SUBRAMANIAN-DISSERTATION

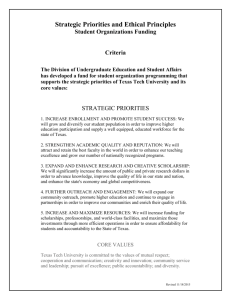

advertisement

TIME DOMAIN RESPONSES OF GLASSY POLYMERS

by

SHANKAR KOLLENGODU SUBRAMANIAN

A DISSERTATION

IN

CHEMICAL ENGINEERING

Submitted to the Graduate Faculty

of Texas Tech University in

Partial Fulfillment of

the Requirements for

the Degree of

DOCTOR OF PHILOSOPHY

Approved

111111111111111111111111111111

Gregory B. McKenna

(Chairperson of the Committee)

111111111111111111111111111111

Sindee L. Simon

111111111111111111111111111111

Brandon Weeks

111111111111111111111111111111

Edward L. Quitevis

111111111111111111111111111111

Peggy Gordon Miller

Dean of the Graduate School

May, 2011

Copyright 2011 Shankar Kollengodu Subramanian

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

ACKNOWLEDGEMENT

I would like to thank my advisor and chair of my committee Prof. Gregory

B.McKenna for his role in mentoring, guiding and encouraging me. He provided a

great environment to learn and ample space for me to think and grow. I would also

like to extend my gratitude to Prof Sindee Simon for her positive words and valuable

feedback on my dissertation. Further, I would like to extend my thanks to Prof

Edward Quitevis and Brandon Weeks for agreeing to be part of my committee and for

their insightful inputs.

I would like to appreciate the encouragement and camaraderie of all my

colleagues and coworkers at Texas Tech University. I would like to recognize Dr.

Prashanth Bardinarayanan for his words of encouragement and Dr. Paul O Connell,

Babji Srinivasan, Dr. Lameck Banda, Dr. Mataz Alcoutlabi, and Jing Zhao for helping

me with my experiments.

I would like to thank my mother, sisters, in-laws and my entire family for their

unconditional love, belief and support. Finally I would like to acknowledge my wife,

Harini for being my cheer leader.

I would like to dedicate this thesis to my late uncle Dr Natrajan, who has been one of

my inspirations for becoming a Chemical Engineer.

ii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

TABLE OF CONTENTS

ACKNOWLEDGEMENTS……………………………………………………….......ii

ABSTRACT……………………………………………………………………...….viii

LIST OF TABLES………………………………………………………………….....x

LIST OF FIGURES…………………………………………………………………..xi

CHAPTER

1

INTRODUCTION…………………………………………………………….1

1.1

Glassy Phenomena……………………………………………..……...1

1.2

Dielectric responses in glassy polymers……………………………....2

1.3

Structural recovery and aging in glassy polymers…………………….6

1.3.1 Intrinsic isopiestics…………………………………………....6

1.3.2 Memory effect ………………………………………………...7

1.3.3 Asymmetry of approach………………………………………7

1.3.4 τeff paradox……………………………………………………8

1.3.5 Physical aging………………………………………………...9

2

1.4

Effect of plasticizer in glassy behavior……………………………….9

1.5

References…………………………………………………………...12

EXPERIMENTAL SYSTEM ……………………………………………….29

2.1

Time domain dielectric spectrometer……………………………..…29

iii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

2.2

Experimental setup for studying the aging and structural recovery

responses of glassy polymers subjected to plasticizer environment………..31

3

2.3

Linear Variable Differential Transformer calibration………………32

2.4

References…………………………………………………………..33

A DIELECTRIC STUDY OF POLY (VINYL ACETATE) USING A PULSEPROBE TECHNIQUE………………………………….…………………..39

3.1

Motivation…………………………………………………………..39

3.2

Introduction………………………………………………………....39

3.3

Sample preparation..………………………………………………...42

3.4

Method of analysis………………………..…………………………43

3.5

Results ………………………..……………………………………...45

3.5.1 Single step response………..………………………………..45

3.5.2 Time-frequency conversion……………...………………….48

3.5.3 Two step (pulse-probe) response………...………………….49

3.6

Discussion…………………………………………..……………….50

3.7

Conclusion…………...……………………………………………...52

3.8

Appendix……..……………………………………………………...53

3.8.1 Algorithm to obtain true compliance………………...……...53

iv

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

3.8.2 Boltzmann superposition algorithm to delineate linear and

nonlinear behaviors………………….……………….……..57

3.9

4

References……………………………………………..…………...60

APPLICATION OF EMPIRICAL MODE DECOMPOSITION IN THE

FIELD OF POLYMER PHYSICS................................................................78

4.1

Motivation..........................................................................................78

4.2

Introduction.......................................................................................79

4.3

Methodology......................................................................................86

4.3.1 EMD based FFT filerting algorithm..........................................87

4.4

Results and discussion........................................................................88

4.4.1 Simulation studies..................................................................88

4.4.2 Filtering of the simulated data...............................................90

4.4.3 Discussion of results obtained from filtering methods..........96

4.4.4 Experimental case study I......................................................97

4.4.5 Experimental study II............................................................99

4.4.6 Practical benefits due to use of the proposed EMD based FFT

filtering algorithm............................................................................103

4.5

Conclusions.....................................................................................106

4.6

Appendix.........................................................................................107

v

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

4.6.1 Mathematical details of various filtering techniques...........107

4.7

5

References........................................................................................110

AGING AND STRUCTURAL RECOVERY BEHAVIORS IN EPOXY

FILMS SUBJECTED TO CARBON DIOXIDE PLASTICIZATION JUMPS:

EVIDENCE FOR A NEW GLASSY STATE……………………………….……138

5.1

Motivation…………………………………………….…………...138

5.2

Introduction……………………………………..…………….…..138

5.3

Experimental……………….…………………………….………..140

5.4

Method of analysis………………………………..……………….141

5.5

Results and discussion……………………………………..……...142

5.5.1 Structural recovery experiments…………………..………142

5.5.2 Aging experiments………………………………………...143

5.6

Conclusions……………………………………………..…………146

5.7

References……………………………………..………………….147

6

SUMMARY AND CONCLUSIONS …………………………………….166

7

FUTURE WORK………………………………..………………………..170

7.1

Introduction ……………………………………………………..170

7.2

Time domain nonlinear dielectric……………………………......170

vi

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

7.3

Isobaric time domain dielectric measurements……………..……171

7.4

Physical aging and structural recovery of glassy polymers……...172

7.5

References……………………………………………..………...173

vii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

ABSTRACT

The properties of glassy polymers are generally studied in the vicinity of the glass

transition temperature using frequency and time domain responses. In this work, we

focus on the dielectric, the structural recovery, and aging responses in the time

domain. A proper understanding of these properties is essential for a better prediction

of the performances of polymers.

Time domain dielectric measurement provides a powerful means to study the

glassy responses in short times (as low as micro seconds) to long times (>200

seconds) in a single measurement device. We built a Time Domain Dielectric

Spectrometer (TDS) in our laboratory at Texas Tech to take advantage of this ability.

Successful working of the spectrometer was demonstrated by studying the dielectric

response of poly (vinyl acetate) in a pulse-probe experiment. We see memory effect

and this was in quantitative agreement with linear Boltzmann superposition for small

applied fields. However, evidence of breakdown of linearity was observed at larger

applied fields. This is the first demonstration in time domain dielectric measurement

of the ability to delineate between linear and nonlinear behaviors.

Noise in the TDS set up was a hindrance for performing more sensitive experiments.

The dielectric data obtained from TDS was non stationary in nature (with respect to

time) and corrupted with nonlinear noise. Popular methods like fast Fourier transform

or moving average are not entirely suitable to handle this type of noise. We introduce

a filtration tool called Empirical Mode Decomposition (EMD) to improve the data

analysis for these types of data corrupted with noise. An advantage of this method is

viii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

that it aids in the improvement of the experimental setup by giving useful information

on the noise. EMD based filtering was also applied to the data obtained from

structural recovery experiments which are the other time domain response studied in

this work.

Structural recovery and aging experiments of glassy polymers are very well

understood for temperature formed glasses compared to concentration formed glasses.

Previous work from our group has shown that concentration formed glasses

qualitatively mimic temperature formed glasses but were quantitatively different.

Further, our preliminary work on the structural recovery of an epoxy film subjected to

CO2 plasticizer jumps showed that the effective retardation time for concentration

formed glass and temperature formed glass (subjected to same final condition) do not

converge to the same point as equilibrium is approached. This result was unexpected;

as we had hypothesized that both concentration and temperature formed glasses come

to the same apparent equilibrium state. Hence, we further investigated this behavior

by studying the aging and structural recovery of epoxy film subjected to CO2

plasticizer jumps. We observe evidence for the existence of a new metastable glassy

state.

ix

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

LIST OF TABLES

3.1

Fit parameters for equation 4 at 308 K. Errors represent standard error of

estimate on the fit parameters……………………………………………………….. 64

3.2

A, B and T0 from VFT fits for the retardation time and the dc conductivity

term vs. temperature obtained by fitting the data in Figure 2a to equation 4. Errors

represent standard error of estimate on the VFT fit parameters……………...……... 64

4.1

Sum squared error between the MKWW model data and filtered data obtained

from various filtering approaches…………………………………………...………116

5.1

KWW parameters for the longest aging time (230400s) of T and P jump

experiments…………………………………………………………………….…...152

x

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

LIST OF FIGURES

1.1

Specific volume vs Temperature plot for different cooling rates (q). Here, q1>

q2>q3 ………………………...………………………………………………………17

1.2

Classifications of dipoles in amorphous polymers………………...…………18

1.3

Schematic representation of two different sources of non-exponential

correlation decays……………………………….…………………………………...19

1.4

Schematic of the protocol for dielectric hole burning experiment……...……20

1.5

Time dependent dielectric permittivity of propylene carbonate at 157.4K......21

1.6

Empirical mode decomposition schematic to filter noise in time domain

responses………………………..……………………………………………………22

1.7

(a) Schematic of intrinsic isotherm experiment (b) Intrinsic isotherm

experiment performed by Kovacs on PVAc ………………………………………...23

1.8

(a) Schematic of memory effect experiment (b) Memory effect experiment of

PVAc performed by Kovacs………………………………..………………………..24

1.9

(a) Schematic for asymmetry of approach experiment (b) Asymmetry of

approach experiment of PVAc performed by Kovacs…………………………...…..25

1.10

Schematic of Struik’s protocol……………………………..………………..26

xi

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

1.11 Creep compliance of poly(vinyl chloride) quenched from above to below Tg at

different aging times after quenching…………...……………………………………27

1.12 Effective retardation time plot for temperature and concentration formed

glasses to the same final condition….………………………………………………..28

2.1

Schematic of time domain dielectric spectrometer built at Texas Tech taken

from reference ………………………………………………………….……………34

2.2

Sample setup schematic for the time domain dielectric spectrometer…..…...35

2.3

The creep apparatus that was built in our laboratory to perform experiments

under different CO2-pressure and temperature conditions…………………………..36

2.4

Pressure vessel used to perform the experiments under CO2 …………...…..37

2.5

LVDT calibration plot where the displacement of the core is measured as a

function of voltage……………………..……………………………………………38

3.1

(a) Isothermal measurement and (b) Master curve for PVAc with 308 K as

reference temperature ………………………………………………………..……..65

3.2

Equation 3.4 parameters ε1 and ε2 as a function of temperature…...………..66

3.3

Dielectric retardation time τ and dc conductivity τc term plotted as a function

of inverse temperature. The solid lines represent the VFT fits………………..……67

xii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

3.4

(a) Dielectric recoverable compliance and (b) master curve for PVAc with 308

K as reference temperature………..………………………………………….……68

3.5

Time-temperature shift factors as a function of temperature for PVAc.

Comparison of current dielectric results with literature reports for dielectric and

mechanical behaviors………………………………..…………………………….69

3.6

Dielectric storage compliance response for PVAc………………..………70

3.7

Dielectric loss compliance of PVAc ………………………..…………….71

3.8

Comparison of apparent dielectric compliance with true dielectric compliance

for an applied electric field of 5.4*105Vm-1 ………………………………….…..72

3.9

Dielectric compliance response in two step pulse-probe experiments with

varying time duration t1 of the first step ………………………………………….73

3.10 Dielectric compliance response in two step pulse-probe experiments with

varying electric field E1 of the first step………………………………….……….74

3.11 Dielectric strain response for the 1second jump of Figure 8. The solid line

represents the Boltzmann prediction……………………………………………...75

3.12 Single step responses for applied electric field of 44.6*105 Vm-1 and 89.2*105

Vm-1 …………………………………………………………………………...…76

xiii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

3.13 Two step dielectric compliance response (jump from 89.2*105 Vm-1 to

44.6*105 Vm-1) with linear Boltzmann prediction showing deviation from linear

behavior…………………………………………………………………………77

4.1

Data generated using the MKWW model (without noise)……………..117

4.2

Simulated noise added to the data generated from the MKWW model

(equation 4.4)…..………………………………………………………………118

4.3

Autocorrelation function of the white noise...........................................119

4.4

Simulated MKWW model data with noise n(t) added………………..120

4.5

MA filtered noisy model data – Window size 5................................121

4.6

MA filtered noisy model data – Window size 10..............................122

4.7

FFT filtered noisy model data...............................................................123

4.8

Schematic of DWT for the simulated data............................................124

4.9

Filtered data using Discrete Wavelet Transform – Five level

decomposition...............................................................................................125

4.10 Filtered data using Discrete Wavelet Transform – Six level

decomposition....................................................................................................126

4.11 IMFs and their corresponding magnitude at various frequencies obtained

from FFT for the simulated data with noise.................................................127

4.12

Filtered data using EMD based FFT approach......................................128

xiv

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

4.13 Squared error comparison plots for the filtered data obtained using FFT, DWT

and EMD based FFT Approach…………………………………………….…129

4.14 (a) Zero voltage time domain data, (b) Magnitude spectrum of the data at

various frequencies using FFT...........................................................................130

4.15

Experimental dielectric time domain data.........................................131

4.16 IMFs and their corresponding magnitude at various frequencies obtained for

the experimental dielectric data………………………..……………………...132

4.17

Comparison of experimental dielectric data and filtered data from EMD based

FFT approach (Inset shows a zoomed version)..................................................133

4.18

Comparison of volume recovery data after performing a down jump

experiment from 85oC to 75oC and 72oC without filtering............................134

4.19

Comparison of volume recovery data after performing a down jump

experiment from 85oC to 75oC and 72oC after filtering using EMD method.135

4.20

IMFs and their corresponding magnitude at various frequencies obtained for

the experimental volume recovery after a down jump in temperature to 75o.....136

4.21 MKWW generated data after removing the noise at 14Hz........................137

5.1

Schematic representation of specific volume as a function of temperature or

concentrations……………………..……………………………………………153

xv

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

5.2

A comparison of departure from equilibrium as a function of time for T jump

and P jump experiment subjected to same final condition of 72oC and 0 MPa……152

5.3

Effective retardation time as a function of departure from equilibrium for T

and P jump experiments of same final condition…………………………………..155

5.4

Creep compliance curves for different aging time plotted as a function of time

for T jump experiment………………………………………………………….......156

5.5

Time-aging time superposition of creep curves of the T jump

experiment…………………………………………………………………………..157

5.6

Creep compliance curves for different aging time plotted as a function of time

for P jump

experiment……………………………………………………………......................158

5.7

Time-aging time superposition of the creep curves of P jump experiment…159

5.8

Creep compliance curves for different aging time for T and P jump

experiments subjected to same final condition 0MPa and 69.3oC…………...……..160

5.9

Time aging time superposition curves for P jump experiment superposed to

the longest aging time of T jump experiment…………………………………….…161

5.10 Horizontal shift factor as a function of aging time. The concentration glasses

are shifted with respect to the longest aging time of temperature formed glass……162

xvi

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

5.11 Retardation time obtained from KWW function for T and P jump creep curves

plotted against the aging………………………………………………...…………..163

5.12 Retardation time as function of aging time for humidity and T jump

experiments of same final condition taken from reference ………………………...164

5.13 Volume recovery of epoxy film showing the reversal of concentration formed

glass to temperature formed glass upon heating above its Tg followed by cooling to

room temperature and heating………………………………………….…………...165

7.1

Schematic of time domain dielectric spectrometer with modifications to

perform isobaric measurements of dielectric compliance………….……………….174

xvii

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

CHAPTER 1

INTRODUCTION

1.1 Glassy Phenomena

Glassy behavior of amorphous polymers is one of the most widely studied

topics in Applied Sciences and Engineering for the last half a century. When

amorphous polymers are cooled from a higher temperature, the thermodynamic

properties such as volume, enthalpy or entropy deviate from the equilibrium path. The

point at which the thermodynamic property (volume, entropy or enthalpy) depart from

equilibrium path is called the glass transition temperature (Tg) [1-3]. As shown in the

Figure 1.1, the glass transition temperature is rate dependent and hence can be looked

upon as a kinetic phenomenon [4, 5]. However, there are certain aspects of the glassy

behavior which support the idea of thermodynamic origin [5-7]. The question of

glassy behavior being a thermodynamic or kinetic phenomenon is not our area of

interest in this work. For the purpose of clarity, as stated by McKenna, we can

consider glassy behavior as a “kinetic phenomena with underlying thermodynamic

transition” [2].

Understanding the properties of amorphous (glassy) polymers in the vicinity

of, as well as below the glassy transition temperature is very important to predict their

long term performance and stability [8-10]. The glassy behaviors are generally

studied in both time and frequency domain. In this work, we primarily focus on

1

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

studying two time domain responses of glassy polymers, namely dielectric, and

structural recovery and aging responses.

1.2 Dielectric responses in glassy polymers

Dielectric spectroscopy is a powerful method to study the glassy behavior of

materials spanning 10 decades in both frequency and time response using a single

measurement device, and more than 18 decades using multiple devices [11]. They

work on the principle of measuring the polarization (dipole moment) of the material

when subjected to an applied field (current or voltage) [11-13]. Dipole is a pair of

electrical charges of “equal magnitude and opposite polarity” and dipole moment is

defined as the vector quantity obtained by the “product of the magnitude of one of the

poles and the distance separating the two poles” [14]. Polymers in general are weakly

polar when compared to small molecule glass formers. However, based on the

dipole’s arrangement they are classified as Type A, Type B and Type C, as shown in

the Figure 2 [15].

In Type A polymers, relatively strong dipole moments typically occur along

the backbone of the polymer chain. They are characterized by a slow relaxation mode

with strong molecular weight dependence [15]. In Type B polymers, the dipole

moments occur in the main chain, but perpendicular to the backbone chain. They are

characterized by a fast segmental relaxation with no molecular weight dependence

[15]. Type C polymers have the weakest dipole moments and they occur along the

side chains of the polymers. They also show no molecular weight dependence like

Type B polymers [15]. The material investigated in this work is poly (vinyl acetate)

2

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

(PVAc) which is a Type B dipole. PVAc is a model polymer used for dielectric

studies of segmental relaxation. Most of the work on PVAc has been performed in

frequency domain (linear and nonlinear studies) [16, 17] with limited work in time

domain responses [18]. However, it may be noted that the dielectric responses can be

transformed from time domain to frequency domain and vice versa using Laplace

transformation in the linear regime [11, 19]. The relationship between dielectric time

and frequency domain responses is given by equation1.1 and 1.2 [11, 18, 19].

= − "

(1.1)

= + "

(1.2)

Where ε(t) is the dielectric compliance, ε’(ω) is the dielectric storage compliance,

ε”(ω) is the dielectric loss compliance, M(t) is the dielectric modulus, M’(ω) is

dielectric storage modulus and M” (ω) is the dielectric loss modulus. Furthermore, the

dielectric compliance and modulus can also be transformed from one form to the

other using equations similar to that used for conversion between creep compliance

and shear modulus [11, 20].

In general, most of the dielectric measurements reported in the literature are

performed in frequency domain, despite time domain measurements being much

faster compared to frequency sweeps because of the difficulty is filtering noises in

time domain data [11, 16, 17, 21]. However, the potential of using time domain

dielectric spectrometry (TDS) to study the glassy responses in polymers is

tremendous. Probing dynamic heterogeneity is one of the potential areas of study

which could be tapped using TDS. As shown in Figure 1.3, the overall macroscopic

3

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

picture of a homogeneous and heterogeneous material is same, although

microscopically the each spatial domain in a heterogeneous material can be different

[22]. This behavior can be well understood by subjecting these materials to a high

sinusoidal frequency probe, wherein particular domain in the material relaxes slower

or faster compared to the macroscopic response of the material. This is known as

dynamic heterogeneity [22].

Hole burning experiment is an excellent technique to demonstrate the

dynamic heterogeneity in materials [23, 24]. Figure 1.4 is the protocol for the hole

burning experiment. It comprises of 4 experimental steps. In step 1, a positive

sinusoidal probe of high frequency is applied, followed by a suitable waiting time and

a small voltage step. In step 2, the same experiment is repeated with a negative pulse.

Then, the signals from step 1 and step 2 are summed to give the modified response.

Step 3 and step 4 are the positive and negative pulse respectively without the

sinusoidal probe. Summation of the signals from step 3 and 4 is called the unmodified

response. If there is no difference between the modified and unmodified response

then the material is homogeneous; else it is the evidence for dynamic heterogeneity

[23, 24]. Bohmer and coworkers, [23] and Richert and coworkers [24] have

demonstrated the hole burning technique to probe dynamic heterogeneity in small

molecule glass formers. Figure 1.5, is the result of a hole burning experiment of

propylene carbonate showing horizontal and vertical holes from Bohmer’s group [23].

Shi and McKenna, [25] and Qin and McKenna [26] have also probed dynamic

heterogeneity using mechanical hole burning experiments for small molecule glass

formers and polymers. It may be noted that the small molecule glass formers used in

4

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

these dielectric studies have a larger signal to noise ratio compared to polymers. This

is precisely the challenge we have currently in probing the dynamic heterogeneities in

glassy polymers.

We have demonstrated in our work on time domain dielectric responses

(Chapter 3) that using the simple Boltzmann superposition principle, linear and

nonlinear behaviors can be delineated [27]. It is a progress in the direction of tapping

the potential in TDS experiments. However, noise in the data was proving detrimental

for performing more sensitive experiments like the hole burning experiments with

polymers as the signal to noise ratio is very low to sense holes as discussed above.

Time domain dielectric data are time varying in nature and are corrupted with

nonlinear noise. Widely popular filtration techniques like Fast Fourier Transform

(FFT), and Moving Average (MA) filters are not appropriate for filtering these types

of data [28]. We found out that the Empirical Mode Decomposition (EMD) with FFT

based algorithm was an effective method to filter non stationary data corrupted with

nonlinear noise. EMD filter works on the principle of splitting the given signal into

various individual components in time domain called intrinsic mode functions (IMF),

using in-situ generated cubic splines as shown in Figure 1.6 [ 28, 29]. Then the

frequency information of each IMF component is obtained using FFT algorithm.

Based on the prior knowledge of these experiments, we can then determine whether

that IMF should be removed or retained. IMFs deemed as noise components are

omitted and the signal is reconstructed using other IMFs. The biggest advantage of

the EMD based approach is that we do not lose any information about the actual data

5

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

besides giving valuable information on the noise, which could be further used to

improve the instrumentation wherever possible [28, 29]. The EMD based approach is

covered more elaborately in chapter 4 of this thesis work.

With improved data analysis using EMD based filtration; there is a potential to

expand the horizon of time domain dielectric spectroscopy to probe the nonlinearity

and dynamic heterogeneity in glassy polymers. Below is another study in time domain

responses of glassy polymers, which has also been benefited from using EMD based

filtration.

1.3 Structural recovery and aging in glassy polymers

On cooling amorphous glassy polymers from above to below the glass

transition point, the sample moves into a non equilibrium state and hence will tend to

evolve back towards the equilibrium state. The study of thermodynamic properties

(volume, enthalpy or entropy) as the material evolves towards equilibrium is called

structural recovery [7] and the changes associated with the viscoelastic properties

such as mechanical, optical or dielectric during this process is called physical aging

[7]. Kovacs was the first to comprehensively demonstrate the structural recovery

phenomenon using three classic experiments namely the intrinsic isotherm, the

memory effect and the asymmetry of approach [7].

1.3.1 Intrinsic isotherm

Figure 1.7(a) is the schematic of the intrinsic isotherm experiment. When a

glassy material is cooled from above the glass transition temperature (Tg) to a certain

6

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

temperature Ta below the glass transition temperature and held there isothermally, the

thermodynamic property (volume, enthalpy or entropy) will slowly recover towards

equilibrium. The further the departure from Tg , the longer it takes to reach the

equilibrium. This could be well understood in terms of molecular mobility and free

volume. As we go deeper into the glassy regime, the free volume, and hence the

molecular mobility, decreases. Figure 1.7(b) is the intrinsic isotherm plot of PVAc,

performed by Kovacs in his classic structural recovery experiment, after quenching

from 40oC to different temperatures (Ta) [7].

1.3.2 Memory effect

Memory effect is a two step experiment as shown in Figure 1.8(a). Initially,

the material is cooled from above the glass transition temperature to Point 1 far below

Tg and partially aged for some time. After that, the material is then jumped to Point 2

(up jump), such that the departure to equilibrium is very close to zero and aged.

Instead of directly returning to equilibrium, the sample goes through a maximum

before reaching the equilibrium remembering the previous thermal history. It may be

noted that the farther the first jump (point 2) is, the bigger is the memory. The

memory effect is evidence that it needs more than one exponential function to capture

the spectrum of data. Figure 1.8(b) is the memory experiment on PVAc performed by

Kovacs [7].

1.3.3 Asymmetry of approach

Figure 1.9(a) is the schematic of the asymmetry of approach experiments. It

comprises of two experiments, namely, up jump and down jump experiments. In

7

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

down jump experiment, a jump in temperature is made from Point A closer to glassy

transition temperature, to Point B further away in the glassy regime. In up jump

experiments, a jump is made from Point C (well below Point B) to point B. It may be

noted that the magnitude of temperature jump for the up jump and down jump

experiments should be the same. On measuring the departure from equilibrium for

both cases, we can observe that the up jump and down jump responses are nonlinear.

The down jump experiment behaves like an auto retardation experiment such that

initially the recovery is faster. This is due to the higher mobility as a result of the

departure from equilibrium (δ) being greater than zero. In time, the recovery slows

down as the molecular mobility decreases. In the up jump experiments, the reverse

happens and it behaves like an auto catalytic experiment. Initially, the recovery is

slower as δ < 0. In time, the recovery accelerates due to the increase in molecular

mobility as δ approaches zero. Figure 1.9 (b) is the asymmetry of approach

experiment as performed by Kovacs on PVAc [7].

1.3.4 τ eff paradox

Kovacs’ initial work on the effective retardation time, which is the slope of

departure from equilibrium (δ) as a function of time plot for different magnitudes of

asymmetry of approach experiments, showed that the material doesn’t come to

equilibrium at the same time as the departure from equilibrium approaches zero. This

was considered a paradox because the material violates the fundamental law that the

equilibrium is path independent [7]. McKenna and his coworkers later reanalyzed

some of Kovacs’ original data, and concluded that the expansion gap and error in

8

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

measurements close to equilibrium could, to some extent, be the reason for the

paradox [30]. Simon and coworkers have shown in their volume recovery work, that

for a smaller δ, the paradox is resolved as the expansion gap vanishes [31]. Hence, the

expansion gap occurs only for large T-jumps, i.e., when the response is nonlinear.

1.3.5 Physical Aging

According to Struik’s protocol, the sample loading-unloading for the aging

experiment is performed in such a way that the loading-unloading time is one tenth of

the waiting time. This is done so that each loading-unloading step is independent of

the previous event [8]. As seen in the Figure 1.10, the loading-unloading time is

sequentially increased by a factor of 2. Figure 1.11 is the first demonstration of aging

experiment performed by Struik [2] on poly (vinyl chloride). He showed that the

creep curves at various aging times can be superimposed, similar to time temperature

superposition and is called time-aging time superposition [2].

1.4 Effect of plasticizers on glassy behavior

Plasticizers are small molecules like moisture or carbon dioxide, which cause

considerable changes in the properties of glassy polymers upon constant exposure

[32-34]. Understanding these behaviors can add to exploring new areas of application

as well as preventing unexpected material failures [35, 36]. Despite a considerable

amount of work on the effect of plasticizers on polymers in general, there are very

few studies in understanding the glassy behavior in terms of structural recovery and

aging [37-41]. In our group, there has been tremendous impetus in this aspect.

Previous work from our group has shown that concentration formed glasses using a

9

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

strongly polar plasticizer (H2O) and a weakly polar plasticizer (CO2) qualitatively

mimic temperature formed glasses but were quantitatively different [37-41]. The

concentration formed glasses had a larger departure from equilibrium than

temperature formed glasses. Further, our preliminary work on the structural recovery

of epoxy film subjected to CO2 plasticizer jumps, showed that the effective

retardation time for concentration formed glasses and temperature formed glasses

(subjected to same final condition) do not converge to the same point as equilibrium is

approached [see Figure 1.12]. This is similar to the τeff paradox observed by Kovacs.

This problem is discussed more elaborately in chapter 5.

This dissertation is organized as follows:

In chapter 1, the background of glassy phenomena, dielectric spectroscopy, its linear

and nonlinear behavior in time domain responses, correlation between frequency and

time domain responses, kinetic manifestation of glassy behaviors and impact of

plasticizers in aging and recovery responses are discussed.

In chapter 2, the experimental set up used for the time domain dielectric

spectrometer and the pressure vessel set up for aging recovery experiments are

discussed. Chapters 3, 4 and 5 are elaborated versions of publications in the peer

reviewed journals.

In chapter 3, we present an investigation of the dielectric behavior of

poly(vinyl acetate) (PVAc) using a two step pulse-probe technique. Time domain

dielectric experiments were performed in the vicinity of the glass transition

temperature. After establishing the linear response function in single step

10

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

experiments, two types of pulse-probe experiments were performed. In one, the time

duration t1 of the first step in the probe was varied. In the second case, the magnitude

of the field E1 applied to the sample for the first step was varied. We observe the

memory effect and the responses were analyzed in the context of a linear Boltzmann

rule. Evidence of deviations from linear superposition at the highest electric fields are

also presented.

Noise in the dielectric experimental data limited the application of the time

domain dilectric set up built at Texas Tech. In chapter 4, we propose an algorithm

for effective filtering of noise using an EMD based FFT approach for applicatons

in polymer physics. The advantages of the proposed approach are: (i) it uses the

precise frequency information provided by the FFT and therefore efficiently filters

a wide variety of noise and, (ii) the EMD approach can effectively obtain IMFs

from both non-stationary as well as nonlinear experimental data. The utility of the

proposed approach is illustrated using an analytical model and also through two

typical laboratory experiments, namely, the dilectric experiments and structural

recovery experiments in polymer physics, wherein the material response is nonstationary; standard filtering approaches are often inappropriate in such cases.

By taking advantage of the EMD based filtering technique, in chapter 5, we

investigate the structural recovery and physical aging of an epoxy film subjected to

carbon dioxide pressure jumps and compare the results with temperature jump

experiments, such that the final conditions are identical. This a continuation of work

done previously in our group where we have shown using strong and weakly polar

plasticizers, that they qualitatively mimic the behaviors of temperature jumps but

11

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

quantitatively they are different [8-10, 13] . In chapter 6, we summarize the

conclusion of this work and the future scope is discussed in chapter 7.

1.5 References

1.

Plazek DJ, Ngai KL. In: Mark JE, editor. Physical properties of polymers

handbook. NY: American Institute of Physics; 1996 (chapter 12).

2.

McKenna GB. In: Booth C, Price C, editors. Comprehensive Polymer Science,

Polymer Properties, Vol.2, Oxford: Pergamon Press, 1989 (chapter 2).

3.

McKenna GB, Simon SL. In: Cheng SZD, editor. Handbook of Thermal

Analysis and Calorimetry, Applications to Polymers and Plastics, Vol.3,

Elsevier Science, 2002.

4.

Kovacs AJ. Transition vitreuse dans les polymères amorphes. Etude

phénoménologique. Adv Polym Sci 1964; 3:394.

5.

Kovacs AJ. La contraction isotherme du volume des polymères amorphes.

J.Polym Sci. 1958; 30:131.

6.

Chang SS. Thermodynamic properties and glass transition of polystyrene.

J.Polym Sci, Poly. Sympo 1984; 71:59.

7.

Kovacs AJ. Transition vitreuse dans les polymères amorphes. Etude

phénoménologique. Fortschr. Hochpolym.-Forsch. 1963; 3:394.

8.

Struik LCE. Physical aging in polymer and other amorphous materials.

Elsevier: Amsterdam, 1978

9.

McKenna GB. On the physics required for the prediction of long term

performance of polymers and their composites. J. Res. NIST 1994; 99:169.

12

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

10.

Alcoutlabi M, McKenna GB, Simon SL. Analysis of the development of

isotropic residual stresses in a bismaleimide/sprio orthocarbonate

thermosetting resin for composite materials. J Appl Polym Sci 2003; 88:227

11.

Kremer F, Schonhals A. Broadband Dielectric Spectroscopy. 1st ed. New

York: Springer-Verlog; 2003.

12.

Mopsik FI. Precision Time-Domain Dielectric Spectrometer. Rev. Sci. Inst.

1984; 55: 79.

13.

Smith JW. Electric dipole moments. London: Butterworths scientific; 1955.

14.

www.awnsers.com

15.

Watanabe H. Dielectric relaxation of type -A polymers in melts and solutions.

Macromol. Rapid Commun. 2001; 22:127.

16.

Mashimo S, Nozaki R, Yagihara S, Takeishi S. Dielectric relaxation of poly

(vinyl acetate). Journal of Chemical Physics. 1982; 77:6259.

17.

Rendell RW, Ngai KL, Mashimo S. Coupling model interpretation of

dielectric relaxation of poly (vinyl acetate) near Tg. Journal of Chemical

Physics. 1987; 87: 2359.

18.

Richert R, Wagner H. The dielectric modulus: relaxation versus retardation.

Solid State Ionics 1998; 105:167.

19.

Mopsik FI. The transformation of time-domain relaxation data into the

frequency domain. IEEE Trans. Elec. Insul 1985; 20:957.

20.

Ferry JD. Viscoelastic Properties of Polymers. 3rd ed. New York: John Wiley

and Sons; 1980.

13

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

21.

Serghei A, Huth H, Schick C, Kremer F. Glass dynamics in thin polymer

layers having a free upper interface. Macromolecules 2008; 41:3636.

22.

Richert R. Homogeneous dispersion of dielectric responses in a simple glass. J

Non Cryst Sol 1994; 209.

23.

Bohmer R, Schiener B, Hemberger J, Chamberlin RV. Pulsed dielectric

spectroscopy of supercooled liquids. Z.Phys. B. 1995; 99:91-99.

24.

Duwuri K, Richert R. Dielectric hole burning in the high frequency wing of

supercooled glycerol. J Chem. Phys 2003, 118: 1356.

25.

Shi X, McKenna GB. Mechanical hole-burning spectroscopy. Demonstration

of hole-burning in the terminal relaxation regime. Phys. Rev. B 2006, 73:

014203-1.

26.

Qin Q, Shi X, McKenna GB. Mechanical holeburning spectroscopy in a SIS

tri-block copolymer. J. Polym. Sci Part B Polym. Phys 2007; 46:3277.

27.

Kollengodu-Subramanian S, McKenna GB. A dielectric study of poly (vinyl

acetate) using a pulse probe technique. Journal of Thermal analysis and

calorimetry 2010; 102:477.

28.

Kollengodu-Subramanian S, Srinivasan B, Rengaswamy R, Zhao J, McKenna

GB. Application of empirical mode decomposition in the field of polymer

physics. J. Polym Sci. Part B Polym phys, 2011; 49:277.

29.

Huang N.E.; et al. The empirical mode decomposition and the Hilbert

spectrum for nonlinear and non-stationary time series analysis. Proceedings of

Royal society of London 1998; 454:903.

14

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

30.

McKenna GB, Vangel MG, Rukhin AL, Leigh SD, Lotz B, Straupe C. The τEffective paradox revisited: An extended analysis of Kovacs volume recovery

data on poly (vinyl acetate). Polymer 1999; 40:5183.

31.

Kolla S, Simon SL. Tau-effective paradox: New measurements towards a

resolution. Polymer 2005, 46:733.

32.

Knauss WG, Kenner VH. On the hygrothermomechanical characterization of

polyvinyl acetate. J. Appl. Phys. 1980; 51:5531.

33.

Wang WCh, Kramer EJ, Sachse WH. Effect of high pressure CO2 on the glass

transition temperature and mechanical properties of polystyrene. Journal of

polymer science Part B: Polymer Physics 1982; 20:1371.

34.

Chiou JS, Barlow JW, Paul DR. Plasticization of glassy polymers by CO2. J.

Appl. Polym. Sci. 1985, 30, 2633-2642.

35.

Van der Vegt NFA, Briels WJ, Wessling M, Strathman H. The sorption

induced glass transition in amorphous glassy polymers. J Chem Phys 1999;

110:11061.

36.

Cotugno S, Larobina D, Mensitieri G, Musto P, Ragotsa G. A novel

spectroscopic approach to investigate transport process in polymers: The case

of water-epoxy system. Polymer 2001; 42:6431.

37.

Alcoutlabi M, Vangosa Briatico F, McKenna GB. Effect of chemical activity

jumps on the viscoelastic behavior of an epoxy resin: physical aging response

in carbon dioxide pressure jumps. Journal of polymer science Part B: Polymer

Physics 2002, 40:2050.

15

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

38.

Zheng Y, McKenna GB. Structural recovery in a model Epoxy: Comparison

of responses after temperature and humidity jumps. Macromolecules 2003,

36:2387.

39.

Zheng Y, Priestley RD, McKenna GB. Physical aging of an epoxy subsequent

to relative humidity jumps through the glass concentration. Journal of

polymer science Part B: Polymer Physics 2004; 42: 2107.

40.

Alcoutlabi M, Banda L, McKenna, GB. A comparison of concentrationglasses and temperature-hyperquenched glasses: CO2 formed versus

temperature formed glass. Polymers. 2004; 45:5629.

41.

Alcoutlabi M, Banda L, Kollengodu-Subramanian S, Zhao J, McKenna GB.

Environmental effects on the structural recovery responses of an epoxy resin

after carbon dioxide pressure-jumps: Intrinsic isopiestics, asymmetry of

approach and memory effect. Macromolecules 2010 (Under Review).

16

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.1: Specific volume vs Temperature plot for different cooling rates (q). Here,

q1> q2>q3

17

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.2: Classifications of dipoles in amorphous polymers [15]

18

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.3: Schematic representation of two different sources of non-exponential

correlation decays [24].

19

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.4: Schematic of the protocol for dielectric hole burning experiment [23].

20

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.5: Time dependent dielectric permittivity of propylene carbonate at 157.4K

[23].

21

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.6: Empirical mode decomposition schematic to filter noise in time domain

responses [29]

22

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

δ x 1000

Figure 1.7 (a): Schematic of intrinsic isotherm experiment

5.0

o

4.5

T0 = 40 C

4.0

o

19.8 C

3.5

3.0

22.4

24.9

2.5

27.5

2.0

1.5

30

1.0

32.5

0.5

35

0.0

-3

-2

-1

0

1

10

10

10

10

10

2

10

t-ti (h)

Figure 1.7(b): Intrinsic isotherm experiment performed by Kovacs on PVAc digitized

by Zheng and McKenna [38]

23

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.8(a): Schematic of memory effect experiment

2.0

o

T 0=40 C

(1)

δ x 1000

1.5

1.0

(2)

(3)

(4)

0.5

0.0

-2

10

-1

10

10

0

1

10

2

10

10

3

t-ti (h)

Figure 1.8(b): Memory effect experiment of PVAc performed by Kovacs digitized by

Zheng and McKenna [38].

24

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.9(a): Schematic for asymmetry of approach experiment

1.5

o

T0=40 C

1.0

δ x 1000

0.5

0.0

-0.5

o

T a=35 C

-1.0

-1.5

o

T0=30 C

-2.0

-2.5 -3

10

-2

10

-1

10

10

t-ti (h)

0

1

10

2

10

Figure 1.9(b): Asymmetry of approach experiment of PVAc performed by Kovacs

digitized by Zheng and McKenna [38].

25

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.10: Schematic of Struik’s protocol

26

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 1.11: Creep compliance of poly(vinyl chloride) quenched from above to

below Tg at different aging times after quenching [8].

27

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

-1

T-jump 85-62C at 0MPa

PCO2-jump 3.9 to 0MPa at 62C

-2

-log(τ)/s

-3

-4

-5

-6

-1

0

1

2

3

4

5

6

δ*1000

Figure 1.12: Effective retardation time plot for temperature and concentration formed

glasses to the same final condition [41].

28

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

CHAPTER 2

EXPERIMENTAL SYSTEM

2.1 Time domain dielectric spectrometer

The dielectric responses of glassy polymers were studied using the time

domain dielectric spectrometer built in the Polymer and Condensed Material lab at

Texas Tech University. This setup was built as a part of this thesis work. The general

idea for this experimental system was based on the earlier works pioneered by Mopsik

[1] and Bohmer and his coworkers [2]. The working principle of the dielectric time

domain spectrometer is based on the ability to measure the capacitance of the sample

film as a function of time. It may be noted that when a polymer film is placed between

the two well polished metal plates, it acts as a capacitor. Using the capacitance of the

sample, we can calculate the dielectric compliance of the material as a function of

time.

The experimental set up comprises of a high voltage supply source, sample

setup and electrometer interfaced with PC using a DAQ board and controlled using a

LabView program [3]. The schematic of the system is shown in Figure 2.1 Trek

model 610 E is used as the high voltage supply source. The Trek system can be used

in two voltage ranges, namely, 0 to 1000V range and 0 to 10000V range. For the

current work, we have used the low voltage range as it also gives a better resolution.

Further, very high voltage on thin films also caused dielectric breakdown of the

material. Keithley 6514 model is used as the electrometer to measure voltage or

29

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

current response of the material under investigation. In this work, the electrometer is

used to measure the voltage response from the sample setup. The electrometer can

measure a maximum output voltage of 200V. The electrometer operates in 3 ranges

namely 0 to 2V, 0 to 20V and 0 to 200V range. The desired range is selected based on

the response of the output voltage. This type of measurement leads to resolution

problems which are addressed in chapter 4. A surge protector is used to prevent any

damage to the electrometer if the voltage exceeds 200V range. The measured output

voltage is then stored in the PC using an NI instrument DAQ board of 12 bit

resolution.

The schematic of the sample set is shown in Figure 2.2. It comprises of the

sample and integrating capacitor. The sample capacitor (SC) comprises of two well

polished flat stainless steel plates with thin polymer film placed between them. The

thickness of the SS steel plate is about 0.5 mm. The diameter of the lower and upper

plate is 3 cm and 2 cm respectively. The plates are held tight using a spring setup

shown in Figure 2. Mylar capacitor of capacitance 2.2 nF purchased from Digi-Key

was used as the integrating capacitor (IC). As shown in the schematic, the sample

capacitor and integrating capacitor are connected in series, such that one end of the IC

is connected to the SC and the other end is grounded. The high voltage is applied on

the SC and the response is measured between the junction of SC-IC and ground using

the electrometer. The entire sample set up is placed in an enclosed aluminum casing

and the temperature is applied using a cone heater and controlled to a range of ±0.1oC.

The total set up is placed in a temperature controlled box made from polycarbonate.

30

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

The time domain dielectric spectrometer built at Texas Tech University can operate in

the temperature range of 25oC to 80oC.

The capacitance of the sample C(t) is measured using the equation 2.1.

×

= (2.1)

Where, Vin is the applied voltage from the high voltage supply, Vo is the

output voltage measured by the electrometer, and Ci is the capacitance of the

integrating capacitor.

The dielectric compliance ε(t) of the sample is then measured using equation

2.2.

=

×

×

=

∆

× ∆

(2.2)

Where, d is the thickness of the sample, A is the surface area of the plate, εo is

the dielectric permittivity in vacuum, ∆P is the polarization and ∆E is the applied

electric field.

2.2 Experimental setup for studying the aging and structural recovery responses

of glassy polymers subjected to plasticizer environment

The physical aging and structural recovery experiments after pressure jumps (P Jump)

were performed using the experimental setup built at Texas Tech University shown in

Figure 2.3 [4]. The set up comprises of a pressure vessel (Figure 2.4) with a capacity

to handle up to 8 MPa of pressure, the sample set up comprising of the sample holder,

31

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

linear variable differential transformer (LVDT) to measure the change in length (HR

100, Lucas Schaevitz inc;) and a motor to apply and retract the load, pressure sensors

(Omega Electrovalves, SV128) to control the pressurization and depressurization

rates, an oil bath filled with silicone oil and a heating coil to heat the pressure vessel

to the desired temperature with a stability of ±0.1oC. The entire system is controlled

using a DAQ board interfaced with the computer using a LabView program. It may

be noted that for the P jump experiments, the set up was first subjected to vacuum for

20 minutes, followed by pressurization to about 4MPa at a pressurization rate of

0.0016 MPa/s, maintained at 4 MPa for about an hour, and then depressurized to 0

MPa at the depressurization rate of 0.0016 MPa/s.

The temperature jump experiments were performed in an oven using the same

experimental setup instead of a pressure vessel. The reason for using the oven instead

of a pressure vessel for temperature jump (T jump) experiments is because of the very

low cooling rate in the pressure vessel. A complete detail on the experimental set up is

given in the reference [4].

2.3 Linear Variable Differential Transformer calibration

The LVDT used for the aging and recovery experiments for the current work

was performed using a higher resolution mode of the signal conditioner such that

maximum length change measured is about 1 mm. Figure 2.5 is the calibration plot

for the LVDT, where length change (the distance the core is moved inside the LVDT)

is plotted against the voltage response. From the calibration plot it was that calculated

that 0.0985mm length change corresponds to a 1V response.

32

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

2.4 References

1. Mopsik FI. Precision Time-Domain Dielectric Spectrometer. Rev. Sci. Inst.

1984; 55: 79.

2. Schiener B, Bohmer R, Loidl A, Chamberlin RV. Non resonant spectral hole

burning in the slow dielectric response of super cooled liquids. Science. 1996;

274:752.

3. Kollengodu-Subramnain, S, McKenna, G.B. A dielectric study of poly(vinyl

acetate) using pulse probe technique. Journal of Thermal analysis and

calorimetry 2010, 102, 477.

4. Alcoutlabi, M.; Banda, L.; Kollengodu-Subramnain, S.; Zhao, J.; McKenna,

G.B. Environmental effects on the structural recovery responses of an epoxy

resin after carbon dioxide pressure-jumps: Intrinsic isopiestics, Asymmetry of

approach and memory effect. Macromolecules (2010 : Under review)

33

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 2.1: Schematic of time domain dielectric spectrometer built at Texas Tech

taken from reference 3

34

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 2.2: Sample setup schematic for the time domain dielectric

spectrometer [3]

35

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

A

D

B1

E

F1

G

H

Sample

C

F2

LVDT

CO2 vent

Weight

B2

Lift

Motor

I

Pressure vessel

CO2

Supply

Mixer

Oil bath

A

Pressure Controller

Temperature Controller

Signal Conditioner

Motor Controller

PC

A/D

A/D Board

Board

Air Drive

A) Regulator B1) Inlet automatic valve B2) Outlet automatic valve C) High pressure pump D) Filter E) Safety

valve F1) Inlet needle valve F2) Outlet needle valve G) Pressure sensor H) One way valve I) Three-way valve

Figure 2.3: The creep apparatus that was built in our laboratory to perform

experiments under different CO2-pressure and temperature conditions [4].

36

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 2.4: The pressure vessel used to perform the experiments under CO2 pressure

[4].

37

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Figure 2.5: LVDT calibration plot where the displacement of the core is measured as

a function of voltage

38

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

CHAPTER 3

A DIELECTRIC STUDY OF POLY (VINYL ACETATE) USING A PULSEPROBE TECHNIQUE

3.1 Motivation

There is considerable literature available that describes our understanding of

the viscoelastic properties of polymers subjected to mechanical stresses or

deformations. What we refer to here as a pulse-probe technique is one method that is

commonly used to study the time dependent behavior of materials in histories, e.g.,

temperature-jump or step-deformations, that exhibit fading memory responses. In the

linear case the behavior is well understood in the context of Boltzmann superposition

ideas. However, there is only limited work available that investigates the dielectric

response of materials within this same context

3.2 Introduction

Dielectric spectroscopy is normally performed in the frequency domain and in

the linear response regime [1-3]. It is used as a tool to characterize materials and

often the results of dielectric response in the linear regime are compared with

mechanical and rheological measurements. The pulse-probe technique is one method

used to study time dependent responses in temperature jumps [4] and nonlinear

mechanical or rheological measurements [5-8]. In the present work, we present results

from time domain dielectric spectroscopy experiments in which we explore the limits

of linearity in poly (vinyl acetate) (PVAc). In particular, we used a pulse-probe

method. The way in which the experiments are carried out is similar to the single and

39

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

double step strain or stress experiments commonly used in nonlinear viscoelasticity

investigations. [5- 8].

Dielectric properties such as dielectric compliance and modulus are analogous

to mechanical properties such as shear compliance and modulus [9]. The equivalents

to mechanical stress and strain in a dielectric measurement are the dielectric stress

(applied electric field) and the dielectric strain (polarization). The equation relating

the time dependent dielectric compliance (ε(t)) to the applied field (∆E) and the

polarization (∆P) is [9]

ε (t ) =

DielectricStrain

∆P (t )

⇔

∆Eε 0

Dielectricstress

(3.1)

where ε0 is the dielectric permittivity of vacuum. Importantly, equation 3.1 is valid in

ideal situations in which the field is applied instantaneously, i.e., a step-pulse

measurement and does not decay with time. Here, we found that the time decay of ∆E

is small enough that errors introduced by treating the data as ideal constant dielectric

stress experiments are negligible.

In the present work we use time domain dielectric spectroscopy, a method

pioneered by Mopsik [10-12] to investigate the dielectric responses of small molecule

liquids and polymers. The method has been extended by Richert and Wagner [13]

through the development of time domain modulus spectroscopy to investigate

dynamic heterogeneity in small molecule glass formers and polymers. These works

were confined to the linear domain and the responses were well explained using

classic descriptions such as the Kohlrausch-Williams-Watts (KWW) [14, 15] and

40

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

modified KWW [16] functions to describe the time-domain responses and the VogelFulcher-Tammann [17-19] expression to describe the temperature dependence of the

relaxation or retardation times near to the glass transition temperature.

As noted above, linear dielectric spectroscopy is generally used in the

frequency domain rather than the time domain. Frequency domain measurements,

however, have also been used to study the nonlinear dielectric response of materials.

For example, Furukawa et al [20] studied the nonlinear dielectric response of PVAc

by obtaining the first and third harmonics in the frequency domain in samples

subjected to increasing electric field. This is similar to attempts by Davis and

Macosko [21] to use modified Boltzmann superposition [22, 23] to study the

nonlinear viscoelastic behavior of polymers subjected to large mechanical

deformations. A similar body of work has recently appeared from Wilhelm’s group in

which Fourier Transform Rheology is used to characterize the higher harmonics of the

extremely nonlinear rheolgical response of polymers and other complex fluids [24,

25]. In addition, mixed mode experiments have been carried out in which large

amplitude sine waves are followed by single step small probes or time domain

measurements to examine the nonlinear response of glass-forming liquids and

polymer melts and solutions. For example, Schiener et al [26] established the

dielectric hole burning method using experiments on supercooled propylene

carbonate, and Shi and McKenna [27] developed a mechanical hole burning

experiments using a polyethylene melt and a polystyrene solution as example systems.

Richert and coworkers [28, 29] have studied the nonlinear dielectric behavior of

41

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

supercooled liquids by subjecting them to several cycles of sinusoidal waves of high

amplitude followed by a wait time and a small step (time domain) probe.

Prior to the present work, there have been only limited reports in the literature

of using the pulse-probe technique to study the dielectric behavior of materials.

Bohmer et al [30] used the pulse-probe technique to study the dielectric responses of

supercooled liquids. They observed the memory effect similar to that observed in

thermal and mechanical measurements [4, 5]. An interesting early work from the

1890’s by Hopkinson reports a memory effect in simple glasses subjected to reversing

polarity is cited by Whitehead in a 1927 treatise [31]. There, the Boltzmann

superposition principle [22] was used to predict the same.

In the present investigation, we test the limits of Boltzmann superposition [22]

for the dielectric response of poly(vinyl acetate) (PVAc) in pulse-probe experiments.

For this, we have performed a single step time domain response and two step (pulseprobe) measurements having different amplitudes and durations in the vicinity of the

glass transition. This is the first of a series of work to be later extended to study the

nonlinear dielectric time domain response using the modified Boltzmann

superposition principle [21, 23] and the pulse-probe method as developed here.

3.3 Sample Preparation

Dielectric experiments were performed using a time domain dielectric

spectrometer built at Texas Tech University (Figure 2.1). The working of the

instrument is well described in the chapter 2.

42

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Poly(vinyl acetate) of molecular weight 157,000 g mol-1 purchased from Scientific

Polymer Products, Inc. was used for the experiments. The glass transition temperature

Tg of this PVAc as previously measured by our group using DSC at a cooling rate of

10 K min-1 was reported to be 303.6 K [32]. The sample was made by placing the

pellets between thin brass sheets placed between two thick brass plates and then

pressed at 333 K in a platen press. After that, the sample is cut into a circular section

to fit the electrode plate, then held tight using a spring support and annealed at 338 K

(above the Tg) before performing the experiments. The loaded spring set up helps to

establish and maintain good contact between electrodes and polymer. The figure for

the sample support set up is given in Figure 2.2. PVAc films of thickness 185 ± 10

microns were used for the single step isothermal measurements used to examine the

time-temperature superposition behavior of the PVAc. The same film thickness was

used for two step pulse-probe experiments in which the first step duration t1 was

varied. Films of 112 ± 8 micron thickness were used for the experiments in which the

electric field E1 was varied. The sample was cut to size and placed into the dielectric

cell for measurement.

3.4 Methods of analysis

The dynamic response of many liquids can be described by the stretched

exponential or so-called KWW function shown in equation 3.2 [14-16, 33]. However,

because the shape of the dielectric compliance response shows a sigmoidal-like shape,

it can be necessary to apply a modified KWW function [16] as shown in equation 3.3

to capture the full response. Furthermore, when there is a long time process such as

43

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

the viscosity in viscoelastic creep measurements [34], or the conductivity in dielectric

creep it may be necessary to add an additional term as in equation 3.4.

ε (t ) = ε 1 * e

t

τ

β

ε (t ) = ε 1 + ε 2 * (1 − e

ε (t ) = ε 1 + ε 2 * (1 − e

(3.2)

t

−

τ

β

t

−

τ

β

)

(3.3)

)+

t

(3.4)

τc

Where ε1, ε2, τ, τc, and β are fit parameters. Here τ is the retardation time and τc is the

conductivity term. We find that equation 3.3 describes the recoverable part of the

dielectric compliance and the full response of ε(t) is well described by equation 3.4.

This separation of equation 4 into a recoverable term and a conductivity term is used

subsequently.

To test the validity of Boltzmann superposition for the two step dielectric

response, we used the Boltzmann equation as rearranged by Riande et al [35] and

implemented numerically in our group [32]:

∆P (t ) = ε g E (t ) + ∫ E (t − t ' )

dε ( t )

dt '

dt '

(3.5)

Hence, ∆P is the predicted dielectric strain, E(t) is the applied dielectric stress for the

two step test in the experiment analyzed, εg is the dielectric compliance at zero time

44

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

and ε(t) is the modified KWW (equation 3) fit to the single step, recoverable, linear

dielectric compliance response.

3.5.0 Results

3.5.1 Single step response

Isothermal measurements of the dielectric response (compliance) for the

PVAc were performed in a temperature range of 303 K to 333 K and the data are

shown in Figure 3.1(a). The solid lines in Figure 3.1(a) are the fits to the data at each

temperature using the modified KWW function with conductivity contribution given

in equation 4. Similar studies on PVAc have been performed by various groups [1, 13,

36]. The reason for using equation 4 is to separate the effect of dc conductivity from

the dielectric compliance response and also to examine the time-temperature

superposability of the dielectric response separate from the dc conductivity. The fit

parameters for equation 4 for the 308 K reference temperature are given in Table 3.1.

The β parameter obtained at the reference temperature was kept fixed for fitting the

data at the remaining temperatures. We observed an increase in the ε1 parameter and

decrease in ε2 parameter with increasing temperature for the above used function as

shown in Figure 3.2. Both the conductivity term and retardation time decreased with

increasing temperature.

Figure 3.1(a) shows that, with increasing temperature, the curves shift to

shorter times. We attribute the steep rise after the secondary plateau to the dc

conductivity [9, 13]. Richert and Wagner used two KWW functions to capture the

entire spectrum of data in their work on dielectric modulus [13]. As noted above, we

45

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

have used a term similar to the viscosity term in linear viscoelasticity but for the

conductivity added to a modified KWW function to fit our data (see equation 4).

Figure 3.1(b) is the master curve for the data of Figure 3.1(a) with 308 K as the

reference temperature. The data at the longer times do not superimpose and we

hypothesize this to be due to the domination of dc conductivity over dielectric

response.

The retardation time τ and the conductivity term τc obtained from equation 4

for the isothermal measurements of PVAc shown in Figure 3.1(a) are plotted as a

function of inverse temperature in Figure 3.3. The data are fitted using the VFT

function given in equation 3.6 [37]. The fit parameters are given in Table 3.2. The fit

parameters for the dielectric retardation time and the dc conductivity term are

different which explains the spread of the dielectric response at longer times in Figure

3.2(b).

log τ = − A +

B

(T − T o )

(3.6)

Where A, B and To are fit parameters.

To confirm the above hypothesis, the recoverable dielectric compliance

(which is the difference between the dielectric compliance and the conductivity term)

was estimated using equation 3.7.

t

ε (t ) − − ε 1

τc

ε R (t ) =

ε2

(3.7)

46

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

Where εR(t) is the recoverable dielectric compliance

For each fit of equation 3.4 to the data of Figure 3.1(a) εR(t) was determined

and the recoverable dielectric compliance response functions are plotted in Figure

3.4(a). In fact, these are described by the modified KWW function presented in

equation 3.3. Figure 3.4(b) gives the master curve for the recoverable compliance

data with 308 K as the reference temperature. We also observed softening like

behavior of the secondary plateau with increasing temperature. This can be explained

by the increase in ε1 and decrease in ε2 parameters of equation 4 with temperature as

shown in Figure 3.2. In equation 3.4 the parameter ε1 is related to the glassy (short

time) response and ε2 is related to the transition towards the long time plateau

response. This kind of softening behavior with increasing temperature is also

observed for dielectric responses in the frequency domain in the literature [9]. By

shifting the curves vertically for the higher temperature data in addition to the

horizontal shift, we obtain a reasonable time temperature superposition. In Figure 3.5

we compare the horizontal shift factor data for the dielectric recoverable compliance

with the Plazek’s recoverable creep compliance data [38] and Richert’s (digitized)

dielectric modulus [13] data. The results are in good agreement with Richert’s

dielectric data. Somewhat surprisingly, the data of Figure 3.5 show that the dielectric

response seems to follow Plazek’s terminal dispersion data rather than the softening

dispersion data. A similar sort of behavior has also been observed by Zorn et al. in

their work on polybutadienes [12].

47

Texas Tech University, Shankar Kollengodu Subramanian, May 2011

3.5.2 Time-frequency conversion

It is possible to calculate the frequency domain response namely the dielectric

loss compliance (ε”() and the dielectric storage compliance (ε’() from time

domain response and vice versa using Fast Fourier transformation. The relationship

between the dielectric compliance and its corresponding frequency components is

given by the equation 3.8.

= ′ − "

(3.8)

Figure 3.6 is the dielectric storage compliance plot calculated from the MKWW fit

(Equation 4) of isothermal measurements of dielectric compliance shown in Figure

3.2(a). Similar to what is observed in the compliance data, the secondary plateau

shows softening like behavior with increasing temperature. Figure 3.7 is the dielectric

loss compliance for the data given in Figure 3.1(a).

Dielectric compliance in general is a sum of contribution from dielectric relaxation,

electrode polarization and conductivity [9]. What is the contribution of electrode

polarization and conductivity to memory effect in the dielectric response is a

worthwhile question to ask here. In the dielectric loss compliance plot, the features of

dielectric relaxation, electrode polarization and conductivity appear in that order as

we move from a higher frequency to a lower frequency [9]. It can be clearly seen, for

the above temperature data, the conductivity as well as electrode polarization effect in