer 0 to +220 °C for surface temperature measurement. - 1 litre washing bottle, for surface wetting. - Tool set with case, for machine assembly. - Rule for sliding length verification. - Carrying case. - Calibration certificate conforming to EN 1097-8 issued by Controls. It is also possible to use it for Polished Stone Value specimens, by a metal base plate and of the small rubber sliders (see Accessory List). Road wheel speed: 315 to 325 r.p.m. Electric motor: 370 W fan-cooled B Dimensions: 1520x870x680 mm (hxwxd) A Weight approx.: net 175 kg; shipping 250 kg Supplied complete with road wheel, side plate, rubber rings, tired wheels, drive belt, abrasive feed mechanism, corn emery, flour emery, tool kit, set of 4 specimen moulds, and 2 mould plates. B Case dimensions: 790x760x320 mm A Weight approx. (including case): 34 kg Accessories and spare parts s48-B0190/1 Mounted rubber slider for Polished Stone Value tests (laboratory) s48-B0190/2 Spare mounted rubber slider for site use s48-B0190/4 Metal base plate for Polished Stone Value specimen clamping s48-B0190/5 Metal base plate for surface friction properties (natural stones paring blocks). EN 1341,1342,1338 48-D5252 198 Testing equipment for the construction industry AGGREGATES . . . . . . . . . . . . . . . . . Mechanical and physical properties 48 Determination of the polished stone value Skid resistance and friction tester (continued) - New low frictionrelease mechanism of the pendulum arm for better accuracy. - Extremely light pointer, for high precision results. - Slider lifting system integrated in the pendulum foot, that guarantees reliable adjustment operations. - Stiff and stout twin column structure. - Easy and reliable height adjusting system. - Integrated additional scale for tests on PSV specimens. - Provided complete with certificate set, as required by standards. - Controls calibration certificate conforming to EN 1097-8. 48-B0190 skid tester 48-B0190/5 48-B0190 complete set Testing equipment for the construction industry 199 48 AGGREGATES Thermal and weathering properties . . . . . . . . . . . . . . . . Resistance to freezing and thawing Determination of resistance to freezing and thawing q STANDARD EN 1367-1 Also comparable to ASTM C671 - C682, UNI 8520-20, CNR No. 80 and to BS 812:124 CLIMATIC CHAMBERS Introduction We propose two versions of this new and advanced Climatic cabinet: Model 10-D1429 with digital controller for temperature from –25 to +70°C, conforming to EN 1367-1 for Aggregate testing and many other similar tests on concrete and other construction materials Model 10-D1429/A with digital controller for both temperature from –25 to +70°C and humidity from 10 to 95%, also suitable for many other tests as for example concrete and cement curing (EN 12390-2, EN 196-1). Both models can be upgraded with internal data recording facility, data output port and dedicated PC software. See model 10-D1429/REC. M 10-D1429 Temperature controlled cabinet, 520 litres cap., temperature range –25 to +70°C. 230 V, 50 Hz, 1 ph. and other components are located in the top of the cabinet for easy inspection and maintenance. Thermostatic unit The cooling group, CFC free, is overspecified for the maximum reliability. It is designed to condition the air circulating in the cabinet. The cooling group consists of a compressor mounted on antivibration supports with internal thermal protection, copper tube condensers with aluminium fins, motor fans directly connected to the shaft and complete with thermal protection. The cooling circuit is entirely made of copper and is completed with de-water/ receiver filter, spy glass to verify the passage of freon, high pressure manostat and inlet connectors. The evaporator has the same characteristics of the condenser. The de-humidification is obtained by a smooth tube with cyclic thaw. The heating element consists of a stainless steel finned tube with a limit thermostat. The re-cycling fans are connected directly to the low thermal emissions motors. 200 Temperature sensor The PT100 temperature sensor is movable inside the cabinet area and can also be positioned inside the test sample conforming to specific Standard requirement. Humidity sensor Allows measurement of humidity up to RH 100%. Main Features - Advanced controller with cycle programmer for 50 programs and 1000 segments - Temperature sensor movable inside the cabinet orinside the sample conforming to the Standard requirement - High accuracy: ± 1°C, ± 5% RH (RH with model10-D1429/A only) - A multipurpose climatic chamber suitable for-testing applications in Aggregates, Cement,Concrete, Bricks, Blocks, Asphalt and other co-struction materials - Optional internal data recording facility, data output port and dedicated PC software M 10-D1429/A Temperature and humidity controlled cabinet, 520 litres cap., temperature range –25 to +70°C, humidity range from 10 to 95%. 230 V, 50 Hz, 1 ph. General description Cabinet Monobloc cabinet made with stainless steel profiles with external finish in SCTCH-BRITE. All internal angles have been rounded off for easy cleaning. Insulation is provided with high density polyurethane 60 mm thick. The self closing door can open over 100° and is fitted with rechangeable magnetic gaskets. The shelves are supported on stainless steel guides, which prevent them turning, capable of loading heavy specimens. The stainless steel feet are adjustable in height for the best stability. The cooling system Control console Housed in a well protected case, it contains fuses, electroswitches and terminals of all electrical parts. The front panel features a large digital display with switches for fans, compressor, resistances, humidifier (10-D1429/A model only) and the alarm leds. A multifunction control unit displays simultaneously the set points and absolute output values. 10-D1429 Testing equipment for the construction industry AGGREGATES . . . . . . . . . . . . . . . . . Thermal and weathering properties 48 Resistance to freezing and thawing / Magnesium and sodium sulphate test CLIMATIC CHAMBERS Magnesium sulphate test (CONTINUED) Specifications Capacity: 520 litres Function controller: cycle programmer for 50 programs and 1000 segments Temperature range: –25 to +70°C Humidity range (model 10-D1429/A only): from 10 to 95% Temperature accuracy: ± 1°C Humidity accuracy (model 10-D1429/A only): ± 5% RH Power: Cooling system 1000 W; Heating system 1500 W Internal air circulation: 450 mc/h Internal dimensions (wxdxh): 600x670x1300 mm External dimensions (wxdxh): 720x800x2020 mm Shelves dimensions (lxd): 530x580 mm, no. 4 included, 60 kg cap. each A Weight: 180 kg approx. Accessories and spare parts s10-D1429/REC Upgrade of the cabinet controller with internal data recording facility, data output port and dedicated PC software M 48-D0457 Metal can 2000 ml cap., with removable lid and 1 kg ballast. Conforming to EN 1367-1 Used for the determination of resistance to freezing and thawing of aggregates including lightweight types. A q STANDARD EN 1367-2 Also comparable to ASTM C88, UNI 8520-10, UNE 7136 Note. We propose just the specific apparatus as the test requires much other general laboratory equipment such as balances, oven, sieves, etc. For more information ask for our Buyer’s Guide. 48-D0612/11 M 48-D0612/11 Stainless steel mesh basket, 120 mm dia. x 160 mm high, 3.35 mm openings M 86-D1348 Lever lid container 180x240 mm dia. M 48-D0452 Hydrometer range 1200 to 1300 g/ml, accuracy 0.001 g/ml 86-D1348 SOUNDNESS OF AGGREGATES BY USE OF SODIUM SULFATE OR MAGNESIUM SULFATE M 48-D0612/A2 q STANDARD ASTM C88 M 48-D0612/A1 Stainless steel mesh basket, 600 μm (No. 30 ASTM) opening, 120 mm dia., 160 mm high. Weight: 0,3 kg approx. Stainless steel mesh basket, 1.7 mm (No. 12 ASTM) opening, 120 mm dia., 160 mm high. Weight: 0,3 kg approx. M 48-D0612/A3 Stainless steel mesh basket, 9.5 mm (3/8”) opening, 200 mm dia., 200 mm high. Weight: 1 kg approx. Weight: 2.5 kg approx. 48-D0457 48-D0612/A3 Testing equipment for the construction industry 201 48 AGGREGATES Thermal and weathering properties . . . . . . . . . . . . . . . . Determination of drying shrinkage and resistance to thermal shock Determination of drying shrinkage q STANDARD EN 1367-4 The scope of this test is the determination of the effect of aggregates on the drying shrinkage of concrete. The test is based on the testing of concretes of fixed mix proportions and aggregates of 20 mm max. size. M 48-D0453 Prism mould 50x50x200 mm complete with steel inserts. Three gang model A M 62-L0035 Length comparator Determination of resistance M 62-L0035/A Length comparator. Digital version q STANDARD General description and specifications This apparatus is used to determine the changes in length of cement prisms in the accelerated soundness test. It is also used to measure length changes of 40x40x160 mm, and other sizes of cement and concrete specimens. The instrument consists of an analogic or digital dial gauge, which is mounted on a steel frame. The top anvil is adjustable to suit the required specimen. Weight approx.: 8 kg to thermal shock EN 1367-5 This test involves heating soaked aggregates to 700°C for 3 min and comparing the loss in fines, and the strength loss, determined in accordance with EN 1097-2, before and after the heat test. M 10-D1419 Muffle furnace 1100°C max. temperature. High capacity, floor mounting model. 220-380 V, 50-60 Hz, 3 ph. B Overall dimensions: A 48-D0453 180x180x490 mm Weight approx.: 10.5 kg Accessories s62-L0034/3 Reference rod, 205 mm long 10-D1419 Specifications Max. temperature: 1100°C Electronic thermoregulator and 24 hour timer Power: 9000 W Inside dimensions: 300x220x500 mm (wxhxd) B Outside dimensions: 750x1650x1100 mm (wxhxd) A Weight approx.: 400 kg 62-L0035 Detail of the analogic version M 48-D0453/1 Steel inserts for 48-D0453. Pack of 12 Accessories s48-D0454/1 Metal test plate 440x240x4 mm thick with 12 mm high turned lip s48-D0454/2 Metal support frame for metal test plate s48-D0454/3 Fire proof plate 450x250x10 mm thick s48-D0454/4 Stainless steel sieve 62-L0035/A 202 Testing equipment for the construction industry fabric, 2 mm aperture, 250x445 mm size AGGREGATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chemical properties 48 Chloride, carbonate content / Potential reactivity / Organic impurities chloride content of fine aggregates - bs812 M 48-D0543 Quantab chloride titrator, type 1175 (711175), range 0.005% to 0.1% Na Cl. Bottle of 40 strips M 48-D0543/A Quantab chloride titrator, type 1176 (711176), range 0.05% to 1% Na Cl. Bottle of 40 strips General description and specifications A simple and quick method to determine the chloride content of fine aggregates. The silver dichromate strip will react with any chloride in the solution and the calibrated column will indicate the proportional concentration of chloride. Bottle containing 40 strips and calibration chart. carbonate content of aggregates M 48-D0570 Gasometer Dietrich-Früling General description and specifications Used for the determination of CaCO3 especially in limestone and lime marl. It consists of a glass container in which the reaction between the calcium carbonate contained in the products and a solution of hydrochloric acid takes place. The gas given off is collected and measured with a suitable device connected with the container. Being measured the volume of gas (CO2) given off it can be related with the quantity of CaCO3 contained in the sample. Used in the test method for the chemical determination of potential reactivity of aggregates with alkalies in Portland cement concrete. Manufactured from corrosion-resistant metal and fitted with an airtight cover. Capacity: 59 cm3 approx. 48-D0545 Three gang mould q STANDARD UNI 8520-22 M 62-L0009/A Three gang prism mould 25x25x280 mm (gauge length 294 mm) Used for determining the potential reactivity of alkali in aggregates. Made of steel with minimum surface hardness of HV200. B Dimensions of gasometer (assembled): 400x200x1100 mm approx. A Weight approx.: 12 kg Accessories and spares s62-L0035 or 62-L0035/A Length comparator (see page 302 for more information) s62-L0009/A2 Reference rod 294 mm s62-L0009/A1 Spare plugs for 62-L0009/A mould Pack of 20 pieces 48-D0543, D0543/A Organic impurities in fine aggregates q STANDARD ASTM C40, UNI 8020-14 Test bottles 62-L0009/A M 48-D1090 Graduated impurities test bottle 500 ml. ASTM C40 M 48-D1091 Graduated impurities test bottle 1000 ml Colour scale M 48-D0850/A Colour standard with 5 organic glass scales mounted in plastic holder 48-D0570 Potential reactivity of aggregates q STANDARD ASTM C289, UNI 8520-22 (Oct. 86), NF P94 048 M 48-D0545 Reaction container 48-D1090, 48-D1091 48-D0850/A Testing equipment for the construction industry 203 48 AGGREGATES Chemical properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sample reduction M 48-D0535/A Hammer mill for laboratory. 380 V, 50 Hz, 3 ph. Sample reduction M 48-D0530/A Laboratory crusher. 220-380 V, 50 Hz, 3 ph. General description General description and specifications Used to crush aggregates, core samples, and similar materials when a reduction in sample size is necessary. The crusher has a jaw opening of 100x60 mm and can produce from 100 to 400 kg of material per hour. The movement of the jaws can be regulated from 5 to 15 mm. The laboratory crusher is supplyed with a separate control panel Motor: 736 W B Dimensions: 650x550x500 mm A Weight approx.: 90 kg The hammer mill executes the grinding operation using the principle of the combination of three efforts: impact, shear and rebound. Once entered into the grinding chamber through the hopper, the material reaches the wished fineness and trough the filtering hoses arrives to the collector. General specifications - Grinding chamber dia. 180 mm - 3,4 interchangeable fixed hammers - Output grain size: “rise” type (4÷5 mm) - Possibility of installing screens with various opening size according to the wished grain size - Max. hardness of the material to grind: 6÷7 Mohs - Maximum capacity: 50 kg/h - 380 V, 50 Hz, 3 ph., 500 W The machine is supplied complete with: - screens of 1, 2 and 3 mm opening - safety microswitch - electric control board - filtering hose - powder collector B Dimensions: 500x600x900 mm A Weight: 64 kg Accessories s48-D0535/A1 Screen of 4 mm opening Spare parts s48-D0535/A3 Screen of 1 mm opening s48-D0535/A4 Screen of 2 mm opening s48-D0535/A5 Screen of 3 mm opening 48-D0530/A 48-D0535/A 204 Testing equipment for the construction industry AGGREGATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Memorandum Testing equipment for the construction industry 48 205