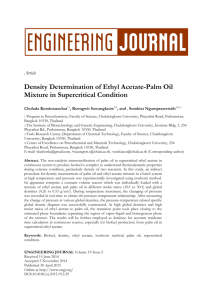

Density of Ethyl Acetate-Palm Oil Mixture in - cu e

advertisement

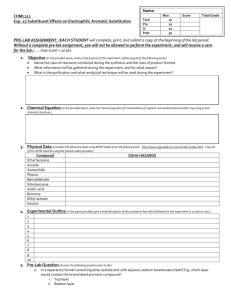

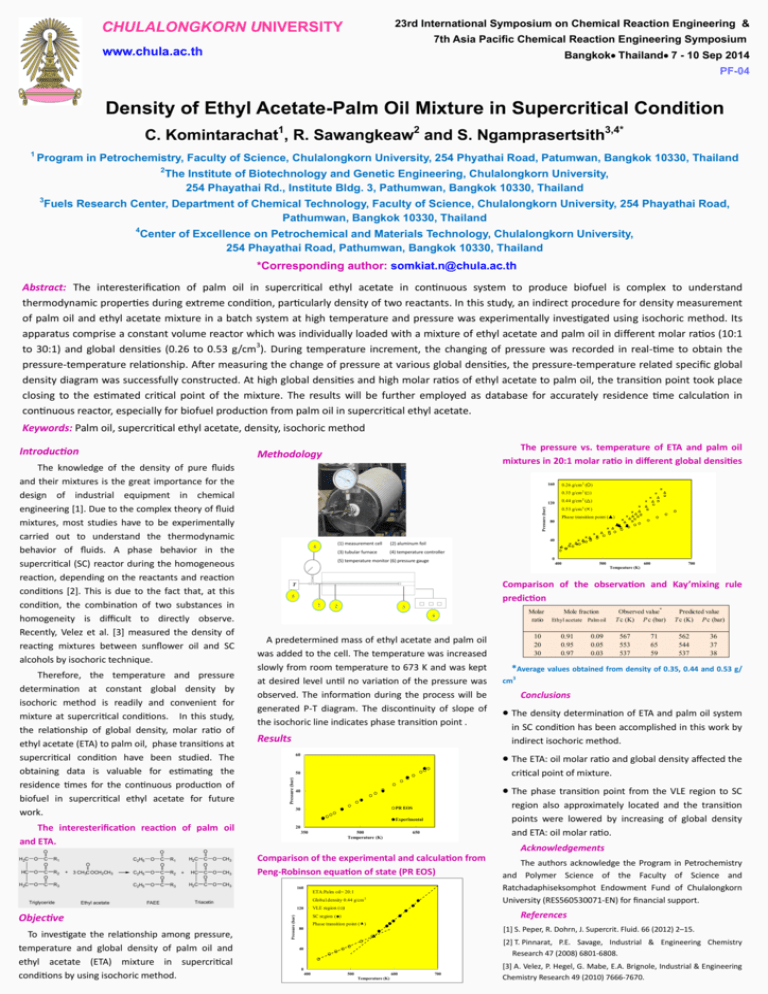

23rd International Symposium on Chemical Reaction Engineering & CHULALONGKORN UNIVERSITY 7th Asia Pacific Chemical Reaction Engineering Symposium www.chula.ac.th BangkokThailand7 - 10 Sep 2014 PF-04 Density of Ethyl Acetate-Palm Oil Mixture in Supercritical Condition 1 2 C. Komintarachat , R. Sawangkeaw and S. Ngamprasertsith 1 3,4* Program in Petrochemistry, Faculty of Science, Chulalongkorn University, 254 Phyathai Road, Patumwan, Bangkok 10330, Thailand 2 3 The Institute of Biotechnology and Genetic Engineering, Chulalongkorn University, 254 Phayathai Rd., Institute Bldg. 3, Pathumwan, Bangkok 10330, Thailand Fuels Research Center, Department of Chemical Technology, Faculty of Science, Chulalongkorn University, 254 Phayathai Road, Pathumwan, Bangkok 10330, Thailand 4 Center of Excellence on Petrochemical and Materials Technology, Chulalongkorn University, 254 Phayathai Road, Pathumwan, Bangkok 10330, Thailand *Corresponding author: somkiat.n@chula.ac.th Abstract: The interesterification of palm oil in supercritical ethyl acetate in continuous system to produce biofuel is complex to understand thermodynamic properties during extreme condition, particularly density of two reactants. In this study, an indirect procedure for density measurement of palm oil and ethyl acetate mixture in a batch system at high temperature and pressure was experimentally investigated using isochoric method. Its apparatus comprise a constant volume reactor which was individually loaded with a mixture of ethyl acetate and palm oil in different molar ratios (10:1 3 to 30:1) and global densities (0.26 to 0.53 g/cm ). During temperature increment, the changing of pressure was recorded in real-time to obtain the pressure-temperature relationship. After measuring the change of pressure at various global densities, the pressure-temperature related specific global density diagram was successfully constructed. At high global densities and high molar ratios of ethyl acetate to palm oil, the transition point took place closing to the estimated critical point of the mixture. The results will be further employed as database for accurately residence time calculation in continuous reactor, especially for biofuel production from palm oil in supercritical ethyl acetate. Keywords: Palm oil, supercritical ethyl acetate, density, isochoric method Introduction Methodology Therefore, the temperature and pressure determination at constant global density by isochoric method is readily and convenient for mixture at supercritical conditions. In this study, the relationship of global density, molar ratio of ethyl acetate (ETA) to palm oil, phase transitions at supercritical condition have been studied. The obtaining data is valuable for estimating the residence times for the continuous production of biofuel in supercritical ethyl acetate for future work. 160 O HC H2C O O C O R1 O C O R2 O C R3 Triglyceride O + 3 CH3C OCH2CH3 Ethyl acetate C2H5 O C O R1 C2H5 O C O R2 C2H5 O C R3 FAEE + H2C C O O CH3 HC C O O CH3 H2C C O CH3 Pressure (bar) (2) aluminum foil (3) tubular furnace (4) temperature controller 80 0 (5) temperature monitor (6) pressure gauge 400 500 Tempeature (K) 600 700 Comparison of the observation and Kay’mixing rule prediction Molar ratio A predetermined mass of ethyl acetate and palm oil was added to the cell. The temperature was increased slowly from room temperature to 673 K and was kept at desired level until no variation of the pressure was observed. The information during the process will be generated P-T diagram. The discontinuity of slope of the isochoric line indicates phase transition point . Results 10 20 30 Mole fraction Ethyl acetate Palm oil 0.91 0.95 0.97 0.09 0.05 0.03 Observed value * T c (K) P c (bar) 567 553 537 71 65 59 Predicted value T c (K) P c (bar) 562 544 537 36 37 38 *Average values obtained from density of 0.35, 0.44 and 0.53 g/ cm3 Conclusions The density determination of ETA and palm oil system in SC condition has been accomplished in this work by indirect isochoric method. The ETA: oil molar ratio and global density affected the 60 critical point of mixture. 50 The phase transition point from the VLE region to SC 40 region also approximately located and the transition points were lowered by increasing of global density and ETA: oil molar ratio. PR EOS 30 Experimental 20 350 500 Temperature (K) 650 Acknowledgements Comparison of the experimental and calculation from Peng-Robinson equation of state (PR EOS) 160 Pressure (bar) 120 To investigate the relationship among pressure, temperature and global density of palm oil and ethyl acetate (ETA) mixture in supercritical conditions by using isochoric method. 40 (1) measurement cell Triacetin Objective 120 The interesterification reaction of palm oil and ETA. O Pressure (bar) The knowledge of the density of pure fluids and their mixtures is the great importance for the design of industrial equipment in chemical engineering [1]. Due to the complex theory of fluid mixtures, most studies have to be experimentally carried out to understand the thermodynamic behavior of fluids. A phase behavior in the supercritical (SC) reactor during the homogeneous reaction, depending on the reactants and reaction conditions [2]. This is due to the fact that, at this condition, the combination of two substances in homogeneity is difficult to directly observe. Recently, Velez et al. [3] measured the density of reacting mixtures between sunflower oil and SC alcohols by isochoric technique. H2C The pressure vs. temperature of ETA and palm oil mixtures in 20:1 molar ratio in different global densities The authors acknowledge the Program in Petrochemistry and Polymer Science of the Faculty of Science and Ratchadaphiseksomphot Endowment Fund of Chulalongkorn University (RES560530071-EN) for financial support. References 80 [1] S. Peper, R. Dohrn, J. Supercrit. Fluid. 66 (2012) 2–15. [2] T. Pinnarat, P.E. Savage, Industrial & Engineering Chemistry Research 47 (2008) 6801-6808. 40 0 400 500 600 Temperature (K) 700 [3] A. Velez, P. Hegel, G. Mabe, E.A. Brignole, Industrial & Engineering Chemistry Research 49 (2010) 7666-7670.