Read More - Lufthansa Technik Philippines

advertisement

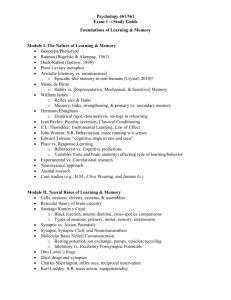

4th Quarter 2010 MRO Lite: Tailor-fit solution for the A320 fleet Phone +63-2-855-9319 Fax +63-2-855-9309 sales@ltp.com.ph Introduction Dominik Wiener-Silva, Vice President — Marketing & Sales, Lufthansa Technik Philippines Dear readers, I was echoing the demands of the market when I stated in a recent interview with one of the top aviation magazines that LTP needs to align its business with low cost carriers to support them. As a response to this need, we have successfully launched a new product that specifically addresses the needs of low cost carriers operating the Airbus A320 aircraft (page 7). As a testament to the success of this new product, we have completed two base maintenance events for Jetstar, our MRO Lite launch customer (page 7). FOUNDED IN the year 2000 as a joint venture of Lufthansa Technik AG and Philippine aviation service provider MacroAsia Corporation, Lufthansa Technik Philippines offers a wide range of aircraft maintenance, repair and overhaul (MRO) services to customers worldwide. The company focuses on base maintenance checks for the A319/A320, A330/A340 types of aircraft. Eight hangar bays and workshops have been designed according to the latest industry standards in order to support aircraft maintenance, major modifications, cabin reconfigurations, engine maintenance and painting for the A319/A320, A330/A340 and B747-400 and B777 aircraft. LTP’s broad experience in A330/A340 base maintenance checks has earned the trust of more than twenty customers worldwide. It is also rendering line maintenance to more than twenty domestic and international carriers. Through a partnership with Lufthansa Technical Training Philippines (LTTP), LTP Our LCC experience, of course, started with our partnership with AirAsia X. Recently, we painted city landmarks of the current international destinations of AirAsia X on one of its A330-300 aircraft (page 3). Amid the economic crisis, the glimmer of hope in Asia came from the aggressive moves being made by LCCs. Thanks to AirAsia X and Jetstar, LTP was able to demonstrate its flexibility in addressing the needs of the LCCs just as it is successful in supporting legacy carriers. While LTP studied and actively participated in new market developments, LTP was also commemorating a milestone that is close to its heart. This year, we celebrated our 10th year anniversary. This was highlighted by a media and advertising campaign that heralded Filipino pride in placing the Philippines in the global aviation map, as well as the Lufthansa Technik Group’s successful establishment of an Asian subsidiary that makes an impact in the market (page 8-9). As a final note, we wish to extend our gratitude to you, our customers for the unceasing trust that you have placed on us this year. It is because of your confidence in us that we are now celebrating “a decade of aviation excellence”. We wish all of you continued success for 2011 and the coming years. Sincerely yours, Dominik Wiener-Silva dws@ltp.com.ph mechanics are certified through EASA Part 66-compliant courses. LTP holds repair station certificates from the FAA, EASA, CAAP and other airworthiness authorities. Our customers: QAircalin QAirAsia X QAir Atlanta Icelandic Q Air Busan Q Air Macau Q Air Mauritius Q Air Niugini Q Air Philippines Q Air Tahiti Nui Q Asiana Airlines Q Austrian Airlines Q bmi Q Cathay Pacific Q China Airlines Q China Eastern Q Etihad Q Eva Air Q Go Air Q Gulf Air Q Hawaiian Airlines Q ILFC Q Japan Airlines Q Jeju Air Q Jet Airways QJetstar Airways QJin Air QKorean Air Q LAN Airlines Q Lufthansa German Airlines Q Malaysia Airlines Q Mandarin Airlines Q MyTravel Airways Q Pacific East Asia Cargo Airlines Q Philippine Airlines QQantas Airways Q Qatar Airways Q Royal Brunei Airlines QSaudia Airlines Q Starflyer Q Strategic Airlines Q Thomas Cook Airlines UK Q Virgin Atlantic Airways QVietnam Airlines QVladivostok Air TechniLink is published quarterly by Lufthansa Technik Philippines for its customers and friends. editorLiza Martija associate editorCarla Martinez art directorSheree Ti adviserDominik Wiener-Silvacontactliza.martija@ltp.com.ph TechniLink 4th Quarter 2010 http://www.ltp.com.ph News & Updates LTP completes AirAsia X paint job with flying colors LAST OCTOBER, a freshly painted AirAsia X A330300 aircraft rolled out of the Lufthansa Technik Philippines hangar with a livery depicting dynamic silhouettes of international landmarks and cityscapes. AirAsia X is widely known for its low-cost and long-haul operations, and with the help of LTP, it is now proudly displaying a new livery that illustrates the scope of its service that links destinations from Asia, Australia and Europe. The paint job was completed in ten days considering it is one of the more detailed and demanding painting tasks LTP has performed. The painting process involved chemical paint stripping of the aircraft fuselage to bare metal, scuff-sanding, and then the repainting of the fuselage to white. The painting crew worked in close collaboration with the drafting team under the Maintenance Program Projects (TS11) and the AO3 Graphics Shop in preparing the technical drawings, and fabricating and installing around 75 meters of livery stencils. The efforts by the TS drafting team and AO3 Graphics Shop helped the Paint Shop in minimizing the turnaround time for these processes while maintaining top quality at all times. Aside from aircraft painting, LTP executed maintenance works on the aircraft such as engine change and rectification of deferred defects, to name a few. Brand-new decals were also installed in the aircraft cabin. Having successfully accomplished the high demands of the project and to the great satisfaction of the customer, LTP’s paint crew has proven that they can take on more intricate livery designs and bigger painting challenges in the future. The future looks colorful for LTP as it continues to push its limits in the field of aircraft painting. t Troubleshooting and Standard Assurance Team (AO/T), reports directly to Bernd Meyer, vice president – Aircraft Overhaul. Lucila Q. Batac still heads AO4 Product Management division, formerly known as AO4 Account Management. Two sections of the former Production Planning and Support division were transferred to Batac’s division: Project Management (AO24) and the Maintenance Manhour Planning section (AO23), now known as Layover and Capacity Planning section. Controlling which used to be part of AO4 was transferred to the Finance department. In addition to the recent changes, Dinnaga Padmaperuma, former Production Planning and Support (AO2) division manager, now handles LTP’s new project, MRO Lite. t Personnel movements Lufthansa Technik Philippines recently welcomed Jan Pfeil as its vice president for Corporate Planning. As LTP’s Vice President for Corporate Planning, Pfeil is responsible for setting up, staging and monitoring transition projects and related activities. He guides LTP through the transition phase and is also responsible for the evaluation of potential new businesses. Significant changes took effect last September regarding the organizational structure of Aircraft Overhaul department. The changes are in line with the company’s goal of streamlining functions. Production Planning (AO21) and Production Controlling Center (PCC) were transferred to Technical Support (TS2) while Maintenance Process Improvement (AO22), now renamed as Pfeil Padmaperuma Batac TechniLink 4th Quarter 2010 Line maintenance Jeju Air signs up with LTP LTP gains B737-800 capability Malaysia Airlines is launch customer Operators may soon avail of Lufthansa Technik Philippines’ latest line maintenance capability for Boeing’s new generation aircraft. LTP mechanics recently completed their EASA Level III training course on the new generation Boeing 737800 aircraft. First to sign up as customer for this added capability is Malaysia Airlines. The Kuala Lumpur-base airline has been LTP’s customer since 2003 for the handling of their A330 aircraft. Recently, the airline changed operations from the Airbus A330 to the B737-800 aircraft. As the launch customer for LTP’s B737-800 services, they will soon avail of this complete line maintenance service including Release to Service (RTS) once LTP receives the approval from the Malaysian authorities. LTP is looking forward to providing the same service to other airlines currently operating with Boeing 737800 aircraft in Manila’s Ninoy Aquino International Airport. t TechniLink 4th Quarter 2010 Lufthansa Technik Philippines (LTP) recently welcomed South Korean airline, Jeju Air, when its maiden flight landed at Manila’s Ninoy Aquino International Airport (NAIA) Terminal 1. Jeju Air joins the growing roster of LTP’s line maintenance customers. LTP will be providing technical assistance to Jeju Air’s Boeing B737-800 aircraft as it flies to the Philippines five times a week. Jeju Air started operations in 2006 and is considered the most low-priced airline company in Northeastern Asia. Based in Jeju City, Jeju-do, South Korea, the airline runs a fleet of six B737-800 aircraft and frequents cities in Asia like Seoul, Busan, Jeju, Nagoya, Osaka, and Bangkok. Recently, it has expanded its international routes to Manila, Cebu and Hong Kong. t Air Busan is newest line maintenance customer Lufthansa Technik Philippines is pleased to welcome its new line maintenance customer, Air Busan, a regional low-cost carrier based in South Korea. Air Busan is set to fly to Cebu six days a week and will entrust its Boeing 737-400 and A321 aircraft to Lufthansa Technik Philippines (LTP) Cebu for Release to Service (RTS) beginning this December. Air Busan started in 2008 as a regional airline with a firm foothold in Busan and Southeast Asia. A subsidiary of Asiana Airlines, Air Busan operates a network of domestic and regional services within Korea and to Japan and strives to be the best short- and mid-haul airline in Asia. In 2009, just within a year of operation, the airline received the Best Service Innovation Award from the Korea Management Association (KMA). t Base maintenance Focus LTP adds Zest to its expertise Three layovers for Zest Airways before the end of the year is definitely an added flavor to Lufthansa Technik Philippines’ exciting year as the airline’s narrowbody jets undergo bridging checks. Successfully completed during the third quarter of 2010 is a paint job for the operator’s newly-leased A319-100 aircraft from Volito Aviation Services. The aircraft left LTP with a freshly painted livery bearing the Zest Airways logo in green and tangerine colors. Following a successful delivery of the narrowbody aircraft were two bridging checks for two of the airline’s Airbus A320 aircraft. This special layover also covered engine change for one of the A320s. Such engine buildup on a V2500 engine was first for LTP to carry out, and the accomplishment on this task exhibited the ability of the workforce to take on new challenges. “Despite being a new maintenance task on the V2500 engine change build-up, our mechanics’ knowledge and experience had laid a great foundation for them to easily acquire much needed skills for this particular event. LTP is most delighted to have one of the Philippines’ fast-growing airlines be under its maintenance roofs,” shares Ryan Joseph Cariaga, LTP base maintenance project manager. Zest Airways is the third Philippine operator to have been maintained by LTP. Formerly known as Asian Spirit, Zest Airways is a privately-owned airline based in Manila. It utilizes a fleet of narrowbody Airbus A319/20 and MA60 aircraft to serve a network of domestic and regional destinations within the Philippines and Asia. The airline is one of the country’s growing local operator with hubs at Kalibo International Airport and Ninoy Aquino International Airport (Manila).t Volito entrusts A319 maintenance to LTP An Airbus A319-100 from leasing company Volito Aviation Services saw final completion after a bridging check with cabin reconfiguration at Lufthansa Technik Philippines before being fully delivered to Zest Airways. A cabin modification on the aircraft converted its seat layout from bi-class to mono-class to allow its lessee to cater to the growing demands of the flying public. Also covered under the agreement was a bridging check for the A319 which was successfully carried out in the Manila-based facility. Volito is the second leasing organization under LTP’s growing customer base. Previously in 2008 another aircraft lessor company, ILFC, had also contracted LTP with two A340 jets for base maintenance checks. Volito Aviation Services AB is part of the Volito Group, headquartered in Malmö, Sweden, with subsidiaries in Dublin and Singapore. Volito Aviation Services is jointlyowned by Volito Aviation AB (80%) and The Goldman Sachs Group, Inc. (20%). It was established in 2001 by the primary shareholders of Indigo Aviation AB and has since been active in acquiring and leasing commercial jet aircraft.t Focusing on LTP ’s capabilities at the MRO Asia 2010 IT WAS another fruitful participation for Lufthansa Technik Philippines (LTP) to the MRO Asia Conference and Exhibition this November. Held this year at the Suntec Convention Centre in Singapore, the MRO Asia provided a venue for LTP to showcase its maintenance, repair and overhaul (MRO) capabilities to the attendees of the three-day event. Attendees this year included executives and representatives of various airlines, leasing companies, OEMs and MROs who are focused on technical and engineering, maintenance, material and purchasing, contracts, supply chain, business development, IT/software, and customer service. t TechniLink 4th Quarter 2010 Focus: MRO Lite “Guilty as charged” Industry analysts and insiders have been forecasting major changes in how we, Southeast Asian MRO providers, will re-shape our businesses in the coming years. All these changes they say are our response to the tempo that the low-cost carrier sector dictates. For one, the experts say, MROs will be expanding capabilities from a wide-body centric operation to include narrowbody aircraft which LCCs utilize. Two, it is expected that some MROs will tailor fit their operations to the needs of LCCs. The MRO partner of a low-cost operator should have flexible, value-laden and comprehensive solutions that will satisfy the need of the operator. The MRO should also have a group that specializes in trouble shooting in order for it to respond to AOG situations. The MRO should provide access to tooling and materials pool as well. On all these counts, LTP pleads guilty! Yes, we are guilty of listening to the market. To our defense, we have successfully transformed our newest hangar into an A320 LCC location that is capable of accommodating three to four Airbus A320/A321 for light and heavy checks. We have also analyzed our process to configure it according to the needs of our LCC customers. Best of all, we are severely guilty of providing our LCC customers the same “star treatment” that we are known to provide our legacy carrier partners as proven by the successful checks that we have performed for Jetstar Airways, our launch customers for our MRO Lite product. Dinnaga Padmaperuma, MRO Lite Project Head and Owner, explains the rest of our argument in the succeeding page. t TechniLink 4th Quarter 2010 Focus: MRO Lite MRO Lite: Tailor-fit solution for the A320 fleet The low cost carriers (LCC) have taken the aviation industry by storm, and with growing demands from the flying public, the acquisition of the Airbus A320 aircraft alongside the adoption of a value-based business model approach is becoming an unstoppable trend. Lufthansa Technik Philippines (LTP) saw the expansion of the A320 fleet in the Asian region as a viable opportunity to cater to a market that has well-defined needs. “This growth upsurge in the LCC sector has placed airframe maintenance providers into a saturated arena of cut-throat competition. We wanted to be more than just another MRO company out there and this led us to differentiate our services using the Blue Ocean Strategy®. We looked at certain criteria which are important to our LCC customers, and from there we created a whole new product to solely cater to low cost operators of the A320s,” says Dinnaga Padmaperuma MRO Lite Project Owner and Head. The Blue Ocean Strategy® places companies ahead of the game by making the competition irrelevant, and in the socalled blue ocean, there is an untapped market space with a high profit growth potential. “We want to get LTP out of that red ocean of bloody competition where everyone is just waging price wars and outdoing their rivals. We had to understand from the outset what the LCCs really want, rather than us telling them what we think would be something they should have. I believe we have successfully formulated a package that suits the LCC mindset,” adds Padmaperuma. A collective study allowed LTP to clearly identify several factors that make the LCC market tick. From a strategy canvas derived from LTP’s first LCC maintenance event with Jetstar, it was concluded that cost, customer empathy and a flat organization were areas that can further build up this LCC MRO product. “Working with AirAsia X since January 2010 assured us of our capability to carry out this project successfully, but it was our current and future portfolio with our first event under this new product that had established the direction to how we can complement the philosophy of LCCs.” LTP’s fifth and most recently built hangar had been transformed as the LCC location with a capacity to house three to four Airbus A320/A321 aircraft for light C-checks and 4C/6Y checks. Processes were further reviewed and reworked to better suit the cost reduction framework. This included the implementation of LEAN concepts to standardize all areas of the maintenance events involving LCC aircraft. Developed areas within the production site covered materials, tooling and TAKT planning. To further respond to a more affordable maintenance package from LCC operators, all-inclusive prices with volume-driven discounts are being offered by LTP based on high consideration of the operator’s high flight utilization of the LCC’s fleet. “More than bringing down the costs, we want to be able to build rapport with our LCC customers by understanding how they behave, knowing their special needs and making it known to them that they have come to the right place here at LTP. It’s all about them now and what they want. We listen and act on them accordingly,” says Padmaperuma. LCCs thrive on a fast-paced environment driven by a highly demanding workforce and operations. This prompted LTP to restructure to a flat organization for better flexibility and efficiency. With this new setup, a core team now handles all communications relating to the LCC MRO product. “We developed a ‘one face’ system where a single focal point of contact becomes the owner of an event. We rid ourselves of a bureaucratic organization to enhance customer empathy. This suits better with the culture of LCCs,” explains Padmaperuma. t Jetstar Airways makes debut as LTP’s first LCC customer Lufthansa Technik Philippines’ bay five had just been reinvented to house a unique product for the A320 low cost carriers (LCCs) and LTP is proud to have Jetstar Airways as its launch customer. Two Airbus A320s of the valuebased carrier had been scheduled for maintenance events during the last quarter of the year 2010, with the first narrowbody marking Lufthansa Technik Philippines’ first low cost carrier in this new product line. Following the first and successful base maintenance (C6) check for the aircraft was another A320 that had undergone completion for a heavy check (C4). Both aircraft were able to take full use and advantage of the benefits under the newly rolled out project of the Manila-based facility. This included shortened turnaround times (TAT), more efficient data entry, access to a tooling and materials pool, competitive rates, among others. LTP will also start handling line maintenance services for Jetstar once the airline introduces flights to Manila by next year, 2011. t TechniLink 4th Quarter 2010 News & Features Anodized surface to perfection Galley latches/catches get treated in LTP’s anodizing backshop Shiny and new – that’s all about aiming for perfection, and it goes the same with the yearly averaged 4,000 parts that would undergo an electrolytic passivation process called anodizing in Lufthansa Technik Philippines. This process changes the microscopic texture of an aluminum part surface to increase corrosion resistance. Anodizing also contributes to increasing the surface’s hardness and improving its lubrication and adhesion. Anodic films are generally much stronger and more adherent than most other types of paint and metal plating, and at LTP, only the highest quality plating and anodizing solutions are used to achieve the necessary wear ability, radiation shielding and paint adhesion. The first step in the anodizing process is stripping. The disassembled galley latches/catches are dipped into a sodium hydroxide solution until the parts turns black. These are then submerged into a 5% nitric acid mixture for neutralization. After being completely stripped off, the aluminum parts should be degreased by soaking them into a cleaner solution to allow further cleansing. It is important that in between steps or solutions, the parts are rinsed with water. The galley latches/ catches may have nonaluminum parts that do not need to be anodized, and through another process called masking, these parts are covered using aluminum tape. Protecting these areas is crucial, because nonaluminum parts stir up a reaction on the sulfuric acid solution. After masking parts that do not require anodizing, the latches are assembled on titanium-made racks that can hold up to 3050 parts. Following the assembly is the surface preparation that involves acid pickling. This prepares the aluminum and its alloys prior to bonding, painting, and anodizing. Soon after parts are ready to be anodized, they are finally soaked into the tank with the anodizing solution that has been Highly-skilled, hardworking and extremely passionate about their jobs. At par with the world’s bvest. They are the Filipino workers who make Lufthansa Technik Philippines a choice destination for aircraft maintenance, repair and overhaul. Each plane they work on is guaranteed safe and reliable. TechniLink 1st put Quarter 2010 A source pride, they the Philippines on the global aviation map. TechniLink 4th Quarter 1st 2010 of great previously prepared. Certain properties of the solution must be maintained in order to achieve the desired results. A chiller is used to keep the solution at a very low temperature, and a rectifier is set for electricity to run current on the parts. The latches are immersed into the tank for one to one and a half hours. After anodizing, the parts go through the process of neutralization where these are bathed into a sodium bicarbonate solution. Following water rinses in-between, the aluminum latches are then dipped in to the sealing tank maintained at 100 degrees celcius. After an hour of completing the sealing process, the galley latches/catches are given a final rinse and are dried out. To finally complete the entire anodizing process in aluminum surface treatment, the parts become subject to different types of inspection with corresponding tools and equipment to ensure high quality of the anodized parts. A visual inspection is performed using a test piece device, while a corrosion testing machine is utilized for a test on the parts’ corrosion resistance. A gauging tool is likewise used to inspect the thickness of their coatings. LTP’s experts perform anodizing in its own anodizing backshop complete with the latest equipment to support all processes involved to achieve the best quality and wear resistance properties for the aircraft’s galley aluminum parts. Some of the most important factors and equipment that influence these properties can be found in the backshop including but not limited to tanks, cathodes, temperature control devices, titanium racks and power supply requirements. t Philippine Daily Inquirer, Philippine Star, and Overhaul & Maintenance — July 28 and October 2010 Personnel assignment LTP revs it up in Melbourne Line personnel completes three-day engine change Once again Lufthansa Technik Philippines’ skilled manpower made the company proud when eleven of its personnel successfully completed a three-day engine change on a CF6-80E1 for New Caledonia’s international airline, Air Calin. As part of LTP’s Personnel Assignment program, ten mechanics and one inspector from Line Maintenance Department were sent to John Holland Aviation Services (JHAS) in Melbourne for the task. The engine task assignment was completed one day ahead of the scheduled time. “There were always clear lines of communication among LTP, JHAS and Air Calin. Aside from our people’s expertise and not to mention the good traits such as professionalism, adaptability, openness and discipline that we Filipinos exhibit, we attribute our success in this undertaking to the close cooperation we shared with our counterparts,” shares LTP Sales Manager Dino Santos. “We have received very good feedback from Air Calin. We had been reassured that the job assignment went very well and our mechanics have been commended on their systematic work processes and their orderliness in the workplace,” adds Santos. Tracing back in year 2006, LTP had already performed a special layover for the operator covering tasks on the main landing gear of the carrier’s A330 aircraft. Air Calin was established in September 1983 and started operations in December 1983. It flies international destinations from its hub in Noumea’s international airport while utilizing its fleet of Airbus A330 and A320 aircraft. The airline is the first South Pacific Islands customer of LTP. t Philippine Daily Inquirer, Philippine Star — August 9, 2010 TechniLink 4th Quarter 2010 People Behind the lens and beyond flights Gregory Jenkins watched as LTP bore its first LCC star Scenic shots captured by Jenkins. First photo: A nightlit bridge in Toulouse, France. Second photo: Fanny Bay in Darwin, Australia. As if the universe conspired for Gregory Jenkins to get what he always wanted, he is now out and about working with airplanes. This was a clear vision for Greg at a very young age, and fast forward to today, he now works for Jetstar as a Technical Representative at age 46. “As a little boy, I always wanted to be with airplanes, but I was never really sure about what I wanted to do until I decided one day to become a mechanic.” This determination landed him an apprenticeship with Ansett, an Australian airline company. “I was eventually hired as a licensed engineer and stayed there for twenty years,” adds Jenkins. He then joined Jetstar, previously known as Impulse Airlines, and just some four years ago a Technical Representative post was offered to him. Such great opportunity became a ticket to the world. What was once a dream just skyrocketed into a fast-paced reality that has brought him to some of the greatest cities in the world. What better way to capture the realization of his dreams is through photography. “I bring my SLR camera with me whenever my job requires me to go to another country. I like taking pictures of cities that I visit—the scenery and the landscapes, and things that are different from what we are seeing. Every picture does tell a hundred stories.” His most recent stop in Manila was not just another flight around the region. It has made his role in Jetstar as significant as it had been for the aircraft he looked after in Lufthansa Technik Philippines (LTP). “This was our first heavy maintenance C-check with LTP on the A320. Jetstar is likewise the first to have received maintenance in the LCC project,” says Jenkins. Strong communication lines as well as new lessons that rose from this event from both LTP and Jetstar had created a better relationship, and can be attributed to the success of the event. “Since I had been here in LTP for quite a few times before, I already consider most of those I work with as friends and not just mere colleagues. This makes it easier to work with them. Aside from being skilled, they exercise professionalism very well in the work place. LTP really knows how to work with customers.” Asked about what gives LTP the edge above its competitors, Jenkins was quick to reply, “People in LTP have two distinct traits that I find very appealing as a customer – flexibility and adaptability. It becomes so much easier for us to come to a solution if tough situations arise because of these. I strongly believe that the LCC will become a very good product because of LTP’s flexibility and adaptability.” As bright as the first star that had risen from LTP’s new LCC business segment, Jenkins clearly sees a great future for the LTP and Jetstar partnership.t LTP joins the Mabuhay Germany 2010 exhibit A familiar sight from last year’s exhibit, Lufthansa Technik Philippines’ booth is yet again one of the most visited among the selection of participants to this year’s Mabuhay Germany, an exhibition organized by the German-Philippine Chamber of Commerce and Industry that celebrates successful Filipino-German companies in the Philippines. 10 TechniLink 4th Quarter 2010 LTP showcased tools, equipment and aircraft parts for visitors to feel, even in a brief moment, how it is to be an aircraft mechanic. A mock- up aircraft skin panel was transported to the venue for the skin repair demo and exercise. The three-day event also featured a life vest demo where guests tried actual inflation of the vests. This year’s main attraction was the Philippine Airlines Boeing 747 business class seat. As part of the event’s Scavenger Hunt, LTP with special efforts from Lufthansa Technical Training Philippines, set up a wire game outlining the map of Germany for participants of all ages to try for a prize and complete the hunt. t Contacts Marketing & Sales Group Vice President Dominik Wiener-Silva dws@ltp.com.ph Phone +63-2-855-9310 Mobile +63-917-515-1479 Sales — Base Maintenance for A320, A330/A340 Manager Dino Santos dino.santos@ltp.com.ph Phone +63-2-855-9319 Mobile +63-917-838-5746 Sales — Base Maintenance Project Manager Ryan Cariaga ryan.cariaga@ltp.com.ph Phone +63-2-855-2222 ext. 8540 Mobile +63-917-515-9177 Sales — Line Maintenance and AOG Senior Account Executive Erick Bautista erick.bautista@ltp.com.ph Phone +63-2-855-2222 ext. 8527 Mobile +63-917-850-7147 Sales — Personnel Deployment Account Executive Edherlina Pili edherlina.pili@ltp.com.ph Phone +63-2-855-2222 ext. 8526 Key Account — Philippine Airlines Manager Pearl Rubio pearl.rubio@ltp.com.ph Phone +63-2-855-9315 Mobile +63-917-793-1509 Marketing Communications Section Manager Liza Martija liza.martija@ltp.com.ph Phone +63-2-855-9215 Mobile +63-917-857-7127 For Technilink Magazine subscription, email us at sales@ltp.com.ph • Press and public relations • Brochures • Technilink Magazine • Advertising materials • Conferences and events • Website and intranet AOG desk TechniLink TechniLink 3rd 4th+63-2-855-9122 Quarter Quarter 2009 2010 11 Address: MacroAsia Special Economic Zone, Villamor Air Base, Pasay City 1309 Philippines Phone: +63-2-855-9311 AOG desk: +63-2-855-9122 E-mail: sales@ltp.com.ph Website: www.ltp.com.ph