Optimization of the mid-term master production schedule using SAP

advertisement

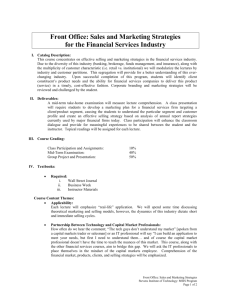

Optimization of the mid-term master production schedule using SAP-APO Dr. Ulf Neuhaus, Dr. Markus Storz Bad Dürkheim, 25.04.2008 GOR-Arbeitsgruppentreffen BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 1 Agenda 01 01 Introduction Introduction 02 02 Planning Planning problem problem 03 03 Model Model overview overview 04 04 Numerical Numerical results results 05 05 Conclusion Conclusion BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 2 Agenda 01 01 Introduction Introduction 02 02 Planning Planning problem problem 03 03 Model Model overview overview 04 04 Numerical Numerical results results 05 05 Conclusion Conclusion BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 3 Bayer Business Services in the Bayer Group Bayer AG Business Areas Service Areas Bayer Business Services Bayer Technology Services Bayer HealthCare Bayer CropScience Bayer MaterialScience Currenta BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 4 Our Service – Your Advantage Bayer Business Services is the Bayer Group’s international competence center for IT-based services. ~~ EUR EUR 11 billion billion in in sales sales** ~~ 5,000 5,000 employees employees** * 2007 globally BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 5 BBS GmbH Struktur BBS IT Services Integrated Services Specialty Services HR HR COM M&S ITO IBS S&T FAS IES P&T BC L&P MS BPA ITO IBS S&T = IT Operations = IT Business Solutions = Science & Technology FAS IES P&T = Finance & Accounting Services = Integrated Employee Services = Procurement & Transport BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 6 BC L&P MS = Business Consulting = Law & Patents = Media Services Central Functions BPA HR COM = Business Planning & Administration = Human Resources = Communications Agenda 01 01 Introduction Introduction 02 02 Planning Planning problem problem 03 03 Model Model overview overview 04 04 Numerical Numerical results results 05 05 Conclusion Conclusion BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 7 Introduction Environment: Pharmaceutical industry Capacitated lot sizing Horizon: Scope: up to 36 months API-production ¼ Formulation ¼ Packaging Tool: SAP SCM 5.0 ¼ SNP-Optimizer BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 8 Supply Chain Planning Process Afilliate DC Production Sub-contractor Step 1: (SNP heuristics) Step 2: (SNP optimization) Step 3: (PPDS) BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Step 4:of the(SNP Optimization mid-term deployment) master production schedule using SAP-APO • Seite 9 Structure – Production Plant Formulation Packaging FormSol API PackSol Bulk FG Solida FG Materia Prima FG Liquida MatPrima FormLiq PackLiq API Bulk BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 10 SNP optimization - Overview Function Demand (customer VMI orders, Distr. demands) Actual Plan (PP/DS planned orders) • • • • • • BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 11 Erase not fixed PP/DS orders Perform SNP-Optimization SNP planned orders Output • Monthly buckets Multi-level simultaneous (formulation, packaging) Dynamic (real demands) Finite capacity planning Only bottleneck resources and major items considered Usage of alternative resources No rounding values and minimal lot sizes Process Features Input Bucket based rough cut planning • Determine optimized campaign sizes (considering setup-, inventory holding costs) • Hierarchical planning approach month M month M+1 month M+2 Horizons … Time SNP (36 m) MRP (12 m) Det. Scheduling (6 m) SNP Pl.-ord. finite SNP PP/DS Pl.-ord. infinite prescheduled PP/DS PP/DS Pl.-ord. finite scheduled Unit Information content of the planning levels J Campaign sizes J Capacity utilization J Dep. demands for all components J Technical lot sizes J Sequence dep. setup times J Campaign sizes J Capacity utilization J Dep. demands for all components J Technical lot sizes BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 12 J Campaign sizes J Capacity utilization J Dep. demands for major components Former methodology Annually determination of the „optimal” lot-size based on Andler → Used as fixed lot size in MRP Assumptions: Andler SNP-Opt. Demands Constant rate Real demands Æ i.e. seasonal fluctuations Set-up costs Average value (product specific) Average value (product specific) Storage costs Capital lockup (product specific) Capital lockup (product specific) Production process Single-level Single- or Multi-level Products One N Resources Infinite Finite Receipts Date: Depending on demands Quantity: Fixed Date: Depending on demand/capacity Quantity: Dynamic Determination Iterative Simultaneous BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 13 Agenda 01 01 Introduction Introduction 02 02 Planning Planning problem problem 03 03 Model Model overview overview 04 04 Numerical Numerical results results 05 05 Conclusion Conclusion BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 14 Overview: SNP optimization Actual Plan Demands Fixed PP/DS planed orders Technical Settings Optimization profile Constraints Production capacity Production calendar Due dates Safety stock Cost model Storage Set-up Penalties Priorities Updated Plan SNP-Planed orders BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 15 SNP optimization - Constraints Constraints to be taken into account: Soft Hard Production capacity Due dates (demand) Calendar Safety Pseudo Hard Shelf Material availability BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 16 stock life SNP cost profile The following cost model is used 1) inventory holding cost 2) fixed production cost (based on standard price R3) (based on cost calculation for setup / cleaning / qc) The following additional penalties are considered 3) penalty for safety stock violations 4) penalty for non delivery 5) penalty for shelf life (maximum range of coverage) BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 17 Storage cost Inventory holding costs based on standard price R3 for plant location product 12345 R/3 Sample APO 100 12345 Sample APO BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 18 15 Setup cost Calculate set-up costs, using cost estimation for each material, based on the standard production version Identify relevant cost elements by a set of activity types (per plant) Product calculation (R/3): Machine set-up Mach. clean-out Pers. set-up Pers. clean-out Sample Changeover-costs (APO): BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 19 QA Maximum range of coverage Soft shelf life (with continued using of expired product) Storage costs per BMU and bucket Penalty Max. Range of coverage BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 20 Range of coverage Supply of relevant costs (1) Customizing Table Additional Parameter CIF R/3 Master-Data Transaction APO Master data maintenance Planning Transactional-Data BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 21 Supply of relevant costs (1) Source Cost element Supply R/3 Cust. table Set-up X X Storage X Automatic Manually (CIF) (Mass) Detail X Location product X Location product Non Del. X X Shelf Life X X Safety stock X X BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 22 X Plant Location product Product group X Plant Agenda 01 01 Introduction Introduction 02 02 Planning Planning problem problem 03 03 Model Model overview overview 04 04 Numerical Numerical results results 05 05 Conclusion Conclusion BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 23 Decomposition sub-plants Parallel processing of disjunctive sub-models: Formulation Packaging FormSol PackSol Solida MatPrim Materia prima PackLiq Liquida Sub-model 1 FormLiq Sub-model 2 BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 24 Product-Decomposition Total model Solution step 1 Packaging Determination of the global solution ¼ Pre-allocation Formulation Solution step 2 Definition of sub-models for connected components Sequential solution of the sub-models ¼ Local optimization Sub-model 1 Sub-model 2 Packaging Formulation BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 25 Numerical results Solida Model data Sub-plants Solution indicator SolPack +SolForm +MatPr CPU Intel Xeon (Netburst) 4 X 3 Ghz CPU-time (h) Products 2.148 Planned orders PDSe 3.978 Service level Demands 14.081 Resources 63 Horizon (Months) 24 Binary variables Opt. Gap ~ 2:50 1.688 ~ 98 % ~ 0,005 % Opt. Gap* ~ 3,3 % *(Based on production-/storage costs) 64.371 BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 26 Agenda 01 01 Introduction Introduction 02 02 Planning Planning problem problem 03 03 Model Model overview overview 04 04 Numerical Numerical results results 05 05 Conclusion Conclusion BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 27 Benefits Capacitated, dynamic lot sizes Based on real demands Consideration of production capacities Multi level optimization (packaging <> formulation) ¼ Generation of a feasible and optimized medium term plan ¼ Reduction of manual planning activities ¼ Alert based planning Decision support Capacity planning Material requirements planning BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 28 Challenges High expectations Quality of input data Short term planning horizon Optimization based on real costs Master data ¼ Reviewing process Transactional data User acceptance Problem complexity Transparence of solution CPU-time vs. level of detail Global vs. local view ¼ Appropriate modeling approach BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 29 Vielen Dank für Ihre Aufmerksamkeit Dr. Franz-Josef Toelle Manager of the Department “Supply Chain Management” Telefon: +49 214 30 71346 E-Mail: Franz-Josef.Toelle@bayerbbs.com Dr. Markus Storz Team Lead “Demand & Network Planning” Telefon: +49 214 30 56855 E-Mail: Markus.Storz@bayerbbs.com Dr. Ulf Neuhaus Supply Chain Consultant Telefon: +49 214 30 72736 E-Mail: Ulf.Neuhaus@bayerbbs.com BBS-IBS-SCM-D&NP • Dr. U. Neuhaus, Dr. M. Storz • 25.04.2008 Optimization of the mid-term master production schedule using SAP-APO • Seite 30 Bayer Business Services GmbH Customer & Sales Service Center 51368 Leverkusen E-Mail: Service@BayerBBS.com Internet: www.BayerBBS.com