UPC-32/UPC-12 Operation Manual

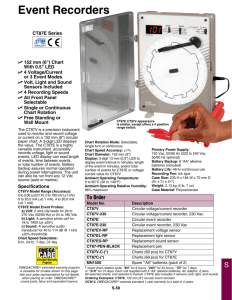

advertisement