Aggregate Planning

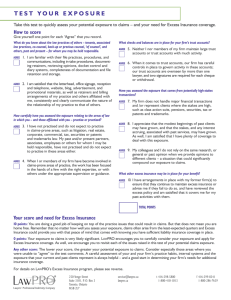

advertisement

Chapter Three

Chapter Overνiew

Purpose

Το develop techniques for aggregating units of production, and determining

levels a nd workforce

levels based οη predicted demand for

Key Points

1. Aggregate units of production. Thi$ chapter could also have been called Macro

Production Planning, since the purpose of aggregating units ί$ to be able to

develop a top-down plan for the entire firm ΟΓ for some subset of the firm, such

as a product line ΟΓ a particular plant. For large firms producing a wide range of

products ΟΓ for firms providing a service rather than a product, determining

appropriate aggregate units can be a challenge. The most direct approach is to

eχpress aggregate units ίη some generic measure, such as dollars of sales, tons of

steel, ΟΓ gallons of paint. For a service, $uch as provided by a consulting firm ΟΓ a

law firm, billed hours would be a reasonable way of eχpressing aggregate units.

2. Aspects of aggregate p/anning. The following

aggregate planning:

are the

σιοει

• Smoothing. (05tS that arise from changing production

• Bott/enecks. Planning in anticipation

important feature5 of

and workforce levels.

• Treatment of demand. ΑΙΙ the mathematical model5 in thi5 chapter consider

demand Ιο be known, i.e, have zero forecast error.

3. Costs ίπ aggregate p/anning.

• Smoothing costs. The CO$tof changing production

and/or workforce

level5.

C05t of dollar5 inve5ted in inventory.

• Shortage costs. The CO$t$associated with back-ordered

ΟΓ

105t demand.

• Labor costs. These include direct labor costs on regular time, overtime,

5ubcontracting costs, and idle time cost$.

4. So/ving aggregate p/anning prob/ems. Approχimate solutions Ιο aggregate

planning problem5 can be found graphically, and eχact solutions via lίnear

programming. When solving problem5 graphically, the first 5tep is to draw a

124

5. The /inear decision ru/e. The aggregate planning concept had its ωοιε ίη the

work of Holt, Modigliani, Muth, and Simon (1960) who developed a model for

Pittsburgh Paints (presumably) to determine their workforce and production

level5. The model used quadratic approχimations for the costs, and obtained

simple lίnear equations for the optimal policies. This work 5pawned the later

interest in aggregate planning.

6. Mode/ing management behavior. Bowman (1963) considered linear decision rules

similar to tho$e derived by Holt, Modigliani, Muth, and Simon eχcept that he

suggested fitting the parameters of the model based on management's actions,

rather than prescribing optimal actions ba$ed on ωει minimization. Thi$ is one of

the few eχamples of a mathematical model used to describe human behavior ίπ

the conteχt of operations planning.

7. Oisaggregating aggregate p/ans. While aggregate planning is useful for providing

approχimate solutions for macro planning at the firm level, the que$tion is

whether these aggregate plans provide any guidance for planning at the lower

levels of the firm. Α disaggregation scheme is a means of taking an aggregate

plan and breaking it down to get more detailed plans at lower levels of the firm.

of peak demand periods.

• P/anning horizon. One mU$t cho05e the number of period5 considered

carefully. If too short, 5udden changes in demand cannot be anticipated. If Ιοο

long, demand foreca5ts become unreliable.

• Ho/ding costs. The opportunity

125

graph of the cumulative net demand curve. If the goal ί5 to develop a level plan

(i.e., one that has constant production ΟΓ workforce levels over the planning

horizon), then one matches the cumulative net demand curve as closely as possible

with a straight lίne. If the goal is to develop a zero-inventory plan (i.e., one that

minimizes holding and shortage costs), then one tracks the cumulative net

demand curve as cl05ely as possible each period. While lίnear programming

provide5 ωει optimal 50lutions, the method does not take into account

management policy, such Β5 avoiding hiring and firing as much as possible. For

a problem with a Tperiod planning horizon, the linear programming formulation

requires 8Tvariables and 3Τ constraints. For long planning horizons, this can

become quite tedious. Another issue that must be dealt with is that the solution to

a linear program ί5 noninteger. Το handle this problem, one would either have to

specify that the problem variables were integers (which could make the problem

computationally unwieldy) ΟΓ develop some suitable rounding procedure.

Aggregate Planning

suitable production

aggregate units.

Aggr,ga,e Planning

As we go througlllife, we tnake both Illicro and macro decisions. Micro decisions tnight

be \vhat Ιο eat forbreakfast, whatroute Ιο take towork, what auto service ιο use, orwhich

movie to rent. Macro decisions are the kind t!Jat change the course of one's life: where Ιο

lίνe, what Ιο major ίη, whicll job Ιο take, wllom Ιο marry. Α cotnpany also must make

both micro and macro decisions every day. Ιη this cllapter we explore decisions made at

the macro leve!, such as planning companywide workforce and production leνels.

Aggregate planning, which might al50 be called macro production planning,

addresses the problem of deciding how many employees the firm Sllould retain and, for a

manufacturing firm, the quantity and the mix ofproducts to be produced. Macro planning

is ηο! lίmίted Ιο manLIfacturing firms. Service organizations must determine employee

staffing needs as well. For example, airlines must plan staffing levels for flight attendants

and pilots, and !lospitals must plan staffing levels for nurses. Macro planning strategies

are a fundamental part ofthe firm's overall business strategy. Some firms operate οη the

philosophy that costs can be controlled only by making frequent changes ίn tl1e size

andlor composition of the workforce. The aerospace industry ίη Califomia ίη the 1970s

adopted this strategy. As government contracts shifted fron1 one producer Ιο another, so

126

Chapter Three

3.1

Aggregalι! Plαnning

did the technical workforce. Other firιns have.a reputation for retaining employees, even"

ίη bad times. Until recently, ωΜ andAT&Twere two we1J-known examples.

Whether a firm provides a service οτ produces a product, macro planning begins

with the forecast of demand. Techniques for demand forecasting were presented ίη

Chapter 2. How responsive the firιn can be το anticipated changes ίη the demand depends οιι several factors. These factors include the genera], strategy the firm may have

regarding retaining workers and ifs οοτυηιίτυισιιε-το existing empIoyees.

As noted ίη Chapter 2, demand forecasts afe generallY'wrong because there is aImost

always a random οοπιρουεφι ofthe demand that cannot be predicted exactly ίη advance.

The aggregate pIanning methodology discussed ίη this chapter requires the assumption

that demand is deterministic, οτ known ίη advance. This assumption is made Ιο simpIify

the analysis and alJow us το focus οτιthe systematic orpredictable changes ίη the demand

pattem, rather than οτι the unsystematic οτ random changes. Inventory management

subject to randomness is treated ίη detail ίη Chapter 5.

TraditionalJy, most manufacturers have chosen ιο retain primary production ίηhouse. Some components might be purchased from outside suppliers (see the discussion ofthe make-or-buy problem ίη Chapter Ι), but the Ρήmary product is traditionalJy

produced by the firm. Henry Ford was one ofthe firstAmerican manufacturers το design

a completely vertically integrated business. Ford even owned a stand of rubber trees so

ίι wouId υοι have το purchase rubber.for tires.

That philosophy is undergoing a dramatic change, however. Ιιι dynamic environments,

firms are finding that they canbe more flexible ifthemanufacturing

is outsourced; that is,

ifit is done οτι a subcontract basis. One exampIe is Sun Microsystems. a Califomia-based

producer of computer workstations. Sun, a market leader, adopted the strategy of focusing οιι product innovation and desigiJ rather than οιι manufacturing. It has developed close

ties ιο contract manufacturers such as San Jose-based Solecιron Corporation. winner of

the Βaldήge Award for Quaiity. Subcontracting its primary maηufactuήηg function has

allowed Sun Ιο be more flexible and Ιο focus οη innovation ίη a rapidly changing market.

Aggregate plaBning involves competing objectives. One objective is Ιο react quickly

ιο anticipated changes ίη demand, which would require making frequent and potential1y

large changes in the size ofthe labor force. Such a strategy has been called a chase strategy. This may 1Jecost effective, but could be a ροοτ loηg-ruη business strategy. Workers

who are laίd off may ηο! be avaiIable when business tums around. For this reason, the firm

may wish Ιο adopt the objective of retaining a stable workforce. However, this strategy

often results ίη large bUΊldups of inventory duήηg Ρeήοds of low demand. Service firms

may incur substantial debt tomeetpayrolJs in slowperiods. Α third objective is Ιο develop

a production plan for the firm that maximizes profit over the planning hοήΖοn subject Ιο

constraints οη capacity. When profit maximization is the primary objective, explicit costs

ofmaking'changes

mustbe factored ίηΙο the decision process.

Aggregate planning methodology is designed Ιό translate demand forecasts ίηΙο a

blueprint for planning staffing and production levels for the firm over a predetermined

planning horizon. Aggregate planning methodology is ηοΙ lίmίted ιο top-Ievel planning. Although generaJ]y considered Ιο be a macro planning ιοοl for determining

overalJ workforce and production leνels, large companies may find aggregate planning

useful at the plant level as well. Production planning may be viewed as a hierarchical

process ίη which purchasing, production, and staffing decisions must be made at severallevels ίn the firm. Aggregate planning methods may be applied at almost any level,

although tl1e conceptis

one of maήagίηg grotιps of items rather than single items.

The inventory planning methods discussed ίη Chapters 4 and 5 are geared toward

single-item control.

Aggregar< UnitsofPrαlucιion

127

This chapter reviews several techniques for determining aggregate plaίIs. Some.6f

these ετο heuήstίό (i.e., approximate) and some are optimal. We hope tοcοήΎeΥ ιο the

reader ετι understahding of the issues involved ίη aggregate planning'i'a kή6wleage"of

the basic tools available for providing solutions, and an appreciation of the dif!icιJltίes

associated with imp(ementing aggregate plans ίτι the real world.

,~

,

"

AGGREGAtE

.,0

'}'

,,"0

,"~;

\

"1"

,

,'~:r~"';CI'~::,

:

ONITS'"OFpRobuttION.

The agg~ega:te planning approach is predicated οα the e~istence of an aggregate υηίι

ofproduction. When the types ofitems produced are similar, an aggregate production

υηίι can couespond Ιο 'aΠ "av~rage" item, but if many different·types of items are produced, ίι would be more ερρτορτίειε το consider aggregate units ίη terms of weight

(tons of steel), νοίυπισ (gallons of gasoline), amount of work required (worker-years

ofprogramming time), οτ dollar value (value ofinventory ίτι dollars). What the approρτίετε aggregating scheme, should be is πο! always obvious. Ιι depends ωι the context

ofthe'pafticular

planning problem'and the leνel of aggregation required.

Example3.1

Α plant managerworking lor a large national appliarice lίrm is considering implementing an aggregate planning system ιο determine the worklorce and production levels in his plant. This particular plant produces six models ΟΙ washing machines,The characteristics ΟΙ the machines are

Model Number

Α5532

Κ4242

Ι9898

Ι3800

Μ2624

Μ3880

Nlιmber of Worker-Hours

Required to Produce

4.2

4.9

5.1

5.2

5.4

5.8

, SeIIing Price

$285

345

395

425

525

725

The plant manager must decide οπ the particular aggregation scheme Ιο use. One possibilίΙΥ is to deline an aggregate υπίΙ as'on'e dollar ΟΙ όυιρυΙ Unlortunately, the selling prices ΟΙ the

various models ΟΙ washing machines are ποΙ consistent with th·e number ΟΙ worker-hours required Ιο produce them. The ratio ΟΙ the,selling price.divided by the worker-hours is $67,86 for

Α5532 and $125,00 ΙΟΓ M::J880, (The company bas~s its pricing on the faet that the less

expensive models have a higher sales volume.) The manager notices that the percentages οΙ

the total number οΙ sales Ιοτ these si\<models have been fairly constant, with values οΙ 32 percent lοr Α5532, 21 percent lοr Κ4242, 17 percent Ιοτ ~9898, 14 percent for L3800, 1Ο percent

lοr Μ2624, and 6 percent for Μ3880. He decides to define an aggregate uni! ΟΙ production as

a lίctίtίoυs washing machine requiring (.32)(4.2) + (.21)(4.9) + (.17)(5.1) + (.14)(5.2) +

(.10)(5.4) + (.06)(5.8) = 4.856 hours ΟΙ labor time. He can obtain ~ales forecasts for aggregate

produetion units ίπ essentially the same way by multiplying the appropriate Iractions by the

lorecasts lor υπίι sales ΟΙ each type ΟΙ machine.

The apptΌach used by the plant manager ίο Example 3.1 was possible because of the

relative similarity of the jJroducts prodtIced. However, defining an aggregate υη1ι of

production at a higher leνel ofthe firm is more difficult. Ιη cases ίη which the firrn produces a large νaήety ofprodncts, a natural aggregate υπίι is sales dollars. Althollgh, as

we saw ίη the' example, tl1ίs will 110!11ecessarily tral1slate Ιο tbe same nnmber of units

of prodnction 'for each item, ίι wiH generally provide a good approximatio11 for planning at tl1e highest leνel of a firm that produces a diverse product lίηe.

128

Chapter Three

Aggr,gaιc Planning

3.2

FIGURE 3-1

TI,e /1ierarchy of

129

ροτίοσε of time, stIcb as weeks, quarters, ΟΓyears. An important featιιre of aggregate

planning is that the,de,mands are treated as known constants (that is, the forecast error is

assumed ιο be zero). Thereasons for making this assumption will be d,iscussed later.

The goal ofaggregate planning is το determine aggregate production qua.ntities and

the leνels of resources required το achieve these production goals. Ιτι practice, this

translates to nnding the number ofworkers that should be employed and the number of

aggregate tInits ιο be produced ίη each of the planning periods J, 2, ... , Τ. The objective ο[ aggregate planning is to balance the advantages of producing to tneet demand

as closely as possible against the disrtIptions caused by changing the levels of producιίοο and/or the workforce levels.

The primary issnes related ιο the aggregate planning problem include

produclion pIanning

dccisiol1S

Aggregate planning (and the associated problem of disaggregating the aggregate

plans orconverting them ίπΙο detailed master schedules) is closely related το hierarchical

production planning (ΗΡΡ) championed by Hax and Meal (1975). ΗΡΡ considers

workforce sizes and production rates at a variety oflevels ofthe nrm as opposed 10 simply the τορ level, as ίπ aggregate planning. For aggregate planning purposes, Hax and

Meal recommend the foJlowing hierarchy:

Ι. /tenls. These are the nnal products ιο be delivered to the οιιετοηιετ, Απ item is often

referred 10 as an SKU (for stockkeeping ιαιίι) and represents tl1e nnest leνel of detail

ίπ the ρτοοιιοτ είτυοιυτε.

2. FamiIie:,·. These are denned as a group of items that share a οοηιπιοη mantIfactιιring

setιιp cosΙ

3. Types. Types are groups of families with prodtIction quantities that are determined

by a single aggregate production ρlαη.

lπ Exalnple 3.1, items would

Α family might be all washing

Hax-Meal aggregation scheme

the aggregation method shotIld

and prodllCt Ιine.

correspond 10 individuallnodels ofwashing machines.

nJachines, and a type might be large appliances. Τhe

wiII πο! necessarily work ίη every sitιιation.ln general,

be consistent with the nrιn's organizational strιtcΙUre

[η Figure 3-1 we present a sCl1ematic of the aggregate planning fιlnction and its

place ίπ tl1e hierarchy ofproduction planning decisions.

3.2

Overview of the AggregaLe ]Jlαnning IJroblem

OVERVIEW OF ΤΗΕ AGGREGATE PLANNING PROBLEM

Having now denned the appropriate aggregate ιιηίι [or the leνel of the firm [or which αη

aggregate plan is ιο be determined, we assume that there exists a forecast ofthe deInand

for a specined planning horizon, expressed ίη terms of aggregate prodtIction units. Let

DJ, D2, ... , Dr be the demand forecasts for the next Tplanning periods. [π most applications, a planning period is a month, altl10tIgh aggregate plans can be developed for other

Ι. SmooIhing, Smoothing refers το costs that resιιlt from changing production and

workforce levels from ουε period το the ηοχΙ Two ofthe key components of smoothing

costs ΗΓοthe costs that result frol11 hiring and nring workers. Aggregate planning

methodology reql1ires the ερεοίϋοειίοτι of these costs, which may be difficult to εειίmate. Firing workers could have fal'-reaching consequences and costs that may be difficult to evaluate. Firms that hire and nre freqtIently develop a poor public image. This

could adversely affect sales and discourage potential employees frOI11joining the company. Furthermore, workers that are laίd off might not simply wait around for busiiιess

ιο pick up. Firing workers can have a detrimental effect οη the futιιre size ofthe labor

force ifthose workers obtain employment ίτι other indusιries. Finally, tnost companies

ΗΤοsimply πο! at liberty Ιο hire and fire at will. Labor agreements restrict the freedom

of management το freely alter workforce leνels. However, ίι is διίll valtlable for management ιο be aware of the cost trade-offs associated with varying workforce leνels

and the attendant savings Ιτι ίnνentOlΎ costs.

2. Bottleneck probIenIs. We use the term bottleneck ιο refer το the inability of tl1e

system το respond το stIdden changes ίπ demand as a restIlt of capacity restrictions. For

example, a bottleneck cotIld arise when the forecast [οr demand ίη οιιε month is unusually high, and the ρΙΗΩΙdoes υοτ have slIfficient capacity το meet that demand. Α

breakdown of a vital piece of equipment also οοιιί« result ίn a bottleneck.

3. P/anlling horizon. TI,e number of periods for which the deI11and is to be forecasted, and hence the ntImber of periods for which workforce and inventory levels are

Ιο be determined, mlIst be specified ίη advance. The choice oftl1e value ofthe forecast

horizon, Τ, can be significant ίη determining the usefulness of the aggregate plan. If

Τ is 100 sI.nall, then cnrrent production leνels might ηο! be adequate for I11eeting the

demand beyond the horizon length. Jf Τ ίδ 100 large, ίι is likely that the forecasts far

ίηΙο the fιιΙUτo wiII prove inaccurate. If futιιre demands turn out Ιο be very different

from the forecasts, then clIrrent decisions indicated by the aggregate plan could be ίπcorrecΙ Another isstre involving the planning horizon is the end-oJ-hoI'izon effect. For

example, the aggregate plan might recommend that the inventory at the end ofthe horiΖοn be drawn to ΖοΓΟίη order to minimize 110lding costs. This cotIld be a ροοτ strategy,

especiaIIy if demand increases at that time. (However, this particIIlar problem can be

avoided by adding a constraint specifying mil1imnnJ ending inventory leνels.)

Ιπ practice, rolling schedules are almost always tIsed. This means that at the time of

the next decision, a new forecast of demand is appended Ιο the fornJer fΟΓecasts and old

forecasts ll1ight be revised Ιο reflect new information. The new aggregate plan may recommend different production and workforce levels fol' the cwTent period. than were

recomlnended one peTίod ago. When only the decisions fol' the CΙΙΓrentplanning period

need Ιο be illlplemented imJnediately, II,e schedule shotIld be viewed as dYl1anlic ra!her

than static.

130

Chapter Three

Aggr,gaιe Ρ/αηηίηι

3.3

Co,ιs ίη Aggr,gaιe Plaηning

131

Although rolling schedules are common, ίι is possible that because of production

lead times, the schedule must be frozen for a certain number of planning periods. This

means that decisions over some collection of future periods cannot be altered. The

most direct means of dealing with frozen horizons is simply Ιο label as period Ι the first

period ίη which decisions are τιοτ frozen.

οι

4. Treatment

demand. As noted above, aggregate planning methodology requires

the εεειυυριίου that demand is known with certainty. This is simultaneotIsly a weakness and a strength of the approach. Τι is a weakness because ίι ignores the possibiIity

(and, ίη fact, likeIihood) offorecast errors. As noted ίη the discussion of forecasting

techniques ίη Chapter 2, ίτ is virtually a certainty that demand forecasts are wrong.

Aggregate planning does αοι provide any buffer against unanticipatedforecast

errors.

However, most inventory nιodels that allow for random demand require that the average demand be constant over ιίσιο. Aggregate planning aIIows tlle manager Ιο Ιοοιιε οη

the systematic changes that are generaJly αοτ present ίη models that assnme random

demand. ΒΥ assuming deterministic denland, the effects of seasonal fluctuations and

business cycles can be incorporated ίητο the planning function.

3.3

COSTS ΙΝ AGGREGATE PLANNING

As with most ofthe optimization problems considered ίη production managelnent, the .

goal ofthe analysis is to choose the aggregate plan that IIlinimizes cost. Ιι is important

to identify and measure those specific costs that are affected by the planning decision.

Ι. SI1700t!lil1g cσsfs. Smoothing costs are those costs that accrue as a result of

cllanging the production levels from one period το tlle next. Ιη the aggregate pIanning

context, the most salient snιoothing cost is the cost of changing the size of the workforce. Tncreasing the size of the workforce requires time and expense to advertise ροsitions, interview prospectiνe employees, and train new hires. Decreasing the size of

the workforce means that workers ιτιιιετ be laίd off. Severance pay is thus one cost of

decreasing the size of the workforce. Other costs, somewhat 11arder ιο measnre, are

(α) the costs ofa decIine ίη worker morale that lllay result and (b) tlle potential for de-'.·

creasing the size of the labor ροοl ίη tlle future, as workel"s who are laίd off acquire jobs

with otller firnlS ΟΓ ίη otller ίηdustΓίes.

Most of the models that we consider assume that the costs of increasing and deCl"easing the size ofthe workforce are lίnear functions ofthe numbeI' ofemployees that

are hired οτ fired. That is, there is a constant dollar amount charged for each employee'

hired ΟΙ' fired. TIle assumption of linearity is probably reasonable ιιρ Ιο a ροίηι. As the

supply of labor becoInes scarce, there may be additional costs reqLIired 10 hire more

wοrkeΓS, and tlle costs of laying off workers may go ιιρ substantially if the nuιnber όf

workers la.ίd off is Ιοο large. Α typical cost function fol" changing the size of the

workforce appears ίη Figure 3-2.

2. Ho/ding costs. Holding costs are the costs tllat accrue as a Γesιιlt ofllaving capital

tied ιιρ ίη inventoI)'. Jf the firm can decrease its inventory, tlle money saved coLIld be ίπ-.

vested elsewJlere with a return that will vary witll tlle indnstry and with the specific

company. (Α more complete discussion ofholding costs is deferred to ChapteI" 4.) Holding costs are almost always assLImed Ιο be lίηear ίη the number ofunits being 11eldat a

partictIlar ροίηΙ ίη time. We will assunle for the Ρuφοses of the aggregate planning

analysis that the holding cost is eΧΡΓessed ίπ terms of dollars per ιιηίι held per planning

period. We also will assume that Ilolding costs are charged against the inventorY..

remaining οη hand at tlle end of the planning ΡeΓίοd. This assLI1Ilption is Inade fqr'

convenience onJy. Holding costs could be charged against starting inventory

inventory as well.

ΟΓ

average

3. Shortage costs. Holding costs are charged against the aggregate inventory as

long as ίι is positive. Ια some situations ιι may be necessary to incuI" shortages, \vhich

ετο represented by a negative level of inventory. Shortages can occnr when forecasted

denland exceeds the capacity of the production facility ΟΓ when denlands are higher

than anticipated. For the purposes of aggregate planning, ίτ is generally assunled that

excess demand is backlogged and filled ίη a future period. Ιπ a highly competitive situation, however, ίι is possible that excess demand is lost and the customer goes elsewllere. This case, which is known as lost sales, is Inore appropriate ίη the management

of single items and is more common ίη a retail than ίη a manufacturing context.

As with holding costs, shortage costs are generally assumed to be lίnear. Convex

fllnctions also can accllrateIy describe shortage costs, but lίηear flInctions seem Ιο be

the most common. Figure 3-3 shows a typical holding/shortage cost function.

4. Regular time cost~·. These costs involve tlle cost of prodLIcing one nηίι of output

during regular working hours. Included ίη this category are the actual payroll costs of

regular employees working οη Γegular time, the direct and ind.irect costs ofmateriaJs,

and other mannfactιIring expenses. When aII production is carried οιι! οη regular time,

reguIar payroII costs become a "slInk cost," because the number ofunits produced lllust

equal the number ofunits demanded over any planning horizon ofsufficient length. Jf

there is ηο overtime οτ workeI" idIe time, reglllar payroll costs do ηο! have Ιο be

included ίη the evaluation of different strategies.

5. OIIeI·tinze al1d .S1Ibcontracting costs. Overtime and subcontracting costs are the

costs of production of units ηο! produced οη regular time. Overtime refers Ιο producιίοη by regular-time eInployees beyond the normal workday, and subcontracting I'efers

Ιο the production of iteIns by an outside SUΡΡlίeΓ.Again, ίι is generally assumed that

botll of these costs aJ'e lίηear.

6. ldIe time costs. The complete formulatioIl of the aggregate planning problem

also includes a cost for underutilization ofthe workforce, οτ idle tifRe. Ιη most contexts,

,132 'Chapter

Three

,,3.4, "Α j>rororyp<.prρblim

Aggregαιe PIαnning

133

5. :A'large-manufacturer

ofhousehold.consumer

goods ίιι considering ihtegτating ετιaggregateop!anning nΊodel ,ίηιο its rήanιJfacturing 'strategy. Twe· of th.e, company

-νίοε presitlehtsdisagre~

strongly' astot~e'~atΊie ofthe ~pproach. What arguments

. m'ighteach 'of the'Yide:presi'dents',use'fo'sUpport 'his or'Her 'ροίιιτ of view?

'

FIGURE-3=3

Holding and backorder costs

~ '-,

:~ ι"

j~\

T'~

_c(_"----·;"Ξ{·.;;;(ι,j""v~..

.• Ά,;

'·"ί"'ί);;::Jι~-'

.;.' ,

"

6. .Descrioe' th~ follqwing costs and discu'ssΊhe difficu1ties.that arise ίη attempting

'measure them in area1 operating enviromnent.

"

.-

.

)~,

10

'

~;;':-

α.: Smοοthίl1gιcosΙs

b.' Hdldirig costs

σ, ,PayroJ[ costs

7. OiSCtIS§tJle followiiig statenienl: '''Sirlce''we ιise a roiling production

really doii'theed το know tlIe demaridbey~nd'next

πιοητίι,"

schedιtle, Ι

8, St. Clair County Hospital is attempting το asse~k iis needs [or nurses over the coming four montbs (January to April), The need for nurses depends οη both the

riumbers aηd',tneΊΥΡes of patients ϊη the hospita1. Based οο a study conducted by

constIltants, th§nosp1tal has determined that the following ratios of nurses ιο

pati en ts are required:

Patient Type

the idle time cost is zero, as the direct co~ts of i'dle 'time wbϋld' be taken into account ϊη

labor costs and lower production levels, However, idle titιie could have other consequences' for the firm. For exaIi1ple, i,fthe aggregate units aτe ίπρυτ to another process,

idle time οτι theliIie cott1d, resul!'in hi'gher'costs ιο tlle subsequent ρτοοσεε. Ιτι such

cases, one woUld exp!icitly include εροείυνο idle οοει.

When plannitιg is dohe ata re!ativelY'high Ieve! ofthe fiτm: the effects of intangib!e

factors are mbre ρτουοιιαοεο. Any sο!utίόή td the aggregate p!anning prob!ern obtained

from'a cos't-based ιποde!'musΙbe considereίI carefully in'the context of.companypol'icy. Απ optimal so!ution to a t1iathematica!Ίri.ode!'migHt resultin a policy that requires

fTequent hiring and' firing of p~rsoimel. Such a po!icy may' be infeasib!e because of

prior contract agreements, οτ uiJdesirab!'e~because of the potential negative effects οτι

the firm's public image.

Problems for Sections 3.1-3.3.

'Numbers of'Nurses

(Required per Patient

Major surgery

ΜίηΟΓ surgery

Maternity

C ritical care

Other

Forecasts

'·i·Jan.

Feb.

,Mar.

28

12

22

75

80

21

25

43

45'

94

16

45

90

60

73

0.4

0,1

0,5

0,6

0.3

Patient

."',1'"

"

a. How many nurses shollld be working eachmonth

'ΑΡΓ, ";'

18

32

26

30

77

το most close!y match patient

forecasts?

"ψ"ι 'ι:11

b, Suppose the hospita1 does not want το change its'policy of πο! increasing tlle

nursing staff slze by more than 1Ο percentjn any montll'. Suggest.a sehedule, of

nurse staffing over the four months that meets this requirement and a1so meets

the need for n\Jrses each month.

ι

Ι. What does the term aggregαte unit ofpl-oduction mean? 00 aggregate production

units always correspond to actual items?,Oo they ever? Discuss,

2. What isthe aggtegation

scheme recominended

by'Haxarid

3, Oiscuss the following

problem:

terms and their re!ationship

'

3.4

Α PROTOTYPE PROBLEM

'Ι,,,

το the aggregate

planning

a. Smoothing

b, Bottlenecks

c. Capacity

d. Planning horizon

4. iA local macHine shop eIllploys 60 workers whb have a Y'ariety of skills, The shop

accepts one-time orders and a!SΟ'maίήtaίη's a nuTnber ofregu1ar clients, Discuss some

ofthe difficulties with using the aggregate p!anning methodology in this context.

""

'"

,

"

:

",

One can obtairi adeiIl\hte,,,sollltions for many aggregate pla.ιining problems by hand or by

using relativel'y straightfoτwaτd graphical techniques. Linear progranuning is a means

of ob!aining (nearly)·optimal solutions. We illustrate the different solution techniques

with the'fo]Jowing examp!e.

'

Meal?

Example3.2

Densepack is Ιο plan workforce and production levels for the six-month period January ΙΟ June,

The firm produces a lίη-e of disk drives for mainframe computers that are plug compatible with

several computers produced by major πianufacturers, Forecast demands over the' next siχ

months for a ρartίcύ(ar lίne of drives produced ίη the Milpitas, California, plant are 1,280, 640.

900, 1,200, 2,OOO,and.1 ,400, ..There are currently(end of December) 300 workers employed

ίη the Milpitas plant. Ending inventory'in December is eχpected to be 500 units, and the firm

would Iike to have 600 units οη hand at the end of June,

134

Chapter Three

AggregQte Plιtnning

. 3.4

There are several ways ιο incorporate the starting and,the eriding inventory constraints ίη

the formulation. The most convenient iSsimply το modify the values οΙ the predicted dema

Define net predicted demand ίπ period'l ·as.the predicted demand minus initial inventor:y.

there is a minimum ending inventory constraint, then this .amount should be added Ιο the ,c

mand ίπ period Τ. Minimum buffer inventorie.s also can be handled by modifying the predicte

demand. ΙΙ there is a minimum buffer inventory ίπ eve'r'yperiod, this amount should be added't,

the first period's demand. Ιι there is a minimum buffer inventory ίπ only one period, this amourit

should be added το that period's demand and subtracted from the next period's demand. Actual.

ending inventories should be computed using the original demand pattern, however.

.

Returning to ουΓ example, we define the net predicted demand for January as 780 (1,>280.'"",

500) and the net predicted demand for June as 2,000 (1,400 + 600). ΒΥconsidering net de~

mand, we may make the simplifying assumption that starting and ending inventories are both

zero. The net predicted demand and the net cυmulative demand for the six months January to

June are as follows:

Month

January

February

March

ΑΡΓίl

May

June

Net Predicted

Demand

Net CumuIative

Demand

780

640

900

1,200

2,000

2,000

780

1,420

2,320

3,520

5,520

7,520

Α

Prow,:Ype'Probwn

135

Ιπ order to illustrate the costtra.dg,offs οΙvarίρ.u.s ρ(ος!ucψ<n plans, ,we V\(ίΙΙassume' il!1·,the

example that there are~only three.cos'ts to be considered: costof hiring workers, cost ol'fi-ring

workers, and cost οί holding inveniory. De.fine·

.

(Η

t;

= Co~t.of, hi~ing οοε worker = $500,

= C;st6ffiring o~J,w~rker = $f':ooo"

, (, = Cost.of holding oπ~. unit οΙ inventory

(F

for one month

=

$8Ό.

We require a means()f translating ~~gregate production ίπ units to wo'rkforce levels. B~c'ause

ποΙ all months have an equal number οΙ working days, we will us.e a day as an indivisible υπίί of

measure .arid define

'

Κ = Number οΙ aggregate. units produced by one .worker ίπ one day.

In the past, the plant manager observed that over 22 working days,

cbnstant at 76 workers, the firm produced 245 disk drives. That means

duction ratewas 245/22 = 11.1364drives per daywhen there were 76

plant. It follows that one .worker produced an'average'of 11.1364/76

day. Hence, Κ = 0.14653 lοr this example:

with the workforce level

that οπ average the ΡΓΟworkers employed atthe

= 0.14653 drive ίπ one

We will evaluate two alternatiνe plans ,[ΟΤ managing the. worl<.force that represent

two essentially opposite management

strategies. Plan Ι· is to change the workforce

eacll month iη order Ιο produce enough un.its to most closely,matcll tJ1e demand pattem.

This is known as a zero il1vel1tory ρΙαη. Plan 2 is το maintain the minimun1 constant

workforce necessary to satisfy thenet demand. This is known as the constant wοrkjΌΙ'ce

ρΙαη.

The cumulative net demand is pictured ίπ Figure 3-4. Α production plan is the specification

ΟΙ the production levels for each month. ΙΙ shortages are not permitted, then cυmulative

production must be at least as great as cυmulative demand each period. Ιπ addition Ιο the

cumulative net demand, Figure 3-4 also shows one feasible production plan.

Eνaluation cίf a Chase Strategy (Zero Inνentory Plan)

Here, we will deνeIop a 'production, plan Ιοτ Densepack that minimizes

the leνels of

inνentory the firnl must hold during the six-month planning horizon. Table 3-1 sumIllarizes the ίιιρυι ίηίοτυιειίωι [or the calculations al1d Sl10WStl1e minimum number of

workers required ίη each month.

Ol1e obtail1s the entries ίη the final cOll1mn ofTable 3-1, the m.inimum number of

workers required each Illonth, by dividing the forecasted netdeIlland

by the number of

units produced per worker. The νalue of this'ratio is then rounded tιpwαrd ιο tlle next

FIGURE 3-4

Α feasibIe aggregate

plaη for Densepack

5

6

~Ι;{

3.4

136

Chapter Three

Α P,oto<ype P,oblem

137

Aggreg",e Pi<ιnning

ΤΑΒΙΕ 3-3

Computation ofthe

Minimum Workforce

Required by

Densepack

ΤΑΒΙΕ 3-4

higher integer. We.mustround upwardtoguarantee

that shortages do πο! occur. As an example, consider the month ofJanuary. Foτming the ratio 780/2.931 gives 266.12, which

ίε τottnded ιιρ Ιο 267 workers. The number of working days each month depends ιιροο a

variety of factors, such as paid holidays and worker schedules. The reduced number of

days ίπ June is due το.a planned shutdowη ofthe plant ίη the last week of Ιυτιε.

Recall that the nttmber'ofworkers

employed at the end of December is 300. Ηiήηg .

and fiήng workers each month το match forecast demand as close!y as possible resttlts

ίπ the aggregate plan given ίπ Table 3-2.

The number of units prodLIced each month (τοίυαιυ F ίπ Table 3-2) is obtaίned by

the following formula:

'ι

Number of

units ρτοσυοοσ

Number

Average number of

.

of workers χ aggregate LInltSproduced ιτι

a month by a slngle worker

rounded το the nearest integer.

The tota! cost of this ρτοοιιοιίοη p!an is obtained by mtt!tip!ying the totals at the

bottom of Table 3-2 by tbe ερρτορτίειο costs. Ροτ this example, the total cost of hίήng,

firing, and .ho!ding is (755)(500) + (145)(1,000) + (30)(80) = $524,900. This cost

must now be adjusted το ίnc!LIdethe cost ofholding Ιοτ the ending inventory of 600 units,

which was netted ου! of the demand for Ιιιυε, Hence, the tota! cost of this plan is .

524,900 + (600)(80) = $572,900. Note that the initial inventory of 500 units does τιοτ

enter ίηΙο the ca!culations because ίι will be netted ουι dttring the month of January.

Ιι is usually impossible το achieve zero inventory at tl1e end of each planning period

because i(is ποΙ possible το employ a fractiona! number of workers. Ροτ this reason:,

there will almost always be some inventory remaining at the end of each period ίπ

addition Ιο the inventory required Ιο be οτι hand at the end of the planning horizon.

Ιι is possible that ending inventory ίπ one οτ more periods could bui!d ιιρ to a ροίυτ

w.here the size of the workforce could be reduced by one οτ more workers. Ιτι this

example there is sufficient inventory οη hand ιο reduce the workforce by one worker ίπ

the months of both March and May. Check that the resu!ting plan hίΓes a total of

753 woτkers and fires a tota! of 144 workers and has a total of on!y 13 units of inventory. The cost ofthis modified plan comes Ιο $569,540.

Evaluation of the Constant Workforce

Plan

Now assume that t!le goa! is ιο e!iminate complete!y the need for hiring and firing

during the planning horizon. !π order to guarantee tI1at sl10rtages do ποΙ occur i,n any

JIIventory Lcvels for

Constant Workforce

Schedule

period, ίι is necessary Ιο coιnpute the minimum workforce required for everγ month ίη

the planning horizon. Ροτ January, the net cumulative demand is 780 and there are

2.931 units produced per worker, resulting ιτι a τυίυίπιιυ» workforce of267 ίη JanLIary.

There are exact!y 2.931 + 3.5 Ι 7 = 6.448 units produced pel" worker ίη January and

February combined, which have a cumulative demand of 1,420. Hence, !,420/6.448 =

220.22 = 221 workers are required to coverboth January and February. Continuing to

form the ratios of the cumulative net demand and the cumulative number of units

prodLIced per worker for each month ίιι the horizon results ίη Table 3-3.

The minimum number of workers required for the entire sΊX-month planning period

is the Π1aΧίmum entry ίη coluι'nn D ίτι Table 3-3, which is 411 workers. It is on!y a

coincidence tl1at the maximum ratio οccuπed ίη the final period.

Becatlse tllere are 300 wo.rkers employed at the end of DeceΠ1ber, the constant

workforce plan requires hiring 111 workers at the beginning of January. Νο further hiring

and firing ofworkers are required. The inventory leνels that resu!t from a constant work·

force of 411 wo.rkers appear ίη Table 3-4. The monthly production leνels ίη column C ΟΙ

the table are obtained by mtIltiplying the number ofunits prodnced perworker eacll Π10ntt

by the fixed workforce size of 41 Ι workers. The total of the ending ίnνentoΙΊ leνels ί~

5,962 + 600 = 6,562. (Recall the 600 units that were nette<1οιι! of the deιnand for JlIne ..

Hence tl1e total inventory costofthis plan is (6,562)(80) = $524,960. Το this we add t11(

cost of increasing the workforce froιn 300 ιο 411 ίn JanLIary, which is (Ι 11)(500) =

$55,500, giving a total costofthis plan o.f$580,460. This is sσmewhat higherthan the cos

oftlle zero inventory plan, which was $569,540. Howeνer, because costs ofthe ιwo plan

are close, ίι is like!y that the coιnpany would prefer the constant workforce plan ίη orde

to avoid any unaccounted for costs of making freqLIent changes ίn the workforce.

138

Chapter Three

3.4

Aggregare Planrtίng

Mixed Strategies and Additionalfonstraints -

",·1

<. .~

,:i-tπ!~:

Η,1

The zero inventory plan ana constant workforce strategies just treated ate l?uie,.strafe1

gies: they are designed to achieve one objective: With τυοτε flexibility,sιhal1'm6dific~tions can result ίή, dJamaticaliy lower. c6.8t~:;One -migbt que~tion tbe interest }Ίι ίiiιinιrai

calculations cbnsidefing tbat aggregate~planhing 'prohlems can be formuJafJd "and

solved optimally by Jinear programming.".

...

'.

,.'.

.'

Manua). ,αi\cιi1atίοns· eiίhance ίntuitίοrίandιihderstandίήg.

Cbmj:>liters aredumb. It ~\./

easy to overlook a critical constraint (π objectlve when using a computer. Ιι 's inιportant Ιρ ,

bave feel for the rίght soJution beforesolvmg a probJem οτι a computer, so that gJaring'

mistakes are obvious. Απ important skiH, largely ignored these days, is being able to do'a

ballpark calculation ίn one's Ilead before pulling ου! the calculator οτ computer.

Figure 3-4 shows the constant workforce strategy for Densepack. The hatched area

represents tbe inventory carried ίη each month. Suppose we alJow a sίngJe change ίη the

production rate during the six months. Can you identify a strategy fi:om the figύre tI1at

substantially reduces inventor)ι without pennitting shortages?

' ,

",ι,,·, '

Graphically, the problemis

το cover ihe cuΊnulative net demaήtl clIrve with ~ό

straight lines, rather than one straigbt JiJ;1'e.

This can be accompJished by driving'fbe net

inventory ιο zero at the end of perίod 4'(April). Το do so,we'need ιο produce enolIg]j ,

ίη each oftbe months January through Αρτll ιο meet the cumuJative net demand each

month. 'Πιετ means we need το produce3,~20/4

= 880 tJnits ίη each of the .first four

months, Ιπ Figιιre 3-4, the line connecting'the origin το 'the cumulative net dem'and in'

Aprillies wholly above the ουιυιιίειίνε net detnand curve:for tl1e ρτίοτ rtιonths. Ifthe

g.raph is accurate, that means that there shouJd be τιο shortages occurring ίη these

lnonths, The May and Ιιυιε production is then set το 2,000, exactly matching the net

demand ίη these lnonths, With this policy we obtain

Cumulatiνe

NetDemand

.

ΑΡΓίl

May

June':

As we will see ίη Section 3.5, this poJicy .turns·out ιο be optimal for the Densepack

problelll,

:.,

The graphical solution method also can be used when additional constraints are pres-;,

ent. For exanΊPIe, suppose that the production capacity ofthe plant is only 1,800 units "._....

'

per montb. Tben the policy is infeasible in May and June. Ιη this case the constraint ;1Ω\ΊΙ.' Ι,;"~ Γ

means tl1at the slope of the cumulative· ,production curν,e is bounded by ] ,800, One

solHtion ίη this case would be to produce 980 ίη each of tlTe first four months and

1,800 units ίη each of the last two months. Another constraint might be that the maximun1 change fromone τηοηΙlι ιο the next be ηο more than 750 units. Suggest a producιίοη plan ιο meet this constraint.

, TlTes,eare a,few'examp.les of constraintsthat mighι.arise ίη using aggregate planning

methodology, As. the constraints become:. more compJex, finding good solutions

graphically becomes tnore difficult: Fortunatelyl·most cbnstraints of this natl1re can be'

incorporated easily into the lίιιear programming formuJations of aggregate planning

probJeJns.,

ί"l-'

"1

.

"

;:,

"ι . .ι.,·

,~

Ι;

i.~'·

,~-,~I

''1';'':

:τι

\;t~iT ;~;{)

'J ••

';,

,Ι,'

.

,'Γ

,

ιω\ , 'j:or;~asted

Deman,d'

, (t~ousands of, packages)

jf.

300,

120

'1

2

3

4

5

20o'

110

135

, ,A'ssume that ea,ch wοrker,staΥsΌη.the.,jόb, for at!IEast one year, and that,Grey

'currently has three workers οα the payroiI. Heestimates that he wψ have 20,000

.packages on'lfantl'at',the

ofthe ς:urrent y~at: A:ssuiiι~'that, οε theaverage,

ach

worker i,spaid $25,000 per year and is r~s'poiιsible for prodlIcing 30~000 packages.

In"elitO'ry' .costs 'havevl)eeh 'estiInated td"be" 4"ce'ιιts pei package per year, and

shortages fι~e'1)ot aI10\Ved;f' η .:<,

"Ι

'

i

.

Base<;loiι' the effort( of interνiewing and, training new workers, Farmer Grey εεtimates tha.t ίι ,costs $,500 for, each worker hired, Severance pay amounts to $1,000

per worke,r. " _

end

ι::

.. α" Assutning, that sho'rtages are ηοί allowed, determine

the minimum constant

workforce that he will Jieed over the next five years.

Cumulatiνe

Production

880

1,760

2,640

3,520

5,520

7,520

!-\..-

~,:ι

Η; _

~ ,ι

b. Evaluate tbe cost of the pJan found ίη part (α), ,

tl"

January

February

March

'ι:

Pro",rype,ProbJem 139

, 9,. Harold Grey QWΠS)i sm3lI fann ίn .the Salinas Valleythat grows apricots. The. apri; ;"cots,are·dried -οιι the .premise,s and sold· to a ,number,of large supermarket chfiins.

·Based οτι past,~xperϊe\lce,and comllli,tted contracts,h'e,esiimates

that s<ilesΌver the

next five years ihthotlsanos of',I'ackages wil\be as follows:

a

Month

;4;'

'~·ι

Α

10, F,0r'the datagi~eh

ίη ProbJem 9, ιraph the cumulative net demand.

α. Graphically detennine a production plan that changes the production rate exactly

once during tp.e five years, and evιΗuate the cost of that plan.

b, Graphicany deter,mine a product~on plan. that changes the prodlIction

exactly twice dlIrίng the five years, and evallIate the cost of that plan.

rate

11. Αη ilnplicit assurnption made in Problem 9 was that dried aprίcots unsold a( the

end of a year couJd be sold ίη subsequ~nt years, Suppose that apncots unsold at the

end of any year π;ιust be discarde,d, Assume a disposal· cost of $0.20 per package.

Resolve Problelll 9 under these conditions.

12. The personnel departrnent of the Α&Μ Corporation wants to know how many

workers will be needed each month for the next six-month production period, The

following is a monthly demand forecast for the six-month peribd.

Month

July

August

September

October

November

December'

Forecasted' Demand

1,250

1,100

950

909

1,000

1,150

3.5

140

Chapter

Three

Soi"rionσ{Aggregaιe PlanningProblems.1ry

ΙίneΙJi"ΡrΟgTamrhίng

~41

AιweRaι, PlanninR

α. DeterrniI\e. the mίnίmιιm ..constarit:workforGe:i,t)Ίat",will

The lnventoτy οτι harid at tlJe endΌf Ιιπιε was 500 units ..:τheocompany, wants 10

malntaln a mlnimum inventory of 300 tInits each month 'and w~~ld ΊίΊce to have

400 unlts 'οη hatιd at the end of Deeember.!.Each ιιηίί requires five employee-honrs

to ptodnce .•.thereare'20

workingdayseach

mbilth,iιnd each emp1oyeeyνorks an

eight-honr day. Tlie workforceat the end·of June was'·35 workers.

" ';~',

'ο

α. What' ls the' minimum constant workf~rce r~;quired to meet demand over the

next four months?

Ά

b. Αεειισιε that CΙ, = ω cents pec cο(}kίe'Ρer,ιmοnt11;,cΗ

Eva1uate the cost ofthe p1an detlved ·ίη part (α),

=

$100, and cF

=

$206. '

3.5

Days

J'anuary

February

22

March

"6

21

ApriI

19;

[ΊΛaΥ

23

20

June

July

August

September

October

November

December

24

12

19'

22

20

16

'τ,'·,·'.:".-'"

.

,Ι'

-,

ΑGG~~,G~Τ~,~ΡίΑΝΝljΝGPRO'B,LEMS

SOLUTlON OF

Βγ LINEAR PROGRAMMING

_ι~,

\f

Linear prograJI)ffii.ng ί5,a τοσο uS,e<!.

to ,de~cribe a generaJ,class of optimization problems.

The objecti:ve is tp,determine va1ues 9fn n.onnegative rea~variables ίη order το maximize

ΟΓminlmize ε.Ιίαεετ .function of these.yariab1es ψat ls subject.to m lίnear constralnts of

,ιηese variab1es.1 Th,e primary ~dvanta.ge iniformulating a,problem as a 1inear program ls

that ορτίπιε! so!tItlons can be found 'Very efficiently QY'the'si:nιplex method.

When all costf\mctions are lίnear, there ls a linear programming formulation of the

g~ne~a1:aggregat~IPlanning problem.· Because of the efficie)lcy of commerclal 1inear

,ΡrοgramΠ1ίng οοαοε, this means t4aι'(essentίaIlΥ) optima1 sqlutions can be obtained for

2

Cost

Predicted Demand

(ίπ $10,000)

340

380

220

100

490

625

375

310

175

145

120

165

]nventory holding costs are based οη a 25 percent anntIal lnterest charge. !t'is'

anticipated that there will be 675 workers οη the payroll at the end of tlle cnrrent

year and inventories will amοunΙlο $120,000. The firm wotIld like to 11aveat least

$100,000 of inventory at the end of December next year. 1I is estimated tllat eabll

WΟΓkeraccounts for an average of$60,000 ofproduction per year (asstIme that one·

year conslsts of 250 working daYs). The cost of hirlng a new worker ls $200, and

the cost of !aYlng off a worker ls $400.

Parame~ers

and Given Information

The following νείιιεε ar~ asslImed to'be

known:

τ

,CH

= ~ost'of,hiring

one.worker,,,",

,C,p = ,Cost:of firing ουε worker; πΙ"

C[

Month

,ί

very large problems

14. Α local semlconductor firm, Superchip, ls p.1anning lts workforce and productlon

1evels ονετ' the ne~t year. Tlie firm' fnakes a'vIιribty όf'm'icrΟΡrocessοrs and uses sa1es .

doJlars as lts aggregate ρτοσυοιίοιι measure: Βεεοο ση orders recelved and sales ,.

forecasts provided by the marketing department, the estlmate of dol1ar sales for the

next year by month is as follows:

.Production

'r,'

>" .

b. Determine the' prodnction plan that' meets demand but does αοι hire οτ fire

workers dύπng the six-monih period.

13. Mr. Meadows Cookie COJnpany makes a variety of chocolate chip cookies ίη tbe

plant ίη Albion, Michigan. Based ωι orders recelved and forecasts ofbuying babits,

ίτ ls estimated that the demand for the next [οιιτ months is 850, 1,260,51 Ο, and 980,

expressed ίη thousands of cookies. During a 46-day period when there were

120 workers; the-company produced 1.7 mil1ion cookies. Assume that the'ntImber '

of workdays over the [οιιτ months are respectively 26, 24, 20, and 16. There are

currently 100 workers employed, aiid thete ls υσ startlng inventory of cookies.,

;'1- ,\1'":-'

] 5. Fot the datainProblem~14, determine the cost oftheplaiιthat changes theworkforce

size each period to most '~lb!ie1y;n~tch the demaιid.

16. Graph the cumιι1atίve,net'delnand fofthe SUΡerchίΡ data of.Problem ]4. Graphically deterrnin"e' a, Ρrοdιιctίοή;ρ1aπ'that

changes production levels υο mόre that!

tllree tirnes, and deterrnlne the tota1cost of that p1an,

α, Determine,a minimum ίηv~~!ότy jxoduction plan (i.e., one that al10ws arbitrary

hiring andfiring).

meet the predicted

demand fot the comlng ~e&r·,i";.,,, ; ,

";,,

b. Evaluate.the cost όftheρlan deterh1ined Ια -part (αΙ.

= Οοει of holding one υηίι of· stock for one period,

cR = Cost Ο[ΡrοducίηgC;~eΉ~ίt~~

re~lar

time,

Co = lncr~nie,htal cost of,prod~cing o'η~ unit οτι oyertime,

Cu = Idle cost per unit,o~prodtIctjon,

.. ,"

Cs = Cost to subcontriιct one υηίι ofproduction,

'.,

ηι = Number οfΡrοdιιctiοn

daΥs.lrtΡeι'iορ.I",

Κ = Number of aggregate units produced by oIίe worker ίη one day,

10 = 1nitial;inyentory

οη haI)d,atthe.start

o~ the p.lannipg 110τίΖΟΠ,

Wo = !nitia1 workforce at the start of the planning horlzon,

Dt = Fοreca'stΌf demand ίη period t.

The cost parameters a1so may be tirne dependent; thatls, they may change wlth t.Timedependent costparameters could be ύsefυ1 for Π10deiing changes ίη thecosts οfhίήng

or firing due, for example, to shortages ίπ tl1e labor ροοl, οτ changes ίη the costs of ρτοduction and/or storage due to slJortages ίη tiie supply of resources, οτ cllanges ίη interest

rates.

, An overνiew

of Iinear programming

2 The qualifier

is intluded

point Iater.

can be found

because rounding ma{ιjive

ih Supplement

suboptimal

1, which foIIows this chapter.

solutions.

There wiII be more about this

142

Chapter

Three

Aggrcgatf

Planning

3.5

Ρι = Production

ι,

Ιενεί ίη period Ι,

Ιι = Inventory leve] ίη period

ι,

Ηι = Number ofworkers

hired ίη period ι,

FI = Number ofworkers

fired ίη period

υ

ι,

τ

ΟΙ = Overtime production ίη units,

υι = Worker

of Aggre~αte PIanning Problems.by Linear Ρrο.ι:rammίη,(!' 143

lη addition Ιο these constraints, lίnear programming requires that all problem variables

be nonnegative. These constraints and the nonnegativity constraints are the minimum that

must be present ίη any formtllation. Notice that (Ι), (2), and. (3) οοτιετίιιιιε 3 Tconstraints,

rather than 3 constraints, where Tis the length ofthe forecast horizon.

The formu]ation also reqnires specification of the initial inventory, 10, and the ίηίtia] workforce, Wo, and may inc]ude specification of the ending inventory ιτι th.e final

period, lτ.

The objective function inclndes all the costs defined earlier. 'Πιο lίnear programming

forιnll]ation is to choose values ofthe probleIn variables W" Ρι, 1" Η" Ft, Ο"

ι, and S,lo

Problem Variables

The following are the problem variables:

WI = Workforce ]eve] ίη period

Soluιion

Σ (cHH

Minimize

idle time ίη units ("undertime"),

+ cpF, + ctl, + cRP, + coOI + cυU, + C8S,)

I

'=1

SI = Number of units st1bcontracted from ontside.

snbject 10

The overtime and id]e time variables are determined ίη the following way. The

term Knt represents the number of units produced by one worker ίη period t, so that

Kn,W, would be the number ofunits produced by the entire workforce ίη period ι. However, we do υοι require that Kn,W, = Ρ,. If Ρ, > Kn,Jflt, then the number of υυίιε ρτοdnced exceeds what the workforce can ρτοσυοε οη regular time. This Ineans that the difference is being produced οη overtime, so that the number ofunits produced ωι overtime

is exactly ΟΙ = Ρ, - KntW,. If Ρι < KntWt, then the workforce is producing less than ίι

shotIld be οη regular time, which means that there is worker idle time. The idle time is

measured ίη units ofproduction rather than ίη time, and is given by ι = Kn,W, - Ρι.

υ

W, = W,_ 1 + Ηι - F,

(conservation

Ρ, = Kn,WI

+ Ο, -

for Ι :s t :s Τ

of workforce),

U,

for Ι :s t :s Τ

(production and workforce)

1ι = Ιι- ι

+

Ρ,

+ SI

- Dt

for ] :s t:s Τ (inventory balance),

Η" F" Ι,, Οι, U" S" W" Ρι ~ Ο (nonnegativity),

(Α)

(Β)

(C)

(D)

ρίιιε any additiona] constraints that define the values of starting inventory, starting

workforce, ending inventory, οτ any otheI' variab]es with νείιιεε that arefixed ίη advance.

Problem Constraints

Rounding the Variables

Three sets of constraints are required for the ]jnear programming formιιlation. They are

included το ensure that conservation of labor and conservation of units are satisfied.

Ι. Conservation of workforce constraints.

WI

=

Wt-1

Number = Number

of workers

of workers

ίη t

ίη Ι - Ι

+ Ηι

+ Number

hired

ίη Ι

Ft

- Number

fired

ίη Ι

for Ι :s t :s Τ.

2. Conservation of units constraints.

Ιι

=

lι- ι

[nventory = Inventory

ίη ι

ίη ι - Ι

+

+

Ρι

Number

ofunits

produced

ίη Ι

3. Constraints relating production

Ρ,

Nuιnber

of units

prodtIced

ίη t

= KntW,

= Number

of units

produced

by regtIlar

workforce

ίη ι

+

+

+

+

Dt

SI

Number

- Demand

ίη ι

ofunits

subcontracted

ίη ι

for 1 :s ι :s Τ.

levels Ιο workforce levels.

Ο,

U,

NuInber - Number

of units

of units

prodtIced

of idle

οη overproduction

time ίη t

ίη t

fol' ] :s ι :s Τ.

Ιn general, the optimal values ofthe problem variables wiII τιοτ be integers. However,

fractional va]ues for many of the variables do ιιοι make sense. These variables include

tlle size of the workforce, tlle number of workers hired each ρειίοτί, and the number of

workers fired each period, and είεο may include the ηUΠ1ber of units produced each

period. (Ιι is possible that fractional numbers of units could be produced ίη εουιε

applications.) One way Ιο deal with this problem is το require ίη advance ιίιετ some οτ

aII ofthe problem variab]es assume οηlΥ integer values. Unfortunately,

tlliS makes the

solution algoritllm considerably more CΟΠ1Ρ]eχ.The resulting ΡrοbleΠ1, known as an ί ηteger lίnear ΡrοgraΠ1Π1ίηg prob]em, requires mtIch Π10re computational effort Ιο solve

than does ordinary Jinear prograInming. For a moderate-sized pΓOb]em, solving the

prob]em as an integer ]jnear program is certa.inly a reasonabJe alternative.

Ifan integer programming code is l1navailable οτ ifthe problem is simply Ιοο Jarge

Ιο solve by integer programlning, linear programmingstill

provides a workable solution. However, after the lίnear programIning soltItion is obtained, some of the problem

variables must be rounded Ιο integer valtIes. Simply rounding off each variable Ιο the

closest integer may lead Ιο an infeasibJe solution and/or one ίη which prodllction and

workforce levels are inconsistent. It is ηο! obviolls wllat is t]le best way to round the

variables. We recotnmend the following conservative approach: rollfid tlle values ofthe

numbers of workers ίη each period ι to W" the next ]arger integer. Once the va]ues of

W/ are determined, the va]ues ofthe other variables, Η/, Ft, and Ρι, can be fOl1nd along

with the cost of the resulting plan.

Conservative rounding will always result ίη a feasible sollltion, but will ΓarelΥ

give the optimal soltItion. The conservative solution generally can be improved by

trial-and-error experimentation.

144

Chapter Three

3.5

Aggrcgaιe Plann,ng

SQluιionο[ Aggregare Planning Problems by Unear ProgramminR

14!

There iS τιο guarantee that if a problem can be formulated as a lίnear program, the

final solution makes sense ίη the context of the problem. Ιτι the aggregate planning.

problem, ίι does αοι make sense that there should be both oνertime production and idle

time ίη the same period, and ίι does τιοι make sense that workers should be hired and.

fired ίη the same period. This means tllat either one οτ both of tlle variables ΟΙ and U;

must be zero, and either one οτ both of the variables Η, and F, must be zero [οτ each t/:.

Ι ,s; t ,s; Τ. This [eqnirement can be included explicitly ίη the probleIn formtIlation by ~i,

adding the constraints

' .

O,U, = Ο

for Ι ,s; t,s; Τ,

H,F, = Ο

for Ι

,s;

ι,,;; Τ,

since iftlle prodnct oftwo νariables is zero ίι means τίιετ at least one ηιυει be zero. Unfortunately, these constraints are τιοι Ιίαεετ, as they involve a prodnct of probleni

variables. However, ίι turns ου! that ίι is αοτ necessary Ιο explicitly inclnde thes~

constraints, becanse the optimal solntion ιο a lίπear programming problem always οοcurs at an extreme ροίτιτ oftlle feasible regioll. It can be showll that every extreme pdint .

solntion autotnaticaIIy has tlliS property. Ifthis were ιιοτ the case, the lillear prograrrt:

ming solution wotIld be Il1eaningless.

'.

Extensions

Linear programming also can be used to solve somewhat more general νersions ofthe

aggregate planning problem. Uncertainty of demand can be acconnted for indirectly by

asstIming ιίιετ there is a minilllnm bnffer illventory Β, each period. lπ that case we

wotIld include the constra ints

for Ι ,s; ι,,;; Τ.

[,~B,

'Πιε constants Ξ, would have ιο be specified ίπ advallce. Upper bonnds ου the number of workers hired and the nutnber of workers fired each period could be included in',;t.C!

a similar way. Capacity constraints οπ the amount of production each period cduld'

easily be represented by the set of οοηειτείτιιε:

P,,s; C,

for Ι ,s; t ,s; Τ.

The lίπear programming formnlation introduced ίπ tlliS section asstIIned that inνen-:~j'

tory leνels wotIld neνer go negative. However, ίn some cases ίι Inight be desirable oτ~

even necessary to allow demand Ιο exceed slIpply, [οτ example, if forecast demand :

exceeded prodnction capacity over some set of planning periods. lπ ol'der ιο treat

backlogging όf excess demalld, the invelltory level [Ι must be expressed as the djffer:

ence between two nonnegatiνe variables, say [,+ and 1,-, satisfying

[Ι

= [/ - [,-'

1/ ~ Ο,

lπ the developmellt ofthe lίπear programming model, we stated the requirement that

all the cost functions ηιυετ be lίπear. This is ιιοι strictly correct. Linear programming

also can be nsed when the cost flInctions are C017vex piecewi8e-li17ear !ul1ctions.

Α οουνοκ function is one with an illcreasillg slope. Α piecewise-linear function is

one that is composed of straight-line segments. Hence, a convex piecewise-linear

functioll is a function composed of straight lίnes that Ιιενε increasing slopes. Α typical

exalnple is presented ίπ Figure 3-5.

[η practice, ίι is likely that some ΟΓ all of the cost Ιιιαοιίωιε for aggregate planning

are convex. For example, if Figure 3-5 τερτοεεητε the cost of hiring workers, then tlle

marginal cost of IJiring οιιε additiollal worker increases with the number of workers

that Ιιενο already οεετι Ilired. This is probably more accnrate than asstIIning that the

cost of hiring ουε additional worker is a οοπετωιτ jlldependent of tlle nnmber of

workers previously hired. As more workers are hired, the available labor ροοl shrirιks

and lnore effort mIIst be expended Ιο hire tlle remailling available workers.

lη order Ιο see exactly how convex pίecewίse-~jllear functiolls would be incorporated

ίnΙο the lίnear ΡrοgΓaιnιnίπg formlllatioll, we wil1 consider a very silnple case. Snppose

that the cost oflliring new workers is represented by the function pictured ίπ FίgUΓe3-6.

Accordillg Ιο the figure, ίι costs CHI Ιο Ilire each worker υπιίΙ Η* workers are hired, and

ίι costs C/12 for each worker hired beyond Η* \vorkers, with CHI < Cfl2. The variable Η"

the number ofworkers hired ίll period ι, mnst be expressed as the stlln of two variables:

ζ ~Ο.

The holding cost wonld 1l0Wbe charged against [/ and the penalty cost for back οτ'

ders (say cp) agaillst [,-. However, notice that for the solIItioll to be sensible, ίι mnst be

true that [/ and 1,- are ηοΙ botll positive ίη the same period t. As witlJ the oνertitne and

idle tilllC and the hirillg alld. firing variables, the properties of lίπear programming wil1

guaralltee that this holds wi Ιπου! having Ιο explicitly illclude the constraint [/ ς = ο:

ίπ the fOI·mlIlation.

Η, = Ηι,

+ Η2,.

Interpret Ηιι as the nUlllber ofworkers hired up Ιο Η* and Η2, as tlle llutnbeI' of

workers hired beyolld Η* ίπ period Ι. The cost οΓ hiring is now reΡΓesented ίη the

objective fUllction as

τ

Σ

I=Ι

(CI'IIHII

+ CInH2'),

146

Chapter Three

3.6

."'κgregare Plαnning

SoI<ing Aggregαte Planning Problemsby,Lineαr

Progrcmm'ng' Ah. EXDmple

147

be.J;Iloreefρcient for)argeproblem~ aηq <eOUldpI9y,idesoMions whep, some ofthe cost

functions are nonlinear. Α paper that details a transportation-type procedure ιυοτε. effic

cient than thesimplex method for solving aggregate planning problems is Erengιic and

FIGURE 3-6

Convex piecewiseIinear- hiring cost

function

>':

Tufekci(1988

SOιVING AGGREGATE Pi:.ANNiNGPROBLEMSBYLINEAR

PROGRAMMING: ANE~AMPΙE

We ,wiHdemonstrate the use oflinear programming'by:(Jnding

theoptimal solution ιο

the example presented ίn Sectlon 3.4. As there is υο subcontracting,.overtime,

στ id1e

time aHowed, and the cost coefficients are constant with respect το time, the objective

function is simply

" ·6

Σ Ηι + 1,000Σ

Minimize. ( 500

,t=l

6

.,.

Ρ, +80

ι=\

6

ΣI

ι=ι

t).

The boundary conditions .comprise .the specifications of .:the initial inventoτy οί

500 unlts, .theinitlal wprkforce of 300 work:ers, and. the. ending inventory of 600 units.

These are besthanp1edby including a separate additional constralnt for each boundary

and the additional

condition.

The constraints are~.όbtaίηed by substltutlng t "=1, ... , 6 ίηΙο Equations (Α), (Β).

and.(C). The·fuH set:qf.constraints expressed ίη st~ndard Ιίτιεετ programmίng forma1

(with all problemvariables

the 1eft-hand side and nonnegatlve constants ση thε

right-hand side) is as fol1ows:

ση

constraints

Ht ='Ηιι + H2t

Ο :5 Ηιι:5 Η*

Ο

:5

H2t

must also be included.

Ιη order for the final solution (α make'sense, itcan never be the case that Ηιι < Η*,

and H2t > Ο for Some t. (Why?) Ηοινενοτ; because lίnear programming searches for ιΜ

minimum costsolution,

ίι will force Ηιι ΙΟ its maximum value before aIIowing H2t Ιο

become positive, since CHl < CH2' This is the reason that the cost functions must be

convex. This approach can easily be extended το more than two linear segments and to

any of the other cost functions ρτεεέιιι ιιι the objective function. 'Πιε technique is

known as separable convex programming and is discussed ίη greater detail ίn Hillier

and Lieberman (1990).

.

.'

Other SοlutίοnΜetl1όds

Bowman (1956) suggested a transportation form.ulation ofthe aggregate planning problem when back orders are ηοι permitted. Several authors have explored solving aggregate

pIanning problems with specially tailored algorithms. These algorithms could be faster

[ατ solving large aggregate planning problems than a generallinear programming code

such as υΝΟο. Ιτι addition, some of these formulations allow for certain types of nonlinear costs. For example, if there are economies of scale ίn production, the production

cost function is likely Ιο be a concave function ofthe number of units produced. Concave

cost Ιϊυιοιίοηε are not as amenable το linear programming formnlatio11s as convex funcc

tions. We believe tllat a general-purpose linear programrning package is sufficient for

most reasonable-sized problems that one is likely ιο encounter ίη the real wOl·ld. Ηοινever, the reader sho.uld be aware that there are alternative solution techniques that conld

·= Ο,

W1

-

Wo - Ηι + Fι

W2

-

Wl

-

W] - W2-

.=

Η2 + F2

Η]

Ο,

+ F3\=0,

W4 - W3 - Η4 + F4 = Ο,

Ws - W4 - Hs + F'i;= Ο,

W6 -

-

Ws

Η6

+ Ψ6

(Α

= Ο;'

+ 10 = 1,180,

+ I1 =640,

Ρ3 - Ι] + 12 = 9ΡΟ,

Ρ4 - 14 + /3= 1;200,

Ps - 15 + 14= 1,000,

Ρ6 - 16 + 15 = I?~OO;

Ρι - I1

Ρ2 - /2

Pj

-

Ρ2

-

3.517W2 = Ο,

Ρ3

-

2.638W] = Ο,

Ρ4

-

3.81Or1l4 = ο,

2.931 Wl = Ο,

Ρ5 - 3.224W5 =0,

Ρ6 -

(Β

2.198W6 = Ο;

(C

148

Chapter

Three

ΑglζΓeφιe

Plonning

3.6

WI,·

.. ,

W6, Ρι,· .. , Ρ6, lι,· .. ,/6, FJ,

•••

,

F6, Ηι, ... ,Η6;ΞΞ:

SoIving Am,rregate [)!anning Problems b-yLinear Programming:

An ExαmfJle

149

Ο;

Wo = 300,

10 = 500,

/6 = 600.

We Ιιενε solved this lίnear progranl using the LlNDO system deve]oped by Schrage

(Ι 984). The output ofthe LINDO program is given ίη Table 3-5. Ιη the ειιρρίοηιεητ οο

linear programming, we a]so treat so]ving linear programs with ExceJ. The Exce!

ΤΑΒΙΕ 3-5

Linear Programming Solution of Densepack Problem

Solver, of course, gives the same resυlts. The value of the objective function at the ορtimal solution is $379,320.90, Wllich is considerably less than that achieved with eith.eI"

the zero inventory plan ΟΓ the constant workforce plan. Ηωνενετ, this cost is based ου

fractional values ofthe variables. The actnal cost wiJJ be slightly higher after rounding.

FoJJowing the τουικίίιη; procedure recommended earlier, we will τοιιικί alJ the valιιοε of W, το the next higher integer. That gives WI = ... = W4 = 273 and Ws = W6 =

738. This determines the νείαοε ofthe other problem variables. This means that the fίrm

shonld fire 27 workers ία JanlIary and hire 465 \vorkers ίη May. The complete solution is

given ίη Table 3-6.

Again, because co!umn Η ίη Table 3-6 corresponds το net demand, we add th.e

600 ιυυτε of ending inventory ίη June, giving a total inventory of 900 + 600 = 1,500

units. Hence, the total cost ofthis plan is (500)(465) + (1,000)(27) + (80)(1,500) =

$379,500, \vhich represents a sHbstantial savings over both tlle zero inventory plan and

the constant workforce plan.

'Πιε restIlts of the !inear programming ana!ysis suggest another plan that might

be more suitable for the company. Βεοειιεε the optimal strategy is το decrease the

workforce ίη .fanuary and blIild ίι back ιιρ again ίη May, a reasonab]e alternative

might be to πο! fire tlle 27 workers ίπ JanlIary and ιο Ιυτε fewer workers ίη May.

]η this case, the most efficient method for finding tJle οοσεοι nl1mber of wοrkeΓS

to hire ίπ May is ιο simp]y re-solve the lίnear pτogram, bl1t without the variables

FI, ... , F6, as αο firing of workers means that these variables are forced ιο zero.

(lf νου wish το avoid reentering the problem ίπΙο the computer, simply append the

old formυlation with the οοηετιείατε Ρι = Ο, Fz = Ο, ... , F6 = Ο.) The optima!

nl1mber of workers to hire ίη May turns οιιι το be 374 if ηο workers are fίred, and

the cost ofthe plan is approximately $386,120. This is only slightly more expensive

than the optimal plan, and has the important advantage of ποι requiring the firing of

any workers.

Problems for Sections 3.5 and 3.6

17. Formnlate Problem 13 as a Jinear program.

include all tlle reql1ired constraints.

Be sure ιο define aJJ variables alld

1 SO

Chapter

Three

Aggre~αte ΡΙαπnίιιι

3.6

18. Problem 17 was solved οα the computer. The lίnear ΡrogΓammίng ουιρυι of the

ΡrοgΓam is as follows:

SoI'Iinf:" Aggregαιc I)kInning

α. Write down tl1e complete

ΡrοblCΠL~by Uneαr Programfning:

lίnear programnling

'forιntIlation

Απ Example

ofthe

151

revised

problem.

b. Solve the revised problem using a lίηear programming code. What difference

does the new 11iringcost function make ίn the εοίυτίοη?

LΡ ΟΡΤ1ΜυΜ

FOUND

ΑΤ STEP

OBJECT1VE

1)

FUNCT10N

{~:~.{~)~~1;:,

.~~:;:

14

*22.

VALUE

36185.0600

VAR1ABLE

Η1

Η2

Η3

Η4

F1

F2

F3

F4

11

12

13

W1

w2

W3

W4

Ρ1

Ρ2

Ρ3

Ρ4

14

VALUE

6.143851

64.310690

.000000

116.071400

.000000

.000000

87.662330

.000000

.000000

.000000

.000000

106.143900

170.454500

82.792210

198.863600

850.000000

1260.000000

510.000000

980.000000

.000000

REDUCED

.000000

.000000

300.000000

.000000

300.000000

300.000000

.000000

300.000000

59.415580

189.285700

31.006490

.000000

.000000

.000000

.000000

.000000

.000000

.000000

.000000

120.292200

COST

Month

1

2

3

4

5

6

Belts

Handbags

Attache Cases

22

20

19

24

21

17

2,500

2,800

2,000

3,400

3,000

1,600

1,250

680

1,625

745

835

375

240

380

110

75

126

45

α. Using worke!" hours as an aggregate

measlIre of ρτοτίυοτίοη, convert the forecasted demands ιο demands ίη terms of aggregate units.

b. Determine another plan that achieves a lower cost than that determined ίη

part (α) while still retaining feasibility (tl1at is, having a nonnegative amount

of inventory οη hand at the end of each period).

b. What wotIld be the size of the workforce needed το satisfy the deInand for

the coming six months οη Γegular time only? Would ίι be to the conιpany's

advantage το bring the permanent workforce ιφ to this level? Why οτ WllYτιοι?

α. Formulate Problem 9 as a lίnear program.

c. Determine a production plan that meets the demand lIsing only regular-time

employees and tl1e total cost of that plan.

b. Solve the problem usi.ng a linear programming code. Round the variables ίη

the resulting solution and determine ιίιε cost of tl1e plan you obtain.

*20.

Number of

Working Days

The belts reqιIire an aνerage of two Ιιοιιτ» to ρτοοιιοο, the handbags three

Ιιουτε, and the attache cases six hours. ΑΙΙ the workers have the skill ιο work ση

any itetD. LeatheΓ-ΑlΙ11as 46 employees who each has a share ίη the firm and canσοι be fired. There are an additional 30 locals that are available and can be hired

for short periocls at higher cost. Regular employees earn $8.50 per hour οιι reglIlar time and $14.00 per hoιIf ου overtime. ReglIlar time comprises a εενεη-Ιιουτ

workday, and the regular employees will work as much overtime as is available.

The additional workers are hired for $11.00 per Ιιουτ and are kept οτι the payrol\

for at least one flIll mOI1t11.Costs of hίι-ίηg and fiι-ίng are negligible.

Because of the competitive natnre of the indlIstry, LeatheΓ-ΑIΙ does τιοτ want

to incur any demand back orders.