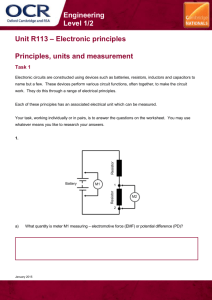

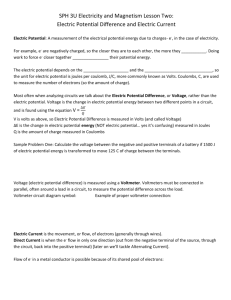

Introduction to Circuit Protection, Control, and Measurement

advertisement