Lightweight Activities at Georg Fischer

advertisement

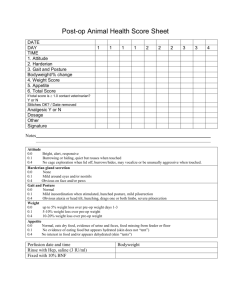

GF Automotive AG Lightweight Activities at Georg Fischer Workshop: Functional and Innovative Lightweight Concepts and Materials for HEVs Lightweighting 2 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Georg Fischer AG 3 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Georg Fischer Corporation Georg Fischer AG: Three strong Divisions GF Piping Systems GF Automotive GF Machining Solutions Facts & Figures Foundation: Headquarter: 1802 Switzerland 124 companies in 32 countries Listed (Swiss stock exchange) For over 200 years independent Employees: Sales 2013: 4 14.000 CHF 3.8 billion Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Georg Fischer Three strong Divisions 100% = CHF 3,77 billion ~ EUR 3,06 billion 40% GF Lightweight Solutions 37% GF Piping Systems 23% GF Machining Solutions 5 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Georg Fischer Piping Systems Your solution GF Piping Systems is a leading supplier of piping systems made of plastics and metal 6 Overview 2014 | 03/2014 | GF Automotive Georg Fischer Automotive Lighter Future GF Automotive is a leading global supplier of iron and light metal cast components for the automotive industry and industrial applications. 7 Overview 2014 | 03/2014 | GF Automotive Georg Fischer Machining Solutions Keeping promises GF Machining Solutions’ electric discharge, high-speed milling and laser texturing machines, along with automation solutions, make it the world’s leading provider 8 Overview 2014 | 03/2014 | GF Automotive Georg Fischer Clean Water Foundation Main purpose of the foundation is the financial support of projects related to the improvement of access to clean drinkable water for human beings Founded in 2002 Over 110 Projects in over 50 Countries GF Automotive has injected over CHF 8 million 9 Overview 2014 | 03/2014 | GF Automotive GF Automotive 10 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Passion for your Lighter Future EUR 1.22 Bill. Sales 11 4 940 Employees Lightweight Activities at Georg Fischer | 10/2014 | K. Decking 9 Production Locations GF Automotive Segments & Products ~ 3000 Products ≙ 100 000 000 Parts Iron: 62% 12 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Light Metal 38% GF Automotive Product Segment – Passenger Cars Powertrain Chassis Body / Structure 13 Overview 2014 | 03/2014 | GF Automotive GF Automotive Product Summary – Passenger Cars Average Production per Year 14 Chassis Powertrain Body / Structure Axle Steering Brake Subframe Engine Transmission Drive Train Interieur Exterieur > 15 000 000 > 1 300 000 > 450 000 > 3 700 000 > 9 000 000 > 1 300 000 Overview 2014 | 03/2014 | GF Automotive GF Automotive Product Segment – Comm. Vehicles Powertrain Chassis Frame / Cab 15 Overview 2014 | 03/2014 | GF Automotive GF Automotive Product Summary – Comm. Vehicles Average Production per Year 16 Chassis Powertrain Frame/ Cab Axle Steering Brake Engine Transmission Drive Train Structuremounting parts > 2 500 000 > 200 000 > 1 750 000 > 450 000 Overview 2014 | 03/2014 | GF Automotive > 700 000 > 300 000 GF Automotive Product Segment – Industrial Application Energy & Engine Industry & Consumer Offroad 17 Overview 2014 | 03/2014 | GF Automotive GF Automotive Global Locations Cooperation Grede Iron Casting Mettmann Singen Herzogenburg Leipzig LMDC Werdohl Altenmarkt Herzogenburg Iron Casting Kunshan LMDC Suzhou Cooperation Riken Headquarter and R&D Schaffhausen Sales Office Yokohama Seoul Countries delivered by GF Lightweight Solutions Production Site / Headquarter Sales Office Cooperation 18 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Added Value: It does not stop with a casting 19 Casting Machining Heat Treatment Coating Joining Assembly Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Future Drivers for Lightweighting E- Mobility Downsizing Design CO2 Footprint Material Development 20 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Development Competence State-of-the-art processes: From design phase to serial production Virtual Development: The complete component development from material selection to casting process is simulated, validated and continuously improved 21 Overview 2014 | 03/2014 | GF Automotive GF Automotive Material – Optimal Characteristics Design Maximize material advantages: GF Automotive´s R&D Department develops state-ofthe-art alloys and maximizes the specific characteristics of iron, aluminum and magnesium consequently Process Validation Material 22 Overview 2014 | 03/2014 | GF Automotive GF Automotive Design – Ideal Shapes Design Using degree of freedom: Virtual tests, simulations and analyses shorten development time and reduce costs for real test runs. In addition it is possible to define dimensions, visualize shapes, anticipate noise and vibrations, simulate casting processes and calculate the lifetime of components. Process Validation Material 23 Overview 2014 | 03/2014 | GF Automotive GF Automotive Process Material Validation We know how to cast: Our knowledge in innovation and light weight construction requires a continuous evolution of proven procedures. GF Automotive relies on iron-sandcasting and aluminum and magenesium die-casting technologies to cast products in best shape. Our engineers will find the optimal process for every part. Design Process – Precise Procedures 24 Overview 2014 | 03/2014 | GF Automotive GF Automotive Validation – Testing Materials and Parts Design Testing functions: Our conviction, that our products guarantee the expected advantages, relies on our accredited testing laboratory. By state-of-the-art testing methods, GF Automotive validates inhouse and other parts already during development phase. Process Validation Material 25 Overview 2014 | 03/2014 | GF Automotive GF Automotive Material 26 Overview 2014 | 03/2014 | GF Automotive GF Automotive Casting or Carbon Composites? Carbon Iron Aluminum Magnesium Recycling Herstellung Lower Energy Consumption Repair Recycling Costs Corrosion Resistance Repair Lighter Resistance Material Cycle Production 27 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Material Comparison GJS 400-15 GJS 450-10 SiboDur 700-10 Aluminum Magnesium Carbon Fiber Tensile Strength Rm (N/mm2) Min. 400-450 Min. 700 277-338 217.5-230 3530-4560 0.2%-Yield Stress Rp0,2 (N/mm2) Min. 250-310 Min. 440 142-196 112.5-155 - Elongation (%) Min. 10-15 8-12 3.5-12.5 3.5-10 1.1-1.5 Young’s – Modulus (kN/mm2) 175 175 72-77 43-45 230-395 Density (g/cm3) 7.1 7.1 2.6-2.7 1.8 1.8 28 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Lightweighting Potential Weight Reduction Source University of Cambridge 29 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Repair Job Metal Repair Carbon Fiber Repair 30 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Production Chain of Carbon Fiber and Magnesium Carbon Fiber Magnesium 31 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Carbon Fiber Production Chain cracking ammoxidation plastics polymerisation oxidation carbonisation take effect stack recycle preform assembly use crude oil propylene acrylonitrile precursor oxidised fiber carbon fiber carbon fabrics package 32 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking mould CF part scrap GF Automotive Magnesium Production Chain high-pressure casting electrolyse melting machining assembly use dolomite sea water raw magnesium liquid magnesium recycle casted product finished product part 33 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Manufacturing Climate Balance Sheet CO2 Emissions Due to pidgeon process Source University of Cambridge 34 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Manufacturing Energy Consumption Energy Energy Consumption Consumption Due to pidgeon process Source University of Cambridge 35 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Emission over Life-Cycle Change of Perspective: Break-Even Break Even: 0 km High Strength Steel 90.000 km Aluminum 120.000 km Magnesium 170.000 km Carbon Fibre Source: VW, University of Cambridge 36 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Availability Magnesium: 8th abundant element in earth’s crust Carbon fiber: Uses polyacrylonitrile 37 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Recycling Metals Fully recyclable Used in new alloys Used as a mixture in new alloys 38 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Carbon Fiber Recyclable? At least downcycling or scrap GF Automotive Cost Comparison Costs per Part (in % of Steel) Steel Aluminum Magnesium 100 130 155 570 Carbon Today Tomorrow Up to 3 times higher costs for carbon fibre With new precursors and technological progress improving production processes, a decrease of almost 30% in the global cost of composites is expected between now and 2020 Source: McKinsey&Company, Magnesium own Research University of Cambridge 39 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Lightweighting Potential Weight Reduction Source University of Cambridge 40 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Substitution of Sheet Metal Constructions Weight Reduction Casted aluminum compared to steel sheet assembly out of 10 parts up to 45% less weight 41 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Carbon Fiber vs. Aluminum 100% Carbon? Source: BMW AG 42 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Substitution of Sheet Metal Constructions Weight Reduction Seat frame in casted Magnesium up to 30% less weight than metal sheet assembly 43 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Carbon Fiber vs. Magnesium Carbon Fiber Magnesium Source BASF - 30% Weight Reduction compared to conventional Steel-based Designs 44 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking - 30% Weight Reduction compared to conventional Steel-based Designs GF Automotive Bionic Design Weight reduction Iron steering knuckle up to 35% less weight through bionic design 45 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive High Design Freedom for Castings Front Steering Knuckle Carbon - 40% 46 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Iron - 35% GF Automotive Material Strengths and Weaknesses 47 Iron / Steel Aluminum Magnesium Carbon Strength ++ + o ++ Costs ++ + o -- Energy Consumption + o - - Weight Reduction - + ++ ++ Repair ++ + + -- Recycling ++ + o -- Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Material Comparison Weight per Part Costs per Part In % of Steel In % of Steel Steel 100 Aluminum 60 100 Steel 130 Aluminum Magnesium 50 Magnesium Carbon 50 Carbon 155 570 Process Reliability Energy Consumption Repair Production Sustainability Recycling Material Cycle Serial Production Process Reliability Costs Material Source: McKinsey&Company, Magnesium own Research 48 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Which Material? 49 Steel Carbon Aluminum Magnesium Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Design 50 Overview 2014 | 03/2014 | GF Automotive Bionic Design Start Principle Topological Optimization CAD (Quelle: Prof. Dr. Claus Mattheck) 51 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Bionic Design Before After GJS 700 7,2 kg SiboDur® 700 6,3 kg -12,5 % 52 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Bionic Design Weight Reduction Differential housing in iron casting up to 15% less weight than predecessor through bionic design 53 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Substitution of System Parts Weight Reduction Crossmember, completely casted in iron has 17% less weight than combined assembly out of steel sheet and iron 54 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Substitution of Sheet Metal Constructions Weight Reduction Inno Door Frame in casted Aluminum up to 40% less weight than metal sheet assembly 55 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Additional Lightweighting Examples 56 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Maserati Quattroporte Inner Door Frame Alloy: Weight : AlMg5Si2Mn 4,8 kg (- 40%) Copyright by Maserati 57 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Porsche Panamera Cam Cover V6 (1-3 and 4-6) Alloy: Weight : AE 44 / MgAl4RE4 1,36 / 1,2 kg (- 44%) Copyright by Porsche 58 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Porsche Panamera Oil Separator V6/V8 Alloy: Weight: AM50 / MgAl9Zn1 0,25 / 0,18 kg (-28%) Copyright by Porsche 59 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Porsche Panamera Oil Sump V6 2WD Alloy: Weight: AE 44/MgAl4RE4 4,6 kg (- 47%) Copyright by Porsche 60 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Porsche Panamera Engine Front Cover Alloy: Weight: AE 44/MgAl4RE4 2,6 kg (- 47%) Copyright by Porsche 61 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Opel Cascada Convertible Roof Top Alloy: Weight: AM50HP 2,2 kg (- 40%) Minimum wall thickness 1,2 mm Anchor points for counter ropes without processing Copyright by Opel 62 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Smart fortwo Instrument Panel Crossbar Alloy: Weight: MgAl5Mn 2,4 kg Copyright by Smart 63 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: BMW X3 BMW X3 Box Swing Arm Alloy: Weight: MgAl9Zn1 (AZ91) 0,8 kg (-35%) Copyright by BMW 64 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Product Samples in Series: Porsche Macan Engine Front Cover Alloy: Weight: AE44 2,6 kg (- 40%) Copyright by Porsche 65 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking E-Mobility – New Applications E- Mobility: Advantages of Castings Flexibility Integration Design Freedom Economic Efficiency Material Characteristics Part Characteristics … 66 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking E-Mobility – New Applications Wheel carrier with integrated planetary gear Formula Student 67 Overview 2014 | 03/2014 | GF Automotive E-Mobility – New Applications Battery Housings VW E-Golf 68 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking E-Mobility – New Applications Powertrain Applications Single-Piston Audi A1 e-Tron Prototype 69 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Lightweigthing – Industrial Applications Converter Housing Drum Support 70 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Lightweigthing – Conclusion Proved solution for lightweigthing? Castings offer… High functional integration High design freedom Broad choice of materials Large potential for weight savings Compared to carbon fiber much lower costs and better recyclability 71 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Passion … … for your Lighter Future 72 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Contact Klaus Decking Head of Marketing, Communication & Services Business Development New Markets Phone +41 52 631 21 17 Mobile +41 79 633 11 37 Fax +41 52 631 28 59 klaus.decking@georgfischer.com GF Automotive Georg Fischer Automotive AG Amsler-Laffon-Strasse 9 8201 Schaffhausen Switzerland www.gfau.com 73 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Disclaimer This document is for presentation purposes only and should not be construed as an offer, invitation or solicitation to subscribe for, purchase or sell any investment. Neither it nor anything it contains shall form the basis of any contract whatsoever. Opinions expressed herein reflect the current judgement of the management of Georg Fischer. The presentation contains forward-looking statements that involve risks and uncertainties. The actual results of Georg Fischer may differ materially from those anticipated in these forward-looking statements and forecasts as a result of a number of factors. 74 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking The management of Georg Fischer does not accept any liability whatsoever with respect to the use of this presentation. Backup 75 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Lightweighting Material Bionic Design - 45% Function Integration - 32% - 45% 76 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Product Segment – Passenger Cars Powertrain Chassis Body / Structure 77 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Product Segment – Comm. Vehicles Powertrain Chassis Frame / Cab 78 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Product Segment – Industrial Application Energy & Engine Industry & Consumer Offroad 79 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Lightweight Solutions Rohstoff- und Energieversorgung Beschaffung und Sicherung von Rohstoffen und Energie Rohstoff- und Energierückgewinnung mit Hilfe moderner Techniken Einkauf über weltweit agierende Spezialistenteams Mehrjahresverträge mit strategischen Partnern Virtuelle Beteiligungen bei Rohstoff- und Energielieferanten 80 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Vergleich von Aluminium und Magnesium Aluminium Magnesium 2,7 g/cm3 1,8 g/cm3 70 GPa 45 GPa Wärmeleitfähigkeit 238 W/mK 156 W/mK Wärmeausdehnungskoeffizient 23,5 10-6/K 26,0 10-6/K + ++ 710 – 740 °C 670 - 690°C > 2,0 mm > 1,5 mm nicht notwendig SO2, (SF6) Werkzeugstandzeit 100.000 150.000 (Kontakt)-Korrosion + - Fügetechnologie ++ o Recyclingfähigkeit ++ + Dichte E-Modul Gießbarkeit Gießtemperatur Wandstärken Schutzgas (Brandgefahr) Lightweight Activities at Georg Fischer | 10/2014 | K. Decking 81 Weitere Merkmale Magnesium / Aluminium Aluminium Magnesium > 3,5 > 2,5 Festigkeit + 0 Gießbarkeit + ++ Werkzeugstandzeit 0 ++ Korrosion + - Kosten + 0 Gewinde + + Nieten + + Stanznieten + - Stanzen + + Schweissen + - Wandstärken 02/2011 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking Magnesium-Druckguss im Motorenbau 82 Produkteigenschaften: Magnesium im Vergleich zu Aluminium Bessere Fliessfähigkeit dünnwandigere Bauteile möglich (<1,5mm) geringere Auszugsschrägen möglich komplexere Bauteile möglich hohe Oberflächengüte erreichbar Geringere Toleranzen im Gusszustand erreichbar Tlws. geringere Nacharbeit notwendig Tlws. geringere Bearbeitung notwendig, da fertiggegossen Mg-Legierungen haben starke Neigung zu Kontaktkorossion Tlws. ist zusätzliche Beschichtung erforderlich Ggfs. spezielle Fügetechnik erforderlich Lightweight Activities at Georg Fischer | 10/2014 | K. Decking 83 GF Automotive Development Competence State-of-the-art processes: From design phase to serial production Virtual Development: The complete component development from material selection to casting process is simulated, validated and continuously improved 84 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Innovation in Material, Design & Process Material: e.g. AluSiDur Process: Core Technology High Strength Aluminum Lightweight Crankshafts Design: e.g. Cross Member Design: e.g. Structural Parts Substitution Lightmetal 85 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Bionic Design Principals: Resources in Nature are limited Biological mass must be applied efficiently Structures in nature aim to maximal light weight construction with minimum stress loads 86 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Bionic Design Examples Before After GJS 700 7,2 kg SiboDur® 700 6,3 kg - 12,5% 87 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Bionic Design Examples Topologieoptimierung Start Model Topologie Optimierung Bionic Design Finite Element Analyse 88 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Bionic Design Examples Befor After GJS 400 4,4 kg SiboDur® 700 3,0 kg - 32% 89 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Bionic Design Weight reduction Differential housing in iron casting up to 15% less weight than predecessor through bionic design 90 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Substitution of System Parts Weight reduction Crossmember, completely casted in iron has 17% less weight than combined assembly out of steel sheet and iron 91 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Emission during Production Process counts Change of Perspective Source: VW 92 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Development Competence State-of-the-art processes: From design phase to serial production Virtual Development: The complete component development from material selection to casting process is simulated, validated and continuously improved 93 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking GF Automotive Substitution of Aluminum through Magnesium in Powertrain Applications Weight reduction Front cover in casted Magnesium up to 45% less weight than aluminum 94 Lightweight Activities at Georg Fischer | 10/2014 | K. Decking