Gas Welding and Flame Cutting Gas Welding and Flame Cutting

advertisement

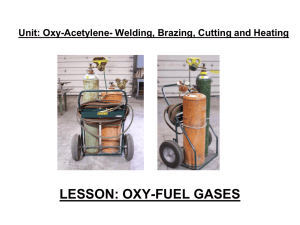

A Guide to Safety and Health at Work for Gas Welding and Flame Cutting Occupational Safety and Health Branch Labour Department Occupational Safety and Health Branch Labour Department 4/99-1-B59 A Guide to Safety and Health at Work for Gas Welding and Flame Cutting This guidebook is prepared by the Occupational Safety and Health Branch Labour Department First Edition April 1999 This guidebook is issued free of charge and can be obtained from offices of the Occupational Safety and Health Branch. Addresses and telephone numbers of the offices can be found in the booklet“The Labour Department Offers You its Services” or by telephone 2559 2297. Contents 14. Useful Information If you wish to enquire about this guidebook or require advice on occupational safety and health, please contact the Occupational Safety and Health Branch of the Labour Department through: Telephone : 2559 2297 (auto-recording after office hours) Fax : 2915 1410 E-mail : laboureq@labour.gcn.gov.hk Page 1. Introduction ............................................................ 1 2. Fire and Explosion Hazards ................................... 2 3. Health Hazards ...................................................... 3 4. Gas Supply System and Associated Safety Devices .................................................................. 5. Information on the services offered by the Labour Department and on major labour legislation can also be found by visiting our Home Page in the Internet. Address of our Home Page is http:// www.info.gov.hk/labour. 4 Safe Storage and Handling of Gas Cylinders ................................................................ 6 6. Fire Prevention and Protection ............................... 7 7. Health Protection and Ventilation ........................... 8 8. Personal Protective Equipment ............................. 9 9. General Safe Practices .......................................... 10 10. Equipment Checking and Maintenance ................ 12 11. Emergency Procedures ......................................... 14 12. Instruction and Training ......................................... 16 13. Unsafe Acts ............................................................ 17 14. Useful Information .................................................. 19 19 ◆ 1. Introduction In gas welding and flame cutting, a fuel gas is mixed with oxygen or air in a blowpipe to produce a flame hot enough to fuse the surfaces together, or in case of cutting hot enough for the formation of molten oxides of the metal involved. Fire and explosion are the hazards that may be encountered due to problems with the gas supply system or due to the hot slag resulted from the process. Besides, toxic fumes and radiation produced during the process may also pose health hazards to the people at work. Warming up gas cylinders Warming up gas cylinders by any means in order to increase gas flow or to extract the last bit of gas stored in the cylinder for use is extremely dangerous. Fire and explosion may occur due to: ● ● the gas supply system not capable of withstanding the resulted increase in gas pressure; evaporation of the solvent (acetone in general) for storing acetylene in the gas cylinder by the heat, causing damage to the gas hose and blowpipe and change in composition of the fuel/oxidant mixture for the flame. This guidebook presents the safe practice in gas welding and flame cutting with the commonly used oxy-acetylene flame. The safe practice is also applicable to welding and cutting with flames using other fuel gases such as propane (commonly known as 'liquefied petroleum gas' or 'LPG') and hydrogen. It is intended to provide proprietors, managers, safety personnel and supervisors of industrial undertakings general guidelines in protecting people at work from the hazards of gas welding and flame cutting, and in reducing the injuries and damage caused by fires and explosions. 1 18 13. Unsafe Acts 2. Fire and Explosion Hazards Many serious accidents have occurred in the industry due to misuse of oxygen, gas decanting and warming up gas cylinders. These are unsafe acts. Fire and explosion hazards of gas welding and flame cutting are mainly due to problems with the gas supply system, or due to the high temperature of the flame used or the hot slag produced in ◆ the process. These hazards include: Misuse of oxygen Explosion may occur when oxygen contacts combustible materials. Never use oxygen to: ● provide a source of pressure or a substitute for compressed air, such as to clear blockages in pipelines, ● ● ● ◆ ◆ fuel gases or oxygen into the atmosphere from leaks at joints, hose connections or fittings of the gas supply system; ◆ to power air-driven tools; blow-down clothing, equipment or work areas to remove dust, etc.; ventilate a confined space instead of air; or sweeten the air of any work area or space. as oxygen is charged into an acetylene cylinder. Fires and explosions in the gas supply system caused by ● flashback from the blowpipe due to gas lines not completely purged before lighting up, or back-feeding of fuel gas into the oxygen line or vice versa; ● decomposition or detonation of acetylene in the absence of oxygen or air due to flashback at the blowpipe or overheating of gas cylinder; Gas decanting Recharging gas cylinders by connecting them to other cylinders or a gas supply (known as gas decanting) is extremely dangerous. Explosion may occur if ● the gas line or its connections or the gas cylinders cannot withstand the high pressure during decanting; ● the decanting involves mixing of incompatible gases, such Fires and explosions resulted from the release of flammable ● high-pressure oxygen (without fuel gas) which promotes combustion of materials such as oil, grease, organic compounds, aluminium metal and its alloys, and elastomers used in valve seats and seals; ◆ Explosions from over-pressurisation of the gas supply system; ◆ Fires from the ignition of flammable or combustible materials in the vicinity by the flame of the blowpipe, hot surfaces of the workpiece or hot slag from the process. 17 2 3. Health Hazards 12. Instruction and Training Health hazards of gas welding and flame cutting are mainly due to the radiation and toxic fumes or gases emitted during the process. These hazards include: ◆ Eye injuries ● ● heat cataract caused by infra-red radiation from molten All personnel involved in gas welding and flame cutting operations should be fully instructed and trained on the safety and health aspects of the work under normal operation as well as in case of emergency. The instruction and training should appropriately cover: metal, resulted in not able to see things clearly; ◆ hazards in gas welding and flame cutting; arc eye caused by ultra-violet radiation emitted during ◆ selection and use of the appropriate equipment for the the process, resulted in very painful and watery eyes; ● foreign particles e.g. slag and cutting sparks; ◆ Skin irritation and reddening due to over exposure to radiation; ◆ Inhalation of fumes or gases produced during the process ● ◆ ◆ the role of the safety devices and their limitations; ◆ selection and use of the ventilation system and personal protective equipment and their limitations; metal fume fever which is a febrile illness due to freshly formed metal oxide fumes; ◆ safe operating procedures; ● toxic fumes of metals such as lead, cadmium, beryllium; ◆ emergency procedures; ● toxic gases such as oxides of nitrogen, fluorides resulted ◆ other aspects specific to the operation such as in bronchial and pulmonary irritation; ◆ operation; other injuries such as corneal ulcer and conjunctivitis from Burns from the blowpipe flame, hot slag or hot surfaces of ● manual handling operation of large workpieces, the workpiece; ● safe operation during working at height or in confined Personal injuries due to handling gas cylinders or large spaces. workpieces. 3 16 ◆ Fires involving acetylene cylinders are always best dealt with by firemen from the Fire Services Department. However, the following initial response may be appropriate: ● cool the cylinder by spraying with water only if it is safe to do so; ● ● close the cylinder valve to control the fire only if it is safe to do so; evacuate the building by activating the fire alarm or by any other means. Never attempt to move an acetylene cylinder that has been involved in a fire, or move one which has been affected by heat from a nearby fire even if it appears to have been cooled down. Moving the cylinder may lead to explosion! 4. Gas Supply System and Associated Safety Devices In general, each one of the two gases (the fuel gas and oxygen) used in gas welding and flame cutting is supplied from a single gas cylinder. Other methods of supply may be from a number of gas cylinders connected by a manifold, or from a bulk supply installation. Each gas is supplied through a flexible hose to the blowpipe where the fuel and oxygen are mixed in an appropriate proportion and combusted to form the required flame for welding or cutting. For distinguishing between the fuel gas and oxygen supplies, the gas cylinder and hose for each gas should be appropriately coloured. Other safety devices necessary for reducing the risk of fire and explosion in the gas supply system include: ◆ Pressure regulator and pressure gauges to control and monitor the pressure of the gas supply; ◆ Non-return valve at each gas inlet of the blowpipe to prevent back-feeding of oxygen to the fuel line and vice versa; ◆ Flashback arrester (flame arrester) incorporating pressure or temperature cut-off valve to prevent propagation of flashback from the blowpipe and gas hoses into the gas cylinders. 15 4 Typical equipment for gas welding and flame cutting using oxy-acetylene flame Emergency procedures should be established which workers should follow if a situation presenting serious and imminent danger arises. The procedures should include guidance for the workers explaining when and how they should stop work and move to a safe location, or even fully evacuate the workplace. Actions for pressure regulator with pressure gauge nozzle flashback arrester 11. Emergency Procedures flashback arrester cylinder valve dealing with some of the possible emergency situations in gas welding and flame cutting are listed in the following: ◆ If there is a sustained backfire in a blowpipe, ● first close the oxygen valve of the blowpipe, followed by the fuel valve and then close both cylinder valves; ● investigate the cause and rectify the fault; ● blowpipe ◆ non-return valve If there is a flashback into the hose and equipment, or a hose fire or explosion, or a fire at the gas regulator connections, ● isolate the fuel gas and oxygen supplies by closing the ● ● flexible hose (acetylene - red) (oxygen - blue) acetylene cylinder (maroon) 5 re-light the blowpipe only after it is completely cooled down. cylinder valves only when this can be done safely; may attempt to control the fire by fire-fighting equipment only when there is no undue risk of personal injury; activate the fire alarm and call for the Fire Services Department. oxygen cylinder (black) 14 such as the aggressive nature of the working environment. Defective or damaged equipment should be taken out of service immediately and repaired by competent person if applicable. The regular examination of equipment should include checking for the following defects: arresters, resulted in low gas flow rates; Fuel gases and oxygen are commonly stored under pressure in gas cylinders. Fuel gases such as acetylene, hydrogen and propane are flammable. Moreover, acetylene is potentially unstable and may decompose violently in the absence of oxygen or air. Safe practice in storing and handling gas cylinders includes the following: incorrect operation of non-return valves, resulted in ◆ ● internal gas leakage in pressure regulators; ● incorrect operation of pressure gauges; ● build-up of deposits of combustion products in flashback ● 5. Safe Storage and Handling of Gas Cylinders reverse flow not shutting off; ● defective blowpipe such as internal gas leakage, blockage at the nozzle. ◆ ◆ ◆ ◆ ◆ 13 Ensure that gas cylinders upon receipt are appropriately coloured and correctly labelled, and have no sign of gas leakage. Store gas cylinders in a cool and well-ventilated place, away from any heat or ignition source, and keep cylinders in use away from the welding and cutting work. Always keep gas cylinders in an upright position and securely anchored to strong supports, no matter during storage or when in use. Keep the quantity of gas cylinders under storage to a practical minimum and in compliance with the requirements under the Dangerous Goods Ordinance. Handle gas cylinders with care and do not throw or bump the cylinders heavily. Inform the supplier immediately if the gas cylinder is found to be physically damaged. Move gas cylinders on wheeled trolleys designed for the purpose and securely fasten the cylinder to the trolley during movement to prevent damaging the cylinder valves and to minimise the risk of injury. 6 6. Fire Prevention and Protection In gas welding and flame cutting, fires may arise from ignition of flammable or combustible materials not only by direct contact with the flame, but also by contact with the hot slag or workpiece which may take a considerable time to cool down. The following precautions are necessary to prevent fires: Move all flammable or combustible materials to a safe place away from the work area. Use suitable means to protect combustible materials that cannot be moved from close contact with flame, heat, hot slag or sparks such as covering with fire resistant materials. ◆ Use suitable means to prevent slag or spark from reaching combustible materials along or down ducts, channels and through holes in walls and floors, such as covering the openings by fire resistant materials. ◆ Prevent equipment for gas welding and flame cutting from being contaminated with oil or grease. ◆ Before starting welding or cutting work on used containers, ensure that the container is free from any substance that may emit flammable or toxic vapours upon heating by washing with suitable solvents and purging with inert gas. ◆ Provide suitable fire-fighting equipment such as fire extinguishers, buckets of sand near by the work area. ◆ Ensure that sparks and slag from the work are extinguished ◆ and cooled before leaving the work area. 7 10. Equipment Checking and Maintenance ◆ Pre-use equipment check Each time before starting a welding or cutting operation, it is necessary to check that equipment and safety devices are correctly installed and in good working condition. Pre-use equipment check includes: ● ● ● ● ensuring that each gas cylinder is fitted with regulator of the correct type and is correctly connected to the blowpipe; checking for defective or damaged hoses such as cuts, cracks and abrasion; replacing or repairing the hose by a competent person if necessary; checking all gas line connections for leakage by using soapy water; ensuring that the routing of the gas hoses will not cause severe bending of the hose or will not be run over by other heavy equipment so as to prevent gas flow being obscured or hose being damaged. ◆ General examination and maintenance of equipment In addition to the pre-use equipment check, all the equipment should be regularly examined for defects and malfunctions. The frequency of examinations depends on the frequency of use of the equipment and the conditions in which it is used 12 ◆ ◆ After the operation ● Extinguish the flame of the blowpipe. ● Close the gas cylinder valves for both fuel gas and oxygen. ● Ensure that slag, sparks and workpieces have been completely cooled down before leaving the work area. Operation in a confined space Special precautionary measures should be taken to protect the workers at work when gas welding or flame cutting is carried out in a confined space. The likelihood of accumulating gas from leakage is greater and hazards from welding fumes are more significant. ● Adopt a permit-to-work system, and comply with the safety ● ● requirements for working in a confined space. Provide a system for fresh air ventilation and fume extraction, and supply air type respirators to all workers working in a confined space. Do not take gas cylinders into a confined space whenever practicable. If it is necessary to do so, keep the number and size of gas cylinder taken into a confined space to a minimum and remove them when work stops. 11 7. Health Protection and Ventilation The risks of burns and injuries due to radiation and manual handling operations during gas welding and flame cutting are minimised by using appropriate personal protective equipment and safe work procedures. Health hazard due to the hazardous fumes or gases emitted during the process should first be reduced by provision of suitable engineering control ventilation. Ventilation provides a means to remove hazardous fumes and gases emitted during the process and to supply fresh breathing air for the workers. The type of ventilation required should be assessed according to the workplace environment, the volume of the work and the toxicity of the fumes or gases emitted during the process. Toxic fumes include those derived from metals such as lead, cadmium, beryllium and zinc. ◆ General ventilation General ventilation (preferably by mechanical means) is adequate for infrequent and short duration welding and cutting work, not emitting toxic fumes performed in the open air or in large well-ventilated workshops. ◆ Local exhaust ventilation Local exhaust ventilation is required for welding or cutting operation that involves heavy in-door production work or emits toxic fumes or gases. The local exhaust hood should be placed as close as possible to the work for effective removal of the toxic fumes. 8 8. Personal Protective Equipment ◆ Eye protection Welding and cutting of metals by means of oxy-acetylene flame is a specified process under the Factories and Industrial Undertakings (Protection of Eyes) Regulations. Workers engaged in the process and other persons that may be affected shall be provided with, as appropriate ● approved eye protectors such as goggles, visors, spectacles, face screens; ● approved shield such as helmet, hand shield; ● approved fixed shield such as screen. ◆ Protective clothing The main aim of protective clothing is to protect worker against burns by the flame of the blowpipe, the hot slag or workpiece. Appropriate protective clothing should be selected according to the nature, volume and location of the welding or cutting work. These include facemasks, aprons, gloves, safety shoes and spats. ◆ Respirator Respirator provides additional protection to the worker from inhalation of toxic fumes, and should be used in supplement to, but not in lieu of, the use of an efficient ventilation system. When welding and cutting is performed in a confined space, workers should be provided with supply air type respirators in addition to provision of efficient ventilation. 9 9. General Safe Practices The following safe practices provide general guidelines for establishing safe operating procedures used in gas welding and flame cutting operations. ◆ Preparation before commencement of the operation ● Assess the hazards of the operation to enable selection of appropriate engineering control measures (refer to Section 7) and personal protective equipment (refer to Section 8). Pay special attention to specific work conditions such as handling of large workpieces, working at height, working in confined spaces. ● Establish safe operating procedures. ● Provide training and instructions to the workers (refer to Section 12). ● Ensure cleanliness of the work area and that measures have been taken to prevent fires (refer to Section 6). ● Conduct pre-use equipment check (refer to Section 10). ◆ During the operation ● ● Wear personal protective equipment and follow safe operating procedures. Handle lit blowpipe with great care. Do not hang it on a gas cylinder shroud or leave it unattended even for a short period of time. 10 8. Personal Protective Equipment ◆ Eye protection Welding and cutting of metals by means of oxy-acetylene flame is a specified process under the Factories and Industrial Undertakings (Protection of Eyes) Regulations. Workers engaged in the process and other persons that may be affected shall be provided with, as appropriate ● approved eye protectors such as goggles, visors, spectacles, face screens; ● approved shield such as helmet, hand shield; ● approved fixed shield such as screen. ◆ Protective clothing The main aim of protective clothing is to protect worker against burns by the flame of the blowpipe, the hot slag or workpiece. Appropriate protective clothing should be selected according to the nature, volume and location of the welding or cutting work. These include facemasks, aprons, gloves, safety shoes and spats. ◆ Respirator Respirator provides additional protection to the worker from inhalation of toxic fumes, and should be used in supplement to, but not in lieu of, the use of an efficient ventilation system. When welding and cutting is performed in a confined space, workers should be provided with supply air type respirators in addition to provision of efficient ventilation. 9 9. General Safe Practices The following safe practices provide general guidelines for establishing safe operating procedures used in gas welding and flame cutting operations. ◆ Preparation before commencement of the operation ● Assess the hazards of the operation to enable selection of appropriate engineering control measures (refer to Section 7) and personal protective equipment (refer to Section 8). Pay special attention to specific work conditions such as handling of large workpieces, working at height, working in confined spaces. ● Establish safe operating procedures. ● Provide training and instructions to the workers (refer to Section 12). ● Ensure cleanliness of the work area and that measures have been taken to prevent fires (refer to Section 6). ● Conduct pre-use equipment check (refer to Section 10). ◆ During the operation ● ● Wear personal protective equipment and follow safe operating procedures. Handle lit blowpipe with great care. Do not hang it on a gas cylinder shroud or leave it unattended even for a short period of time. 10 ◆ ◆ After the operation ● Extinguish the flame of the blowpipe. ● Close the gas cylinder valves for both fuel gas and oxygen. ● Ensure that slag, sparks and workpieces have been completely cooled down before leaving the work area. Operation in a confined space Special precautionary measures should be taken to protect the workers at work when gas welding or flame cutting is carried out in a confined space. The likelihood of accumulating gas from leakage is greater and hazards from welding fumes are more significant. ● Adopt a permit-to-work system, and comply with the safety ● ● requirements for working in a confined space. Provide a system for fresh air ventilation and fume extraction, and supply air type respirators to all workers working in a confined space. Do not take gas cylinders into a confined space whenever practicable. If it is necessary to do so, keep the number and size of gas cylinder taken into a confined space to a minimum and remove them when work stops. 11 7. Health Protection and Ventilation The risks of burns and injuries due to radiation and manual handling operations during gas welding and flame cutting are minimised by using appropriate personal protective equipment and safe work procedures. Health hazard due to the hazardous fumes or gases emitted during the process should first be reduced by provision of suitable engineering control ventilation. Ventilation provides a means to remove hazardous fumes and gases emitted during the process and to supply fresh breathing air for the workers. The type of ventilation required should be assessed according to the workplace environment, the volume of the work and the toxicity of the fumes or gases emitted during the process. Toxic fumes include those derived from metals such as lead, cadmium, beryllium and zinc. ◆ General ventilation General ventilation (preferably by mechanical means) is adequate for infrequent and short duration welding and cutting work, not emitting toxic fumes performed in the open air or in large well-ventilated workshops. ◆ Local exhaust ventilation Local exhaust ventilation is required for welding or cutting operation that involves heavy in-door production work or emits toxic fumes or gases. The local exhaust hood should be placed as close as possible to the work for effective removal of the toxic fumes. 8 6. Fire Prevention and Protection In gas welding and flame cutting, fires may arise from ignition of flammable or combustible materials not only by direct contact with the flame, but also by contact with the hot slag or workpiece which may take a considerable time to cool down. The following precautions are necessary to prevent fires: Move all flammable or combustible materials to a safe place away from the work area. Use suitable means to protect combustible materials that cannot be moved from close contact with flame, heat, hot slag or sparks such as covering with fire resistant materials. ◆ Use suitable means to prevent slag or spark from reaching combustible materials along or down ducts, channels and through holes in walls and floors, such as covering the openings by fire resistant materials. ◆ Prevent equipment for gas welding and flame cutting from being contaminated with oil or grease. ◆ Before starting welding or cutting work on used containers, ensure that the container is free from any substance that may emit flammable or toxic vapours upon heating by washing with suitable solvents and purging with inert gas. ◆ Provide suitable fire-fighting equipment such as fire extinguishers, buckets of sand near by the work area. ◆ Ensure that sparks and slag from the work are extinguished ◆ and cooled before leaving the work area. 7 10. Equipment Checking and Maintenance ◆ Pre-use equipment check Each time before starting a welding or cutting operation, it is necessary to check that equipment and safety devices are correctly installed and in good working condition. Pre-use equipment check includes: ● ● ● ● ensuring that each gas cylinder is fitted with regulator of the correct type and is correctly connected to the blowpipe; checking for defective or damaged hoses such as cuts, cracks and abrasion; replacing or repairing the hose by a competent person if necessary; checking all gas line connections for leakage by using soapy water; ensuring that the routing of the gas hoses will not cause severe bending of the hose or will not be run over by other heavy equipment so as to prevent gas flow being obscured or hose being damaged. ◆ General examination and maintenance of equipment In addition to the pre-use equipment check, all the equipment should be regularly examined for defects and malfunctions. The frequency of examinations depends on the frequency of use of the equipment and the conditions in which it is used 12 such as the aggressive nature of the working environment. Defective or damaged equipment should be taken out of service immediately and repaired by competent person if applicable. The regular examination of equipment should include checking for the following defects: arresters, resulted in low gas flow rates; Fuel gases and oxygen are commonly stored under pressure in gas cylinders. Fuel gases such as acetylene, hydrogen and propane are flammable. Moreover, acetylene is potentially unstable and may decompose violently in the absence of oxygen or air. Safe practice in storing and handling gas cylinders includes the following: incorrect operation of non-return valves, resulted in ◆ ● internal gas leakage in pressure regulators; ● incorrect operation of pressure gauges; ● build-up of deposits of combustion products in flashback ● 5. Safe Storage and Handling of Gas Cylinders reverse flow not shutting off; ● defective blowpipe such as internal gas leakage, blockage at the nozzle. ◆ ◆ ◆ ◆ ◆ 13 Ensure that gas cylinders upon receipt are appropriately coloured and correctly labelled, and have no sign of gas leakage. Store gas cylinders in a cool and well-ventilated place, away from any heat or ignition source, and keep cylinders in use away from the welding and cutting work. Always keep gas cylinders in an upright position and securely anchored to strong supports, no matter during storage or when in use. Keep the quantity of gas cylinders under storage to a practical minimum and in compliance with the requirements under the Dangerous Goods Ordinance. Handle gas cylinders with care and do not throw or bump the cylinders heavily. Inform the supplier immediately if the gas cylinder is found to be physically damaged. Move gas cylinders on wheeled trolleys designed for the purpose and securely fasten the cylinder to the trolley during movement to prevent damaging the cylinder valves and to minimise the risk of injury. 6 Typical equipment for gas welding and flame cutting using oxy-acetylene flame Emergency procedures should be established which workers should follow if a situation presenting serious and imminent danger arises. The procedures should include guidance for the workers explaining when and how they should stop work and move to a safe location, or even fully evacuate the workplace. Actions for pressure regulator with pressure gauge nozzle flashback arrester 11. Emergency Procedures flashback arrester cylinder valve dealing with some of the possible emergency situations in gas welding and flame cutting are listed in the following: ◆ If there is a sustained backfire in a blowpipe, ● first close the oxygen valve of the blowpipe, followed by the fuel valve and then close both cylinder valves; ● investigate the cause and rectify the fault; ● blowpipe ◆ non-return valve If there is a flashback into the hose and equipment, or a hose fire or explosion, or a fire at the gas regulator connections, ● isolate the fuel gas and oxygen supplies by closing the ● ● flexible hose (acetylene - red) (oxygen - blue) acetylene cylinder (maroon) 5 re-light the blowpipe only after it is completely cooled down. cylinder valves only when this can be done safely; may attempt to control the fire by fire-fighting equipment only when there is no undue risk of personal injury; activate the fire alarm and call for the Fire Services Department. oxygen cylinder (black) 14 ◆ Fires involving acetylene cylinders are always best dealt with by firemen from the Fire Services Department. However, the following initial response may be appropriate: ● cool the cylinder by spraying with water only if it is safe to do so; ● ● close the cylinder valve to control the fire only if it is safe to do so; evacuate the building by activating the fire alarm or by any other means. Never attempt to move an acetylene cylinder that has been involved in a fire, or move one which has been affected by heat from a nearby fire even if it appears to have been cooled down. Moving the cylinder may lead to explosion! 4. Gas Supply System and Associated Safety Devices In general, each one of the two gases (the fuel gas and oxygen) used in gas welding and flame cutting is supplied from a single gas cylinder. Other methods of supply may be from a number of gas cylinders connected by a manifold, or from a bulk supply installation. Each gas is supplied through a flexible hose to the blowpipe where the fuel and oxygen are mixed in an appropriate proportion and combusted to form the required flame for welding or cutting. For distinguishing between the fuel gas and oxygen supplies, the gas cylinder and hose for each gas should be appropriately coloured. Other safety devices necessary for reducing the risk of fire and explosion in the gas supply system include: ◆ Pressure regulator and pressure gauges to control and monitor the pressure of the gas supply; ◆ Non-return valve at each gas inlet of the blowpipe to prevent back-feeding of oxygen to the fuel line and vice versa; ◆ Flashback arrester (flame arrester) incorporating pressure or temperature cut-off valve to prevent propagation of flashback from the blowpipe and gas hoses into the gas cylinders. 15 4 3. Health Hazards 12. Instruction and Training Health hazards of gas welding and flame cutting are mainly due to the radiation and toxic fumes or gases emitted during the process. These hazards include: ◆ Eye injuries ● ● heat cataract caused by infra-red radiation from molten All personnel involved in gas welding and flame cutting operations should be fully instructed and trained on the safety and health aspects of the work under normal operation as well as in case of emergency. The instruction and training should appropriately cover: metal, resulted in not able to see things clearly; ◆ hazards in gas welding and flame cutting; arc eye caused by ultra-violet radiation emitted during ◆ selection and use of the appropriate equipment for the the process, resulted in very painful and watery eyes; ● foreign particles e.g. slag and cutting sparks; ◆ Skin irritation and reddening due to over exposure to radiation; ◆ Inhalation of fumes or gases produced during the process ● ◆ ◆ the role of the safety devices and their limitations; ◆ selection and use of the ventilation system and personal protective equipment and their limitations; metal fume fever which is a febrile illness due to freshly formed metal oxide fumes; ◆ safe operating procedures; ● toxic fumes of metals such as lead, cadmium, beryllium; ◆ emergency procedures; ● toxic gases such as oxides of nitrogen, fluorides resulted ◆ other aspects specific to the operation such as in bronchial and pulmonary irritation; ◆ operation; other injuries such as corneal ulcer and conjunctivitis from Burns from the blowpipe flame, hot slag or hot surfaces of ● manual handling operation of large workpieces, the workpiece; ● safe operation during working at height or in confined Personal injuries due to handling gas cylinders or large spaces. workpieces. 3 16 13. Unsafe Acts 2. Fire and Explosion Hazards Many serious accidents have occurred in the industry due to misuse of oxygen, gas decanting and warming up gas cylinders. These are unsafe acts. Fire and explosion hazards of gas welding and flame cutting are mainly due to problems with the gas supply system, or due to the high temperature of the flame used or the hot slag produced in ◆ the process. These hazards include: Misuse of oxygen Explosion may occur when oxygen contacts combustible materials. Never use oxygen to: ● provide a source of pressure or a substitute for compressed air, such as to clear blockages in pipelines, ● ● ● ◆ ◆ fuel gases or oxygen into the atmosphere from leaks at joints, hose connections or fittings of the gas supply system; ◆ to power air-driven tools; blow-down clothing, equipment or work areas to remove dust, etc.; ventilate a confined space instead of air; or sweeten the air of any work area or space. as oxygen is charged into an acetylene cylinder. Fires and explosions in the gas supply system caused by ● flashback from the blowpipe due to gas lines not completely purged before lighting up, or back-feeding of fuel gas into the oxygen line or vice versa; ● decomposition or detonation of acetylene in the absence of oxygen or air due to flashback at the blowpipe or overheating of gas cylinder; Gas decanting Recharging gas cylinders by connecting them to other cylinders or a gas supply (known as gas decanting) is extremely dangerous. Explosion may occur if ● the gas line or its connections or the gas cylinders cannot withstand the high pressure during decanting; ● the decanting involves mixing of incompatible gases, such Fires and explosions resulted from the release of flammable ● high-pressure oxygen (without fuel gas) which promotes combustion of materials such as oil, grease, organic compounds, aluminium metal and its alloys, and elastomers used in valve seats and seals; ◆ Explosions from over-pressurisation of the gas supply system; ◆ Fires from the ignition of flammable or combustible materials in the vicinity by the flame of the blowpipe, hot surfaces of the workpiece or hot slag from the process. 17 2 ◆ 1. Introduction In gas welding and flame cutting, a fuel gas is mixed with oxygen or air in a blowpipe to produce a flame hot enough to fuse the surfaces together, or in case of cutting hot enough for the formation of molten oxides of the metal involved. Fire and explosion are the hazards that may be encountered due to problems with the gas supply system or due to the hot slag resulted from the process. Besides, toxic fumes and radiation produced during the process may also pose health hazards to the people at work. Warming up gas cylinders Warming up gas cylinders by any means in order to increase gas flow or to extract the last bit of gas stored in the cylinder for use is extremely dangerous. Fire and explosion may occur due to: ● ● the gas supply system not capable of withstanding the resulted increase in gas pressure; evaporation of the solvent (acetone in general) for storing acetylene in the gas cylinder by the heat, causing damage to the gas hose and blowpipe and change in composition of the fuel/oxidant mixture for the flame. This guidebook presents the safe practice in gas welding and flame cutting with the commonly used oxy-acetylene flame. The safe practice is also applicable to welding and cutting with flames using other fuel gases such as propane (commonly known as 'liquefied petroleum gas' or 'LPG') and hydrogen. It is intended to provide proprietors, managers, safety personnel and supervisors of industrial undertakings general guidelines in protecting people at work from the hazards of gas welding and flame cutting, and in reducing the injuries and damage caused by fires and explosions. 1 18 Contents 14. Useful Information If you wish to enquire about this guidebook or require advice on occupational safety and health, please contact the Occupational Safety and Health Branch of the Labour Department through: Telephone : 2559 2297 (auto-recording after office hours) Fax : 2915 1410 E-mail : laboureq@labour.gcn.gov.hk Page 1. Introduction ............................................................ 1 2. Fire and Explosion Hazards ................................... 2 3. Health Hazards ...................................................... 3 4. Gas Supply System and Associated Safety Devices .................................................................. 5. Information on the services offered by the Labour Department and on major labour legislation can also be found by visiting our Home Page in the Internet. Address of our Home Page is http:// www.info.gov.hk/labour. 4 Safe Storage and Handling of Gas Cylinders ................................................................ 6 6. Fire Prevention and Protection ............................... 7 7. Health Protection and Ventilation ........................... 8 8. Personal Protective Equipment ............................. 9 9. General Safe Practices .......................................... 10 10. Equipment Checking and Maintenance ................ 12 11. Emergency Procedures ......................................... 14 12. Instruction and Training ......................................... 16 13. Unsafe Acts ............................................................ 17 14. Useful Information .................................................. 19 19 A Guide to Safety and Health at Work for Gas Welding and Flame Cutting Occupational Safety and Health Branch Labour Department Occupational Safety and Health Branch Labour Department 4/99-1-B59