High Rise Multi-Residential

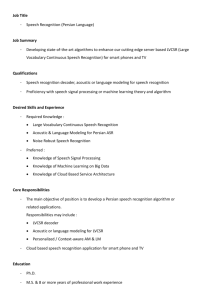

advertisement