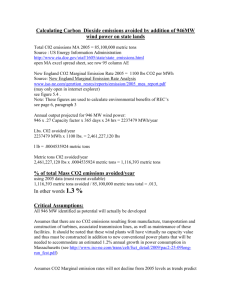

Summary - Climate Mitigation Services

advertisement