accidents and their effects

advertisement

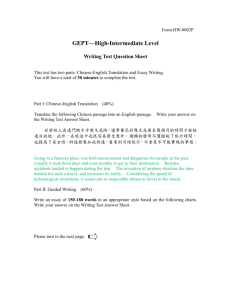

M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 18 C H A P T E R ACCIDENTS AND THEIR EFFECTS 2 Major Topics ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ Costs of Accidents Accidental Deaths in the United States Accidents versus Other Causes of Death Work Accident Costs and Rates Time Lost Because of Work Injuries Deaths in Work Accidents Work Injuries by Type of Accident Death Rates by Industry Parts of the Body Injured on the Job Chemical Burn Injuries Heat Burn Injuries Repetitive Strain/Soft Tissue Injuries Estimating the Cost of Accidents Global Impact of Accidents and Injuries There is a long history of debate in this country concerning the effect of accidents on industry (the workers and the companies) and the cost of preventing accidents. Historically, the prevailing view was that accident prevention programs were too costly. The more contemporary view is that accidents are too costly and that accident prevention makes sense economically. As a result, accident prevention, which had been advocated on a moral basis, is now justified in economic terms. Accidents are the fourth leading cause of death in this country after heart disease, cancer, and strokes. This ranking is based on all types of accidents, including motor vehicle accidents, drownings, fires, falls, natural disasters, and work-related accidents. Although deaths from natural disasters tend to be more newsworthy than workplace deaths, their actual impact is substantially less. For example, natural disasters in the United States cause fewer than 100 deaths per year on average. Workplace accidents, on the other hand, cause more than 10,000 deaths every year in the United States.1 The following quote from the National Safety Council (NSC) puts workplace accidents and deaths in the proper perspective, notwithstanding their apparent lack of newsworthiness. While you make a 10-minute speech—2 persons will be killed and about 170 will suffer a disabling injury. Costs will amount to $2,800,000. On the average, there are 11 accidental deaths and about 1,030 disabling injuries every hour during the year.2 This chapter provides prospective and practicing safety and health professionals with the information they need to have a full understanding of workplace accidents and their effect on industry in the United States. Such an understanding will help professionals play a more effective role in keeping both management and labor focused appropriately on safety and health in the workplace. 18 M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 19 Accidents and Their Effects Figure 2–1 Accident costs by accident type (in billion, in a typical year). Motor vehicle accidents 19 $72 Workplace accidents 48 Home accidents 18 Public accidents 12 COSTS OF ACCIDENTS To gain a proper perspective on the economics of workplace accidents, we must view them in the overall context of all accidents. The overall cost of accidents in the United States is approximately $150 billion. These costs include such factors as lost wages, medical expenses, insurance administration, fire-related losses, motor vehicle property damage, and indirect costs. Figure 2–1 breaks down this overall amount by categories of accidents. Figure 2–2 breaks them down by cost categories. Notice in Figure 2–1 that workplace accidents rank second behind motor vehicle accidents in cost. Figure 2–2 shows that the highest cost category is wages lost by workers who are either injured or killed. The category of indirect losses from work accidents consists of costs associated with responding to accidents (i.e., giving first aid, filling out accident reports, handling production slowdowns). Clearly, accidents on and off the job cost U.S. industry dearly. Every dollar that is spent responding to accidents is a dollar that could have been reinvested in modernization, research and development, facility upgrades, and other competitiveness-enhancing activities. ACCIDENTAL DEATHS IN THE UNITED STATES Accidental deaths in the United States result from a variety of causes, including motor vehicle accidents, falls, poisoning, drowning, fire-related injuries, suffocation (ingested object), firearms, medical complications, air transport accidents, interaction with machinery, mechanical suffocation, and the impact of falling objects. The NSC periodically computes death totals and death rates in each of these categories. The statistics for a typical year are as follows: • Motor vehicle accidents. Motor vehicle accidents are the leading cause of accidental deaths in the United States each year. They include deaths resulting from accidents involving mechanically or electrically powered vehicles (excluding rail vehicles) that occur on or off the road. In a typical year, there are approximately 47,000 such deaths in the United States. • Falls. This category includes all deaths from falls except those associated with transport vehicles. For example, a person who is killed as the result of falling while boarding Figure 2–2 Accident costs by categories (in billions, in a typical year). Wages lost $37 Medical expenses 24 Insurance administration 29 Property damage (motor vehicle) 27 Fire losses 10 Indirect losses for work accidents 23 M02_GOET9169_07_SE_C02.QXD 11/27/09 20 CHAPTER 2 • • • • • • 10:13 AM Page 20 a bus or train would not be included in this category. In a typical year, there are approximately 13,000 deaths in the United States from falls. Poisoning. The poisoning category is divided into two subcategories: (1) poisoning by solids and liquids and (2) poisoning by gases and vapors. The first category includes deaths that result from the ingestion of drugs, medicine, widely recognized solid and liquid poisons, mushrooms, and shellfish. It does not include poisoning from spoiled food or salmonella. The second category includes deaths caused by incomplete combustion (for example, gas vapors from an oven or unlit pilot light) or from carbon monoxide (for example, exhaust fumes from an automobile). In a typical year, there are approximately 6,000 deaths in the first category and 1,000 in the second. Drowning. This category includes work-related and non-work-related drownings but excludes those associated with floods or other natural disasters. In a typical year, there are approximately 5,000 deaths from drowning in the United States. Fire-related injuries. This category includes deaths from burns, asphyxiation, falls, and those that result from falling objects in a fire. In a typical year, there are over 4,000 fire-related deaths in the United States. Suffocation (ingested object). This category includes deaths from the ingestion of an object that blocks the air passages. In many such deaths, the ingested object is food. In a typical year, there are approximately 4,000 suffocation deaths in the United States. Firearms. This category includes deaths that result when recreational activities involving firearms or household accidents involving firearms result in death. For example, a person killed in the home while cleaning a firearm would be included in this category. However, a person killed in combat would not be included. In a typical year, there are approximately 2,000 such deaths in the United States. Others. This category includes deaths resulting from medical complications arising out of mistakes made by health care professionals, air transport injuries, interaction with machinery, mechanical suffocation, and the impact of falling objects. In a typical year, there are over 14,000 deaths in these subcategories.3 ACCIDENTS VERSUS OTHER CAUSES OF DEATH Although there are more deaths every year from heart disease, cancer, and strokes than from accidents, these causes tend to be concentrated among people at or near retirement age. Among people 37 years of age or younger—prime working years—accidents are the number one cause of death. Figure 2–3 summarizes the causes of death for persons from 25 to 44 years of age. Notice that the leading cause is accidents. Figure 2–3 shows that accidents represent a serious detriment to productivity, quality, and competitiveness in today’s workplace. Yet accidents are the one cause of death and injury that companies can most easily control. Although it is true that companies Figure 2–3 Causes of accidents (ages 25 to 44 years in a typical year). Accidents 27,500 Cancer 20,300 Motor vehicle 16,500 Heart disease 16,000 Poison (solid, liquid) 2,700 Drowning 1,500 Falls 1,100 Fire related 900 M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 21 Accidents and Their Effects 21 may have some success in decreasing the incidence of heart disease and stroke among their employees through such activities as corporate wellness programs, their impact in this regard is limited. However, employers can have a significant impact on preventing accidents. WORK ACCIDENT COSTS AND RATES Workplace accidents cost employers millions every year. Consider the following examples from the recent past. Arco Chemical Company was ordered to pay $3.48 million in fines as a result of failing to protect workers from an explosion at its petrochemical plant in Channelview, Texas. The steel-making division of USX paid a $3.25 million fine to settle numerous health and safety violation citations. BASF Corporation agreed to pay a fine of $1.06 million to settle Occupational Safety and Health Administration (OSHA) citations associated with an explosion at a Cincinnati chemical plant that caused two deaths and 17 injuries. These examples show the costs of fines only. In addition to fines, these employers incurred costs for safety corrections, medical treatment, survivor benefits, death and burial costs, and a variety of indirect costs. Clearly, work accidents are expensive. However, the news is not all bad. The trend in the rate of accidents is downward. Work accident rates in this century are evidence of the success of the safety movement in the United States. As the amount of attention given to workplace safety and health has increased, the accident rate has decreased. According to the NSC, Between 1912 and 1998, accidental work deaths per 100,000 population were reduced 81 percent, from 21 to 4. In 1912, an estimated 18,000 to 21,000 workers’ lives were lost. In 1998, in a workforce more than triple in size and producing 11 times the goods and services, there were approximately 10,000 work deaths.4 As Figure 2–1 shows, the cost of these 10,000 work deaths and work injuries was $48.5 billion. This translates into a cost of $420 per worker in the United States, computed as the value-add required per worker to offset the cost of work injuries. It translates further into $6.10,000 per death and $18,000 per disabling injury.5 Although statistics are not available to document the supposition, many safety and health professionals believe that the major cost of accidents and injuries on the job results from damage to morale. Employee morale is a less tangible factor than documentable factors such as lost time and medical costs. However, it is widely accepted among management professionals that few factors affect productivity more than employee morale. Employees with low morale do not produce up to their maximum potential. This is why so much time and money are spent every year to help supervisors and managers learn different ways to help improve employee morale. Because few things are as detrimental to employee morale as seeing a fellow worker injured, accidents can have a devastating effect on morale. Whenever an employee is injured, his or her colleagues silently think, “That could have been me,” in addition to worrying about the employee. Morale is damaged even more if the injured employee is well-liked and other employees know his or her family. TIME LOST BECAUSE OF WORK INJURIES An important consideration when assessing the effect of accidents on industry is the amount of lost time due to work injuries.6 According to the NSC, approximately 35 million hours are lost in a typical year as a result of accidents. This is actual time lost from disabling injuries and does not include additional time lost for medical checkups after the injured employee returns to work. Accidents that occurred in previous years often continue to cause lost time in the current year. M02_GOET9169_07_SE_C02.QXD 11/27/09 22 CHAPTER 2 10:13 AM Page 22 Figure 2–4 Work deaths by cause for a typical year. Motor vehicle related 37.2% Falls 12.5 Electric current 3.7 Drowning 3.2 Fire related 3.1 Air transport related 3.0 Poison (solid, liquid) 2.7 Water transport related 1.6 Poison (gas, vapor) Other 1.4 31.6 DEATHS IN WORK ACCIDENTS Deaths on the job have decreased markedly over the years. However, they still occur. For example, in a typical year, there are 10,400 work deaths in the United States. The causes of death in the workplace vary. They include those related to motor vehicles, falls, electric current, drowning, fires, air transport, poisoning, water transport, machinery, falling objects, rail transport, and mechanical suffocation.7 Figure 2–4 gives a complete breakdown of the percentages for the various categories of causes. WORK INJURIES BY TYPE OF ACCIDENT Work injuries can be classified by the type of accident from which they resulted. The most common causes of work injuries are • • • • • • • • • Overexertion Impact accidents Falls Bodily reaction (to chemicals) Compression Motor vehicle accidents Exposure to radiation or caustics Rubbing or abrasions Exposure to extreme temperatures Overexertion, the result of employees working beyond their physical limits, is the leading cause of work injuries. According to the NSC, almost 31 percent of all work injuries are caused by overexertion. Impact accidents involve a worker being struck by or against an object. The next most prominent cause of work injuries is falls.8 The remaining accidents are distributed fairly equally among the other causes listed above. DEATH RATES BY INDUSTRY A variety of agencies and organizations, including the Bureau of Labor Statistics, the National Center for Health Statistics, and the NSC, collect data on death rates within industrial categories.9 Such information can be used in a variety of ways, not the least of which is in assigning workers’ compensation rates. The most widely used industrial categories M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 23 Accidents and Their Effects 23 Discussion Case What Is Your Opinion? Mack Jones has been a safety engineer at Zumwalt Processing Company for almost 25 years. His son David is a recent college graduate who has been the assistant safety director at another company for just six months. Over supper last night, they had a discussion about work injuries. During the discussion, Mack said he thought back injuries were still the problem that safety professionals should worry about the most. David disagreed. He said repetitive strain/soft tissue injuries such as carpal tunnel syndrome were a bigger problem in the modern computerized workplace. What is your opinion? are agriculture, including farming, forestry, and fishing; mining/quarrying, including oil and gas drilling and extraction; construction; manufacturing; transportation/public utilities; trade, both wholesale and retail; services, including finance, insurance, and real estate; and federal, state, and local government. When death rates are computed on the basis of the number of deaths per 100,000 workers in a given year, the industry categories rank as follows (from highest death rate to lowest): 1. 2. 3. 4. 5. 6. 7. 8. Mining/quarrying Agriculture Construction Transportation/public utilities Government Manufacturing Services Trade The rankings sometimes change slightly from year to year. For example, agriculture and mining/quarrying may exchange the first and second ranking in any given year. This is also true at the low end of the rankings with services and trade. However, generally, the typical ranking is as listed. PARTS OF THE BODY INJURED ON THE JOB To develop and maintain an effective safety and health program, it is necessary to know not only the most common causes of death and injury but also the parts of the body most frequently injured. The NSC stated the following: Disabling work injuries in the entire nation totaled approximately 1.75 million in 1998. Of these, about 10,400 were fatal and 60,000 resulted in some permanent impairment. Injuries to the back occurred most frequently, followed by thumb and finger injuries and leg injuries.10 Typically, the most frequent injuries to specific parts of the body are as follows (from most frequent to least): 1. 2. 3. 4. 5. 6. 7. Back Legs and fingers Arms and multiple parts of the body Trunk Hands Eyes, head, and feet Neck, toes, and body systems M02_GOET9169_07_SE_C02.QXD 11/27/09 24 CHAPTER 2 10:13 AM Page 24 The back is the most frequently injured part of the body. Legs and fingers are injured with approximately the same frequency, as are arms and multiple parts of the body; the hands are next in frequency, followed by the eyes, the head, and feet; and neck, toes, and body systems. This ranking shows that one of the most fundamental components of a safety and health program should be instruction on how to lift without hurting the back (see Chapter 15). CHEMICAL BURN INJURIES Chemical burn injuries are a special category with which prospective and practicing safety professionals should be familiar. The greatest incidence of chemical burns (approximately one-third) occurs in manufacturing.11 Other high-incidence industries are services, trade, and construction. The chemicals that most frequently cause chemical burn injuries include acids and alkalies; soaps, detergents, and cleaning compounds; solvents and degreasers; calcium hydroxide (a chemical used in cement and plaster); potassium hydroxide (an ingredient in drain cleaners and other cleaning solutions); and sulfuric acid (battery acid). Almost 46 percent of all chemical burn injuries occur while workers are cleaning equipment, tools, and vehicles.12 What is particularly disturbing about chemical burn injuries is that a high percentage of them occur in spite of the use of personal protective equipment, the provision of safety instruction, and the availability of treatment facilities. In some cases, the personal protective equipment is faulty or inadequate. In others, it is not properly used in spite of instructions. Preventing chemical burn injuries presents a special challenge to safety and health professionals. The following strategies are recommended: • Familiarize yourself, the workers, and their supervisors with the chemicals that will be used and their inherent dangers. • Secure the proper personal protection equipment for each type of chemical that will be used. • Provide instruction on the proper use of personal protection equipment and then make sure that supervisors confirm that the equipment is used properly every time. • Monitor that workers are wearing personal protection equipment and replace it when it begins to show wear. HEAT BURN INJURIES Heat burn injuries present a special challenge to safety and health professionals in the modern workplace. Almost 40 percent of all such injuries occur in manufacturing every year. The most frequent causes are flame (this includes smoke inhalation injuries), molten metal, petroleum asphalts, steam, and water. The most common activities associated with heat burn injuries are welding, cutting with a torch, and handling tar or asphalt.13 Following are several factors that contribute to heat burn injuries in the workplace. Safety and health professionals who understand these factors will be in a better position to prevent heat burn injuries. • Employer has no health and safety policy regarding heat hazards. • Employer fails to enforce safety procedures and practices. • Employees are not familiar with the employer’s safety policy and procedures concerning heat hazards. M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 25 Accidents and Their Effects • • • • • • 25 Employees fail to use or improperly use personal protection equipment. Employees have inadequate or worn personal protection equipment. Employees work in a limited space. Employees attempt to work too fast. Employees are careless. Employees have poorly maintained tools and equipment.14 These factors should be considered carefully by safety and health professionals when developing accident prevention programs. Employees should be familiar with the hazards, should know the appropriate safety precautions, and should have and use the proper personal protection equipment. Safety professionals should monitor to ensure that safety rules are being followed, that personal protection equipment is being used correctly, and that it is in good condition. REPETITIVE STRAIN/SOFT TISSUE INJURIES Repetitive strain injury (RSI) is a broad and generic term that encompasses a variety of injuries resulting from cumulative trauma to the soft tissues of the body, including tendons, tendon sheaths, muscles, ligaments, joints, and nerves. Such injuries are typically associated with the soft tissues of the hands, arms, neck, and shoulders. Carpal tunnel syndrome (CTS) is the most widely known RSI. There are also several other RSIs to the body’s soft tissues. The carpal tunnel is the area inside the wrist through which the median nerve passes. It is formed by the wrist bones and a ligament. CTS is typically caused by repeated and cumulative stress on the median nerve. Symptoms of CTS include numbness, a tingling sensation, and pain in the fingers, hand, and/ or wrist. Stress placed on the median nerve typically results from repeated motion while the hands and fingers are bent in an unnatural position. However, sometimes the stress results from a single traumatic event such as a sharp blow to the wrist. Evidence suggests a higher incidence of CTS among women than men. Scientists have found that the incidence rate for CTS among women was 1.96 per 1,000 full-time equivalent (FTE) workers and 1.58 per 1,000 FTE for men. The overall incidence rate for CTS is increasing at a rate of more than 15 percent per year.15 A common misconception about RSI is that it is synonymous with CTS. It isn’t. In fact, CTS is relatively rare among RSI patients. Following is a list of the broad classifications of RSI and the types commonly associated with each classification: • • • • Muscle and Tendon Disorders Tendinitis Muscle damage Tenosynovitis Stenosing tenosynovitis • • • • • • DeQuervain’s Disease Flexor tenosynovitis (trigger finger) Shoulder tendinitis Forearm tendinitis Cervical radioculopathy Epicondylitis Ganglion cysts Tunnel Syndromes • Carpal tunnel syndrome • Radial tunnel syndrome M02_GOET9169_07_SE_C02.QXD 11/27/09 26 CHAPTER 2 10:13 AM Page 26 Ulnar Nerve Disorders • Sulcus ulnaris syndrome • Cubital tunnel syndrome • Guyon’s canal syndrome Nerve and Circulation Disorders • Thoracic outlet syndrome • Raynaud’s disease • • • • • Other Associated Disorders Reflex sympathetic dysfunction Focal dystonia (writer’s cramp) Degenerative joint disorder (osteoarthritis) Fibromyalgia Dupuytren’s contracture16 RSI and its manifestations are explained in greater detail in Chapter 10. ESTIMATING THE COST OF ACCIDENTS Even decision makers who support accident prevention must consider the relative costs of such efforts. Clearly, accidents are expensive. However, to be successful, safety and health professionals must be able to show that accidents are more expensive than prevention. To do this, they must be able to estimate the cost of accidents. The procedure for estimating costs set forth in this section was developed by Professor Rollin H. Simonds of Michigan State College working in conjunction with the Statistics Division of the NSC. Cost-Estimation Method Professor Simonds states that in order to have value, a cost estimate must relate directly to the specific company in question. Applying broad industry cost factors will not suffice. To arrive at company-specific figures, Simonds recommends that costs associated with an accident be divided into insured and uninsured costs.17 Determining the insured costs of accidents is a simple matter of examining accounting records. The next step involves calculating the uninsured costs. Simonds recommends that accidents be divided into the following four classes: • Class 1 accidents. Lost workdays, permanent partial disabilities, and temporary total disabilities. • Class 2 accidents. Treatment by a physician outside the company’s facility. • Class 3 accidents. Locally provided first aid, property damage of less than $100, or the loss of less than eight hours of work time. • Class 4 accidents. Injuries that are so minor that they do not require the attention of a physician, result in property damage of $100 or more, or cause eight or more work hours to be lost.18 Average uninsured costs for each class of accident can be determined by pulling the records of all accidents that occurred during a specified period and by sorting the records according to class. For each accident in each class, record every cost that was not covered by insurance. Compute the total of these costs by class of accident and divide by the total number of accidents in that class to determine an average uninsured cost for each class, specific to the particular company. Figure 2–5 is an example of how the average cost of a selected sample of Class 1 accidents can be determined. In this example, there were four Class 1 accidents in the pilot M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 27 27 Accidents and Their Effects Class of Accident Accident Number Class 1 1 2 3 4 5 Cost A $ 16.00 $ 6.95 $ 15.17 $ 3.26 Cost B 72.00 103.15 97.06 51.52 Cost C 26.73 12.62 — 36.94 Cost D — 51.36 — 38.76 Cost E — 11.17 — 24.95 Cost F — — — –13.41 Cost G — — — — 114.73 185.25 112.23 142.02 Total 6 7 8 Grand Total: $554.23 Average Cost per Accident: $138.56 (Grand Total Number of Accidents) Signature: _______________________________________ Date: _________ Figure 2–5 Uninsured costs worksheet. test. These four accidents cost the company a total of $554.23 in uninsured costs, or an average of $138.56 per accident. Using this information, accurate cost estimates of an accident can be figured, and accurate predictions can be made. Other Cost-Estimation Methods The costs associated with workplace accidents, injuries, and incidents fall into broad categories such as the following: • • • • • • Lost work hours Medical costs Insurance premiums and administration Property damage Fire losses Indirect costs Calculating the direct costs associated with lost work hours involves compiling the total number of lost hours for the period in question and multiplying the hours times the applicable loaded labor rate. The loaded labor rate is the employee’s hourly rate plus benefits. Benefits vary from company to company but typically inflate the hourly wage by 20 to 35 percent. A sample cost-of-lost-hours computation follows: Employee Hours Lost (4th quarter) ⫻ Average Loaded Labor Rate ⫽ Cost 386 ⫻ 13.48 ⫽ $5,203.28 In this example, the company lost 386 hours due to accidents on the job in the fourth quarter of its fiscal year. The employees who actually missed time at work formed a pool of people with an average loaded labor rate of $13.48 per hour ($10.78 average hourly wage plus 20 percent for benefits). The average loaded labor rate multiplied by the 386 lost hours reveals an unproductive cost of $5,203.28 to this company. By studying records that are readily available in the company, a safety professional can also determine medical costs, insurance premiums, property damage, and fire losses for the time period in question. All these costs taken together result in a subtotal M02_GOET9169_07_SE_C02.QXD 11/27/09 28 CHAPTER 2 10:13 AM Page 28 cost. This figure is then increased by a standard percentage to cover indirect costs to determine the total cost of accidents for a specific time period. The percentage used to calculate indirect costs can vary from company to company, but 20 percent is a widely used figure. Estimating Hidden Costs Safety professionals often use the iceberg analogy when talking about the real costs of accidents. Accident costs are like an iceberg in that their greatest portion is hidden from view.19 In the case of icebergs, the larger part is hidden beneath the surface of the water. In the case of an accident, the larger part of the actual cost is also hidden beneath the surface. According to Daniel Corcoran, When a serious accident occurs, there is usually a great deal of activity associated with the accident. There may be a slowdown in production near the site of the accident, for instance. There also will be a need to replace the injured worker, at least temporarily, and there will be costs associated with the learning curve of the replacement worker. The supervisor and the accident investigation team probably will need to spend time conducting an investigation, and there will be a lot of time spent on the administration of paper work related to the accident.20 There are many different models that can be used for estimating both the direct and indirect costs of accidents. Some of these models are so complex that their usefulness is questionable. The checklist in Figure 2–6 is a simple and straightforward tool that can be used to estimate the hidden costs of accidents. Checklist for Estimating the Hidden Costs of Accidents √ Paid time to the injured employee on the day of the accident. √ Paid time of any emergency-responder personnel involved (including ambulance driver). √ Paid time of all employees who were interviewed as part of the accident investigation. √ Paid time of the safety personnel who conducted the accident investigation. √ Paid time of the human resources personnel who handled the workers’ compensation and medical aspects of the accident. √ Paid time of the supervisor involved in the accident investigation and accident response. √ Paid time to employees near the accident working (or slowed down) temporarily as a result of the accident. √ Paid time to employees who spent time talking about the accident as news of it spread through the company’s grapevine. Figure 2–6 Some accident costs that might be overlooked. M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 29 Accidents and Their Effects 29 GLOBAL IMPACT OF ACCIDENTS AND INJURIES According to the International Labour Organization (ILO) of the United Nations, approximately 2.2 million people die every year of work-related injuries and occupational diseases.21 Actually, due to poor record keeping and reporting in underdeveloped countries, it is estimated that this figure is low. Rapid development and the pressure of global competition are resulting in increased workplace fatalities in China and the Pacific Rim countries. What is missing in many of the developing countries that are becoming industrialized is a safety and health infrastructure. Such an infrastructure would include governmentenforced safety and health regulations, company-sponsored safety and health training, record-keeping and reporting systems, and management practices that make occupational safety and health a fully integrated component of work processes and the competitive philosophy of organizations. Occupational safety and health must come to be seen as a strategy for sustaining economic growth and social development in emerging countries. There is much to be done if developing countries are going to provide safe and healthy working conditions for their citizens. The ILO reports: • Record-keeping and reporting systems in developing countries are deteriorating instead of improving. Consequently, only a fraction of the real toll of workplace accidents and injuries is being reported. • Men in developing countries tend to die as the result of accidents, lung diseases, and work-related cancers such as those caused by asbestos. Women in developing countries suffer more from musculoskeletal disorders, communicable diseases, and psychosocial problems. • Occupational injuries in developing countries are more prevalent in such high-risk industries as mining, construction, and agriculture. • Younger workers in developing countries are more likely to suffer nonfatal injuries, while older workers are more likely to suffer fatal injuries. • In developing countries, more than half of retirements are taken early to collect pensions based on work-related disabilities rather than normal retirement. SUMMARY 1. The approximate cost of accidents in the United States is $150 billion annually. This includes the direct and indirect costs of accidents that occur on and off the job. 2. The leading causes of accidental deaths in the United States are motor vehicle accidents, falls, poisoning, drowning, fire-related injuries, suffocation, firearms, medical complications, air transport accidents, machinery-related injuries, mechanical suffocation, and the impact of falling objects. 3. The leading causes of death in the United States are heart disease, cancer, and stroke. However, these causes are concentrated among people at or near retirement age. Among people 37 years of age and younger, accidents are the number one cause of death. 4. Between 1912 and 1998, the number of accidental work deaths per 100,000 population declined by 81 percent, from 21 to 4. 5. Approximately 35 million work hours are lost annually as a result of accidents. This is actual time lost from disabling injuries and does not include additional time lost to medical checkups after the injured employee returns to work. 6. The leading causes of death in work accidents are motor vehicle related, falls, electric current, drowning, fire related, air transport related, poisoning, and water transport related. 7. The leading causes of work injuries are overexertion, impact accidents, falls, bodily reaction, compression, motor vehicle accidents, exposure to radiation or caustics, rubbing or abrasions, and exposure to extreme temperatures. M02_GOET9169_07_SE_C02.QXD 11/27/09 30 CHAPTER 2 10:13 AM Page 30 8. When death rates are computed on the basis of number of deaths per 100,000 workers, the industry categories are ranked as follows (from highest death rate to lowest): mining/quarrying, agriculture, construction, transportation/public utilities, government, manufacturing, services, and trade. 9. Typically, the ranking of injuries to specific parts of the body are as follows (from most frequently injured to least): back; legs and fingers; arms and multiple parts of body; trunk; hands; eyes, head, and feet; and neck, toes, and body systems. 10. The chemicals most frequently involved in chemical burn injuries include acids and alkalies; soaps, detergents, and cleaning compounds; solvents and degreasers; calcium hydroxide; potassium hydroxide; and sulfuric acid. 11. The most frequent causes of heat burn injuries are flame, molten metal, petroleum, asphalt, steam, and water. 12. Carpal tunnel syndrome (CTS) is an injury to the median nerve in the wrist that typically results from repeated stress placed on the nerve. Symptoms of CTS include numbness, a tingling sensation, and pain in the hand and/or wrist. 13. Repetitive strain injury (RSI) is a broad and generic term that encompasses a variety of injuries resulting from cumulative trauma to the soft tissues of the body, including tendons, tendon sheaths, muscles, ligaments, joints, and nerves. Such injuries are typically associated with the soft tissues of the hands, arms, neck, and shoulders. 14. Accident rates are especially high in developing countries because these countries are responding to the pressures of global competition without first putting a safety and health infrastructure in place (for example, regulations, training, and record keeping). KEY TERMS AND CONCEPTS Accident prevention Accident rates Accidents Cancer Carpal tunnel syndrome (CTS) Chemical burn injuries Death rates Drownings Falls Fire-related losses Heart disease Heat burn injuries Impact accidents Indirect costs Insurance administration Lost time Lost wages Mechanical suffocation Medical complications Medical expenses Natural disasters Overexertion Poisoning Property damage Repetitive strain injury (RSI) Safety and health professionals Strokes Suffocation Work injuries Workplace accidents REVIEW QUESTIONS 1. 2. 3. 4. What are the leading causes of death in the United States? When the overall cost of an accident is calculated, what elements make up the cost? What are the five leading causes of accidental deaths in the United States? What are the leading causes of death in the United States of people between the ages of 25 and 44? M02_GOET9169_07_SE_C02.QXD 11/27/09 10:13 AM Page 31 Accidents and Their Effects 31 5. Explain how today’s rate of accidental work deaths compares with the rate in the early 1900s. 6. What are the five leading causes of work deaths? 7. What are the five leading causes of work injuries by type of accident? 8. When death rates are classified by industry type, what are the three leading industry types? 9. Rank the following body parts according to frequency of injury from highest to lowest: neck, fingers, trunk, back, and eyes. 10. Name three chemicals that frequently cause chemical burns in the workplace. 11. Identify three factors that contribute to heat burn injuries in the workplace. 12. Explain the difference between repetitive strain injury and carpal tunnel syndrome. 13. Explain the reasons for high accident rates in developing countries. ENDNOTES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. National Safety Council, Accident Facts (Chicago: National Safety Council, 2008), 37. Ibid., 25. Ibid., 4–5. Ibid., 34. Ibid., 35. Ibid., 35. Ibid., 36. Ibid., 36. Ibid., 37. Ibid., 38. Ibid., 39. Ibid., 40. Ibid., 41. Ibid., 41. ErgoOutfitters.com, www.ergooutfitters.com, March 31, 2006. Ibid. National Safety Council, Accident Prevention Manual for Industrial Operations: Administration and Programs (Chicago: National Safety Council, 1997), 158. Ibid., 158. Daniel Corcoran, “The Hidden Value of Safety,” Occupational Health & Safety 71, no. 6: 20–22. Corcoran, “The Hidden Value of Safety,” 22. Occupational Health & Safety Online, “Study: 2.2 Million People Die Worldwide of Work-Related Accidents, Occupational Diseases.” Retrieved from www.ohsonline. com on September 20, 2005, 1–3.