UNIVERSITI MALAYSIA SABAH BORANG PENGESAHAN

advertisement

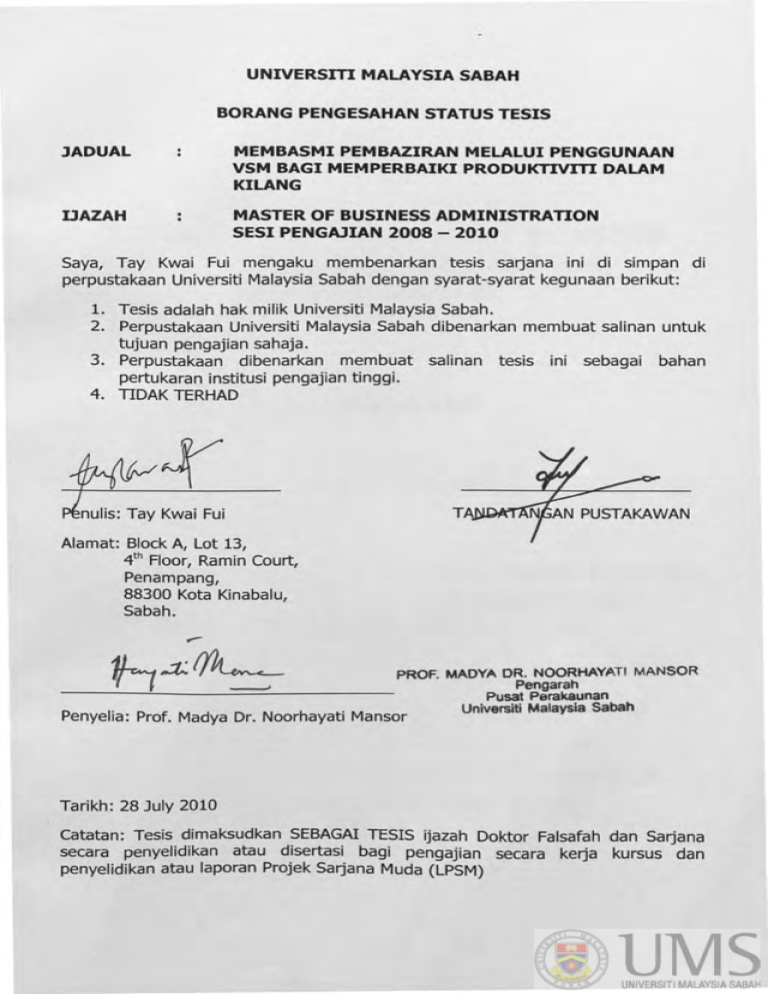

UNIVERSITI MALAYSIA SABAH BORANG PENGESAHAN STATUS TESIS lADUAL MEMBASMI PEMBAZIRAN MELALUI PENGGUNAAN VSM BAGI MEMPERBAIKI PRODUKTIVrn DALAM KILANG IlAZAH MASTER OF BUSINESS ADMINISTRATION SESI PENGAlIAN 2008 - 2010 Saya, Tay Kwai Fui mengaku membenarkan tesis sarjana ini di simpan di perpustakaan Universiti Malaysia Sabah dengan syarat-syarat kegunaan berikut: 1. Tesis adalah hak milik Universiti Malaysia Sabah. 2. Perpustakaan Universiti Malaysia Sabah dibenarkan membuat salinan untuk tujuan pengajian sahaja. 3. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran institusi pengajian tinggi. 4. TIDAK TERHAD Alamat: Block A, Lot 13, 4th Floor, Ramin Court, Penampang, 88300 Kota Kinabalu, Sabah. PROF. MADYA OR. NOORHAYATI MANSOR Penyelia: Prof. Madya Dr. Noorhayati Mansor Pengarah Pusat Perakaunan Universitl Malaysia Sabah Tarikh: 28 July 2010 Catatan: Tesis dimaksudkan SEBAGAI TESIS ijazah Doktor Falsafah dan Sarjana secara penyelidikan atau disertasi bagi pengajian secara kerja kursus dan penyelidikan atau laporan Projek Sarjana Muda (LPSM) WASTE ELIMINATION TO IMPROVE PRODUCTIVITY BY USING VALUE STREAM MAPPING (VSM) IN THE FACTORY TAY KWAI FUI PE PUSTAKAAN UM¥tNSITI MAlAYSIA SABAH THESIS SUBMITTED IN FULFILLMENT FOR THE DEGREE OF MASTER OF BUSINESS ADMINISTRATION SCHOOL OF BUSINESS AND ECONOMICS UNIVERSITI MALAYSIA SABAH 2010 DECLARATION I hereby declare that the material in this dissertation is my own and original work except for quotations, excerpts, summaries and references, which have been duly acknowledged. Tay Kwai Fui PE-2008-8268-C 21 July 2010 ii ACKNOWLEDGEM ENT First and foremost, I would like to express my gratitude and appreciation to supervisor, Prof. Madya Dr. Noorhayati Mansor for her kind support and help, advice and guidance provided by her were extremely beneficial to accomplish dissertation. I thank also for her unwavering patience and sincerity along journey until I completed my dissertation. my the my the Besides that, I would like to express my heartfelt gratitude to my parents for their constant support and understanding. Not forget also to express my grateful appreciation to all my MBA coursemates for their support and inputs which eventually led to the betterment of my research. Special thanks to all the individuals and SEC's factory employees that have partiCipated in the survey. Your value contribution is greatly appreciated. iii ABSTRAK Kajian ini menerangkan kepelbagaian proses bukan tambah nilai (iaitu, pembaziran) yang akan menyebabkan kemerosotan produktiviti dalam industri pengeluaran elevator. Oleh kerana persaingan global dan permintaan para pengguna berubah dari masa ke semasa, pengeluar perlu mengambil tindakan untuk mengubah strategi perniagaan dan pengurusan kifang agar dapat membuat penyesuaian selaras dengan perubahan yang berlaku secara pantas. Pengeluar juga perlu kekal kompetetif dalam era ini. Walau bagaimanapun, adalah tidak mudah bagi pengeluar untuk mencapai tahap ini kerana wujud pelbagai faktor luaran dan dalaman yang berupaya menyebabkan kemerosotan produktiviti dan memberi kesan terhadap daya saing organisasi dan seterunya menyebabkan kelewatan dalam proses kerja dan penghasilan produk yang berkuafiti rendah. Sehubungan itu, adalah penting bagi pengeluar untuk memiliki strategi berkesan yang dapat menjamin atau sekurang-kurangnya dapat mengurangkan atau meminimumkan kos operasi dengan mengenal pasti dan membasmi proses bukan tambah nilai (iaitu, pembaziran) dalam kifang. Hal ini bertujuan untuk memperbaiki kualiti dalam setiap bidang value streams, iaitu satu koleksi aktiviti yang memberikan hasif kepada pengguna. Salah satu bidang yang dikenal pasti ialah pengurusan kifang. Kajian ini juga menerangkan keberkesanan penggunaan Value Stream Mapping (VSM) sebagai satu kaedah untuk membendung impak daripada pembaziran terhadap produktiviti kifang. Oapatan tinjauan fiteratur yang diguna pakai untuk mengenal pasti amalan perkilangan dan VSM turut ditunjukkan dalam kajian ini. Oi samping itu, satu current state map yang menunjukkan aliran proses dalam kifang Sabah Elevator Company (SEC) juga ditunjukkan dalam kajian ini. Justeru, dapatan literatur menjadi medium untuk memperoleh data berkenaan tahap pembaziran dan produktiviti dalam kilang ini. Kajian ini berbentuk eksploratori dan hasil analisis soal selidik menunjukkan masa menunggu dan kecacatan memberi impak negetif terhadap produktiviti kifang SEC. Penggunaan VSM pula membantu mengurangkan impak daripada masa menunggu terhadap produktiviti kilang. Kajian ini dapat menyumbang kepada pengetahuan ten tang bagaimana proses bukan tambah nilai (iaitu, pembaziran) boleh menyebabkan kemerosotan produktiviti dalam kilang ini. Justeru, para pengeluar boleh mendapat pemahaman yang lebih jelas ten tang masalah ini. Implikasi daripada setiap angkubah, termasuk implikasi pengurusan mencadangkan supaya diadakan state map masa depan serta cadangan untuk kajian lanjutan bagi tujuan penambahbaikkan. iv ABSTRACT WASTE ELIMINATION TO IMPROVE PRODUCTIVITY BY USING VALUE STREAM MAPPING (VSM) IN THE FACTORY This research describes the various types of non-value added processes (i.e. waste) that will downgrade the productivity of the elevator manufacturing factory in the industry. As the international competition and customers' demanqs are changing from time to time, manufacturer has to change their business strategy and factory management in order for them to adapt and accommodate to these kinds of rapid changes. Not only that, it is also crucial for the manufacturer to remain competitive in the industry, however this is not easy to achieve for most of the manufacturer as there are many internal and external factors that will downgrade the productivity and affect the competitiveness of the firm, thereafter deliver poor quality of products and delay the work processes in the factory. Therefore it is important for the manufacturer to have an effective strategy that will guarantee, or at least help to reduce or minimize the operation cost by identify and eradicate non-value added processes (i.e. waste) in the factory, hence to improve the quality in every area of the value streams, this shall inclusive of factory management. Furthermore, the research also describes the effectiveness of the Value Stream Mapping (VSM) in moderating the impacts of the waste towards the factory productivity. Results of the literature review, which was used to identify both manufacturing an9 VSM practises, are presented. Current state map of the SEC's factory processes flow also being documented and discussed in this research. The findings of this literature review were synthesized to adapt its instrument to assess both the waste and productivity level in this factory. This is an exploratory study and the analysis of the survey results had shown that waiting time and defect has negative impact on factory productivity in the Sabah Elevator Company (SEC). VSM does show the moderating effect towards the waiting time on the factory productivity. The major contribution of this research enables the manufacturer to gain better understanding on how the non-value added processes (Le. waste) can downgrade the productivity in this factory. The implication of each variable as well as managerial implications, proposed future state map, and further suggestions for future research were identified and proposed. v TABLE OF CONTENTS PAGE TOPIC DECLARATION ii ACKNOWLEDGEMENT iii ABSTRAK iv ABSTRACT v TABLE OF CONTENTS vi LIST OF FIGURES ix LIST OF TABLES x LIST OF APPENDICES xi CHAPTER 1: INTRODUCTION 1.1 Introduction 1 1.2 Research Problem 3 1.3 Research Objectives 3 1.4 Scope of Study 4 1.5 Significance of Study 5 1.6 Organization of the Dissertation 5 CHAPTER 2: LITERATURE REVIEW 2.1 Introduction 6 2.2 Definition of Productivity (Dependent Variable) 6 2.3 Definition of Waste (Independent Variable) and Hypotheses Development 2.3.1 10 Overproduction 11 vi 2.3.2 Waiting Time 13 2.3.3 Transportation 14 2.3.4 Processing 14 2.3.5 Inventory 17 2.3.6 Motion 18 2.3.7 Defects 19 2.4 Definition of Value Stream Mapping (Moderating Variable) 20 2.5 VSM - Current State Map of SEC's Factory 24 2.6 Previous Studies on the Adoption of VSM to Eliminate Waste In order to Improve Factory Productivity 28 2.7 Summary of Research Hypotheses 31 2.8 Summary 32 CHAPTER 3: RESEARCH FRAMEWORK AND METHODOLOGY 3.1 Introduction 33 3.2 Explanatory Case Study 33 3.3 Research Framework 34 3.4 Nature of Study 35 3.5 Instrument 35 3.6 Population of Sample 36 3.7 Data Collection Method 36 3.8 Data Analysis 3.9 3.8.1 Factor Analysis 37 3.8.2 Reliability Test 37 3.8.3 Correlation Analysis 37 3.8.4 Regression Analysis 38 38 Summary CHAPTER 4: RESEARCH FINDINGS 4.1 Introduction 39 4.2 Factory Analysis 39 vii 4.3 Descriptive Statistics of Respondents Profile 40 4.4 Reliability Test 44 4.5 Correlation Analysis 45 4.6 Regression Analysis 46 4.6.1 Multiple Regression 47 4.6.2 Hierarchical Regression 50 Summary of Findings 52 4.7 CHAPTER 5: DISCUSSION AND CONCLUSION 5.1 Introduction 53 5.2 Recapitulations of Study 53 5.3 Discussion and Implications of Study 53 5.3.1 The impact of Overproduction on Productivity 54 5.3.2 The impact of Waiting Time on Productivity 54 5.3.3 The impact of Inappropriate Transportation on 55 Productivity 5.3.4 The impact of Inappropriate Processing on 56 Productivity 5.3.5 The impact of Excess Inventory on Productivity 56 5.3.6 The impact of Inappropriate Motion on Productivity 57 5.3.7 The impact of Defect on Productivity 57 5.3.8 The impact of VSM as Moderator on Productivity 58 5.3.9 Managerial Implications 59 5.4 VSM - Proposed Future State Map 62 5.5 Limitations of Study 64 5.6 Suggestions for Future Research 65 5.7 Conclusion 66 REFERENCES 67 APPENDICES 71 viii LIST OF FIGURES PAGE Figure 2.1 VSM - Current Stat e Map of SEes Factory 27 Figure 3.1 Research Framework 34 Figure 5.1 VSM - Proposed Future State Map 61 ix LIST OF TABLES PAGE Table 4.1 Summary of Fdctor Analysis KMO and Bartlett's Test 40 Table 4.2 Summary of Respondents Profile 42 Table 4.3 Summary of Descriptive Statistics for Variables 43 Table 4.4 Summary of Cronbach's Alpha of Variables 45 Table 4.5 Summary of Correlation Analysis between Variables 46 Table 4.6 Multiple Regression of Waste 47 Table 4.7 Analysis of Variance of Waste 47 Table 4.8 Variables in Equation of Waste 47 Table 4.9 Model Summary of llierarchical Analysis 50 Table 4.10 Hierarchical Regression with Moderating Variable - VSM 51 Table 4.11 Summary of the Hypotheses 52 x LIST OF APPENDICES PAGE APPENDIX A: Instrument (Questionnaire) xi 71 CHAPTER 1 INTRODUCTION 1.1 Introduction International competition and customers' demands are changing from time to time. Manufacturers have to change their business strategy and factory management in order for them to adapt and accommodate to these kinds of rapid changes. In relation to this, it forces a drastic change for most of the manufacturing. As a result, manufacturers are aggressively searching for an appropriate and effective operational strategy in order to increase their competitiveness in the global market (Rawabdeh, 2005). As the international competition is growing intensely, this has caused the traditional types of manufacturing paradigms are being opposed and forced the new manufacturing concepts are being developed (Hines & Rich, 1997), such development and invention are crucial for the firm to remain competitive in the global market. In order to increase the competitiveness over the competition in the industry, manufacturers have been putting a lot of effort to deliver the quality products in order to faster respond and achieve the quality requirements that are demanded by the customers. However, this is not easy to achieve for most of the manufacturers as there are many internal and external factors that will downgrade the productivity and affect the competitiveness of the firm, thereafter deliver poor quality of products and delay the work processes in the factory. For instance, inappropriate segregation of works, inappropriate of the machine used, employee delay the works in the organizations, waiting for the instruction to be given from management and others, over processing, excessive of inventory, inefficient of supply chain and defects of the products, are amongst the most critical factors that need to be resolved. Nowadays, as there are many manufacturers struggle in the global markets, the attention has been diverted to reduce the operation costs and 1 eliminate waste in the factory, thereafter to increase the competitiveness in the industry. In relation to this, organizations and academic institutions have adopted the concept of benchmarking as an ideal approach to identify and detect the intercompany performance gaps, thereafter to seek for alternative strategies in order to be implemented in the organizations. Benchmarking is actually a concept in which the organizations will continually study, observe and review the operation and production line, thus identify the ways to improve the manufacturing processes in order to produce a better output in the organizations (Holloway et al., 1998). In many organizations, benchmarking is accomplished by comparing the outputs for the months throughout the year. However, a general drawback for this type of traditional benchmarking concept is that, it shows only little guidance of how to close the gaps although its primary purpose is to highlight and raise awareness of the intercompany performance gaps (Hines & Rich, 1997). In relation to this, early work in this area suggests that it is difficult to standardize and benchmark processes in different organizations. This is because different organizations are implementing different strategies and processes in managing the operation and production line (Hines et al., 1999). That is, organizations will have their own methodologies to be adopted in the factory. As a result, a new type of benchmarking tool called Value Stream Mapping (VSM) has been developed (Hines and Rich, 1997). The rationale behind the effectiveness of this VSM is that, it is not comparing a firm's work processes with others, but oppositely, it internally compares how good the process itself could be in relation to increasing and improving the overall factory productivity (Hines et al., 1999). Specifically, the VSM compares the value adding processes and wasteful activities in the factory. Not only that, VSM also provides guideline and a clear picture of how to improve the processes flow by removing a realistic percentage of the nonvalue added processes (i.e. waste) in the current factory system. Adopting VSM could be an essential step as it promises to reduce costs, . improve quality and productivity by eliminating non-value added processes (i.e. 2 waste) in every area of the value streams in the factory. This shall be inclusive of factory management and supplier networks. According to Abdulmalek and Rajgopal (2007), the concept of VSM is crucial and vital for most of the firms especially in this difficult economic time as its goal is to eliminate, or at least reduce the nonvalue added processes (i.e. waste) in the factory, thus enabling less inventory, less space, less time, less cost and less resource to produce more, or alternatively to produce the same output with less resources. Therefore, this study examines various types of wastes that are occurred in the Sabah Elevator Company (SEC). The author will study and document the current processes flow in the SEC's factory, thereafter to propose the adoption of VSM in order to improve its productivity and efficiency of the factory. 1.2 Research Problem According to Seth et al. (2008), most activities in the factory create waste, therefore attention needs to be given to improve the productivity in the factory, and immediate actions need to be taken for the firm to remain competitive in the global market. In relation to this, removal of non-value added processes (i.e. waste) from the factory is essential to improve the factory productivity (Conner, 2001). Therefore, this study examines the impacts of non-value added processes (Le. waste) towards productivity in the SEC's factory. From the review of the literature, studies which focus directly on waste elimination in improving factory productivity by using VSM is rather lacking. Therefore, the research problem shall focus on identifying the non-value added processes (Le. waste) which reduce the factory productivity, and determining how would the VSM assists in eliminating the non-value added processes, hence improving the factory productivity and efficiency. 1.3 Research Objectives The main objective of this study is to demonstrate how the VSM tool when used appropriately, can help in eliminating waste, reducing factory throughput time, improving product quality, achieving better overall financial and operational control, thus improving productivity and efficiency of the factory. 3 An elevator factory is used to illustrate the approach in order to identify and eliminate the types of wastes in this factory, thereafter to increase its productivity and efficiency within the manufacturing transformation processes. Since some of the information is confidential, the company is referred to as Sabah Elevator Company (SEC) throughout this study. The specific research objectives for this study are listed below: i) To identify major types of non-value added processes (i.e. waste) in the existing system. ii) To document the current flow of the sales orders (current state map) in the SEC's factory. iii) To apply VSM to determine the improved flow of sales order. iv) To determine the total reduction of time (in hours) associated with the elimination of non-value added processes in the factory. v) To propose a new flow (future state map) of the processes that will help to improve the factory productivity. 1.4 Scope of Study Factory productivity is a major concern for most of the manufacturers because it is the important criteria to determine the competitiveness of the factory in the industry. Therefore, waste elimination and reduction of factory throughput time can be a daunting task due to their complex interactions in the factory processes. Besides that, many internal and external factors will also influence and affect the factory productivity. However, there are basic principles such as adoption of VSM, if applied correctly, can be adopted to identify and eliminate various types of nonvalue added processes in the factory. Therefore, the scope of this study is to focus on productivity and efficiency of the SEC's factory processes from the point of sales order to final delivery to customers. In between the .factory processes, there are ma~y wastes which can be identified and eliminated in order to improve the flow and thus, productivity and the efficiency of the sales order processes in the factory. 4 1.5 Significance of Study This study contributes to improving factory productivity by eliminating waste using VSM . The outcome of the elimination process will reduce operational and production costs, thus reducing the final price to the end consumers. This will increase the competitiveness and SEC's sustainability in a long run and promote steady growth stream for the factory. 1.6 Organization of the Dissertation This study contains of 5 chapters. Chapter 1 consisted of a description and introduction of the study, research problem, objectives of study, scope of study, significance of study and overview of the dissertation of organization of this study. Chapter 2 is all about the review of the literature which is related to this study, the definition of the variables and the proposed hypotheses will be discussed. This chapter is mainly focused on the review of "productivity", "waste" and the adoption of "value stream mapping" in the factory. The intention of this chapter is to provide the history and common methods of measuring the variables as mentioned above. Besides that, the current flow of sales order in the SEC's factory is being documented and discussed in this chapter. Chapter 3 is an explanation and discussion pertaining to the research framework and methodology that is used in this study. Chapter 4 discusses the finding of this study. Chapter 5 consisted of the discussion on the implications (both theoretical and practical). A proposed future state map also being documented and discussed in this chapter. Furthermore, research limitations, suggestions for future research and conclusion for the study also included in this chapter. 5 CHAPTER 2 LITERATURE REVIEW 2.1 Introduction From the review of the literature, there are indeed not many studies directly addressing the issues and impacts of the waste towards the productivity in the factory. In this chapter, the literature review will focus on providing an overview of various types of wastes, and will describe how VSM can be adopted and used as a fundamental component in eliminating waste in order to improve the productivity in the SEC's factory. 2.2 Definition of Productivity (Dependent Variable) Quesnay (1766) first introduced the term of "productivity" in the Journal de l'Agriculture. Since then, the word "productivity" has been widely applied in many different circumstances in the different industries, mostly in relation to the organization economic systems (Tangen, 2002). Furthermore, it has been strongly argued that productivity is one of the most important criteria that should not be neglected in improving the overall financial and productivity controls in the factory (Singh et al., 2000). Specifically, manufacturers should focus and concentrate on how to improve the productivity in order to remain competitive in the global market. Grossman (1993) also discusses that manufacturers should perceive the productivity improvement as one of the key competitive task in the factory. In order to remain competitive in the industry, it is necessary for the manufacturers to improve the productivity and efficiency as this will lead to greater cost reduction in the operation and production line. In spite of the fact that productivity is perceived as the most important factors that affect the manufacturing competitiveness (Porter, 2000), however, many researchers state that, productivity is always being neglected and ignored by manufacturers who do not realize the importance of improving productivity in the factory (e.g. Sink & Tuttle, 1989; Singh et al., 2000; Broman, Z004). 6 Chew (1988) also states that, even though the concept and theory of the productivity has already existed for a long time, surprisingly management may still do not know how to answer the simple question of what productivity is all about. According to Forrester (1993), this is because there is no common agreement and aligned objective from the management on what the term "productivity" actually represents in the organization. Tangen (2005) suggests that the definitions of productivity are based on individual opinions instead of a shared and common perception that are perceived by the others. In the industrial engineering field, productivity is being defined as the relation of output (which is the goods produced) to input (which is the resource consumed) in the factory transformation process (Sumanth, 1994). Furthermore, according to Moseng and Rolstadas (2001), productivity can be described as the ability to fulfil the customers' demands with a minimum consumption of the resources. That is, with the minimum consumption of the resources, it is able to produce quality goods and increase the output. Bernolak (1997) provides an explanation in which productivity is highly associated with manufacturing. According to this researcher, productivity means how much and how well the production line can produce the goods from the resources consumed. The researcher also claims that, if the firm is able to produce more and quality goods from the same resources, it is to be known as increased in productivity. On the other hand, if the firm produce the same goods with lesser resources, factory productivity is considered to be increased as well. The researcher also provides the meaningful explanation for the term resources. "By resources, it means all human and physical resources, which are the people who produce the goods or service providers, and the assets with which the people can produce the goods or provide the services. The resources that people use include the land and buildings, fixed and moving machines and equipment, tools, raw materials, inventories and other current asset." (Bernolak, 1997, p.206). According to Tangen (2005), the above definitions given by Bernolak confine two important descriptions. First, the productivity is very much related to 7 the availability and consumption of the resources. That is, the firm's productivity is said to be downgraded if the resources are not properly being utilized. On the other hand, if there is often a lack of resources in the factory, this will downgrade the firm's productivity as well. Second, productivity is closely related to the value creation for the manufacturers. That is, high productivity can be achieved if resources and activities in the factory transformation processes create value to the goods that are produced. Hence, it is important for the manufacturers to eliminate non-value added processes (i.e. waste) in order to improve factory productivity and efficiency. This is because waste is considered to be opposite of what productivity denoted (Tangen, 2005). In general, productivity means how well the workers can perform in the factory. It is also covers the investment of the tools and machines in the factory. Besides that, the employee education and training of human resources shall also be taken into consideration when defining the terms of productivity in the factory (Helms, 1996). Employee (or to be known as operator in the factory) who performs a job in the factory is a producer, they are responsible for and contribute to the improvement of the productivity. When comparing the total time spent by the workers and total materials consumed in producing a goods, it is important to have a measurement for the productivity in order to benchmark the processes, which means if the workers can perform their jobs better, with the same total time spent and materials consumed, they are able to produce more goods, therefore the firm is considered having an overall increase in productivity and efficiency. Throughout the review of the literature, productivity has been defined as the key to economic prosperity for an organization (e.g.: Tangen, 2005; Helms, 1996). As being argued by Stainer (1997) and Bernolak (1996), most of the manufacturers assume that the definition of productivity is similar with production. Manufacturers always make a wrong assumption that increased in production represents increased in productivity. This is not necessary true as productivity cannot be said to increase or decrease unless an actual comparison is made in the factory by comparing the outputs for the consecutive months throughout the year. Manufacturers have to compare the production volume and numbers of outputs 8 produced by the operators before the judgement is made to the increase or decrease of the firm's productivity. Moreover, as stated by Misterek et al. (1992), improvements in productivity can be caused by five different relationships, which can be summarized as below: i) Increased in output faster than the increased in input. The increase in input is proportionately less than the increase in output (managed growth); ii) With the same input, more output is produced (working smarter); iii) With the reduction in input, more output is produced (the ideal); iv) With the reduction in input, same output is produced (greater efficiency); and vi) Decreased in input more than decrease in output. The decrease in input is proportionately greater than the decrease in output (managed decline). In a nutshell, productivity is a multidimensional term, according to Tangen (2005). The definition and concept of the term productivity are different depending of what context it is placed in. For instance, productivity measured for management staffs is usually different from the productivity measured for the operators or technicians of an assembly line. The variance and reasoning of this indicates that, productivity must be perceived from a different perspective and view from a different angle at each level. The precise definition shall therefore depending on which context it is applied for. 9 2.3 Definitions of Waste (Independent Variables) and Hypotheses Development A fundamental approach to improve the factory productivity and efficiency is the ability to identify the non-value added processes (Le. waste), thus eliminate or at least reduce all forms of waste within the value streams in the factory. The rationale behind this rectification and elimination of waste in the factory need to be understood by the manufacturers in order to effectively identify and adopt the waste elimination tool to improve productivity and efficiency in the factory. According to Hicks (2007), there are few techniques that can be adopted in order to identify and eliminate the various types of waste that is a burden and barrier to the productivity improvement in the factory. The techniques include the five "S"s (Warwood & Knowles, 2004), Kaizen (Imai, 1986), Six Sigma (Pyzdek, 2003), Single Minute Exchange of Die - SMED (Shingo, 1985), and Value Stream Mapping (Hines and Rich, 1997). Often in practise, most activities in the factory create wastes (Seth et al., 2008). Within the context of manufacturing system, there always exist seven types of waste. These are the commonly identified and accepted wastes in the Toyota Production System (TPS) as introduced by Ohno (1988) of Toyota and thereafter reported by Womack and Jones (1996). The seven types of wastes include overproduction, waiting, transportation, processing, inventory, motion, and defect. According to Ohno (1988), wasteful activities do not add value to a product. For instance, products sit in the storage, products being moved around from one location to another location, raw materials are queuing and waiting to be processed, all. these activities indeed add no value to the products, hence downgrade the productivity and efficiency of the factory. Explanation is further explored and discussed by Rawabdeh (2005), in which the researcher states that the seven types of wastes can be eventually categorized into four main groups. These are man, machine, material and method. Each category of these represents the different types of wastes that occur in the traditional manufacturing processes in the factory. In short, the man category 10 contains the type of waste for overproduction, waiting and motion; the machine category contains the type of waste for over-processing; whereas the material category shall contain the type of waste for transportation, inventory and defects; and the method shall inclusive of all types of the wastes, as improper methodologies being implemented in the factory will downgrade the productivity of the factory. 2.3.1 Overproduction Overproduction is said to occur when operations in the factory continue after they should have to be ceased (Hicks, 2007). In other words, overproduction is the production of material in which it is not needed now by the manufacturers and customers. This is often occurs in the large batches production, products being made too early and faster than the speed at which they are needed by the customers. Manufacturers found that it is difficult to estimate precisely the actual numbers of goods that they should have to produce. As discussed by Nielsen (2008) in his research, overproduction means working on something before it is required by the next step in the process flow, or before it is required by the customers. As a result, product sits in work in process queues or in a finished goods stock, and it is indeed not needed now. This kind of phenomenon is considered non-value added processes (Le. waste) for the manufacturers that will downgrade the productivity and efficiency in the factory. Generally, overproduction can be caused by a few factors in the factory, such as poor quality and design of the factory layout, long setups, over complexity of interactions and unreliability of the machine used within the manufacturing environments. To rectify and resolve this type of waste, the manufacturers should avoid using the complicated and long setups in the factory in order to make the production line run effectively and efficiently. Furthermore, manufacturer should also avoid running the production line with inappropriate type of machine as this will lead to overproduction that in turn cause the increase of the operation cost, thereafter downgrade the productivity and efficiency of the factory. 11 Overproduction will also cause an excess of products, products being produced too early and thereafter increased the unnecessary inventory. Always, overproduction happens when the manufacturer over purchase resources than they are needed to be delivered to the customers. Manufacturers found that it is difficult to estimate the actual amount of products that need to be purchased and produced. For example, because of the long change over time in the large batch production, it is often to exceed the quantity that are ordered and needed by the customers, thereafter lead to increase in the inventory. In Ohno (1988) view, overproduction is the worst amongst all these seven types of waste in the factory. This is because this type of waste usually generates all the other forms of waste, especially inventory. Rationally, overproduction causes the increase of the amount of the space to store the raw materials as well as overly produced goods. By keeping large batches of finished goods in the store, this is often being referred to as non-productive cost, and this is the cost that increases the operational cost. Furthermore, the waste from overproduction will lead to not only excess in inventory, but also tonnes of unnecessary paperwork, double handling cost, extra space, extra storage, interest finance charges, machinery, defects and poor quality of goods, human resources and overhead cost. All of these are initially downgraded the productivity of the factory. Generally, overproduction is being viewed as the most serious waste as it discourages a smooth flow of the production in the manufacturing environments. It is expected to restrain quality and productivity in the factory as well. The statement is supported by Hines and Rich (1997) that, such overproduction tends to lead to excessive storage times in the factory. As a result, defects may not be detected early as problems hide in the inventory, products may deteriorate in its quality and pressures on work rate from the factory staff may be generated. Ohno (1988) also states that, overproduction causes the excessive work-in-progress stocks which result in the physical disturbance of operations that lead to poor communication that downgrade the productivity and efficiency of the factory. This kind of phenomenon is indeed having a negative impact on the productivity. 12 REFERENCES Abdulmalek, Fawas, A., & Rajgopal, J. (2007). Analyzing the benefits of lean manufacturing and Value Stream Mapping via simulation: A process sector case study. International Journal of Production Economics, 107, 223-236. Bernolak, 1. (1996). Productivity gain sharing. Working Paper on International Labour Organisation, Geneva. Retrieved from http://oracle02.ilo.org/dyn/empentidocs/F111PUB9801/PUB9801.htm Bernolak, 1. (1997). Effective measurement and successful elements of company productivity: the basis of competitiveness and world prosperity. International Journal of Production Economics, 52 (1-2), 203-213. Broman, M. (2004). Assessing productivity in assembly systems. Licentiate thesis, Department of Production Engineering, The Royal Institute of Technology, Stockholm. Browning, T. (1998). Modelling and analyzing cost, schedule and performance in complex system product development. Unpublished PhD's thesis, Massachusetts Institute of Technology, Cambridge, MA. Brunt, D. (2000). From the current state to the future state: Mapping the steel to component supply chain. International Journal of Logistics: Research and Applications 3 (3), 259-271. Chew, W. (1988). No-nonsense guide to measure productivity. Harvard Business Review, 66 (1), 110-118. Coakes. SJ, Steed. Land Ong. C. (1998). Multivariate Data Analysis (3rd edition). New York: Macmillan Coakes. SJ, Steed. Land Ong. C. (2009). SPSS for Windows (Version 16.0). Australia: John Wiley & Sons Australia Ltd. Conner, G. (2001). Lean Manufacturing for the Small Shop. Manufacturing Engineers (SME), Dearborn, M1. Society of Djumin, Sadono, c., Wibowo, Yuri, Irani & Shahrukh, (2004). Value Stream Mapping from an Industrial Engineering Viewpoint. Retrieved from http://wwwiwse.eng.ohiostate.edu/ISEFaculty/irani/lndustrial%20Engineering%20Studies/V alue%20Stream%20Mapping%20from%20an%20Industrial%20Engineering%2 OViewpoi nt. htm Duggan, K. J. (2002). Creating Mixed Model Value Streams: Practical Techniques for Building to Demand. Productivity Press, New York, NY. 67 Forres~er, J. W. (1993). Low Productivity: is it a problem or merely a symptom? In Christopher, W. & Thor, C (Eds.). Handbook for Productivity Measurement and Improvement. Productivity Press, Cambridge, MA. Grossman,.~. (1993). How to Measure Company Productivity: Handbook for ProductIVIty Measurement and Improvement. Productivity Press Cambridge MA. ' , Helms, M. M. (1996). Perspectives on quality and productivity for competitive advantage. The TQM Magazine, 8, 5-10. MCB University Press. Hicks, B. J. (2007). Lean information management: Understanding and eliminating waste. International Journal of Information Management, 27, 233-249. Hines, P., & Rich, N. (1997). The seven value stream mapping tools. International Journal of Operations & Production Management, 17 (1), 46-64. Hines, P., Rich, N., & Esain, A. (1999). Value stream mapping: A distribution industry application. An International Journal, 8 (1), 60-77. Hines, P., Rich, N., & Hittmeyer, M. (1998). Competing against ignorance: Advantage through knowledge. International Journal of Physical Distribution & Logistics Management, 28(1), 18-43. Holloway, J., Francis, G., Hinton, M. and Mayle, D. (1998). Making the Case for Benchmarking. Performance Management Research Unit, Open University Business School, Working Paper 95-98. Imai, M. (1986). Kaizen: (Ky'zen), the key to Japan's competitive success. New York, London: McGraw-HilI. Jones, D., Womack, J. (2003). Seeing the Whole: Mapping the Extended Value Stream. The Lean Enterprise Institute, Inc., Brookline, MA. King, .5., G. (2004). Using Value Stream Mapping to Improve Forging Processes. Unpublished master's thesis, Massachusetts Institute of Technology, Cambridge, MA. McDonald, T., Vanaken, E.M., & Rentes, A.F. (2002). Utilizing simulation to enhance Value Stream Mapping: A manufacturing case application. International Journal of Logistics: Research and Applications 5 (2), 213-232. Misterek, 5., Dooley, K., & Anderson, J. (1992). Productivity as a performance measure. International Journal of Operations & Production Management, 12 (1), 29-45. Moseng, B., & Rolstadas, A. (2001). Suc~ess factors in the productivity process, 10th World Productivity Congress. Retrieved from http://www.catriona.napier.ac.uk/resource/wpc10th/moseng.htm 68 Nielsen, A. (2008). Getting Started with Value Stream Mapping. Gardiner Nielsen Associates Inc. Nunally, J.e. (1978). Psychometric Theory, New York, NY, McGraw-Hili. Ohno, T. (1988). The Toyota production system: Beyond large-scale production. Portland: Productivity Press. Porter, M.E. (2000). Location, Competition and Economic Development: Local Clusters in a Global Economy. Economic Development Quarterly, 14 (1), 15-34. Pyzdek, T. (2003). The Six Sigma Handbook: The complete guide for greenbelts, blackbelts and managers at all levels (2 nd revised ed.). New York: McGraw-Hili. Quensnay, F. (1766). Analyse de la formule arithmetique du tableau economique de la distribution des depenses annuelles d'une nation agricole. Journal de l'Agriculture, du Commerce & des Finances, 11-41. Rawabdeh, A. 1. (2005). A model for the assessment of waste in job shop environments. International Journal of Operations & Production Management, 25 (8), 800-822. Rother, M. (2004). What we are learning since we started learning to see, NAMonline. Retrieved from http://www.nam.org/tertiarv.asp?TrackID=&CategoryID=253&DocumentID=24 567 Rother, M., & Shook, J., (1999). Learning to See: Value Stream Mapping to Add Value and Eliminate Muda. The Lean Enterprise Institute, Inc., Brookline, MA. Salzman, R. A. (2002). Manufacturing System Design: Flexible Manufacturing Systems and Value Stream Mapping. Unpublished master's thesis, MIT, Cambridge. Seth, D., Seth, N., & Goel, D. (2008). Application of Value Stream Mapping (VSM) for minimization of wastes in the processing side of supply chain of cottonseed oil industry in Indian context. Journal of Manufacturing Technology Management, 19 (4), 529-550. Shingo, S. (1985). A revolution in manufacturing: The SMED system. USA: Productivity Press. Singh, H., Motwani, J. & Kumar, A. (2000). A review and analysis of the state-ofthe-art research on productivity measurement. Journal of Industrial Management & Data Systems, 100 (5), 234-241. Sink, D.5. & Tuttle, T.e. (1998). Planning and Measurement in your Organisation of the Future. Industrial Engineering and Management Press, Norcross, GA. 69 Stainer, A. (1997). Capital input and total productivity management. Journal of Management Decision, 35 (3), 224-232. Sumanth, D. (1994). Productivity Engineering and Management. McGraw-Hili, New York, NY. Tangen, S. (2002). A theoretic foundation for productivity measurement and improvement of automatic assembly systems. Licentiate thesis, The Koyal Institute of Technology, Stockholm. Tangen, S. (2005). Professional Practise: Demystifying productivity and performance. International Journal of Productivity Petformance Management, 54 (i), 34-46. Warwood, S. J., & Knowles, G. (2004). An investigation into Japanese 5-S practice in UK industry. The TQM Magazine, 16 (5). Womack, J. P., & Jones, D. T. (1996). Lean thinking: Banish waste and create wealth in your corporation, 1996. London: Simon and Schuster. 70