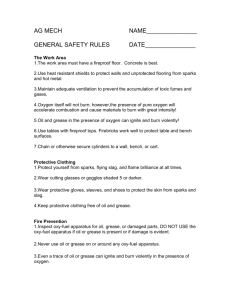

Oxygen-Fuel Gas Welding and Cutting

advertisement