FWPC - Procedures Manual - Logistics Insights Corporation, Inc

Logistics Insight Corporation – Hammond Consolidation Center

Process Manual

SUBJECT: Section 2.0 FREIGHT MANAGEMENT

Issue: Version 1.0

Date: Nov. 11, 2011

1.4 OUTBOUND SHIPPING

SCOPE

This procedure describes the actions to be taken when processing material out of the facility for onward shipment to pre-identified and scheduled destinations. Once material is cross-docked and outbound loading is completed (see PM12), the trailer load closeout is performed to initiate the outbound process.

Critical material (TAB) and deconsolidated shipments for other Wal-Mart distribution centers (DSDC) have specific processing requirements that are noted in this process. Details of all outbound shipment releases will be recorded into the respective systems (GFCS and DC Yard) and filed by designated dock and office staff.

RESPONSIBILITY

The Facility Manager is responsible for all actions described in this procedure and for the provision of sufficient and adequately trained resources.

The Operations Manager and Office Manager are responsible for ensuring all aspects of this procedure are performed, including the allocation of workloads.

Dock and Office Supervisors and Clerks are responsible for ensuring all of the processes described in this procedure are effectively completed.

Questions on this procedure should be raised with the Facility Manager.

MEASUREMENTS

It is expected that the following elements can be measured:

1. 100% of outbound shipments will be loaded and verified against source documents.

2. 100% outbound material will be inspected with zero parts being handled or loaded improperly.

3. All failures will be recorded and used as the performance measure of the outbound shipping process.

PROCEDURE

See flow chart on next page.

SPECIAL INSTRUCTIONS

Where poor loading (not meeting Wal-Mart-specified requirements) on any outbound trailers is identified, document and identify with digital camera and fill out all pertinent information to a discrepancy report and forward to the dock supervisor or a Manager.

Return material will be processed according to their tagged instructions (i.e. return to Supplier). Material to be returned directly to supplier must have an RMA number cut by Wal-Mart. Untagged return material will be called into the Wal-Mart Material department for proper disposition.

Process Owner: Operations Manager Approved: JH - Facility Manager Page: 1 of 3

Printed: 10/30/13 Copies of this document are considered uncontrolled as of date of printing.

Logistics Insight Corporation – Hammond Consolidation Center

Process Manual

SUBJECT: Section 2.0 FREIGHT MANAGEMENT

1.4 OUTBOUND SHIPPING (continued)

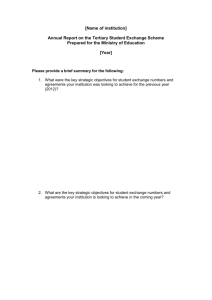

Loading & Closeout

PM12

From cross dock process

Material cross docked and loaded to specified DC outbound trailer

PLTID freight for that

DC has been loaded

Issue: Version 1.0

Date: Nov. 11, 2011

NOTES

No

DSDC,

HAZMAT or

TAB?

No

Trailer load complete?

Yes

Assign seal and Close

Door in the systems and at the dock

Pull dock plate, raise safety

Chain following safety procedures

Finalize

IDOC

Yes

WI02

Walmart RDT

Scanner

Update

GFCS

From PM12: Cross Dock process, including page 3 for loading

PLTID freight

DSDC, HAZMAT and TAB PO’s are clearly identified on IDOC’s, listed below “normal” PO’s and can not be split. DSDC and TAB

PO’s are always prioritized.

Multiple DSDC PO’s on the same

IDOC are staged, cross docked and loaded on a single PO to that

DC. TAB PO’s are considered critical and are assigned immediately, ahead of loads currently being worked. HAZMAT

PO’s are specifically routed and must be handled with care when loading

Refer to WI02: Safe Trailer Entry standardized work instruction

Refer to related Walmart

Procedural instructions

Interface

System alerts

Yard Driver

DC Yard

Switcher receives assignment via

DC Yard monitor in unit or verbally from Supervisor to pull trailer from closed door

Forward completed

IDOC’s to Office

Completed

IDOC’s

Office Staff

GFCS

Process Outbound loads

& assemble OTR/RAIL

Packets

Outbound Carrier arrives

Outbound

Load

Packets

Refer to related Outbound standardized work instruction

Refer to related Walmart

Procedural instructions

Issue Load Packet

& direct driver back to Gate

Gate

Clerk

DC Yard

Go to next page for releasing departing loads through the Gate

P3

Process Owner: Operations Manager Approved: JH - Facility Manager Page: 2 of 3

Printed: 10/30/13 Copies of this document are considered uncontrolled as of date of printing.

Logistics Insight Corporation – Hammond Consolidation Center

Process Manual

SUBJECT: Section 2.0 FREIGHT MANAGEMENT

1.4 OUTBOUND SHIPPING (continued)

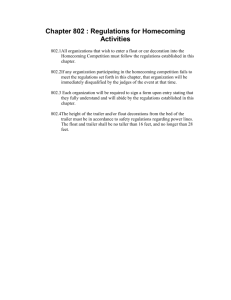

Gate Releases

72360

38578113

53

WT or MT

CI or AP

Issue: Version 1.0

Date: Nov. 11, 2011

Empty trailer

Gate Clerk enters trailer # into RDT scanner, hits “enter” and screen will show

“not found”

Hit “F4” for next screen

Always enter “ 53 ” for Eq Type

Enter empty Status:

WT for Walmart

MT for other carriers

Hit “enter” to print gate tag

1 gate tag

Trailer departs facility gate according to schedule

Gate Clerk collects Outbound Load

Packet from driver (if no Packet, Clerk confirms trailer is empty)

Outbound

Load

Gate Clerk collects load paperwork and enters Load

# (or Delivery # under Dely) into RDT scanner/PC

Hit “Return” for next screen

Load number (TV) and Trailer number (Trlr) will populate

Physically walk to rear of trailer and inspect seal # on trailer doors and enter seal # to the RDT scanner

NOTES

Route schedules are located in the Walmart

Scheduler system for integrated release.

Gate Clerk confirms trailer number matches outbound load packet. If no packet,

Clerk has driver accompany him to rear of trailer to open doors and confirm that it is empty

+

For empty trailers, Gate

Clerk only has to enter the trailer #, Eq Type and empty status (WT or MT) to create & print a single gate tag for the driver

Note: Any outbound freight loads that depart without a seal are assigned a LINC seal and the Clerk notates that seal # to the paperwork for OS&D and supplier compliance processing (Empty trailers will not be sealed).

Rail containers depart with paperwork in the container. Clerks enter seal

# in the RESEAL area & hits F2.

Clerk hands the gate tag to the driver & releases the empty trailer

Walmart RDT &

DC Yard systems

Enter carrier’s Walmart

SCAC code to Eq Owner

Always enter “ 53 ” for Eq Type

Walmart’s GFCS (Global

Freight Consolidation

Strategy) system

Outbound

Load

Packet

Gate Clerk confirms load

Status with driver and enters to

Scanner

Hit “Enter” to create and print gate tags

Once outbound trailer is released, the carrier driver leaves the Gate with his outbound load packet

Process Owner: Operations Manager Approved: JH - Facility Manager Page: 3 of 3

Printed: 10/30/13 Copies of this document are considered uncontrolled as of date of printing.