CCIL / LABORATORY INSPECTION CHECKLIST Standard Test

advertisement

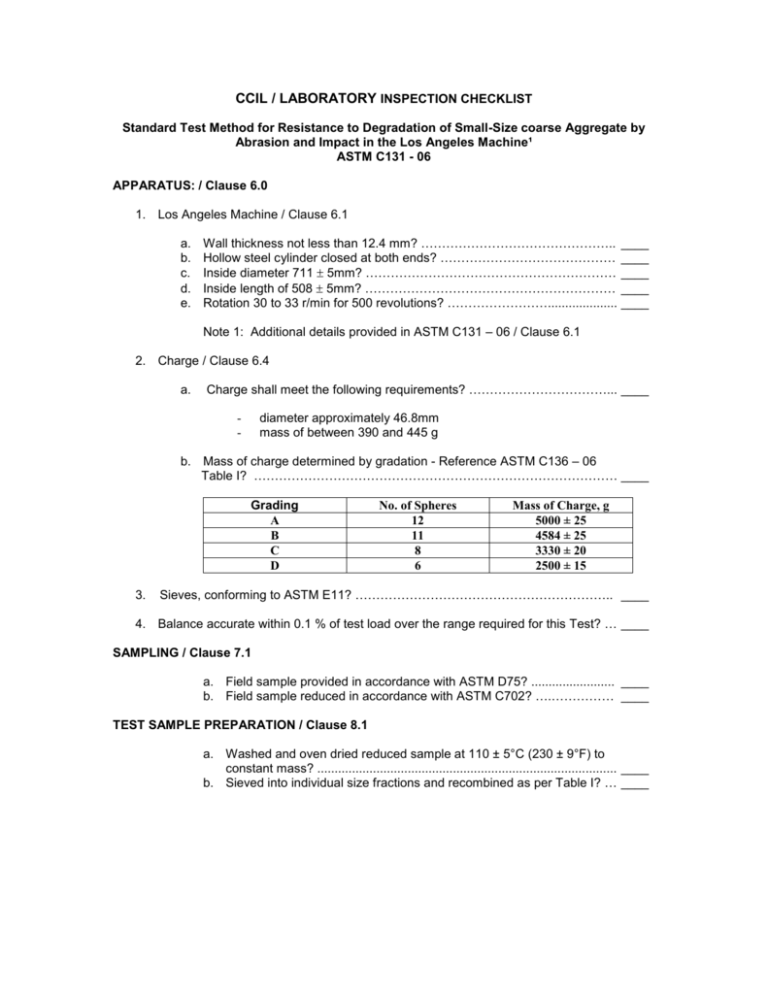

CCIL / LABORATORY INSPECTION CHECKLIST Standard Test Method for Resistance to Degradation of Small-Size coarse Aggregate by Abrasion and Impact in the Los Angeles Machine¹ ASTM C131 - 06 APPARATUS: / Clause 6.0 1. Los Angeles Machine / Clause 6.1 a. b. c. d. e. Wall thickness not less than 12.4 mm? ……………………………………….. Hollow steel cylinder closed at both ends? …………………………………… Inside diameter 711 ± 5mm? …………………………………………………… Inside length of 508 ± 5mm? …………………………………………………… Rotation 30 to 33 r/min for 500 revolutions? …………………….................... ____ ____ ____ ____ ____ Note 1: Additional details provided in ASTM C131 – 06 / Clause 6.1 2. Charge / Clause 6.4 a. Charge shall meet the following requirements? ……………………………... ____ diameter approximately 46.8mm mass of between 390 and 445 g - b. Mass of charge determined by gradation - Reference ASTM C136 – 06 Table I? …………………………………………………………………………… ____ Grading A B C D 3. No. of Spheres 12 11 8 6 Mass of Charge, g 5000 ± 25 4584 ± 25 3330 ± 20 2500 ± 15 Sieves, conforming to ASTM E11? …………………………………………………….. ____ 4. Balance accurate within 0.1 % of test load over the range required for this Test? … ____ SAMPLING / Clause 7.1 a. Field sample provided in accordance with ASTM D75? ........................ ____ b. Field sample reduced in accordance with ASTM C702? ….…………… ____ TEST SAMPLE PREPARATION / Clause 8.1 a. Washed and oven dried reduced sample at 110 ± 5°C (230 ± 9°F) to constant mass? ...................................................................................... ____ b. Sieved into individual size fractions and recombined as per Table I? … ____ Page 2 Standard Test Method for Resistance to Degradation of Small-Size coarse Aggregate by Abrasion and Impact in the Los Angeles Machine¹ ASTM C131 – 06 PROCEDURE / Clause 9.0 a. Test sample and charge placed in LA machine – rotated machine at 30 to 33 r/min for 500 revolutions? ……………….................................. ____ b. On completion, material discharged from LA machine and separated on a sieve coarser than 1.70 mm (No. 12)? ……………………………... ____ c. 1.70 mm sieve used to separate the remaining material as per Test Method C136? ……………………………………………………............................ ____ d. Material coarser than 1.70 mm sieve washed and oven dried at 110 ± 5°C (230 ± 9°F) to a constant mass? ………………………………………….. ____ e. Determined mass to the nearest 1 g? ………………………................... ____ Note 2: - Wash requirement for test is optional if aggregate is free of coating and dust. Washing procedure shall be performed in case of referee testing. CALCULATIONS / Clause 10.1 a. Loss calculated as a % of the original mass of the test sample? ……… ____ REPORTING / Clause 11.0 a. Identification of the aggregate: Source, type and nominal maximum size? ………………………………………………………………………….. ____ b. Grading used from ASTM C131 / Table I? ………………………………. ____ c. Loss expressed to the nearest 1% by mass? …………………………… ____ COMMENTS: _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________