7. Experiment # 7: Using the Temperature Measurement and

advertisement

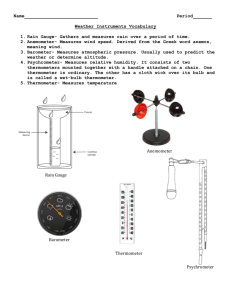

7. Experiment # 7: Using the Temperature Measurement and Calibration Unit 7.0 Objectives The objectives of this experiment are to 1. Familiarize students with different ways of temperature measurements, fixed points and transient response. 2. Indicating differences between measuring devices and showing calibration procedure for some probes (Thermistor) 3. Verifying the Seebeck effect experimentally 7.1 Unit Description Please refer to the Schematic Diagrams in Figures 1 and 2. 7.1.1 The Control Console: The control console contains a number of instruments, round Din connectors and 2mm connector sockets. These are used together with the sensors supplied and a set of 2mm stackable connecting leads to investigate the various electronic methods of temperature measurement. In addition, inside the console is a voltage amplifier and a constant current source that are also used as part of the investigations. For operator safety, on the rear panel is an earth leakage circuit breaker (RCCB) (21). This will isolate the unit from the mains in the event that the incoming and outgoing currents do not balance by more than 3 mA as in a leakage to earth situation. 7.1.2 The Heater Plate A heater plate(25) and stainless steel beaker are also supplied to provide students with a variable temperature source that can be used to provide a test environment for the various sensors. The hot plate power is supplied from either of the two auxiliary power outlets (22,23) on the rear panel. The stainless steel beaker is supplied with a number of temperature indicating self adhesive strips attached, These demonstrate to students an additional method of temperature indication and the use of color change crystals that are sensitive to a particular range of temperatures. On the front panel, the Main switch (1) is a combined double pole miniature overload cut out and switch. The components on the front panel are arranged in logical groups according to their function. The main components are as follows: 7.1.3 Platinum Resistance Thermometer, PRT The direct reading platinum resistance thermometer (12) is connected to the socket PRT thermometer input (11). Connecting the PRT probe supplied to this socket will allow the Page 1 of 15 temperature to be displayed on the digital display. Note that the PRT probe supplied has a plug that will only fit the PRT associated sockets on the panel. A second socket PRT probe resistance (10) allows the resistance of the probe to be directly measured using the digital hand held meter supplied. To investigate the operation of a PRT probe, an internal constant current source (9) is available. Adjacent to this are sockets connected to internal resistors that can be used to simulate connecting wire resistances (8). Finally an additional 4 wire probe input output (7) socket allows students to investigate the wire connections of the PRT probe that is supplied 7.1.4 Thermistor The direct reading thermistor thermometer (15) is connected to the socket thermistor thermometer input (14). Connecting the Thermistor probe supplied to this socket will allow the temperature to be displayed on the digital display. Note that the Thermistor probe supplied has a plug that will only fit the Thermistor associated sockets on the panel. A second Thermistor Resistance socket (13) allows the resistance of the probe to be directly measured using the digital hand held meter supplied. 7.1.5 Thermocouples The direct reading thermocouple thermometer (16) is connected to the thermocouple sensor sockets (17) and the associated switches. Any of the type K thermocouples supplied may be connected to the sockets and when the switch is pressed Down, the thermocouple is connected directly to the thermocouple thermometer(16). In order to investigate the fundamental principles of thermocouples, the connectors grouped as amplifier input (3) connect any of the three types of thermocouples supplied (and any locally available thermocouple) to an internal voltage amplifier. The resulting amplifier output is available at the amplifier output(4) terminals. The amplifier has a fixed gain to allow calculations to be undertaken. In order to display the resulting voltage a panel mounted millivolt meter(6) is supplied. To allow investigation of the effect of lead resistances and the input impedance of measuring instruments three internal resistors(19) off different ‘values are located at the bottom of the panel. There are also sockets (18) that are not connected and spring terminals(2) (for bare wires) that allow thermocouples to be linked in various ways. 7.2 Accessories A number of accessories are supplied with the unit and are normally contained in a carrying case. 7.2.1. Red Spirit in Glass Thermometers A number of red spirit in glass thermometers are provided. For new students these are probably the most familiar type of temperature measuring device. 7.2.2. Bi-metalic Thermometer A bi-metal thermometer is provided using the differential expansion of metals. 7.2.3. Vapour Pressure Thermometer Page 2 of 15 A thermometer using the change in vapor pressure of a volatile fluid is supplied. 7.2.4. Thermocouples Three types of thermocouples are supplied Type Thermocouple Nickle-Chrome + Nickle-Aluminium Type K Copper+Copper-Nickle. Type T lron+Coppcr-Nickle Type J Color Code +ve Green +ve Brown +ve Black -ve White -ve White -ve White Tables showing the voltage output from type K, T and J Thermocouples are given in appendix A Of the type K thermocouples, one set are shrouded within a stainless steel tube and the others are exposed. All of the thermocouples are connected to stackable 2mm plugs that fit fire various sockets on the panel. 7.2.5. Connecting Leads In order to interconnect the various components on the panel, a number of color coded 2mm stackable leads are supplied. 7.2.6. Rubber Disc A large robber disc with holes is also supplied to be placed on top of the stainless steel beaker. The holes may be used to support the various temperature sensing devices when undertaking experiments. 7.2.7. Vacuum Insulated Flask A vacuum insulated flask is provided to contain either an ice-water mixture (for the zero 0oC reference) or alternatively heated water. Due to the insulation the ice in the water will remain solid for an extended period of lime and the heated water temperature will remain constant for long enough to allow temperature measurement, It is recommended that the accessories are kept in the carrying case for security. Page 3 of 15 Page 4 of 15 Page 5 of 15 7.3 PRECAUTIONS AND WARNINGS (SAFETY) The Temperature Measurement Methods and Calibration unit H981 involves the use of both electrical equipment and heated water. The following precautions must be observed. 1. In the event of a water spillage on or near the unit, DO NOT TOUCH THE CONTROL CONSOLE. Isolate the unit electrically at the local supply point and then remove the power supply lead from the main power inlet (20) on the rear panel. The unit can then be dried in the normal manner. 2. The heater plate (25) can (as its name implies) reach temperatures that will cause severe burns if touched with bare hands. 3. In order to demonstrate the boiling water reference point, the beaker is used together with the heater plate (25), rubber disc and one or more temperature sensors inserted in the boiling water. Students should be made aware of the potential for steam to vent through the various boles in the rubber disc and the severe burns that steam can cause. Obviously the potential for bums resulting from spillage of the boiling water must also be mentioned to the operators. It is recommended that when the heater plate (25) and stainless steel beaker are being used, the operators are provided with industrial gloves, or similar with which to move the temperature sensing devices and the beaker. 4. In order to ensure the best possible accuracy and hence illustration of the procedures being demonstrated, it is recommended that pure water distilled is used for both the ice being generated for use in the vacuum insulated flask and the water for the beaker. 5. It is possible for the internal amplifier, constant current source and panel mounted millivolt meter (6) to be severely damaged by incorrect connection when setting up the various experimental circuits. 6. BEFORE turning on the main switch (1), ensure that the connecting leads supplied have been correctly connected according to the diagrams and illustrations detailed in each of the relevant experimental procedures. Page 6 of 15 7.4 OPERATING PROCEDURES It is assumed that the installation procedures have been carried out and that the heater plate (25) is connected to power outlet (22, 23) sockets on the rear panel. Ensure that the Precautions and Warnings detailed on page 6 have been read, understood and explained to the students/operators. Control console Ensure that there are none of the sensors or stackable connecting leads attached to the instrumentation console. Turn on the main switch (1) and the instruments on the panel should illuminate. If this is not the case check the earth leakage circuit breaker (21) on the rear panel. Heater Plate When power is supplied, the main switch on the heater plate (25) may be turned on. The heater plate(25) has a temperature control dial, This is purely an indication of approximate temperature and is similar in accuracy to the scale that may be found on any domestic cooker or electrical appliance. The control method is also similar in that the control is a simple on-off thermostat. Water and Ice For many of the experiments an ice and water mixture is required together with water for heating in the stainless steel beaker. As detailed in the Precautions and warnings on page 6, the water should be pure distilled water or at least de-ionized. If there is an appreciable amount of salts or other impurities in the water, the melting and boiling temperature can vary considerably from 0 and 100oC. After using the stainless steel beaker and vacuum flask it is recommended that these are dried and cleaned in order to prevent the build up of any residual salts on the inside surfaces. Obviously it is recommended that a store of ice is available in advance of the experimental period. For the ice reference it is necessary to have a mixture of solid ice and liquid water in the vacuum flask. The 0oC reference will not be obtained until there is a mixture of BOTH solid and liquid water in the flask. Care of the Equipment As the unit consists of a number of loose items it is recommended that at the end of each experimental period, the components are checked off against the packing list supplied with the unit and the loose items are stored in the carrying case supplied. USEFUL DATA Internal Amplifier Gain: Voltage Out = Voltage In × 40 Internal Constant Current Source: Current Output = 0.5 mA = 0.5 × 10-3 Amps Page 7 of 15 7.5 TEMPERATURE MEASUREMENT OF FIXED SCALE POINTS. 7.5.1 Temperature Temperature is a difficult concept to understand and describing it as the degree of “hotness or coldness” of a body is not sufficient where measurement is concerned. Technically, it is defined as an indication of internal energy. 7.5.2 Temperature Scales and Fixed Points Temperature differs from properties such as mass length and time and cannot be measured by comparison to basic standards. In devising a scale for measurement of temperature, an easily reproducible physical state of a material has to be utilized. The temperature at which this state occurs is called a “fixed point” and a scale may be created by reference to such points. For example, the centigrade scale is based on the points at which (pure water) ice melts and pure water boils (at standard atmospheric pressure). The ice point is given the value 0 Centigrade and the boiling point 100 Centigrade. The range between these two fixed points is divided into 100 equal parts. Modern developments in thermometry have indicated that the ice point be substituted by the triple point of water on the grounds of reproducibility. The triple point of water is an easily reproducible state of pure water existing as a mixture of ice, liquid and vapor in equilibrium. The temperature of the triple point is given the value of 0.01 Celsius. The Celsius scale is the same as and replaced the centigrade scale in modem thermometry. The zero having been shifted to give: 0.010 Celsius (0.0l oC) at the triple point Alternative scales have been derived to define temperature. One example attributed to Lord Kelvin is the Thermodynamic Scale. This scale is independent of material properties and relates to a thermodynamically reversible heat engine. The unit of measurement is the Kelvin and the triple point of water is given the value 273.16 Kelvin (273. l6 K) A similar scale is the Absolute scale which is defined by the relationship PV = RT for a perfect or ideal gas. In both cases, the unit of measurement corresponds to the Celsius unit and absolute measurement of temperature may be stated by adding 273.16 to the Celsius value. e.g. 1000C = 373.16K. 7.5.3 International Temperature Scale (ITS9O) The international temperature scale was devised to permit rapid calibration of scientific and industrial instruments. The scale agrees with the Celsius scale at defined fixed points below and above the 0 – 100 oC range. Typical fixed points are listed below: Page 8 of 15 • Between 0.65K and 5.0K temperature is defined by the vapor pressure-temperature relationship of (liquid) Helium. • Between 3.0K and the triple point of neon( at 24.5561 K), temperature is defined by means of a helium gas thermometer calibrated at three experimentally realizable temperatures. • Between the triple point of hydrogen (at 13.8033K) and the freezing point of pure silver (at 96l.780C) is defined by means of platinum resistance thermometers calibrated at specified sets of points using specified interpolation methods. • The variation in electrical resistance of platinum wire with temperature can be used to measure temperature. • No single platinum resistance thermometer can be used to cover the entire scale but a range of platinum resistance probes are used and calibrated at a range of repeatable fixed points Mathematical equations are then used to define the variation in resistance between the fixed points. The repeatable fixed calibration points are defined between ranges of points as follows. Between triple point of hydrogen (at 13.8033K) and the triple point of pure water (at 273.16K) the thermometer is calibrated at the triple points of: • • • • • • Hydrogen (1 3.8033K) Neon (24.5561K) Oxygen (54.3584K) Argon (83.8058K) Mercury (234.3 156K) Water (273.l6K) From 0oC to the freezing point of pure silver (961.78 oC), the thermometer is calibrated at the following freezing points: o o o o Tin(231.928 oC) Zinc(419.527 oC) Aluminum (660.3 23 oC) Silver(961.78 oC) Above the temperature 961.78 the international Temperature standard refers to the Planck law of black body radiation which is beyond the scope of this experiment. Page 9 of 15 7.6 Experiment 7a: The use of different temperature measuring units to measure fixed scale points 7.6.1 Introduction Having defined a temperature scale, the first experiment will illustrate two fixed calibration points using a red spirit in glass thermometer, vapor pressure thermometer and Bi-metallic expansion thermometer. The liquid-in-glass thermometer uses the volumetric expansion of a colored spirit inside a very small bore glass tube together with a scale engraved on the outside of the tube. The only fixed points on the scale are defined by the melting point of ice(0oC) and the boiling point of water(100 oC). The 100 (and smaller) divisions between are purely equal divisions of length, based upon the assumption that over that range the volumetric expansion of the spirit is linear with respect to temperature. The vapor pressure thermometer utilizes fixed relationship between pressure and temperature that exists when a a liquid and its vapor (only, no other gases or air) are contained in a closed vessel. The P-T relation is well defined. It consists of a metal bulb, partially filled with liquid and its vapor fills the space on top of the liquid. The fluid is connected to the sensing element of a Bourdon tube gage. The gage is calibrated directly to units of temperature. The P-T relation is nonlinear, this is the reason the sensitivity of the unit decreases at low readings. The Bi-metallic expansion thermometer is made of two thin metal strips, having different coefficients of expansion, are mechanically fastened together. This results in a strip that bends significantly when heated. One end is fixed while the other end is attached to a pointer. It is widely used whenever accuracy is not so important. The Platinum resistance sensor The Platinum resistance sensor is one of the most accurate devices available for temperature measurement and is often calibrated for reference purposes. The sensor uses a small length of platinum wire trimmed to have a particular resistance at specific temperature. The current device has a resistance of 100 Ohms at 0oC. The advantage of the PT100 device is that above and below the reference temperature, the resistance change is essentially linear. The Thermistor An alternative device that is used in a similar manner to the PT 100 probe is a thermistor. This is a small resistor that exhibits similar characteristics to the P17100 sensor in that its resistance changes with temperature. However in most cases the resistance change is nonlinear but has a much greater range than the PT100 sensor In addition, the thermistor sensors can have a negative or positive change of resistance with temperature. Because of their low cost, they are often also used in electronic thermostats. The Thermocouples Peltier Thermo-Electric Effect A thermocouple consists of two dissimilar metals joined together at one end. When the metallic junction is heated, a very small voltage is generated known as the Peltier voltage. This voltage is a function of the metals involved and the temperature of the junction. Page 10 of 15 The Seebeck Thermo-Electric Effect If two junctions of a thermocouple were maintained at different temperatures, a voltage will be generated. It is proportional to the temperature difference. Hence the two junctions can be used to determine the differences in temperature. Ice point was used as a reference junction to calculate the temperature using a thermocouple. However, if a junction temperature is known, it is possible to add or subtract the electronic signal resulting from this temperature to or from the measuring junction to determine the measuring temperature. This method is used in thermocouple instruments that display the temperature directly. Ensure the operators have read and understood both the Operating Procedure on page 7 and the Precautions and Warnings on page 6. 7.6.2 Experimental Procedure 1. Partially fill the vacuum flask with ice and water and place one of the glass tube thermometer, the vapor pressure thermometer and the Bimetallic thermometer in the mixture. Carefully stir the mixture with the thermometer to ensure that the thermometers reach the temperature of the mixture. 2. Periodically examine the thermometer in the ice water mix and observe the indicated temperature. This will be close to 0 oC. Note that it is unlikely that the indicated temperature will be Exactly 0 oC. 3. Now remove the vapor pressure thermometer and the Bimetallic thermometer from the mixture in the vacuum flask. Instead, place the PRT100, Thermistor and a K-type thermocouple in the ice-water mixture. The other ends of the PRT100, thermistor and thermocouple probes are to be connected to sockets (11), (14) and (17) in the control console, respectively. Readings are to be recorded from the displays (12), (15), and (16), respectively. 4. Meanwhile 2/3 fill the stainless steel beaker with pure water and place the rubber disc on top. Place this on the heater plate (25) and turn on the main switch (1) and the heater plate (25). Set the heater plate to a temperature of approximately 2000C. 5. As the water is heated, record the readings of the PRT100, Thermistor, liquid-in-glassthermometer and the thermocouples (in Table 1) until water boils. 6. Once the water in the stainless steel beaker has reached boiling point(steam will be issuing from the holes in the rubber disc) turn the temperature setting down to approximately 120-1500C. This will ensure the water continues to boil but does not generate excessive amounts of steam. 7. Remove the probes from the ice-water mixture and place the vapor pressure thermometer and the Bimetallic thermometer carefully into the boiling water. Allow the thermometers Page 11 of 15 time to reach a stable temperature and carefully remove sufficiently to observe the scale measurement. This will be close to 100 oC. Notes i. Note that it is unlikely that the indicated temperature will be exactly 100 oC due to the general purpose nature of the thermometers used. ii. Note that thermometers can be purchased with specified accuracies, specified immersion lengths for specific purposes and calibrated over various ranges depending upon the fluid used and the application iii. The boiling point of water occurs at 100 oC for standard atmospheric pressure only. i.e. the pressure must be 760mm Hg. At lower atmospheric pressure. boiling will occur at lower temperature and, conversely. at higher atmospheric pressures, boding will occur at higher temperatures. For example, a rise in atmosphere of 27mm Hg. above the standard pressure will result in a rise of 1oC in the boiling point of water. iv. A scale which is used in various parts of the world is the Fahrenheit scale. This scale gave the values 32 oF to the ice point and 212 oF to the boiling point of water, being divided into 180 equal divisions. Instrumentation is still used calibrated in degrees Fahrenheit, but these tend to be dual calibration, incorporating Celsius equivalents. Where conversion is necessary, o C= (oF-32)/1.8 o F= (oC × 1.8) +32 Table (1) measurement of temperature using different sensors No 1 2 3 4 5 6 7 8 9 10 11 12 Type thermometer of Liquid in glass Ice-water mixture Vapor pressure Bimetallic PRT100 Thermistor KThermocouple Boiling water Page 12 of 15 7.7 Experiment 7b: Investigation of the Resistance Change of a Negative Temperature Coefficient Thermistor Sensor with Temperature. 7.7.1 INTRODUCTION One obvious disadvantage of the platinum resistance temperature probe is the fact that it utilizes a precious (and hence expensive) metal. This makes the probe relatively expensive and, in addition, it has to be protected. In addition, the electronics required to utilize the probe also tend to be relatively expensive. 7.7.2 Experimental Procedure for Investigation of the Resistance of a Thermistor Probe. • • • • • • • Select the Thermistor probe and insert the probe in the thermistor resistance socket(13). Take the digital multimeter supplied and insert the red probe into the red socket and the black probe into the black socket as shown above. Set the multimeter selector switch dial to the resistance (Ohms) scale and a range to accommodate a resistance of approximately 1000 -30000 Ohms. Partly fill the vacuum flask with pure ice-water and 2/3 fill the stainless steel beaker with pure water (replace the existing water with water at room temperature). Place the flask on the heater plate (25), turn on the main switch(1) and set the heater plate to approximately 120oC. Place the Thermistor sensor in the ice-water and observe the resistance. Record the final resistance when the probe has reached a minimum. It may be necessary to switch the meter to a higher resistance range if necessary Connect the Platinum Resistance temperature sensor probe to the PRT Thermometer input (11) and then place the probe in the stainless steel beaker. The PRT thermometer (PT100) will be used for this experiment to determine die temperature of the heating water. At regular intervals measure the temperature of the water and the resistance of the thermistor sensor up to the point where the water is boiling. Page 13 of 15 Table 2: Measurements of PRT100 Temperature and Thermistor resistance Water temperature oC (PRT100) Thermistor Resistance, Ohm Plot the data (resistance versus temperature). As may be seen the resistance change with temperature is not linear. In addition, as the temperature approaches 100 oC the rate of change of resistance becomes smaller and therefore the thermistor must be chosen with a range of variation that suits the application and the expected range of temperatures. It is to be noted that thermistors are available with a wide range of resistance variation and a wide range of temperatures. 7.8 Experiment 7c: Verifying the Seebeck thermo-electric principle 7.8.1 The following procedure is intended to verify the Seebeck Thermoelectric effect • • • • • • Select two of the shrouded type K thermocouples (green and white insulation) Partially fill the vacuum flask with ice and water Meanwhile 2/3 fill the stainless steel beaker with pure water and place the rubber disc on top. Place this on the heater plate (25) and turn on the main switch (1) and the heater plate (25). Set the heater plate to a temperature of approximately 2000C.Connect the two thermocouples as shown in Figure ensuring that both of the black thermocouple plugs are inserted in one of the white sockets (18) that are not connected. This forms an electrical joining of the similar metals of the two thermocouples. The thermocouples are shown in the figure as “K” and “K” Connect the two red plugs from the thermocouples into the red and black socket of the Amplifier Input sockets. Connect the Amplifier output to the Voltmeter Input using red and black connector cable (red to red and black to black). Turn on the main switch (1). Page 14 of 15 • • • Place both thermocouples in the vacuum flask and gently agitate. The millivoltmeter display will be close to 0.0 (no temperature difference, then no voltage difference) Note, the reading of the millivoltmeter is magnified 40 time. Thus it should be divided by 40 to get the reading as millivolts (note that the thermocouple tables in appendix 1 provide a reading in micro volts) Take one of the thermocouples and place it in hot water, the voltmeter reading will change and the reading can be converted to temperature difference using the Tables in Appendix 1 (divide the reading by 40 then multiply it by 1000 to convert it to microvolts, then obtain the corresponding temperature difference). For example, a reading of 103 mV is converted to a true value by dividing it by 40 so it becomes 2.575 mV = 2575 V. The tables indicate that this is equivalent to approximately 63 oC Therefore, we used two thermocouple junctions at two different temperatures to calculate the temperature difference. 7.9 Report Requirements A technical report is expected where it would include an introduction, objectives of the experiment(s), brief description of what you learned from each of the three procedures. Data tables, graphs and discussions are also expected. Finally, your discussions are expected to shed some light on the following issues: 1. What are the sources of errors in a thermocouple reading 2. What are the advantages of the digital temperature sensor over the thermometer 3. What are the disadvantages of the digital temperature indicator Finally, the report is to have a conclusion (the conclusion may include your suggestions for improvement) and a list of references (if you used any). Page 15 of 15