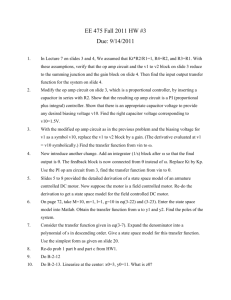

Sensor Signal Conditioning

advertisement