Hydraulics 1 Laboratory: Momentum and Energy (2010)

advertisement

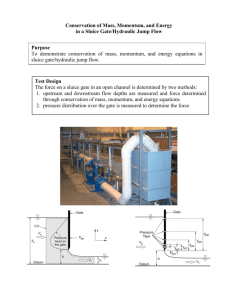

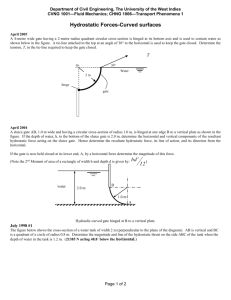

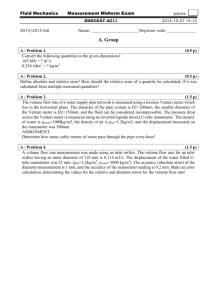

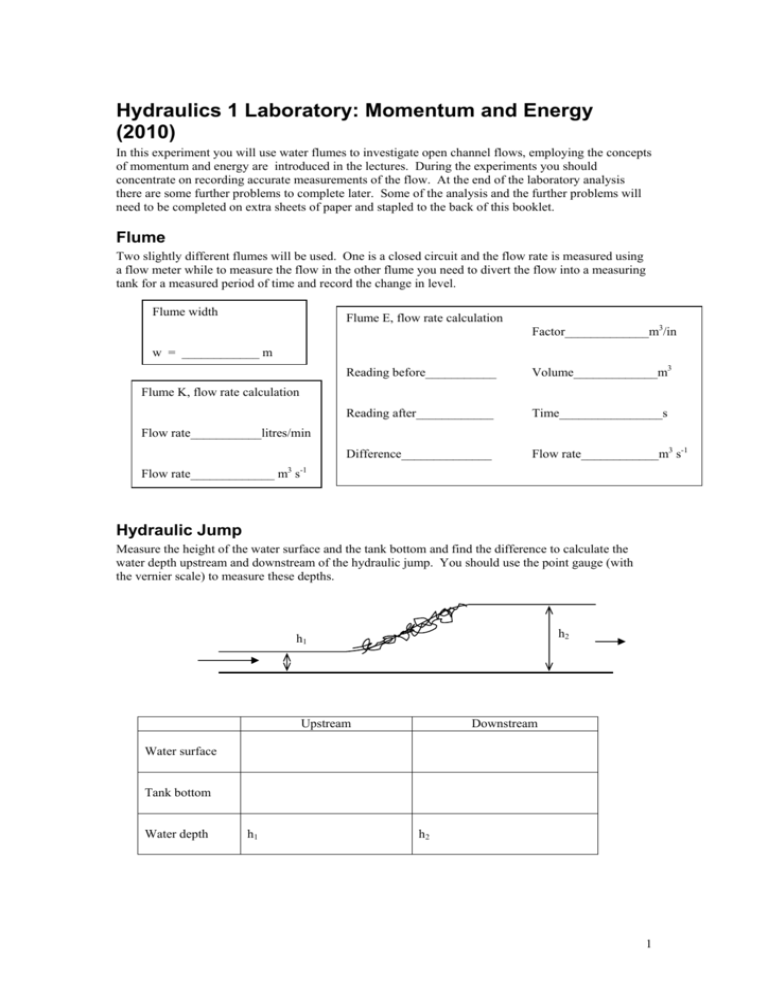

Hydraulics 1 Laboratory: Momentum and Energy (2010) In this experiment you will use water flumes to investigate open channel flows, employing the concepts of momentum and energy are introduced in the lectures. During the experiments you should concentrate on recording accurate measurements of the flow. At the end of the laboratory analysis there are some further problems to complete later. Some of the analysis and the further problems will need to be completed on extra sheets of paper and stapled to the back of this booklet. Flume Two slightly different flumes will be used. One is a closed circuit and the flow rate is measured using a flow meter while to measure the flow in the other flume you need to divert the flow into a measuring tank for a measured period of time and record the change in level. Flume width Flume E, flow rate calculation Factor_____________m3/in w = ____________ m Reading before___________ Volume_____________m3 Reading after____________ Time________________s Difference______________ Flow rate____________m3 s-1 Flume K, flow rate calculation Flow rate___________litres/min Flow rate_____________ m3 s-1 Hydraulic Jump Measure the height of the water surface and the tank bottom and find the difference to calculate the water depth upstream and downstream of the hydraulic jump. You should use the point gauge (with the vernier scale) to measure these depths. h2 h1 Upstream Downstream Water surface Tank bottom Water depth h1 h2 1 Sluice At the start of the flume the water is forced under a sluice gate. The sluice gate has some small holes connected to manometer tubes which allow us to measure the pressure. There are two sets of tubes: those on one side measure the pressure towards the top of the sluice gate while those on the other side measure the pressure near the bottom of the sluice gate where the flow becomes shallower and faster. For this experiment just use the set of seven tubes near the bottom of the gate (fast, shallow flow). All the heights here can just be measured using a ruler. (seven tubes in all) h0 L = water level in manometer tube (relative to tank bottom) h Fluid depth upstream of sluice: h0 = _____________________ For each of the seven tube positions, measure the height of the bottom of the sluice from the tank bottom and also measure the height of the water in the tube (again relative to the tank bottom). It may be hard to measure the water level in the manometer tubes for the last two or three but at least make an estimate of the maximum value the level could be. Position 1 h L 2 3 4 5 6 7 [End of experimental measurements section] 2 Analysis of laboratory experiments Hydraulic Jump u1 u2 h1 h2 Copy the water depths from your experiments (page 1) and calculate the relative size of the jump. h1 = h2 = r = h2/h1 = Using this value of r, calculate the theoretical estimate of the flow speed u1 (see notes). [space for working] Theoretical estimate for u1 (based on r): Now use your measurements of flow rate, channel width and fluid depths to calculate the actual velocities and Froude numbers. Values based on measurements: u1 = u2 = u1 Fr1 = √gh = 1 u2 Fr2 = √gh = 2 Compare the observed velocity with the theoretical prediction. Using the measured depths and the velocities found from the flow rate measurements (not the theoretical estimate), calculate the head loss and thus the power loss at the jump. Head loss Power loss 3 Sluice gate (a) Bernoulli z L (L - h) streamline h Following a streamline just below the gate, the height of the streamline above the bottom of the tank is z = h, while the pressure (relative to atmospheric pressure) is p = ρg(L - h), as (L - h) is the height of the water in the manometer tube. For the seven tubes copy the values of h and L from your results (page 2) and complete the rest of the table (including filling in the missing units). z=h L p ρg = (L - h) units position 1 m u Q = wh dynamic head piezometric head u2 2g p +z ρg total head m 2 3 4 5 6 7 Plot a graph showing dynamic head, piezometric head and total head as functions of position (attach the graph to the end of this booklet). Compare your results with the result you would expect from Bernoulli's equation: 4 (b) Force on sluice gate (control volume) h0 F = horizontal force by water on gate P0 u0 h1 u1 P1 For the control volume sketched above, what is the total (horizontal) hydrostatic pressure force P (remember to include the channel width w)? Calculate the rate of change of momentum of the fluid passing through the control volume, (ρQu1 - ρQu0). The total horizontal force (ignoring friction) on the water in the control volume is P - F (since the force by the gate on the water is -F). Thus calculate the force on the sluice gate, F. 5 Further Problems Attach the answers to the back of the booklet, along with any other extra sheets and graphs used for the experiment sections. 1) Air is flowing through a tapering pipe that connects a larger diameter pipe to a smaller diameter pipe. The upstream pipe has diameter 0.35 m while the downstream pipe has diameter 0.20 m. These two sections are connected by a simple contraction where the diameter changes linearly from 0.35 m to 0.20 m over a distance of 0.5 m. x 0.35 m 0.20 m 0.5 m (a) If the flow rate along the pipe is 0.06 m3 s-1, find an expression for the speed of the flow as a function of the distance from the start of the contraction, x. (b) Find an expression for the acceleration of the air as a function of distance along the contraction. (c) If there is no energy loss in the contraction, find the pressure difference between the ends of the contraction (take the density of air to be 1.20 kg m-3). 2) Air is flowing through a horizontal venturimeter, with a contraction from a diameter of 100 mm to a diameter of 40 mm (take the density of air to be 1.20 kg m-3). A water manometer connected between the inlet and the contraction as shown gives a difference in level of 8.5 cm. If the discharge coefficient for the venturimeter is Cd = 0.95, what is the air flow rate? 3) There is a flow of water of 0.012 m3 s-1, through a 60° (horizontal) bend with a contraction from diameter 85 mm to 50 mm and into the atmosphere. What is the horizontal force required to hold the nozzle in place? (Assume no energy loss in the bend/contraction.) Atmosphere Plan 60° 6