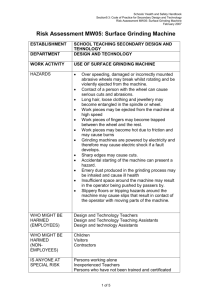

PrecisiON GriNDiNG WHeeLs 2011 Catalogue

advertisement