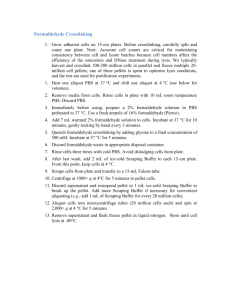

FORMALDEHYDE 1. Exposure Data

advertisement