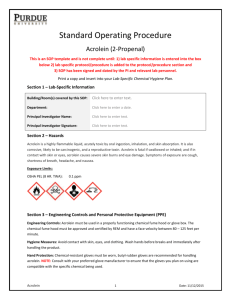

Acrolein - CIRCABC

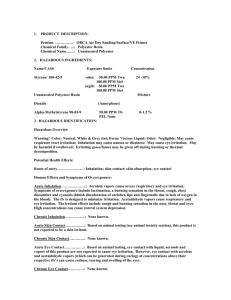

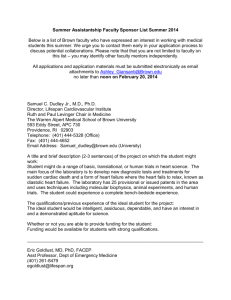

advertisement