A GREEN CHEMISTRYSODIUM HYPOCHLORITE OXIDATION OF 4

advertisement

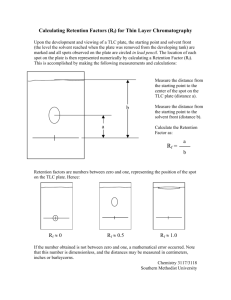

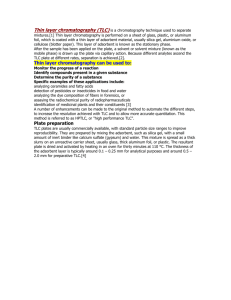

EXPERIMENT 5 A GREEN CHEMISTRYSODIUM HYPOCHLORITE OXIDATION OF 4-tert-BUTYLCYCLOHEXANOL TO 4-tert-BUTYLCYCLOHEXANONE: A REACTION MONITORED BY THIN LAYER CHROMATOGRAPHY1 REACTION: Oxidation of an Alcohol TECHNIQUES: TLC, Extraction, Recrystallization In this experiment, we will explore the oxidation of a secondary alcohol to a ketone using an oxidizing reagent, sodium hypochlorite, which is a readily available and commonly used household cleaning product. We will use thin layer chromatographic (TLC) technique to monitor the progress of oxidation reaction. READING ASSIGNMENT: Ø Background handout Ø This handout for procedure Ø Technique 17 Thin Layer Chromatorgraphy in Techniques in Organic Chemistry 3rd Ed. pgs 221–235. Ø Supplementary information in Janice Gorzynski Smith (2nd ed), Chapter 12 PRE-LAB ASSIGNMENT: Ø In your lab notebook make a table of the chemicals you will use in this experiment. Ø In your lab notebook rewrite the procedure for the oxidation reaction USING YOUR OWN WORDS. Ø In your lab notebook create a flow chart for the work up-procedure of the reaction. For every step label top/bottom and aqueous/organic layers. Keep track of which layer contains your product. Ø In your lab notebook write a procedure for the thin layer chromatography. Use Technique 17.2 as a guide. We will be using 35% acetone/65% hexane as the eluent. EXPERIMENTAL NOTES: IMPORTANT SAFETY INFORMATION 4-tert-butylcyclohexanol and 4-tert-butylcyclohexanone are irritants. Wear gloves and avoid all contact with skin eyes, and clothing. 5.25% Sodium hypochlorite (NaOCl) is commercial bleach. The solution is colorless or slightly yellow with faint chlorine-like odor. Ingestion may cause corrosion of mucouse membranes. Inhalation may produce severe bronchial irritation. Glacial Acetic Acid is an irritant and can cause severe burns. Use in the hood only! Wear gloves and avoid all contact with skin eyes, and clothing. 1 A part of this procedure is adopted from an article published by C.S. Jones and K.Albizati in the Journal of Chemical Education 1994, 71, A271. CHEM 51LB Rev 4/28/12 Page 1 Dissolve 300 mg of 4-tert-butylcyclohexanol in 4 mL of acetone using a 25 mL round bottomflask equipped with a magnetic stir bar on a magnetic stirrer. Place a 100 mL beaker containing water (50 mL) on a hot plate and heat to maintain the water temperature approximately 50 oC. Put the reaction flask into the warm water bath before adding 0.50 mL of glacial acetic acid, and start the oxidation by adding 4.0 mL of a 5.25% (0.75 M) sodium hypochlorite solution (commercial bleach). Stir the mixture vigorously with the help of a magnetic stir bar for 15 minutes and analyze the reaction mixture using TLC for the progress of the oxidation reaction. Take the sample (less than 1 drop using Pasteur pipette) from the organic layer if the reaction mixture separates into two layers. (Which one is the organic layer?) The relative amount of the starting material and of the product indicates the progress of the reaction. Use TLC technique as described in Techniques 17 to monitor the progress of this oxidation reaction. Keep the reaction mixture stirred in the warm water bath until the reaction is judged to be over – no starting material remains in the reaction mixture based on TLC analysis performed every 10 minutes. A total of 5 mL of 5.25% NaOCl should be more than enough to convert all of 4-tert-butylcyclohexanol to 4tert-butylcyclohexanone. However, since NaOCl decomposes rapidly (eq 3), add 0.5 mL of NaOCl solution if there is still starting material after 30 min. NaOCl + NaCl + H2O Cl2 + 2 NaOH (eq 3) Checking Reaction Progress by TLC: Apply the control and the reaction mixture on a silica gel plate (TLC plate). Use 35% acetone/65% hexane, which you will make, as the TLC solvent. Since neither the starting material nor the product is UV active, visualization in this experiment will be accomplished using a KMnO4 stain. Submerge your TLC plate in the jar with the stain and quickly remove it. Allow the excess liquid to drain in the jar or dab the plate excess liquid on a paper towel. The plate will come out dark purple and after a few minutes bright yellow spots will show up. If you are not seeing spots you may place the plate into the oven for one minute. Note the Rf values for the starting material and the product. Once the conversion is complete and the reaction mixture shows no more starting material by TLC analysis, proceed with an extraction of the 4-tert-butylcyclohexanol. Test the reaction mixture for excess hypochlorite by placing a drop of the reaction solution on a piece of wet starch-iodide indicator paper. The appearance of blue-black color from the formation of the triiodide-starch complex on the indicator paper signifies the presence of excess hypochlorite. Add 0.5 mL of 2-propanol (isopropyl alcohol), stir the mixture, and again test the reaction mixture for the presence of any hypochlorite. If necessary, continue adding 2-propanol in 0.1 mL increments and testing with starch-iodide paper until excess oxidant is completely destroyed. Transfer the reaction mixture into a 60 mL separatory funnel. Extract the reaction mixture two times, each with 10 mL hexane. (Note: what does extract mean? Which layer contains your product – water or hexane?) Wash the hexane extracts with 5 mL of 5% sodium bicarbonate solution, then wash with 5 mL of deionized water. Dry the hexane extract with anhydrous sodium sulfate for a few minutes, and transfer the hexane extract to a tared Erlenmeyer flask. Rinse the anhydrous sodium sulfate with 2 mL of hexane and add the rinsed hexane to the hexane extract. Evaporate the hexane in the fume hood using gentle heating on a hot plate or by blowing air to yield an off white or yellow colored residue of crude product. Cool the residue until it becomes a solid. Weigh the pure product, obtain a melting range, and turn it in to your TA in a properly labeled flask. CHEM 51LB Rev 4/28/12 Page 2 LAB WRITE-UP: Introduction: Ø Write a coherent introduction that describes the goals of this four-week project. Theory: Ø An overview of the oxidation and reduction reactions. Include a discussion of the mechanisms for both reactions and any appropriate stereochemistry considerations. CHEM 51LB Rev 4/28/12 Page 3