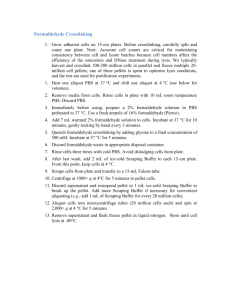

FORMALDEHYDE Z

advertisement