Chap.6 Flow in pipes

advertisement

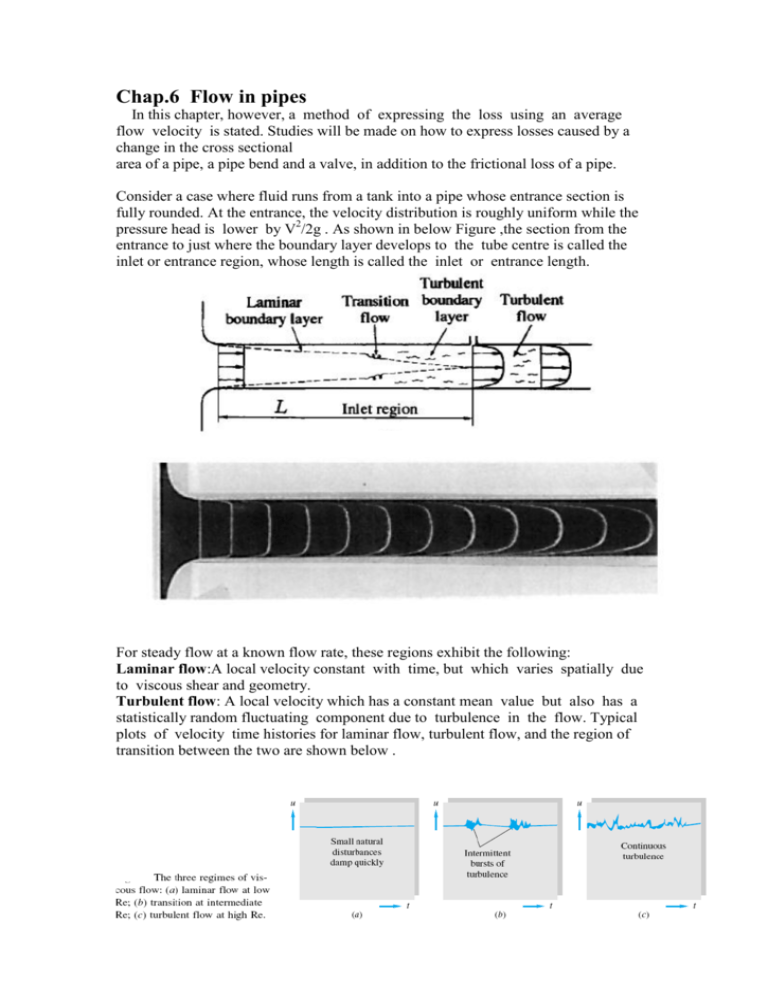

Chap.6 Flow in pipes In this chapter, however, a method of expressing the loss using an average flow velocity is stated. Studies will be made on how to express losses caused by a change in the cross sectional area of a pipe, a pipe bend and a valve, in addition to the frictional loss of a pipe. Consider a case where fluid runs from a tank into a pipe whose entrance section is fully rounded. At the entrance, the velocity distribution is roughly uniform while the pressure head is lower by V2/2g . As shown in below Figure ,the section from the entrance to just where the boundary layer develops to the tube centre is called the inlet or entrance region, whose length is called the inlet or entrance length. For steady flow at a known flow rate, these regions exhibit the following: Laminar flow:A local velocity constant with time, but which varies spatially due to viscous shear and geometry. Turbulent flow: A local velocity which has a constant mean value but also has a statistically random fluctuating component due to turbulence in the flow. Typical plots of velocity time histories for laminar flow, turbulent flow, and the region of transition between the two are shown below . Principal parameter used to specify the type of flow regime is the Reynolds number : V - characteristic flow velocity D - characteristic flow dimension μ- dynamic viscosity υ- kinematic viscosity We can now define the critical or transition Reynolds number Recr Recr is the Reynolds number below which the flow is laminar, above which the flow is turbulent While transition can occur over a range of Re, we will use the following for internal pipe or duct flow: Typical criteria for the length of the entrance region are given as follows: Le = length of the entrance region .The wall shear is constant, nd the pressure drops linearly with x,for either laminar or turbulent flow.All these details are shown in the below Figure Laminar flow: computation by Boussinesq experiment L = 0.065Red by Nikuradse L = O.06Red computation by Asao, Iwanami and Mori Turbulent flow: L = 0.693Re1I4d computation by Latzko L = (25 - 40)d experiment by Nikuradse Developing pressure changes in the entrance of a duct flow Velocity distribution of Laminar Flow in pipe: In the case of axial symmetry, when cylindrical coordinates are used , the momentum equation become as following : ---(1) ---- (2) For the case of a parallel flow like this, the Navier-Stokes equation is extremely simple as follows: 1. As the velocity is only u since v = 0, it is sufficient to use only the upper 2. As this flow is steady, u does not change with time, so ∂u/∂t = 0. 3. As there is no body force, ρX = 0. 4. As this flow is uniform, u does not change with position, so ∂ul∂x = 0 and ∂2u/∂x2=0 5. Since v= 0, the equation 2 simply expresses the hydrostatic pressure variation and has no influence in the x direction. So, equation 1 becomes : Integrating According to the boundary conditions, since the velocity at r = 0 must be finite c1 = 0 and c2 is determined when u = 0 at r = ro: Laminar flow in a circular pipe From this equation, it is clear that the velocity distribution forms a paraboloid of revolution with umax at r = 0 : The volumetric flow rate passing pipe Q becomes : From this equation, the mean velocity v is : The shear stress due to the viscosity is : (Since duldr < 0, T is negative, i.e. leftward.) Thus : Putting the pressure drop in length L as ∆p, the following equation is obtained : ( Hagen-Poiseuille formula ) Using this equation, the viscosity of liquid can be obtained by measuring the pressure drop ∆p. Velocity distribution between parallel plates: Let us study the flow of a viscous fluid between two parallel plates as shown in below Figure , where the flow has just passed the inlet length. The momentum equations in x and y directions as in the following : -------------( 1 ) -------------( 2 ) Under the same conditions as in the previous section , the upper equation (1) becomes : Consider the balance of forces acting on the respective faces of an assumed small volume dx dy (of unit width) in a fluid. Since there is no change of momentum between the two faces, the following equation is obtained: therefore By integrating the above equation twice about y, the following equation is obtained: ---------(3) Using u = 0 as the boundary condition at y = 0 and h, c1 and c2 are found as follows: It is clear that the velocity distribution now forms a parabola. At y = h/2 , du/dy = 0 , so u becomes umax : The volumetric flow rate Q becomes : ---------(4) From this equation, the mean velocity v is : The shearing stress z due to viscosity becomes : Putting L as the length of plate in the flow direction and ∆p as the pressure difference, and integrating in the x direction, the following relation is obtained: Substituting this equation into eqn (4) gives : As shown in the below Figure , in the case where the upper plate moves in the x direction at constant speed U or -U, from the boundary conditions of u = 0 at y = 0 and u = U at y = h, c1 and c2 in eqn (3) can be determined. Thus : and CouettePoiseuille flow Velocity distribution of turbulent Flow For two-dimensional flow, the velocity is expressed as follows: where u and v are the timewise mean velocities and u' and v' are the fluctuating velocities. Now, consider the flow at velocity u in the x direction as the flow between two flat plates as shown in the below Figure , so u = |u| + |u'| but v = v' . The shearing stress τ of a turbulent flow is : τ1 = laminar flow shear stress τt= turbulent shearing where numerous rotating eddies mix with each other. stress Now, let us examine the turbulent shearing stress only. The fluid which passes in unit time in the y direction through dA parallel to the x axis is ρv' dA. Since this fluid is at relative velocity u' , the momentum is pv' dA u'. By the movement of this fluid, the upper fluid increases its momentum per unit area by ρ u' v' in the positive direction of x per unit time.Therefore, a shearing stress develops on face dA. It is found that the shearing stress due to the turbulent flow is proportional to ρ u' v' . Reynolds .Thus Below Figure shows the shearing stress in turbulent flow between parallel flat plates. Expressing the Reynolds stress as follows as in the case of laminar flow produces the following as the shearing stress in turbulent flow: This vt is called the turbulent kinematic viscosity. Vt is not the value of a physical property dependent on the temperature or such, but a quantity fluctuating according to the flow condition. Prandtl assumed the following equation in which, for rotating small parcels of fluid of turbulent flow (eddies) traveling average length, the eddies assimilate the character of other eddies by collisions with them: Prandtl called this I the mixing length. According to the results of turbulence measurements for shearing flow, the distributions of u' and v' are as shown in the Figure , where u' v' has a large probability ----------(1) Assuming זto be the shearing stress acting on the wall, then so far as this section is concerned: and = ( friction of velocity) Putting u = uδ whenever y=yδ gives ------(2) where Rδ is a Reynolds number. Next, since turbulent flow dominates in the neighborhood of the wall beyond the viscous sublayer, assume זo=זt , and integrate eqn (1): Using the relation ū = uδ when y =δo , Using the relation in eqn (2), If ū/ν ٭, is plotted against log10 (ν,y/ν), the value A can be obtained , A = 5.510 This equation is considered applicable only in the neighbourhood of the wall from the viewpoint of its derivation. In additional, Prandtl separately derived through experiment the following equation of an exponential function as the velocity distribution of a turbulent flow in a circular pipe as shown in beow Figure : n changes according to Re , and is 7 when Re = 1* 105. Since many cases are generally for flows in this neighbourhood, the equation where n = 7 is frequently used. Losses By pipe Friction Let us study the flow in the region where the velocity distribution is fully developed after passing through the inlet region as shown below . If a fluid is flowing in the round pipe of diameter d at the average flow velocity v, let the pressures at two points distance L apart be p1 and p2 respectively. The relationship between the velocity u and the loss head h = ( p 1 - p2 ) /pg For the laminar flow, the loss head h is proportional to the flow velocity v while for the turbulent flow, it turns out to be proportional to v1.75-2 . The loss head is expressed by the following equation as shown in this equation : This equation is called the Darcy-Weisbach equation', and the coefficient f is called the friction coefficient of the pipe. Pipe frictional loss Relationship between flow velocity and loss head Laminar flow In this case the equations and f= No effect of wall roughness is seen. The reason is probably that the flow turbulence caused by the wall face coarseness is limited to a region near the wall face because the velocity and therefore inertia are small, while viscous effects are large in such a laminar region. Turbulent flow f generally varies according to Reynolds number and the pipe wall roughness. Smooth circular pipe The roughness is inside the viscous sub layer if the height ε of wall face ruggedness is In the case of a smooth pipe, the following equations have been developed: f f f f f f Re√f f f Rough circular pipe If whenever Re > 900(ε/d) , it turns out that f f A good approximate equation for the turbulent region of the Moody chart is given by Haaland’s equation: For a new commercial pipe , f can be easily obtained from Moody diagram shown in Fig.a using ε/d in Fig.b . Fig,a Mody diagram f f √f Fig,b Re√f Example ( Laminar flow): Water, ρ=998 kg/m3 , = 1.005 ×10-6 m2 /s flows through a 0.6 cm tube diameter, 30 m long, at a flow rate of 0.34 L/min. If the pipe discharges to the atmosphere, determine the supply pressure if the tube is inclined 10o above the horizontal in the flow direction. 30 m 10o 30*sin(10) Example An oil with ρ = 900 kg/m3 and = 0.0002 m2 /s flows upward through an inclined pipe . Assuming steady laminar flow, (a) verify that the flow is up, (b) compute hf between 1 and 2 , and compute (c) V , (d) Q, and (e) Re. Is the flow really laminar? HGL1 < HGL2 hence the flow is from 1 to 2 as assumed. V=2.7 m/s , Q=0.0076 m3/s and Re=810 the flow is laminar Example: (turbulent flow) Oil , ρ = 900 kg/m3 , ν = 1 ×10-5 m2 /s , flows at 0.2 m3 /s through a 500 m length of 200 mm diameter , cast iron pipe ε=0.0013. If the pipe slopes downward 10o in the flow direction , compute hf , total head loss, pressure drop, and power required to overcome these losses. 500 m d=200 m 10o Note that for this problem, there is a negative gravity head loss ( i.e. a head increase ) and a positive frictional head loss resulting in the net head loss of 29.8 m Minor losses in pipes In a pipe line, in addition to frictional loss, head loss is produced through additional turbulence arising when fluid flows through such components as change of area, change of direction, branching, junction, bend and valve. The loss head for such cases is generally expressed by the following equation: hs =k υ is the mean flow velocity on a section loss in a suddenly expanding pipe For a suddenly expanding pipe as shown in below Figure, assume that the pipe is horizontal, disregard the frictional loss of the pipe, let h, be the expansion loss, and set up an equation of energy between sections 1 and 2 as : Apply the equation of momentum setting the control volume as shown in the Figure . Thus : Since Q = A1 v1 = A2 v2 , from the above equation, Substituting into eqn( 1 ) : --------- ( 1 ) This hs is called the Borda-Carnot head loss or simply the expansion loss. Flow in pipes : At the outlet of the pipe as shown in the right Figure, since v2 = 0, the above equation becomes hs = k Flow contraction Owing to the inertia, section 1 (section area A1 ) of the fluid shrinks to section 2 (section area Ac) and then widens to section 3 ( section area A2 ). The loss when the flow is accelerated is extremely small, followed by ahead loss similar to that in the case of sudden expansion . Like eqn ( 1 ) , it is expressed by : Here Cc = Ac / A2 is a contraction coefficient. Inlet of pipe line The loss of head in the case where fluid enters from a large vessel is expressed by the following equation: hs = k f is the inlet loss factor and v is the mean flow velocity in the pipe. The value of f will be the value as shown in below Figure. k= k= k= k= k= k= Divergent pipe or diffuser The head loss for a divergent pipe as shown in below Figure. is expressed in the same manner as for a suddenly widening pipe: hs= k Appling Bernolli equation : ----------- ( 1 ) Putting p2th for the case where there is no loss, The pressure recovery efficiency η for a diffuser : Substituting this equation in equation ( 1): 1-k The value of k varies according to θ . For a circular section k = 0.135 (minimum) when θ = 5o 30' . For the rectangular section, k = 0.145 ( minimum ) when θ = 6o , and k = 1 ( almost constant ) whenever θ = 50o – 60o or more. In the case of a circular pipe , when θ becomes larger than the angle which gives the minimum value of k , the flow separates midway as in Fig.a.The loss of head suddenly increases , this phenomenon is visualized in Fig.b. Fig.a Fig.b Loss whenever the flow direction changes Bend In a bend, in addition to the head loss due to pipe friction, a loss due to the change in flow direction is also produced. The total head loss hb is expressed by the following equation: hb=( f + k ) Here, k is the loss factor due to the bend effect. In a bend, secondary flow is produced as shown in the figure owing to the introduction of the centrifugal force, and the loss increases. If guide blades are fixed in the bend section, the head loss can be very small. Below table shows values of k for the bends. Table , loss factor k for bends (smooth wall Re=225000, coarse wall face Re=146000 ) Elbow The section where the pipe curves sharply is called an elbow. The head loss hb is given in the same form as above equation of the bend . Since the flow separates from the wall in the curving part, the loss is larger than in the case of a bend. Below table shows values of k for elbows. k k Table , Loss factor k for elbows Pipe branch and pipe iunction Pipe branch As shown in below Figure , a pipe dividing into separate pipes is called a pipe branch. Putting hs1 as the head loss produced when the flow runs from pipe 1 to pipe 3 , and hs2 as the head loss produced when the flow runs from pipe 1 to pipe 2 , these are respectively expressed as follows: hs1= k1 hs2= k2 Since the loss factors k1 , k2 vary according to the branch angle θ , diameter ratio d1 /d2 or d1 / d3 and the discharge ratio Q1 /Q2 or Q1 /Q3. Pipe junction Two pipe branches converging into one are called a pipe junction. Putting hs2 as the head loss when the flow runs from pipe 1 to pipe 3, and hs2 as the head loss when the flow runs from pipe 2 to pipe 3 , these are expressed as follows: hs1= k1 hs2= k2 Valve and cock Head loss on valves is brought about by changes in their section areas, and is expressed by this equation provided that v indicates the mean flow velocity at the point not affected by the valve . Gate valve hs =k k Global valve k cock k The values of k for the various valves such as relief valve , needle valve ,pool valve , disc valve ball valve..etc are also depend on the ratio of the valve area to pipe area . Total loss along a pipe line ht = hf + ∑hs ht or ht These equations would be appropriate for a single pipe size ( with average velocity V ) . For multiple pipe/duct sizes, this term must be repeated for each pipe size. Hydraulic grade line and energy line As shown in the Figure, whenever water flows from tank 1 to tank 2, the energy equations for sections 1 , 2 and 3 with losses are as following: h2 and h3 are the losses of head between section 1 and either of the respective sections. Example Water, ρ=1000 kg/m3 and = 1.02 ×10-6 , is pumped between two reservoirs at 0.0508 m3/sthrough 122 m of 5.08 cm diameter pipe and several minor losses,as shown . The roughness ratio is ε/d = 0.001. Compute the pump power required. Take the following minor losses . Loss element Sharp entrance Ki 0.5 Open globe valve 6.9 bend, R/D = 2 0.15 Threaded, 90Þ, reg., elbow Gate valve, 1/2 closed 0.95 2.7 Submerged exit 1 Z2=36 m Z1=6 m 122 m of pipe , d=5.08 c m Write the steady-flow energy equation between sections 1 and 2, the two reservoir surfaces: hs where hp is the head increase across the pump. A=π×0.05082 /4 V=2.81 m/s = 139000.95 the flow is turbulent and Haaland’s equation can be used to determine the friction factor: f= 0.0214 But since p1 = p2 = 0 and V1 =V2 = 0, solve the above energy equation for the pump head : Z2 = 36 m , Z1 = 6 m , L = 122 m hP = 55.78 m The power required to be delivered to the fluid is give by : = 3119 W If the pump has an efficiency of 80 %, the power requirements would be specified Pin= Pf / η = 3119 /0.8 Pin= 3898.75 W Example : Sketch the energy grad line for below Figure . Take H=10 m , KA=1 , KB=(1-(A1/A2))2 , KC(valve) =3.5 , KD=1 and (1) f=0.015 (for all pipes ) 2 2 p1 v1 p v Z1 hL 2 2 Z 2 ...................(1) g 2 g g 2 g hL h f hL 2 2 f Lv f Lv v h f 1 1 1 2 2 2 A1v1 A2 v2 v2 1 2 gd1 2 gd 2 4 0.015 25 v12 0.015 (8 20) v12 hf 0.1319v12 2 9.81 0.15 2 9.81 0.3 16 2 v1 v12 v12 v2 0.15 2 2 v12 hm K (1 ) (1 ) ( 3 . 5 ) ( 1 ) 2g 2 9.81 2 9.81 16 2 9.81 16 0.32 2 9.81 hm 0.093v12 hL 0.1319v12 0.093v12 0.225v12 subs tan ce...in..Eq (1) 0 0 10 0 0 0 0.225v12 ..... v1 6.667 m / s..,..v2 1.667m / s H ( Surface)1 10m (6.667) 2 7.734m 2 9.81 0.015 25 (6.667) 2 H B 7.734 2.07m 2 9.81 0.15 0.15 2 2 (6.667) 2 0.795m H B l 2.07 (1 ) 2 9.81 0.32 0.015 8 (1.667) 2 H C 0.795 0.738m 2 9.81 0.3 (1.667) 2 H C L 0.738 3.5 0.242m 2 9.81 0.015 20 (1.667) 2 H D 0.242 0.1m 2 9.81 0.3 H ( surface) 2 0 H A 10 Multiple-Pipe Systems Series Pipe System: The indicated pipe system has a steady flow rate Q through three pipes with diameters D1, D2, & D3. Two important rules apply to this problem. 1. The flow rate is the same through each pipe section. 2. The total frictional head loss is the sum of the head losses through the various sections. Example: Given a pipe system as shown in the previous figure. The total pressure drop is Pa – Pb = 150 kPa and the elevation change is Zb – Za = 5 m. Given the following data , determine the flow rate of water through the section. The fluid is water, ρ = 1000 kg/m3 and = 1.02 ×10-6 m2/s. Calculate the flow rate Q in m3/h through the system. ……….(1) Begin by estimating f1 , f2 , and f3 from the Moody-chart fully rough regime Substitute in Eq. (1) find : to V1=0.58 m/s , V2= 1.03 m/s , V3= 2.32 m/s Hence, from the Moody chart, e/d with Re Substitute in Eq. (1) : Parallel Pipe System: Example : Assume that the same three pipes in above Example are now in parallel . The total pressure drop is Pa – Pb = 150 kPa and the elevation change is Zb – Za = 5 m. Given the following data . Compute the total flow rate Q, neglecting minor losses. The fluid is water, ρ = 1000 kg/m3 and = 1.02 ×10-6 m2/s. Calculate the flow rate Q in m3/h through the system Guess fully rough flow in pipe 1: f1 = 0.0262, V1= 3.49 m/s; hence Re1= 273,000. From the Moody chart Re with e/d f1 =0.0267; recomputed V1 =3.46 m/s , Q1 = 62.5 m3/h. Next guess for pipe 2: f2 =0.0234 , V2 = 2.61 m/s ; then Re2 =153,000, From the Moody chart Re with e/d f2 = 0.0246 , V2 = 2.55 m/s , Q2 = 25.9 m3 /h . Finally guess for pipe 3: f3 = 0.0304, V3=2.56 m/s ; then Re3 = 100,000 From the Moody chart Re with e/d f3 =0.0313 , V3 = 2.52 m/s, Q3 = 11.4 m3/h. This is satisfactory convergence. The total flow rate is These three pipes carry 10 times more flow in parallel than they do in series. Branched pipes Consider the third example of a three-reservoir pipe junction as shown in the figure . If all flows are considered positive toward the junction, then ………….(1) which obviously implies that one or two of the flows must be away from the junction. The pressure must change through each pipe so as to give the same static pressure pJ at the junction. In other words, let the HGL at the junction have the elevation where pJ is in gage pressure for simplicity. Then the head loss through each , assuming P1 = P2 = P3 = 0 (gage) at each reservoir surface, must be such that We guess the position hJ and solve the above Equations for V1 , V2 , and V3 and hence Q1 , Q2, and Q3 , iterating until the flow rates balance at the junction according to Eq.(1). If we guess hJ too high, the sum Q1 + Q2 + Q3 will be negative and the remedy is to reduce hJ , and vice versa. Example : Take the same three pipes as in the previous example , and assume that they connect three reservoirs at these surface elevations Find the resulting flow rates in each pipe, neglecting minor losses. As a first guess, take hJ equal to the middle reservoir height , Z3 = hJ = 40 m. This saves one calculation (Q3 = 0) and enables us to get the lay of the land : Since the sum of the flow rates toward the junction is negative, we guessed hJ too high. Reduce hJ to 30 m and repeat : This is positive Q, and so we can linearly interpolate to get an accurate guess: hJ = 34.3 m. Make one final list : Hence we calculate that the flow rate is 52.4 m3/h toward reservoir 1, balanced by 47.1 m3/h away from reservoir 2 and 6.0 m3/h away from reservoir 3. One further iteration with this problem would give hJ = 34.53 m, resulting in Q1= 52.8, Q2= 47.0, and Q3 =5.8 m3/h, so that Q = 0 to three-place accuracy.