Poster

advertisement

Reliability Parametric Z-score Monitoring

HanCheng Ong

Design Reliability, Seagate Technology International, Singapore

Reliability engineering has very much been centered on looking at the

percentage of units that survives at some specified time. In fact, monitoring the

parametric performance of the product is also of great importance in areas where

failure rate is low or testing is expensive. By tracking the Reliability parametric,

we can provide feedback to the team on the areas of weaknesses so that product

improvements can be make at early design stage.

A system has been build to enable Reliability parametric data to be extracted and

stored in Oracle database. For each of the parameters that are being monitored,

its descriptive statistics can be tabulated and charted by various product

configurations. JMP scripting is used as the platform to accomplish this. The

parameters can be compared by lot configurations or performance with time.

In addition to the usual descriptive statistics such as mean and standard

deviation, Design for Six Sigma (DFSS) measure is employed. The data set for

each test configurations are distribution fitted using all available parametric

models in JMP. The best-fitted distribution is used to obtain the PPM with the

specification limits for computing the Z-score (DFSS measure of quality) for the

parameter. The Z-scores are tabulated and charted for monitoring as indicators

of quality.

Results

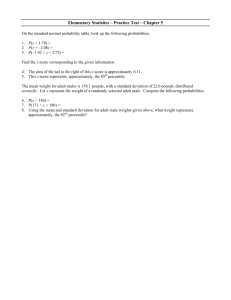

Random Seek Read Time Summary Table

Zscore

Mean(Rnd Seek)

Table

Std Dev(Rnd Seek)

Table

Table

Run1

Run2

Run3

Run1

Run2

Run3

Run1

Run2

Run3

25C

3.6

6.4

7.8

11.1

10.7

10.6

0.3

0.2

0.2

0C

2.8

4.9

5.8

11.6

10.9

10.8

0.2

0.2

0.2

60C

2.9

6.4

6.8

11.2

10.8

10.7

0.5

0.2

0.2

Temperature

Figure 1. Example of Parameter Trend Monitoring Table

Random Seek Read Time Zscore Chart by Run #

9.0

8.0

7.0

6.0

Zscore

Introduction

5.0

4.0

3.0

2.0

Best Fitted Parametric Model

The data set for each test configurations are distribution fitted using all

available parametric models in JMP. JMP provides a relatively large list of

common and useful distribution models (Johnson Sl, Johnson Su, Normal,

Glog, LogNormal, Exponential, Gamma, Weibull and Extreme Value). Each

distribution is tested for Goodness-of-Fit with the data set. The best fitted

distribution is used to obtain the PPM (parts per million) with capability analysis.

The specification limits are specified using the “Set Property” function in JMP.

The PPM from JMP output is then used to compute the Z-score (DFSS

measure of quality) of the parameter for each configuration of interest.

Non-Parametric Smoothing Model

In the event that none of the available distributions shows a good fit

(determined by the p-value output), the non-parametric smoothing available in

JMP will be initiated for the Z-score determination.

The Z-scores are tabulated and charted for monitoring as indicators of quality.

JMP Syntax:

Parametric Method:

Column(dt, “Parameter")<<Set Property( "Spec Limits", {LSL( lsl_para )} );

Distribution( Continuous Distribution( Column( :Parameter ), Fit Distribution( All

) ), By( :Config ));

Non-Parametric Smoothing Method:

Distribution(

Continuous Distribution( Column( :Parameter ), Fit Distribution( smooth Curve(

Spec Limits( LSL(lsl_para) )))), By( :Config ));

Figures 1 and 2 depicts the Trend table and charting of the Random Seek

Read Time parameter at various test temperature for illustration (data are

simulated).

25C

0C

Run3

Run2

Run1

Run3

Run2

Run1

Run3

Run2

0.0

Run1

Methods

1.0

60C

Figure 2. Example of Parameter Z-score Trend Monitoring Chart

Discussion

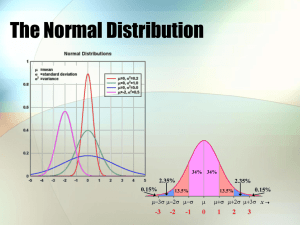

•Besides the usual statistics like mean and standard deviation, the DFSS

measure of quality, Z-score is used as the monitoring metric. Z-score takes into

account both the central tendency and dispersion.

•The parameter tables and charts are used for monitoring and feedback to the

team on the product performance. For areas where the Z-score is deemed to be

low, improvement actions will be put in place and the parameter will be remeasured after the fix is implemented.

•The Z-score is computed based on best fitted distribution and not normal

distribution which many have erroneously assumed (whether it is for convenient

sake or due to lack of knowledge).

•This method of monitoring the parameter performance using Z-score is suitable

during product design stage. When the product is stable and is in production

mode, control chart type of monitoring may be more suitable.

•Parametric Monitoring provides a good additional eye for product reliability

monitoring especially where large sample testing is not viable due to good

reliability and failures are hard to come by. It is also useful where it is expensive

to have large samples and long test duration to detect failures.

Reference

JMP User, Stats and Graph, Scripting Guides