Book : Retail Buying and Merchandising

advertisement

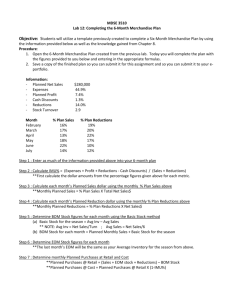

Book : Retail Buying and Merchandising Chapter 5 Determining What To Buy What is Merchandise Planning? • Merchandise planning is the process which helps retailers to make the right product available at the right place. • It can be defined as a systematic approach towards acquiring of merchandise. The Need For Merchandise Planning • Profit improvement • Purchase quantity planning • Implications on other departments like finance, marketing, warehousing and logistics and operations The Merchandise Planning Process • Sales forecast serves as the starting point • The product to be sold influences the environment in which it has to be sold and also the type of services that need to be provided to sell the product Merchandising Budget • Budget takes into consideration the seals that are to be achieved • The inventory levels needed to achieve these sales • The six month merchandise plan is created at this stage • The next step is the creation of the assortment plan • Control Merchandise Hierarchy • The first level of identifications is the store itself • The next level of classification would be the various categories of product that the retailer offers in every department • The next level of classification could be on the basis of style and price point • The classification on the basis merchandise hierarchy is applicable to all types of merchandise • The final level of merchandise classification is the Stock Keeping Unit (SKU) • SKU is the basic level of identification of merchandise and helps the buyer understand the complete break up of the quantities needed in each and every product that needs to be purchased The Process of Merchandise Planning • Top down • Top down planning occurs when the corporate objectives dictate the company’s financial objectives in terms of sales, profit and working capital • Bottom up • Bottom up planning on the other hand takes into consideration the various types of stores existing, the space available in them to sell various types of product, what are the options that will be needed and then arrive at the numbers that are needed The Six Month Merchandise Plan • It is the tool that translates the profit objectives into a framework for merchandising planning and control • Objectives is to prepare a month-by-month purchasing schedule for the retail organizations Key Components of The Six Month Merchandise Plan • Planned seas • Planned Purchases • Planned Purchase = Planned Sales + Planned Reductions + Planned EOM – Planned BOM • Planned Purchases at Cost = Planned purchases at retail x (100%- initial mark up %) • Planned reductions • Markdown, discounts and inventory shrinkage come under the heading of planned reductions • These three figures affect the gross margin, and hence need to be take into consideration while calculating profitability • Since they also affect inventory levels, the must be projected to ensure enough merchandise is on had to attain forecasted sales levels • Planned Markup • Markup in Rupees = Selling price – Cost price • Markup Percent = Markup in rupees Retail Price • Gross Margin • Gross Margin = Selling price- cost of the product- reductions for markdowns • BOM & EOM • Planning End-of –Month (E.O.M.) or Beginning –of-Month (B.O.M.) inventory levels is another important element of the six-month merchandise plan Stock-To-Sales Method • S/S Ratio = Stock on Hand E.O.M Sales fro the same month • A pre-requisite for calculating the stock to sales ratio is for the retailer to have a beginning of the month stock/sales ratio • Stock-seals ratio =Value of inventory/actual sales • BOM inventory = stock-sales ration x planned sales The Basic Stock Method • BS= average stock for the season – average monthly sales for the season where Average monthly sales for the season = Total planned sales for the season Number of months in the season Average stock for the season = Total planned sales for the season Estimated inventory turnover rate for the season The percentage variation method • BOM stock = Avg. stock for season x ½ x [1 = (Planned sales for the month/ Average monthly sales)] Week’s Supply Method • Number of weeks to be stocked = The number of weeks in the period Stock turnover rate for the period Where, Average weekly sales = Estimated total sales for the period The number of weeks in the period