Abnormal Condition Management Services

advertisement

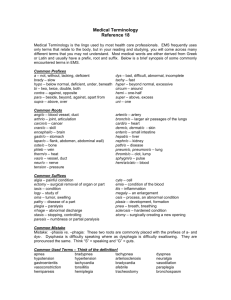

Abnormal Condition Management Services Another Value-Added Service From Mustang Al-Hejailan DAR PI Control Room Design Operator Training Programs If the control room is not designed for use, then the operators can struggle in trying to perform their routine tasks and fail to avert upsets. In the Design for ACM approach, the control room becomes an enabler for high performing teams, supporting communication with all the functional roles. A good corollary to the old adage that “you cannot control what you do not measure” is that you cannot control what you do not understand. Companies focused on achieving operational excellence have acknowledged the need for structured training in emergency operations or abnormal conditions. The degree of training commonly changes as the associated risk of loss increases. Increasingly, training simulators are being used to simulate the operation of the plant offline across modes of operation, but with the same look and feel of the actual plant. Mustang supports the Design for ACM approach across the spectrum of architecture needs, either in our own designs or working with architectural firms specializing in this area of control room and control building design. It is a challenge, but using the Design for ACM approach can make a significant impact on both safety and brofitability. Advanced Advice Systems The key goal of abnormal condition management is to get the correct information to the operator at the correct time to result in the correct intervention. Providing more time to orient the operator with early detection and dynamic real-time advice can be a very effective means of averting abnormal conditions or minimizing their impact. Technologies that support this include knowledge-based systems, model-based systems, heuristic or data driven and basic process control. Mustang Deliverables for Design for ACM We offer services that can help you get started with assessment studies, training, toolkits, standards and specifications. We can also help you manage your project or program over its lifecycle with services tailored to fit your needs. • • • • • • • • • • Design for ACM Assessment Studies Design for ACM Standards/Specifications Alarm Philosophy Development Alarm System Analysis Alarm Rationalization Services User Interface Toolkit Development Design for ACM Project Implementation Design for ACM Training Services Operator Training Program Development Simulator Development Services AbnormalCondition Condition Management Abnormal Management AlarmSystems Systems Alarm The preventable losses due to abnormal conditions The preventable losses due to abnormal conditions are estimated at billions of dol l ars annually. are estimated at billions of dollars annually. Recognition Recognition of this led to the formation of the of this led to the formation of the Abnormal Situation TM Abnormal Situation Management (ASM) Consortium , Management (ASM) Consortium™, a group performing a group performing research and development research and development focused on developing focused on developing technologies to aid in abnormal technologies to aid in abnormal condition management. condition management. Influenced by this and other Influenced by this and other industry best practices, industry best practices, Mustang created what we call Mustang created what we call Design for ACM to help Design for ACM to help clients manage abnormal clients manage abnormal conditions. conditions. Highly Highlyperformant performantalarm alarmsystems systemsminimize minimizelosses losses by by providing concise information to operator providing concise information to thethe operator resulting resulting fewer and improved efficiency. in fewer in trips andtrips improved efficiency. Mustang has Mustang has resources experienced in alarm system resources experienced in alarm system design and design and management for both new construction management for both new construction and existing and existing We havewith experience facilities. Wefacilities. have experience a varietywith of a software variety of commercial alarm management commercial alarm management software for collecting for collecting and managing alarm and information, and a and managing alarm information, recommend recommend a structured process that includes develstructured process that includes development of an opment of an alarm philosophy and includes alarm alarm philosophy and alarm rationalization. rationalization. Themajor majorareas areas of of focus focus for forfor ACM are:are: The for Design Design ACM • • •• •• • • • Alarm Systems Alarm Systems User Interface User Interface Control Rooms Operator Training Programs Control Rooms Advanced Condition Advice Systems Operator Training Programs has skilled staffAdvice with expertise • Mustang Advanced Condition Systemsin all of the major areas that directly impact management of Mustang has skilled staff with expertise in all for of ACM abnormal conditions. Training in the Design the major areas that directly impact management concepts is offered to all Mustangers, building a broad ofbase abnormal conditions. Training in the Design for of knowledge. ACM concepts is offered to all Mustangers, building a broad base of knowledge. User Interface User Interface The user interface in the main means of getting information to the operator. A well-designed user The user interface the main means of interface gets the is correct information to getting the operator at information to the operator. A well designed user the correct time, leading to the correct intervention interface gets the correct information to the operator and abnormal conditions that are minimized or atcompletely the correctaverted. time, leading to the correct intervention It is a simple concept, but and abnormal conditions that are minimized or comdesigning a user interface that directs the operator’s pletely averted. It is a simple concept, but designing attention where it is needed during all modes of aoperation user interface directs the operator’s attention is an that engineering challenge. Sorting out the is where it is needed during allmode modesfrom of operation operational goals for every steady state an engineering challenge. Sorting out the operaoptimization to unit shed to safe mode requires tional goals fortype every mode from steady state optimiadapting the of information displayed and the zation to unit shed to safe mode requires adapting method of display, while maintaining consistency. the type of information displayed and the method of Mustang uses a very structured process to ensure a display, while maintaining consistency. solid Design for ACM. These steps encompass a review of documentation including P&IDs and related Mustang uses a very structured process to ensure operator procedures, a formalized and interactive a solid Design for ACM . These steps encompass review process and end with system documentation. a review of documentation including P&IDs and related operator procedures, a formalized and interactive review process and end with system documentation. Mustang Al-Hejailan DAR PI Adds Value Independent and Full Service Mustang Al-Hejailan DAR PI (Mustang-HDP) is an independent service provider with a team of experts providing consulting and full project implementation services. Mustang-HDP’s team has experience in refining, petrochemicals, chemicals, polymers, upstream oil and gas, and many other process industries. We have experienced staff skilled in: • • • • • • • • • • • • • • • • • • • About Mustang Al-Hejailan DAR PI Mustang-HDP delivers quality engineering design, procurement, construction management and project management services in the Kindom of Saudi Arabia, the Middle East and North Africa. With years of operation in the region, strong international experience and global engineering support, Mustang-HDP offers a complete range of services throughout your project’s full lifecycle. Our focus encompasses upstream oil and gas, refining and chemicals, automation and control, pipeline, power, and infrastructure. Our professionals are backed by a hands-on management team, a solid support staff and the latest technology to provide the best possible project execution. Field Device Design Construction Management Control System Evaluation and Upgrade PLC and Logic System Design SIS Design and Upgrade LOPA and SIL Analysis DCS and Network Design HMI Design and Implementation Regulatory Control Evaluation and Tuning Advanced Process Control (including ADMC) Alarm System Design and Management Operator Training and Process Simulators Real-Time Process Data Historians LIMS Systems and Third-Party Systems Environmental Data Management via E!CEMS™ Yield Accounting and Production Reporting Batch and Recipe Management Manufacturing Execution Systems Integration from the Plant Floor to ERP Systems P.O. Box 3863 Al-Khobar 31952 Saudi Arabia Tel: +966-3-8697100 www.mustangHDP.com