Section

advertisement

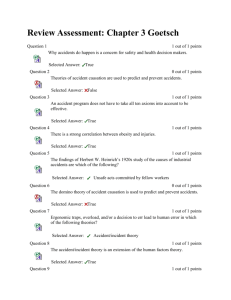

Section 5 Safety P roject safety advisors launched an enhanced accident prevention program in the second quarter — expanding on the project’s behavior-based safety approach emphasizing individual involvement and responsibility for safety. • The launch of the enhanced safety program arrived at an important moment, following two accidents earlier in the year that resulted in four lost time injuries. • Although the project’s overall safety record remains well ahead of industry benchmarks, the accidents contributed to a decline in the project’s overall safety performance statistics. • The drilling operation continues to maintain its safety record of no lost time incidents since project development began in 2000 — 24.6 million work hours without a major on the job accident. Behavior-Based Safety Practices: Program Launch The Loss Prevention System introduced during the second quarter emphasizes behavior based safety principles. The program launch included mandatory classroom training for employees and contractors so they can methodically spread the safety techniques throughout the organization through coaching and mentoring. The program focuses on the study of root causes of near misses and incidents so that underlying behavior can be improved, going beyond symptoms and circumstances, making the point that everyone in the organization shares ownership of safety performance. 23 Safety Behavior-Based Safety Practices: Taking it to the Field Behavior-based safety practices include an array of basic tools that take the concept to the field in a practical yet methodical manner. This pipe laying crew conducts a “tool box” team safety meeting (top) before start of work, including a review of the Job Safety Analysis written in advance for the assignment. Each person signs off on the job site work permit (bottom right), taking personal responsibility for the Job Safety Analysis, acknowledging they have thought ahead about the hazards of the work and how to mitigate them. In addition, and this is a key component of behavior-based safety, workers are trained to do their own last minute risk assessment just before starting their individual tasks. In this situation (bottom left), a member of the team noticed that a team member was wearing only goggles, not the full face shield required for sand blasting a pipe joint, and stopped the work to hand the shield to his colleague. 24 Safety Lost Time Incidents 16 February: A rigger working for the logistics contractor was placing pipes on a rack in a storage yard in Cameroon when he injured his thumb. An accident cause investigation revealed issues involving lack of training, failure to follow safety procedures and inadequate supervision. Several corrective actions have been taken, including the hiring of new safety advisor and supervisory personnel to strengthen safety management. Operational procedures and safety procedures have been improved at the site and an audit of the contractor’s overall safety procedures has been conducted. 25 February: Three of the four people on board a pickup truck operated by a security contractor were injured when the truck rolled over while on night shift patrol in the Komé oilfield. The accident investigation identified a failure to follow minimum rest time requirements and fatigue during a night shift as root causes of the accident. Corrective actions included a safety stand down from work while remedial safety training was conducted with security contractor personnel. Management of the contractor was counseled regarding failure to follow safety procedures. Some patrol responsibilities were switched to another contractor with a better safety record and vehicle patrol procedures and systems were improved. Safety Statistics Recordable Incident Rate — Below Industry Benchmarks (Total Recordable Incidents per 200,000 Work Hours) 1.3 1.40 1.24 1.20 1.03 0.89 Recordable Incident Rate 1.00 0.74 0.80 0.72 Industry Benchmark 0.68 0.60 0.60 0.40 0.39 0.20 0.37 0.48 0.44 0.35 0.35 0.16 0.23 2007 2008 0.00 Project to Date 2002 2003 2004 2005 2006 Last 12 Months The Recordable Incident Rate measures overall safety performance by capturing even minor injury accidents. Although the rate degraded in the first half of 2009, project workers kept their historically low Recordable Incident Rate at a level well below the average rate of the petroleum industry as a whole. The 12 month rolling rate of 0.35 incidents per 200,000 working hours is about two times better than the latest available U.S. petroleum industry average of 0.68 (based on reports from participating companies to the American Petroleum Institute). 25 Safety On-the-Job Injuries (OSHA Reportables) 3rd Qtr 2008 0 0 1 4 26 4th Qtr 2008 0 1 0 3 24 1st Qtr 2009 0 4 0 10 29 2nd Qtr 2009 0 0 1 8 16 Last 12 Months 0 5 2 25 95 Project (Since 2000) 4 27 131 277 2622 Worker Hours (thousands) 4623 4478 4606 4810 18517 224582 Trend Analysis Recordable Incident Rate Lost Time Incident Rate 0.22 0.00 0.18 0.04 0.61 0.17 0.37 0.00 0.35 0.05 0.39 0.02 Fatalities Lost Time Restricted Work Medical Treatment Required First Aid Cases These project safety statistics are for EEPCI, TOTCO, COTCO, other affiliates working for the project and their respective contractors. They include incidents involving a location, property or activities owned, controlled or supervised by those entities. Traffic Safety Tally Traffic Accidents 3rd Qtr 2008 11 4th Qtr 2008 9 1st Qtr 2009 8 2nd Qtr 2009 6 Last 12 Months 34 Project (Since 2000) 822 Includes all project vehicle traffic incidents - minor and major vehicle damage accidents plus injury accidents. Traffic Accident Count 140 136 Number of Motor Vehicle Accidents 120 109 97 100 76 80 58 60 42 40 32 34 20 0 2002 2003 2004 2005 2006 2007 2008 12 Mos The project’s annual vehicle accident count has been cut dramatically over the last seven years. The count of 34 for the last four quarters is a reduction to less than one-fourth the annual level in 2002 during the construction phase. In addition, the vehicle accident rate per million kilometers has been cut from 4.0 in 2005 to 1.2 midway through 2009. The improvement comes from a campaign of rigorous accident prevention including cause investigations, defensive driving training, vehicle and driver spot checks, and disciplinary action. 26 Safety Context: Standards for Safety Reporting Measuring Safety Performance The tabulation and statistical analysis of accident reports plays a crucial role in accident prevention efforts for large industrial projects like the Chad/Cameroon Development Project. • Like many other companies, ExxonMobil has selected the widely recognized OSHA guidelines as a standard for measuring safety performance worldwide. Thus, statistics from the project can be compared to those from other locations. • OSHA guidelines are also widely used by many other oil companies and a number of similar industries, thus providing a further source of benchmarks for measuring the project’s safety performance. In addition to worldwide application of the stringent OSHA guidelines, Esso also complies with all local requirements for compiling and reporting accidents and accident statistics that may be in force in the countries where it operates. However, the governments of Chad and Cameroon have not adopted any detailed standards for accident recording and reporting. Transparency of Results Accident reporting by the project in Chad and Cameroon is consistent with, and in some cases superior to, transparency practices followed in most industrialized nations. • All major accidents, including ones that fall outside the OSHA accident reporting guidelines, are immediately reported to local authorities for investigation. Local law enforcement authorities generally are on the scene shortly after a major accident, and the project cooperates fully in all police investigations. Thus, the project’s reporting of accidents is much the same as in the United States and many other countries, where police, fire or other emergency agencies are called to major accident scenes. • In addition, the project’s OSHA-based safety performance statistics are published in these Project Update reports. As indicated in the Preface, the reports are posted on the Internet (www.essochad.com) and hundreds of printed copies are distributed to a wide array of stakeholders, including NGOs, in the two host countries and in the international community. 27 Safety Family Safety Day at COTCO In Cameroon, the project held a Family Safety Day event at mid-year. At this ceremony in Douala, employees of COTCO brought their spouses and children (top left) to an afternoon of speeches (top right), skits (middle right) and contests (bottom left) — all with the message that the same principles that help make the work place safe can be applied at home as well. Family members received a newly created Off the Job Safety Hand Book (bottom right) to help them to learn about how to be safe at home. 28