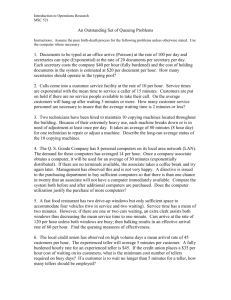

Queuing Theory & Waiting Line Models

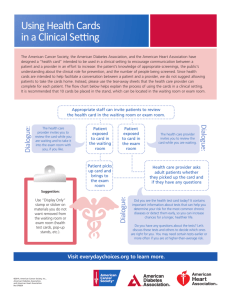

advertisement