THE FUNCTION AND THE DESIGN PROCESS

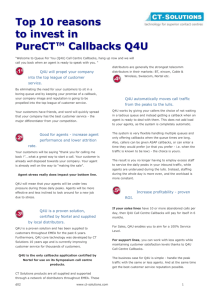

advertisement

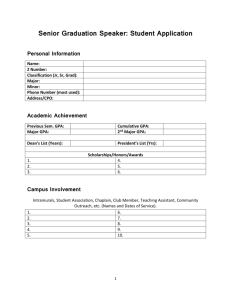

THE FUNCTION AND THE DESIGN PROCESS Robbert J. Hamann Fokker Space B.V. PO Box 32070 2303 DB Leiden The Netherlands E-mail: R.Hamann@fokkerspace.nl Paper presented at the th 15 International Cost Engineering Congress April 20-22 1998 Rotterdam INTRODUCTION In our projects at Fokker Space we are often, if not continuously, confronted with the following issues: • The actual design and development cost is greater than the one estimated at the beginning of the project, • The development time is longer than anticipated, • The product sometimes is not performing according to expectation. All three issues result in a more expensive product than desired. Over the years we have found, that these undesired phenomena can be better managed, when more attention is paid to the product’s functions, as seen from the (internal and external) user’s point of view, and when the product’s functions are used to direct the design and development process and the design choices made in the course of the project. This paper has been written based on experience in development programs for space applications (satellites, launchers). The observations made, however, are equally applicable to products intended for use in our “earthly” environment, certainly if the product is complex or innovative or the project team developing it is large in size. THE ROLE OF FUNCTIONAL ANALYSIS IN THE DESIGN PROCESS Definitions For the purpose of this paper the following definitions are used: A function is a task or activity to be performed by people, equipment, hardware or software. A function relates to the intended use of a product. Design is the activity to convert a Mission Need Statement or a set of User Requirements into a product, which meets the stated needs or requirements. A design is materialised in system elements, like personnel, hardware and software. The user is either the end user of the product or the entity paying for (the development of) the product (customer). User and customer may both be present in a project, but may have (very) different User Requirements. Where to start a design The justification of a product lies in its use, however abstract that use may be (e.g. the use of a car to boost a driver’s image); the product has no right of existence in itself. In this context it is important to note that the physical appearance of a product is only one of the many possible design implementations of the set of functions it is supposed to perform. The purpose of the design activity is to define a product that performs these functions as well as possible within the constraints of cost, (development) time and performance (quality), and the design problem to be solved is how to accomplish this. 15th ICEC; 1998; Rotterdam; the Netherlands -1- The necessary condition to be fulfilled prior to the start of the design activities proper is to know, what the user’s intended use of the product will be: • What he wants to do with the product (so its desired functions), • How well he wants these functions performed and why, • Which functions are the crucial ones. Especially the last item is of importance, as it is the source for the set of criteria to be used in taking design decisions. During the design process the design team must continuously check whether the chosen design implementation meets the requirements from the user’s point of view. To be able to do this, product characteristics must be linked back to the functions the product has to perform. Also, when choosing between design alternatives the key functions, in addition to the major constraints the product has to comply with, again deliver the criteria to screen and rank the alternatives. In the following sections we will illustrate these principles with a number of examples. EXAMPLES OF INCORRECT OR INCOMPLETE FUNCTIONAL ANALYSIS Huygens SM2 test model - Overspecified product performance Huygens is a probe destined to descend in the atmosphere of Titan, one of the moons of Saturn. As it is not possible to monitor and command the descent operation in real-time, it is of utmost importance to thouroughly verify the correct functioning of this mission phase. To this purpose a special test model has been constructed (the SM2), which has been submitted to a droptest from an stratospheric balloon at 40 km altitude. Figure 1 shows the Huygens SM2 under the balloon gondola. The Huygens SM2 test model specification required a Inertial Guidance Package as part of the test model’s instrumentation. This package was a major cost driver (multi-Mfl) and the purpose of it was unclear. After lengthy discussions with the customer it was found out that the only essential function was to enable trajectory reconstruction, other functions being covered by other types of sensors. The prescribed implementation was a personal preference of the customer, allowing to obtain far more detailed information of the parachute Figure 1 The Huygens SM2 test model under the balloon gondola 15th ICEC; 1998; Rotterdam; the Netherlands -2- package behaviour, which had already been covered by other tests. The performance required for the SM2 test has been achieved with a GPS differential mode sensor package at 1/20th of the cost. The lesson learned is: Don’t jump to design implementation before a thorough functional analysis. AR5 Main Engine Frame - Forgotten functions The primary function of the Ariane 5 Main Engine Frame is to transfer the total thrust load of 115 tons during launch. The frame has a diameter of 5.4 m and a height of 3.5 m. Its mass is 1500 kg. Far in the development phase, when full compliance to the specified loads had already been proven, it appeared that the dimensioning load case was not during launch, but during horizontal assembly. Such an event is typically the consequence of an incomplete functional analysis of the (intended) product; both customer and contractor were too much concentrated on primary functions, and did not consider sufficiently other life cycle phases. EXAMPLES OF GOOD FUNCTIONAL DEFINITION European Robotic Arm The Mission Need Statement for the European Robotic Arm (ERA) at a certain time of its life cycle was: Demonstrate the use of robotic means to perform unmanned spacecraft capture, external servicing and supply under ground supervision using an Automatic Transfer Vehicle (ATV) and a dedicated target spacecraft. The first steps toward design were made by analysing the operational functions, which ERA had to perform. An example of part of the function series is shown in Figure 2. 1. 2.0 3.0 4.0 5.0 6.0 8.0 Transport ERA to Check-out and Launch and insert Phase orbit and Check-out ATV and Perform extensive Kourou integrate ATV/ERA ATV in orbit insert in target qualify RVC ERA check-out composite G 9.0 Demonstrate Demonstrate Inspection ORU Exchange orbit 7.0 G Perform contingency actions 11. Demonstrate Re-berthing 10. 12. Demonstrate Relocation O 13. 14. 15. 16. Demonstrate Demonstrate Evaluate Complete ERA Demonstrate ATV Capture Berthing demonstration demonstration departure, de-orbit results mission and disposal 17. G Perform contingency actions 9.1. 9.2.0 Move to ORU 9.3.0 Approach ORU 9.4.0 Grapple 9.5.0 Detach ORU 9.6.0 Extract ORU 9.7.0 Retract 9.8.0 Move with ORU Aproach ORU destination 9.9.0 Insert ORU 9.10. Attach ORU 9.11. Release ORU 9.12. Retract ERA A Figure 2 AND O OR G GO G NO-GO ERA function series As a next step the functions may be assigned to personnel, equipment, hardware and software in general terms. Figure 3 shows such an allocation for function 9.0, “Demonstrate Orbit Replaceable Unit (ORU) exchange”. 15th ICEC; 1998; Rotterdam; the Netherlands -3- no. 9.1.0 9.2.0 function Move to ORU Approach ORU 9.3.0 Grapple ORU 9.4.0 9.5.0 9.6.0 9.7.0 9.8.0 Detach ORU Extract ORU Retract Move with ORU Approach ORU destination 9.9.0 9.10.0 9.11.0 Insert ORU Attach ORU Release ORU 9.12.0 Retract ERA Figure 3 hardware or software allocation Manipulator Joint Subsystem; Environment Data Base Manipulator Joint Subsystem; Proximity Sensor (End Effector Camera) End Effector Grapple Mechanism; Grapple Fixture Presence Sensor Integrated Servicing Tool Manipulator Joint Subsystem; Torque Force Sensor Manipulator Joint Subsystem; Environment Data Base Manipulator Joint Subsystem; Environment Data Base Manipulator Joint Subsystem; Proximity Sensor (End Effector Camera) Manipulator Joint Subsystem; Torque Force Sensor Integrated Servicing Tool End Effector Grapple Mechanism; Grapple Fixture Presence Sensor Manipulator Joint Subsystem; Environment Data Base ERA function allocation Although no detailed design decisions are taken yet, a concept in general terms emerges, and, even more important, the system level functions, which will have to be reflected by the hardware and software characteristics, are clearly identified. This is a sound basis on which the further design can be developed. MIPAS Focal Plane Subsystem MIPAS is an instrument on ENVISAT, an earth observation satellite, and is destined to generate infra-red spectra of the erth atmosphere. The instrument images part of the atmosphere by means of azimuth and elevation mirrors and generates an interferogram by means of a Michelson interferometer. The two resulting beams are sized by a A-Focal Reducer (AFR) and projected on eight detectors in the Focal Plane Inner Structure & Optics (FIS), which is to be kept on low (70 K) temperatures to suppress undesired detector noise. The instrument is very sensitive to contamination. FPS> Interferometer Telescope Photon flux "Object Selection" A-Focal Reducer (2x) FIS Optics Photon flux "Amplitude Modulation; Modulated "Concentration Modulated "Matching incoming Modulated 1 channel Modulation frequency photon flux Photon Flux photon flux Photon Flux and photon flux is function of 2 channels by a factor of 5" 2 channels Detector Area" 2 channels Wavelength" "Reduction Parasitic Photon Fluxes [Key [Transmission [Conversion spectral [Transmission] performance photon flux] resolution to modulation [Flux concentration] parameters] [Pointing accuracy] frequency resolution] [Matching] <FPS SPE/Ground Segment PAC/PAW Detector (8x) Dichroic N (6x) [Transmission] Modulated "Transmit Spectral Spectral band from "Conversion Photon Modulated "Pre-Amplification Modulated "Modulation Frequency photon flux Band Detector N" modulated photon flux Flux to Electron electron flux of Electron Flux" electron flux Determination; Wavelength 2 channels "Reflect Remaining 8 channels Flux" 8 channels 8 channels Determination; Spectral Resolution 4cm-1" Photon Flux" [Transmission and [Detectivity (signal intensity)] [S/N ratio] reflection characteristics] [Responsivity (modulation frequency)] [Gain stability] [Conversion modulated electron flux to wavelength spectrum, with intensity] Figure 4 MIPAS components, main functions and key performance parameters Figure 4 shows the functional block diagram for this process, where the criterion for the functional analysis is “physical quantities flowing through (and being trasformed by) the system”. Although the contract was only for the Focal Plane Subsystem (FPS) the analysis is done for the full instrument in order to better understand the impact of FPS characteristics on the total process. Also, the key performance parameters for each transformation step are identified. In this way the figure contains in a very condensed form all essential functions of the instrument. To obtain a more complete view on the MIPAS instrument figure 5 shows a functional break-down of the Focal Plane subsystem. It shows the FPS components in logical groupings. A main distinction 15th ICEC; 1998; Rotterdam; the Netherlands -4- is made between snesor functions (the essentials), spacecraft functions (which must be present to allow the sensor to function) and ground support functions (which are needed to produce the system). Picturing the product in this way allows to introduce constraints and interfaces in the functional model. Focal P lane S ubsystem S ensor Functions O ptical P ath B eam R eduction B eam A lignm ent S pectral S eparation Transm ission C leanliness S pacecraft Functions C ryogenics FD IR H eat Balance E lectrical S ensors E nvironm ental M onitoring R edundancy O ptical M echanical E lectrical Therm al M echanical O ther E nv. Effects E MC D ata H andling A rchitecture H arness P ow er P hoto-sensitive D evices S ignal P rocessing P re-am plification Figure 5 G round S upport E q. Functions P ow er Interfacing MIPAS Focal Plane Subsystem functional break-down The combination of the two views in figures 4 and 5 gives us a functional structure to which we can attach detailed specified requirements, minimising the risk of overlooking aspects to be specified. ARAFOM - Choosing and presenting the preferred solution The Advanced Ridged Array for Olympus-type Missions (ARAFOM) was a qualification program for a 2 to 7 kW family of solar arrays, primarily ment for telecommunication satellites. Main drivers for the program were cost and production time reduction at equal performance. Basically a solar array consists of the following elements (see Figure 6): • Solar cells, • Honey comb structure with a conducting Carbon Fiber Reinforced Plastic (CFRP) skin, • Kapton foil between cells and structure for electrical isolation. Solar Cell Contact pads Kapton foil Carbon Fiber Reinforced Plastic Honeycomb structure Figure 6 Typical solar array construction The design issue at stake was to find a solution for an electrical short of solar cells to CFRP skin, which occurred on a previous mission. Fokker Space’s solution was to increase the thickness of the 15th ICEC; 1998; Rotterdam; the Netherlands -5- Kapton film to 50 micrometer, while the customer had a preference to replace CFRP with Kevlar, which is an intrinsic isolator. Two other possible solutions were offered. In an objective trade-off all design options have been compared against the same, key driving requirements: development cost, development risk, isolation performance and mass performance. The relative weight of these criteria have been set beforehand as well as the success criteria. Results of the trade have been presented in a simple way (see Figure 7). In this figure the weiight of the criteria is presented by the column width, while the success criterion is presented by a colour ranging from red for “unacceptable” to green for “exceeds requirements”. CRITERION Isolation performance Mass performance Dev. Cost Development Risk CFRP skins + 50 µm Kapton film (current baseline) CFRP skin + alternative film good (no anomalies) nominal no risk very good (TBC by tests) nominal Kevlar composite skin very good 13 % heavier Kevlar composite skin + CFRP doubler Better than baseline (not proven) 5 % heavier zero delta cost slight delta cost high delta cost high delta cost OPTION Figure 7 product not yet developed routine space development possible delamination Excellent; exceeds requirements Correctable deficiencies Good; meets requirements Unacceptable Presentation of trade-off results This very compact presentation convinced the customer in a very efficient way, that the proposed baseline was the optimum choice. OVERVIEW OF TOOLS FOR FUNCTIONAL AND OPERATIONAL ANALYSIS Many tools are available to support functional and operational analysis, ranging from simple multipurpose office tools to more sophisticated specific integrated tools. Figure 8 gives an overview of tools and their major advantages and disadvantages. Tool and use Block diagram drawing S/W (e.g. Visio) for functional flows, breakdown S/W development packages for functional analysis (e.g. System Architect) Spreadsheet for operational timelines (e.g. EXCEL) Advantage Cheap; easy to use; can be customized; generally good presentation Relatively easy to use; good consistency Small Systems Engineering S/W packages (e.g. CASETS) Cheap; incorporate many functional and operational analysis functions; good consistency Big Systems Engineering S/W packages (e.g. RDD-100) Integrate functional and operational analysis with many quantitative aspects; good Cheap; flexible in applications; allow easy incorporation of quantitative data 15th ICEC; 1998; Rotterdam; the Netherlands -6- Disadvantage No other logics behind it than the designer’s; bad consistency Difficult to customize; rigid reporting; allow no exceptions; rather expensive No relation with functional or operational analysis; underlying algorithms difficult to read for nonproject people Bad presentation; inflexible in use; rather difficult to work with; sometimes difficult to map on the company’s design processes and practices Expensive; require expert knowledge to use; sometimes difficult to map on the company’s Tool and use Figure 8 Advantage consistency Disadvantage design processes and practices Comparison of tools for functional and operational analysis The choice of a tool for functional and operational analysis will always depend on the character and size of the project and the company’s way of working. THE POTENTIAL OF FUNCTIONAL ANALYSIS IN DIRECTING THE DESIGN Advantages Advantages of defining a product by means of functions are: • It forces the designer to examine the intended use of the product critically and hence to understand his customer or user well. • It prevents solving the problem (designing the product) before the problem (intended use) is known. • It allows to choose from all possible (design) implementations the one that answers best the intended use of the product. • It allows the identification and definition of modular functions (that is: functions with “clean” interfaces), promoting the definition of modular hardware and software components. • It sponsors the probability for real innovation, as it (temporarily) fences off the rush into re-use of established solutions. Disadvantages There are also some disadvantages: • There is a danger to remain abstract, when thinking in functions. • Engineers like to make something (it is their function), not to be their customer’s shrink. • It may seem superfluous (and costly) to go through this phase when well proven design implementations exist. DO’S and DON’TS Our past experience has led us at Fokker Space to formulate explicitly some guidelines for our design teams: − Even when the design implementation seems straight forward, take the time to establish • the product’s desired functions, • the product’s key functions and resulting (quantified) performance requirements, • all options likely to answer to the desired functions. − Rationally select the better design amongst the alternatives using (key) functional performance requirements as a selection criterion. − Keep an open eye for the product’s undesired functions: emerging properties (e.g. a car, designed to provide individual transportation, produces pollution as a by-product). − When developing the design, continuously check its performance against the key functional performance requirements to obtain a compliant product, which the user wants, and to avoid suboptimization on the total by optimizing the detail. There are also a number of “deadly sins”, which we also canvas in the company: − When choosing for existing design don’t forget to examine the extent up to which the design complies with the intended functions and identify undesired properties of the design for the intended use. − Don’t accept prescribed design implementations without investigating why they are prescribed (what is their intended function); propose your customer alternatives, comparing them to their preferred solution. − Don’t limit yourself to one functional view of your product; the (relatively small) effort of analyzing your system from different functional points of view considerably improves your understanding of the product. CONCLUSIONS 15th ICEC; 1998; Rotterdam; the Netherlands -7- Traditionally engineers tend to start their design implementation activities before they understand their customer’s real problem (hence his real need), which their design is intended to solve. The paper identifies some reasons why this occurs so often. A powerful means to prevent this happening is to spend time, especially early in the design process, in analysing the intended use of the product. The functional and operational analysis plays an important role in this and the primary functions which are identified may be used as the guiding criteria and metrics for design decisions. In summary we may conclude, that defining a product in terms of functions • improves its usefulness, • increases the chance on real innovation, • supports a good rationale for design option selection, • decreases the risk that the final design (unwantedly) does not meet the a priori expectations. ACRONYMS AND ABBREVIATIONS EMC Env. FIDR GPS PAC PAW RVC SPE Electro-Magnetic Compatibility Environmental Fault Isolation, Detection and Recovery Global Positioning System Pre-Amplifier Cold Pre-Amplifier Warm Rendez-Vous and Coupling Signal Processing Electronics 15th ICEC; 1998; Rotterdam; the Netherlands -8-