+GF+ - Independent Pipe Products

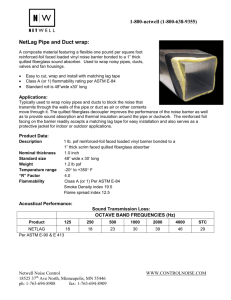

advertisement