Principles of Engineering: Statics & Material Properties Overview

advertisement

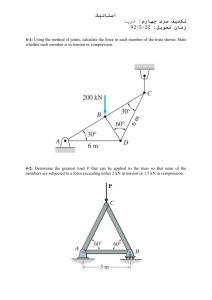

Course: Principles of Engineering Unit: Course Overview Week 4-6 of 12 PLTW Objectives Guiding Questions/ Specificity Statics · Create free body diagrams of objects, identifying all forces acting on the object . · Mathematically locate the centroid of structural members. · Calculate moment of inertia of structural members. · Differentiate between scalar and vector quantities. · Identify magnitude, direction, and sense of a vector. · Calculate the X and Y components given a vector. · Calculate moment forces given a specified axis. · Use equations of equilibrium to calculate unknown forces. 1. Why is it crucial for designers and engineers to construct accurate free body diagrams of the parts and structures that they design? 2. Why must designers and engineers calculate forces acting on bodies and structures? 3. When solving truss forces, why is it important to know that the structure is statically determinate? Course Length: 12 weeks Days to teach: 14 days Assessment Vocabulary Instructional Strategies Explanation Students will explain the importance of free body diagrams. Students will explain how loads are transmitted through a structure. Students will explain how to calculate internal and external reaction forces relating to a structure. Interpretation Students will write journal entries reflecting on their learning and experiences. An example writing prompt: What is something you learned today about structures, mathematics, or forces that you did not understand or know before? Application Students will apply their knowledge of statics to Cable Centroid Compression Force Concurrent Force Systems Cross-Sectional Area Direction Fixed Support Flange Free Body Diagram Gusset Joint Magnitude Member Method of Joints Moment Moment of Inertia Newton’s First Law Newton’s Second Law Newton’s Third Law Pinned Support Planar Truss Resultant Force Roller Support Class Discussion Lectures/Power Points Activities Projects Resources/ Weblinks Presentations Introduction to Statics Centroids Activity 2.1.1 Centroids Activity 2.1.2 Beam Deflection Activity 2.1.3 Free Body Diagrams Introduction to Structural Member Properties Free Body Diagrams Force Vectors Activity 2.1.4 Calculating Force Vectors Activity 2.1.5 Calculating Moments Activity 2.1.6 Step-by-Step Truss Systems Activity 2.1.7 Calculating Truss Forces Moments Calculating Truss Forces Websites: http://www.ac.ww u.edu/~vawter/Phy sicsNet/Topics/Dy namics/Forces/Fre eBodyDiagram.ht ml Course: Principles of Engineering Unit: Course Overview Week 4-6 of 12 PLTW Objectives Guiding Questions/ Specificity · Use the method of joints strategy to determine forces in the members of a statically determinate truss. Course Length: 12 weeks Days to teach: 14 days Assessment Vocabulary Instructional Strategies calculate the internal and external forces acting on a system. Students will create a truss system to withstand design requirements. Perspective At the conclusion of the lesson, students will reflect on what they would have done differently if the truss design project were to be repeated. Empathy Students will describe the experience a structural member undergoes as loads are applied and removed from the member. Scalar Sense Simple Truss Static Equilibrium Statically Indeterminate Structure Tension Force Vector Quantity Project 2.1.8 Truss Design (VEX) Truss Tester Build Instructions (VEX).pdf Truss Tester Build Instructions(VEX) .doc Truss Testing Procedure (VEX) Project 2.1.8 Truss Design (SSA) Lesson 2.1 Key Terms Crossword Resources/ Weblinks http://www.pbs.or g/wgbh/nova/bridg e/ Course: Principles of Engineering Unit: Course Overview Week 4-6 of 12 PLTW Objectives Guiding Questions/ Specificity Material Properties (4 days) · Investigate specific material properties related to a common household product. · Conduct investigative nondestructive material property tests on selected common household product including testing for continuity, ferrous metal, hardness, and flexure. · Calculate weight, volume, mass, density, and surface area of selected common household product · Identify the manufacturing processes used to create the selected common household product. · Identify the recycling codes. · Promote recycle using current media trends. 1. How does an engineer predict the performance and safety for a selected material? 2. What are the advantages and disadvantages of utilizing synthetic materials designed by engineers? 3. What ethical issues pertain to engineers designing synthetic materials? 4. What did you learn about the significance of selecting materials for product design? 5. How can an existing product be changed to incorporate different processes to make it less expensive and provide better performance? Course Length: 12 weeks Days to teach: 14 days Assessment Vocabulary Instructional Strategies Explanation Students will explain the difference between the basic properties of materials, such as electrical, magnetic, mechanical, and physical. Interpretation Students will write journal entries reflecting on their learning and experiences. An example writing prompt: What is something you learned today about material properties, material categories, manufacturing processes, or recycling that you did not understand or know before? Application Students will apply their knowledge of materials, material processes, and recycling in the critique of a product that they use Additive Process Ceramic Codes Composite Decision Matrix Finishing Forming Liability Manufacturing Material Mechanical Properties Metals Physical Properties Polymers Product Life Cycle Raw Material Recycling Subtractive Synthetic Class Discussion Lectures/Power Points Activities Projects Resources/ Weblinks Presentations Introduction to Materials/ Manufacturing Processes Recycling Materials Activity 2.2.1 Product Analysis Activity 2.2.2 Manufacturing Processes Activity 2.2.3 Recycling Activity 2.2.3a Recycling Facts Lesson 2.2 Key Terms Crossword SME Videos (Virtual Academy) Websites: http://www.afandp a.org http://www.eartho dyssey.com/symbo ls.html http://www.enviro nment.gov.au/settl ements/industry/c orporate/eecp/pub lications/images/sh op2.gif http://www.corrug ated.org Course: Principles of Engineering Unit: Course Overview Week 4-6 of 12 PLTW Objectives Guiding Questions/ Specificity Course Length: 12 weeks Days to teach: 14 days Assessment Vocabulary Instructional Strategies every day, such as a cell phone or MP3 player. Material Testing · Utilize a five-step technique to solve word problems. · Obtain measurements of material samples. · Tensile test a material test sample. · Identify and calculate test sample material properties using a stress strain curve. 1. Why is it critical for engineers to document all calculation steps when solving problems? 2. How is material testing data useful? 3. Stress strain curve date points are useful in determining what specific material properties? Explanation Students will explain the importance of material testing as a verification process. Application Students will tensile test a material sample and identify and calculate material properties. Interpretation Students will write journal entries reflecting on their learning and experiences. An example writing prompt: What is something you learned today about material testing, manufacturing processes, or engineering problem solving that you did not understand or know before? Resources/ Weblinks www.epa.gov Axial Stress Breaking Stress Compression Deformation Destructive Testing Elastic Limit Elongation Factor of Safety Failure Point Fatigue Hooke’s Law Modulus of Elasticity Nondestructive Testing Problem Solving Proportional Limit Quality Control Reliability Resilience Rupture Strength Shear Stress Standard Deviation Statistics Strain Stress Stress-Strain Curve Tension Toughness Ultimate Stress Variance Class Discussion Lectures/Power Points Activities Projects Activity 2.3.1 Stress/Strain Calculations Presentations Material Testing Using the Stress Analyzer for Tensile Testing (SSA) Websites: Material Testing Formula Sheet Activity 2.3.2 Tensile Testing (SIM) Activity 2.3.2 Tensile Testing (SSA) Activity 2.3.2a Machining the Test Sample (SSA) Activity 2.3.2 Tensile Testing http://www.mathsi sfun.com/standard -deviation.html http://web.mit.edu /course/3/3.11/ww w/modules/ss.pdf Course: Principles of Engineering Unit: Course Overview Week 4-6 of 12 PLTW Objectives Guiding Questions/ Specificity Course Length: 12 weeks Days to teach: 14 days Assessment Vocabulary Instructional Strategies Resources/ Weblinks (SSA) Lesson 2.3 Key Terms Crossword Materials & Structures (2 days) · Brainstorm and sketch possible solutions to an existing design problem. · Create a decision making matrix for the design problem. · Select an approach that meets or satisfies the constraints given in a design brief. · Create a detailed pictorial sketch or use 3D modeling software to document the best choice, based upon your team’s decision matrix. · Present a workable design solution. 1. What is a design brief? What are design constraints? 2. Why is a design process so important to follow when creating a solution to a problem? 3. What is a decision matrix and why is it used? 4. What does consensus mean, and how do teams use consensus to make decisions? 5. How do the properties and types of materials affect the solution to a design problem? Explanation Students will explain why project design options are determined by criteria and constraints. Application Students will design an alternate solution to the design brief and adjust the solution to include a different material. Interpretation Students will illustrate their proposed solution and use the illustration to explain what they have learned about engineering design. Accuracy Assembly Brainstorming Component Consensus Constraint Decision Matrix Design Brief Design Modification Design Process Design Statement Designer Open-Ended Pictorial Sketch Problem Statement Purpose Sketch Solid Modeling Target Consumer Team Class Discussion Lectures/Power Points Activities Projects Problem 2.4.1 Structural Design Career Field Description Lesson 2.4 Key Terms Crossword Presentations Teamwork Design Process Overview