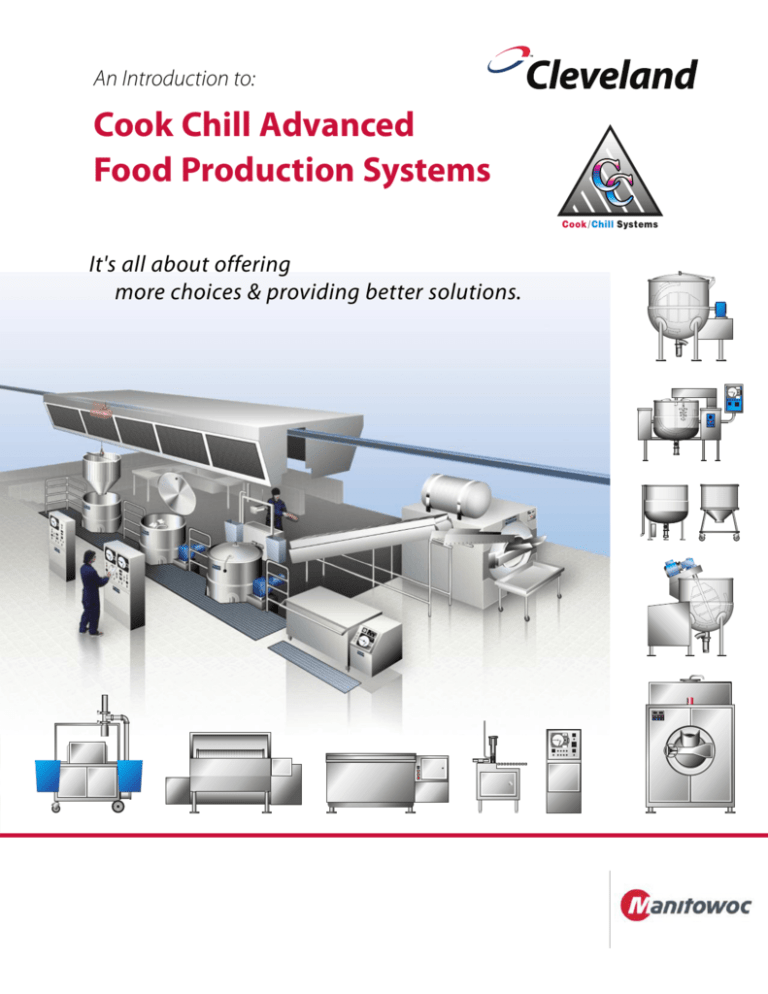

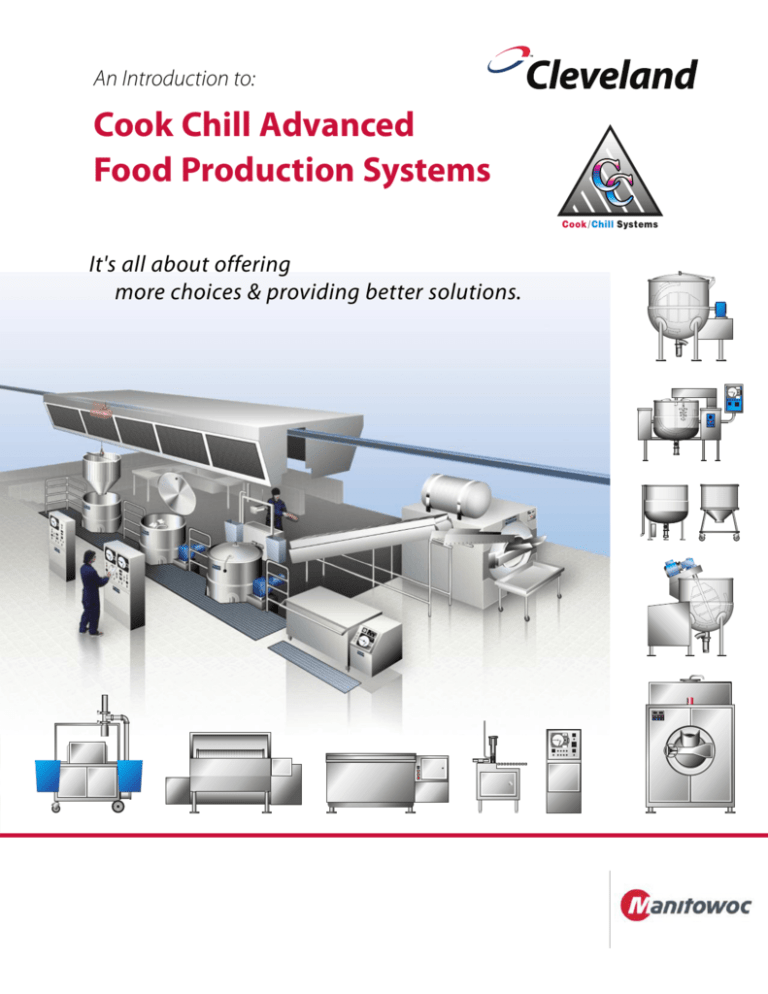

An Introduction to:

Cook Chill Advanced

Food Production Systems

Cook / Chill Systems

It's all about offering

more choices & providing better solutions.

MAN OUT1 OUT2 ALRM

SP

U

AUTO

MAN

AUTO

MAN

MAN OUT1 OUT2 ALRM

SP

U

MAN OUT1 OUT2 ALRM

SP

U

AUTO

MAN

AUTO

MAN

MAN OUT1 OUT2 ALRM

SP

U

Cook Chill

Overview

COOK CHILL FOOD PRODUCTION is a process of cooking food to a "just done state", packaging

in tough oxygen impervious casing at pasteurization temperature, and then rapid chilling to 40°F in less

than one hour. This enables the "Fresh Product", which has not suffered structural degradation via freezing

or high temperature canning to be stored in a refrigerated Food Bank for up to 45 days (depending on

product).

The product can then be:

A/ Rethermalized in its' original casings or in pans at the production location.

B/ Transported cold to satellite locations to reheat and serve in its' original casings or in pans.

With the addition of ancillary support equipment (including conventional production and refrigeration equipment) a

fully integrated, synergistic, operational advanced food production system is ensured.

COOK CHILL PRODUCTION ADVANTAGES

The main difference between Cook Chill and Cook Serve operations is that Cook Chill production fills an inventory or

"Food Bank" for future use, and Cook Serve is intended for immediate use.

• Having a pre-stocked inventory eliminates the peaks and valleys associated with Cook Serve operations.

• Production time is reduced by approximately 45%. Menu items for a seven day around the clock facility can now

be produced in five/eight hour shifts per week.

• Production can be centralized for operations where food is distributed to off-site locations.

• Space allocation for production is usually reduced by employing high volume equipment.

• Quality and consistency of the finished product is improved by the use of controlled production techniques.

CONCLUSION

Cook Chill is not a mystical cooking system. Virtually every step in conventional food production is repeated

during the Cook Chill cooking cycle with exacting standards. The key elements are controlled cooking and rapid

chilling of the product thus eliminating degradation to food quality caused by high temperature holding or

freezing.

The result of a Cook Chill system is consistent food quality, with optimal color, texture, moisture content and

nutritional value.

Menu

Food for Thought

Cook Chill Food Preparation offers flexibility for

a wide array of menu styles. Basically any style

menu, excluding short-order grilled foods, can be

produced and served in a Cook Chill System. Due to

efficiencies in production and a chilled inventory, a

wider variety of daily choices can be made available

to clients with both cycle and restaurant style menus.

Cook Tank items are usually thought of as meat items only.

Here are a few more suggestions:

• Spanish Rice • Potatoes for Hash Browns • Buttered Rice • Beets in Orange

Sauce • Candied Sweet Potatoes • Sweet N' Sour Pork • Harvard Beets •

Parsley Buttered Potatoes • Meat Loaf • Meat Balls • Salisbury Steak • Baked

Chicken Breasts • Quartered Chicken for BBQ • Baked Ham, slices or whole •

Corned Beef • Short Ribs • Pork Chops • Pot Roast • Roast Beef • Roast Turkey

Food quality can actually be

improved with conversion to a

Cook Chill System.

• Rice Pilaf • Swiss Steak • BBQ Ribs

With conventional systems, food

is subject to high temperatures

for long periods of time resulting

in a loss of moisture, color and

texture. Consequently, quality at

the

point

of

service

is

significantly compromised and

often inconsistent.

Any liquid product, or product

that will flow when hot can be

pumped by the Cleveland

Metering Filling Station.

Kettle Products

Sauces & Gravies- An Endless Variety.

• Cream Sauce • Cheese Sauce • Au Jus •

Tomato - Lasagna Marinara, Pizza &

Spaghetti Sauces • Enchilada Sauce •

With a Cook Chill System, the

opportunity exists to serve

consistently high quality food

products by:

Jardiniere Sauce • Cheese Sauce - used

with Au Gratin Vegetables • Mustard Sauce

- Chinese • Orange Sauce for Roast Duck •

Chili Con Quesa • Nacho Sauce • Barbecue

Sauce • Cream Sauce for Vegetables •

1. Standardization of recipes and

batch preparation of products.

Raisin Sauce • Beef, Chicken, Turkey, Pork,

or Veal Gravy • Giblet Gravy • Cream Gravy

2. Cooking only to desired

doneness and rapidly chilling to

stop the cooking process.

• Country Gravy

Cold Products • Fruitbread & Muffin Batters • Salad

3. Rethermalization of products prior

to service, avoiding hot holding for

extended periods of time.

Dressings • Salads - Potato, Macaroni, or

Meat

Chinese Dishes - A few to consider.

Cook Tank Products

Food quality can actually be improved with

conversion to a Cook Chill System.

Because the meat is cooked

slowly, at a low temperature, even the least tender items are

made tender. There is an average of 25% less shrinkage

due to no evaporative and drip loss producing a more juicy

product.

The cooking skill required is in recipe development

and determining sauces, etc.. This type of cooking is

a controlled, even, slow, water bath method, with no

danger of over-cooking. The cook does not have to

remember to turn the pan, take the product out of the

oven or determine doneness. This means the

"guesswork" is taken out of the process, which results

in fewer mistakes and less waste.

• Cashew Chicken • Beef or Chicken Chow

Mein • Beef and Broccoli • Ginger Beef

Mexican Dishes - Always the favorites.

• Refried Beans • Taco Meat • Enchilada Sauce • Nacho Cheese Sauce

Soups - Here is where the real efficiency is. Create your own specialized recipe.

• Broth Soups - Beef or Chicken Noodle, Beef or Chicken Rice, Won Ton,

Alphabet Soup, Beef Barley, French Onion, English Barley • Cream Soups Tomato, Mushroom, Asparagus, Broccoli, Carrot, Chicken, Potato • Hearty

Chowders & Soups - Corn Vegetable, Minestrone, Navy Bean, Clam Chowder,

Split Pea

Dishes to Fit Everyone's Palate - Or convert your own favorite recipe.

• Pork & Beans • Barbecued Beef • Beef Tips in Mushroom Gravy • Beef Cubes

in Brown Sauce • Beef Goulash • Beef & Macaroni Casserole • Macaroni &

Cheese • Beef Stew • Beef Stroganoff • Pot Pie Filling • Chili Con Carne • Stews

After the meat is cooked and chilled it is still protected by

the casing and therefore as it is held in the very low

temperature refrigerator it does not lose or change flavor

and it maintains its' high quality.

of all kinds • Curry dishes of all kinds • Sloppy Joe • Stewed Tomatoes • Turkey

Ala King • Whipped Potatoes • Tuna Noodle Casserole

2. Bulk Purchasing

& Pre-Prep

28°F

to

32°F

Cook/Chill Recipes

7.

Refrigerated

Storage

4. Non Pumpable Food Preparation

• Health Care

Operations

• School Food Service

• College and

University

Food Service

• Restaurant Chains

• Correctional Food

Service

lb

• Military Food

Service

0

.

5

45

0

Kg.

50 lb. x 2 oz.

22 kg. z 50 g.

35

5

• Supermarkets

& Delis

10

20

40

22

15

10

15

30

20

25

• In Plant Service

• Transportation Airlines, Railway

1. Central Planning/

Scheduling

• Recreation - Hotels,

Resorts, Amusement

Parks

3. Pumpable Food Preparation

5. Transfer & Packaging

6. Tumble Chilling

8. Rethermalization & Serving

Planning & Food Preparation

2. Bulk Purchasing & Pre-Prep

1. Central Planning/ Scheduling

To suit the operators volume and menu requirements, Cook Chill products are

prepared to fill an inventory or food bank well in advance of serving.

Production for a seven day around the clock facility is normally handled in

five/eight hour shifts per week instead of the usual seven/twelve hour shifts per

week. Skilled and unskilled labor is more efficiently utilized.

Recipes are standardized for batch preparation guaranteeing consistent high quality

food product with optimal color, texture, moisture content and nutritional value.

Volume purchasing and receiving dramatically reduces ingredient and

handling costs, and allows for a five day receiving schedule.

As per scheduled recipes, ingredients are centrally prepared in advance.

Ingredient quality and recipe consistency are maintained to extremely high

standards.

Cooking, Packaging & Chilling

3. Pumpable Food Preparation

5. Transfer & Packaging

Cook Chill steam jacketed Kettles are designed and equipped for cooking a

variety of pumpable food products with qualities ranging from chunky to smooth.

Horizontal, Vertical (Sweep Fold®), and Inclined Mixer Kettles are available for

mixing ingredients, maintaining product consistency and eliminating

burning/scorching.

Temperature controls, temperature chart recorders and automatic water cooling

ensure the product is consistently cooked and cooled to your specifications.

Product Metering Filling Stations pump the cooked foods while still hot

(180°F), from Mixer Kettles and accurately meter them into flexible casings.

The clipper and label dispenser are conveniently mounted on the cross bar

allowing the operator to seal, label and trim the filled casing in one swift

motion.

The air operated piston pump has infinitely variable volume adjustment and a

2" delivery system allowing the pumping of virtually any product that will flow.

4. Non Pumpable Food Preparation

6. Tumble Chilling

Cook Chill Tanks are designed for water bath cooking of vacuum packaged

meats, and other packaged food items.

Low temperature cooking reduces shrinkage, increases tenderness and

retains natural juices and flavor.

Upon reaching the desired temperature, hot water is automatically

exchanged for ice water, efficiently reducing food temperature below 40°F in

the fastest possible time. Programmable Time/Temperature controls allow for

unattended overnight cooking.

The Tumble Chiller rapidly reduces the temperature of the filled casings with

a gentle tumble action in recirculating potable chilled water without product

damage.

The casings are loaded through an entry chute by hand or conveyor. Fully

automated controls assure correct chilling in the fastest possible time for

maximum refrigerated storage life.

Blast Chillers are also available to provide chilling for short term storage of

products not compatible with water bath chilling methods.

Storage & Rethermalization

7. Refrigerated Storage

8. Rethermalization & Serving

The prepared and chilled foods are safely stored in low temperature walk-in

refrigerators at a temperature of 28°F to 32°F.

Cook Chill food preparation allows for a safe refrigerated storage life of up to

45 days (depending on product). Menu items are now available for use on site,

or to be shipped via refrigerated trucks or holding cabinets to remote serving

points or satellite locations.

Not freezing the foods boasts many benefits; dramatic energy savings, the

freshly prepared qualities of food are maintained, and the nutritional attributes

of food are not lost.

A wide variety of methods and equipment are available to heat the

preprepared food to a safe serving temperature.

Convection Steamers, Kettles, Combination Steamer/Ovens, Tilting Skillets

and other conventional cooking equipment can be used to finish the product.

Kettles and Skillets are used for hot water bath heating of multiple casings.

Convection Steamers and Combination Steamer/Ovens can be used for

heating multiple casings or product emptied on to 2 1/2" solid pans.

3

2

1

8

6

7

5

5

10

9

4

1

6

2

7

3

8

4

9

5

10

When you select a Cleveland

System

you are assured of receiving a completely integrated

system designed to meet you production goals.

Our commitment to technical and operational support

guarantees maximum utilization and satisfaction.

Cooking, Packaging & Chilling

MAN OUT1 OUT2 ALRM

SP

U

AUTO

MAN

AUTO

MAN OUT1 OUT2 ALRM

MAN OUT1 OUT2 ALRM

SP

MAN

MAN OUT1 OUT2 ALRM

SP

SP

U

U

U

MAN OUT1 OUT2 ALRM

SP

AUTO

U

AUTO

MAN

U

Controls the functions and

features of the Mixer Kettles and

the Pasta Kettles.

Cook Chill Tanks

Packages a

variety of products

in random sizes

and widths for

cooking in a Cook

Chill Tank.

MAN

MAN OUT1 OUT2 ALRM

SP

U

Single & Double

Control Centers

Cook Chill Mixer Kettles - Horizontal, Vertical & Inclined

Three styles of mixing kettles are available for your consideration. Each are capable

of cooking and mixing a variety of products with some or all or the following qualities:

heavy, delicate, frozen, crisp, chunky, smooth, hot or cold. All have been

successfully used in the food production and processing industry for many years.

Designed to pump

cooked foods from Mixer

Kettles and accurately

meter them into casings.

The 2" discharge allows for

the pumping of chunky

products without damage.

AUTO

MAN

MAN OUT1 OUT2 ALRM

SP

U

Vacuum

Packaging

Systems

MAN

AUTO

MAN

Metering Filling

Station

AUTO

MAN

AUTO

MAN OUT1 OUT2 ALRM

SP

Designed for water bath cooking of

vacuum packaged meats and other

items. Low temperature cooking

reduces shrinkage, increases

tenderness and retains natural juices

and flavor. When the cooking process

is complete, hot water is exchanged

for ice water for rapid cooling.

Pasta Kettles & Baskets

Designed specifically for cooking

pasta and pasta-like products. The

Kettle is equipped with a large

overflow drain for rinsing the product.

Tumble Chiller/Cook Tank

Combination Units

Saves valuable kitchen space by

combining two important functions into

one piece of equipment. During the

day the Tumble Chilling method is

used to cool Kettle cooked products.

During the night the combination unit

can be utilized as Cook Chill Tank.

Tumble Chillers

A mechanical rotating

machine used to reduce

temperature of the casings

with a gentle tumbling

action in recirculating ice

water. Casings are loaded

through the entry chute by

hand or conveyor.

Support Equipment

Steam Boilers

Necessary whenever food

processing equipment requires

direct steam for operation.

Available in electrically heated,

gas or oil fired.

Condensing Units Air & Water Cooled

Required for mechanical

refrigeration of water in the Ice

Builder by building ice around

the coils.

The Condensing Unit s

capacity should be sized,

based on building a full load of

ice within 16 hours.

Ice Builders

Designed to provide a

continuous supply of ice water

to Tumble Chillers, Cook Chill

Mixer Kettles, Cook Chill Tanks,

etc.. A pump circulates the ice

water, when required, through

heat exchangers located in the

Tumble Chillers, Cook Chill

Mixer Kettles, or Cook Chill

Tanks. Each Ice Builder can

economically build ice for up to

24 hours a day.

Compressed Air

Systems

Hoist Systems

A supply of compressed,

dry, clean air is required to

operate major components

used in Cook Chill Systems

(i.e. Tumble Chillers, Metering

Filling Stations, Clipper, the

Piston Valve on Mixer

Kettles). Compressed Air

Systems consist of an air

compressor and a

refrigerated air dryer.

Recommended for lifting and

transporting large and heavy

product loads from Cook Chill

Tanks, Pasta Kettles and

Cook/Chill Mixer Kettles.

Conveyors

Designed for automatically

transporting the Casing

packaged Food Products from

the Metering Filling Station into

the Tumble Chiller.

Rethermalization

Kettles

Available in over 60 different models, all

steam jacketed to cook quickly and evenly

without sticking, burning or scorching.

Powered by either electric, gas or direct

steam sources.

Heat water bath to 190°F and place

casings into the Kettle for rethermalization.

Gently stir with a paddle to move the

product in the casing for fast and even

heat-up time to 165°F.

Convection Steamers

Cleveland Convection Steamers offer a

creative concept for preparing high

volumes of a variety of food products at an

incredibly fast pace while maintaining a

very high quality standard.

To rethermalize products simply place

casing into 2 1/2" deep perforated pan and

heat to 165°F.

Combi-Oven Steamers

The most advanced family of

commercial cooking equipment available

today. Memory programmability stores

different recipes, making operation

simple and fast for the operator.

To rethermalize products simply place

casing into 2 1/2" deep perforated pan

and heat to 165°F.

Tilting Skillets

Cleveland Tilting Skillets are

designed for exceptional versatility

by functioning as a Griddle, Frying

Pan, Kettle, Braising Pan, Steamer or

a Bain-Marie.

Heat water bath to 190°F and place

casings into the Skillet for

rethermalization. Gently stir with a paddle

to move the product in the casing for fast

and even heat-up time to 165°F.

STEAMERS / COMBI-OVENS / KETTLES / BRAISING PANS / ROTISSERIES / COOK CHILL SYSTEMS

Ph: 1-800-338-2204 / Web: www.ClevelandRange.com / Email: Steam@ClevelandRange.com

Experts in Steam Cooking

Cook Chill System Support

PRE-SALES SUPPORT

Operation & Management Specialists are available for project &

menu evaluation to make recommendations for the facility

layout and equipment sizing.

Factory Engineers/Specialists are available to assist the food

service design consultant:

• Specific shop drawings are provided which include

dimensions, utility connection points, required clearances, etc.

• Typical Cook Chill Systems schematic drawings for piping &

wiring are provided.

• Factory Engineers can check the drawings for accuracy and

make recommendations for changes if required.

PRE-START-UP SUPPORT

Guidelines for Cook Chill recipe development and HACCP are

provided by our Operations Specialists/Registered Dietitians with

emphasis on recipe development for your specific operation.

Prior to installation of the equipment a Factory Specialist is

available to meet with the food service consultant and the

installer to inspect the job site and to review the installation

drawings with the installers.

After the installation has been completed:

• A Factory Specialist is available for inspection of both the

installation and operation of the equipment. Before the

installers leave the site recommendations for installation

changes are made if required. Calibration of the production

equipment is completed at this time.

• In-house maintenance personnel can be trained during startup, in the care of the equipment and preventative

maintenance.

• The Local Cleveland Authorized Maintenance and Repair

Agency will also be available for technical assistance. The local

agency will carry spare parts and is factory trained and

certified prior to start-up.

ACTUAL START-UP with food production and staff training

Training will be provided by our Operations Specialist with

emphasis on:

• Food Sanitation & Handling • Operation of the Equipment •

Recipe Implementation • Food Production

• HACCP and Quality Assurance Guidelines

SITE VISITS & FOLLOW-UP TRAINING can be scheduled to

review and reinforce information.

WARRANTY

All materials and workmanship is warranted for one complete

year.

CLEVELAND RANGE COOK CHILL ADVANCED FOOD

PRODUCTION SYSTEMS ARE

SUPPORTED BY:

• Operators Manuals • Administrative Procedure Manuals •

Service Manuals • Cook Chill Kettle recipes • Cook Tank recipes •

On-site training of the in-house maintenance personnel • Chilled

Food System Guideline Manual • AutoCad drawings • Operator

training and follow-up site visits

SOLUTIONS

Cleveland Range LLC. provides many of the operational solutions from Manitowoc, a global company dedicated to bringing

value to foodservice operators by equipping them with highly individualized real-world answers that enhance menus, service,

profits, and efficiency.

FINANCING

Manitowoc offers low-rate, fast-approval financing on equipment from Manitowoc brands and on other equipment when

purchased with Manitowoc brands. Preserve capital, simplify budgeting, and get the equipment you need today, from

Manitowoc Authorized Dealers with Manitowoc financing.

SERVICE

Cleveland Range LLC. products are backed nationwide by Manitowoc STAR Service. This network of certified service agents

provides fast response with factory-trained experts to assure your equipment will be fixed right the first time. Manitowoc STAR

service agents guarantee their work and use genuine OEM parts for best equipment performance and longer life.

To learn how Cleveland Range LLC. and other leading Enodis brands can equip you,

or to apply for financing, visit www.enodisusa.com, consult your dealer, or call 727-375-7010.

©2006 Enodis plc except where explicitly stated otherwise. All rights reserved.

CC4PC 0309