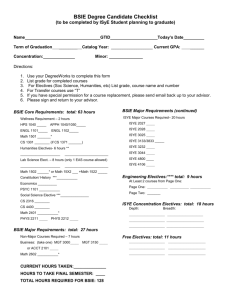

ISyE Undergraduate Handbook: Curriculum & Requirements

advertisement