Wet Brakes: Materials and Concepts

advertisement

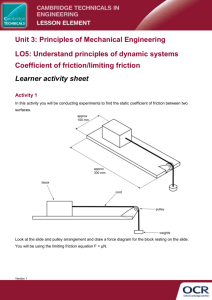

Axle Centers Slide 1 Wet Brakes: Materials and Concepts Slide 2 Wet Brakes – Materials and Concepts Rich Dowell Chief Engineering Director – Asia Pacific Carlisle Brake & Friction INSTRUCTOR BIO Rich Dowell Carlisle Brake & Friction Rich Dowell has 39 years experience in designing, developing and testing wet friction products and systems for the Off‐Highway industry. Rich is called “Mr. Wet Friction” in the braking industry. Rich started his career in 1969 with Lear Sieglar as a design engineer and spent his first 5 years designing and testing power systems for airplanes. Rich joined Carlisle (SK Wellman) in 1974 and has been THE authority in wet friction ever sense. Rich has developed / directed the development of 2 semi‐metallic, 5 metallic and 7 paper friction materials. Rich holds U.S. Patent # 6,277,768 High Energy Friction Product. He has published three technical papers for the Society of Automotive Engineers and has published numerous journal articles. Rich has also presented technical seminars worldwide. Rich holds a Bachelor of Science in Aerospace Engineering and is a 6 Sigma Green Belt. Carlisle Brake & Friction (CBF) is a leading solutions provider of high performance and severe duty brake, clutch and transmission applications to OEM and aftermarket customers in the mining, construction, military, agricultural, motorsports, industrial and aerospace markets. The strength of CBF’s brands, including Wellman Products Group, Carlisle Industrial Brake & Friction, Hawk Performance, Cragar, Black Rock, Japan Power Brake, VelveTouch, and Field Pro, gives our customers access to a diverse range of the most highly engineered braking, friction, clutch, and transmission products available to the market today. With eleven manufacturing facilities globally located in the U.S., U.K., Italy, China, Japan, and India and with over 2,200 employees, CBF serves over 100 leading original equipment manufacturers in 50 countries, making CBF the right choice for your new brake or friction design, no matter where you are in the world or what you want to be. For more information visit www.carlisleCBF.com United States +1 440 528 4000 United Kingdom +44 1495 767 300 Italy +39 030 9942 China +86 21 6100 5222 Wet Brakes - Materials and Concepts October 30-31, 2012 Pune, India Slide 4 Coefficient of Friction 4 Slide 5 Coefficient of Friction Classic Definition f F µ = coefficient of friction ƒ = friction force F = normal force 5 Slide 6 Clutches and Brakes • CBF makes friction materials for Clutches and Brakes • Clutches are a mechanism to force an output shaft to spin at the same speed as the input shaft. It is a dynamic coupling. • A brake does the same as a clutch except that one shaft or side of the brake is always at zero speed. It stops things. 6 Slide 7 Function of a Brake • The primary function of a brake is to stop a vehicle in motion. • Friction material requirements: – Minimal Stopping distance – Smooth stopping – No noise – Good durability 7 Slide 8 Energy • Energy is either Dynamic, Potential (Position), or heat. • In the ordinary Newtonian world energy can neither be created nor destroyed. The amount is constant. • When we stop a vehicle or shaft with friction we turn the energy from that of motion to heat. • How we handle heat is the heart of designing brakes and clutches. 8 Slide 9 Coefficient of Friction and Torque • Equation for Torque is: T FRN • Where: – – – – T = Torque lb-ft F = apply force lbs R = Mean radius ft N = number of friction surfaces or or or N-m N m • There are no units for coefficient of friction. 9 Slide 10 Torque 10 Slide 11 Types of µ • Coefficient of friction can be measured at various times during a stop. Typically we think of four important friction levels: – Initial µ – Dynamic µ – Lockup µ – Static or Breakaway µ 11 Slide 12 Typical Torque Trace Time → 12 Slide 13 Types of µ (cont’d) • Initial µ – Measured when pressure is first applied. This is sometimes called touchup. Can be important especially under inching conditions. A high initial coefficient may result in difficulty inching a vehicle smoothly. • Dynamic µ – Measured at half the initial speed. Typically it is desired to have a high dynamic coefficient. • Lockup µ – Measured at zero speed. Can determine the shift quality in transmissions or the noise level in brakes. If the lockup coefficient is higher than the dynamic coefficient, this will result in rough shifts or noisy brakes. High lockup can be desirable in winch or parking brake applications. • Breakaway µ – Measured by applying torque with pack locked up until the pack breaks free. Important to make sure that the friction pack does not slip after a stop has been made or if a vehicle is parked on a hill. 13 Slide 14 Factors that impact µ • The coefficient of friction for a friction material is dependent on many factors, including: • • • • • • • Oil type Surface temperature Friction material grade Friction material density Apply pressure Rotational speed Groove pattern • The same friction material could probably have a coefficient of friction from .07 to .17 depending on the above factors, so it becomes difficult to answer a question like, “What is the coefficient of friction for N-401?” 14 Slide 15 Wet friction system • Series of friction and reaction plates • Usually 4-8 friction plates in a stack 15 Slide 16 Pros and Cons of Wet Brakes Wet Con Wet Pro – – – – – Longer Life Smoother operation Can run as retarder Immunity to dirt No sparks – – – – – Higher Weight More expensive Lower coefficient Loss of oil is fatal Performance dependent upon oil type – Parasitic Drag higher 16 Slide 17 Typical Wet Applications – – – – – – – – Powershift/Automatic Transmissions Axle Speed Brakes Wheel Speed Brakes Winches Wet Master Clutches Tractors and Motorcycles Steer Clutches and Brakes Tracked Vehicles Synchronizers Swing / Travel motors 17 Slide 18 Agricultural & Forestry Equipment • Wet Transmission Disks (powershift) • Wet sump disk brakes sandwiching the differential 18 Slide 19 Construction & Earthmoving Equipment • Powershift Transmission disks • Wet steer clutches • Wet steer brakes 19 Slide 20 Industrial & Material Handling Equipment • Powershift Transmission Disks • Axle / Wheel speed brakes 20 Slide 21 Application Glossary • Wheel Speed Brakes • Axle Speed Brakes • Steering Brakes and Clutches • Swing/Travel Motor Brake – Typically used in heavy duty off highway vehicles and can be forced cooled or sump type oil systems. Friction material needs are a low static : dynamic ratio and good durability and thermal stability. – Run at higher speeds than wheel speed brakes. Often run in common sump with differential. Similar properties to wheel speed brakes required, although noise is usually less of an issue. – Used in track type vehicles. When driving straight ahead, the clutch on each side is engaged. When steering the vehicle the steer clutch is slipping and the steer brake is applied to the side turning. Friction material needs are good durability, smooth engaging, and thermal stability. – Used in track type excavators to stop the boom rotation and to aid in hold the vehicle stable while digging 21 Slide 22 Wet Friction Material Choices 22 Slide 23 Wet Friction Material Choices • Sintered Metallic – Can withstand high pressure, but have low energy capability and low coefficient of friction. Still used in military and severe duty applications. • Graphitic material (HDT-303) – Can withstand pressures similar to bronze materials with a higher coefficient of friction and higher energy capacity. • Carbon Cloth – Very high energy material, but at a premium price • Paper materials are the material of choice for most of today’s designs, due to: – – – – – High coefficient of friction High energy absorption Low cost Low weight Can be tailored to specific performance requirements 23 Slide 24 Energy Capability Comparison 24 Slide 25 Summary of Friction Materials 85 J/cm2 - 21 bar - 2400 rpm - Cat TO-4 fluid Paper Dynamic Lockup Metallic .060/.080 .150/.170 N-414-5 .090 .153 N-452-2 .135 .150 N-653-4 .113 .142 N-670-4 .121 .144 N-360-2 .135 .174 N-266-4 .130 .172 N-269-4 .140 .200 25 Slide 26 Spec 145 (bronze) in Cat TO-4 oil Low dynamic High lockup 26 Slide 27 N-414 in Cat TO-4 oil Low coefficient paper High ratio 27 Slide 28 N-266 in Cat TO-4 oil 28 Slide 29 N-670 in Cat TO-4 oil Flatter Torque Smooth engmt 29 Slide 30 Paper Friction Materials • Friction papers are papers only in the sense that they are produced on paper making equipment. Typical friction material will contain one or more kinds of fibers, one or more fillers and a binder. • Fibers: – • Fillers – • The fibers used are cellulose, aramid, glass, mineral and carbon based. The fibers serve to establish the desired porous structure of friction papers and to also act as a carrier for the fillers during the paper making process. The fillers are many and varied, with materials such as diatomaceous earth, graphite, coke and metal oxides being very common. The various fillers act as friction modifiers and may also improve the material’s heat resistance. Binders – The binders are almost always thermosetting resins introduced into the papers by a saturation process. The resin binder is the major contributor to the final strength of the material. The resin also affects friction and durability characteristics. 30 Slide 31 Oil Types / Function 31 Slide 32 Function of the Oil • The oil used in a wet friction application has many purposes: – Cool the friction material pack by removing heat energy from the system – Lubricate the gears – Prevent corrosion – Disperse and neutralize contaminants etc. • A variety of oils are available. The type of oil used can have a big impact on friction material performance. • There are three main constituents that affect oil quality: – Viscosity – Base oil – Additives 32 Slide 33 Oil Additives • Additives are put into the Base oil to improve properties of the oil. Our testing has shown that the additives have a greater impact on performance than the type of Base fluid. Dispersants Sludge & varnish control Antioxidants Prohibit oxidation Antiwear Planetary gear, bushing, thrust washer protection Friction modifier Modify friction performance Corrosion inhibitor Prevent corrosion and rust Seal swell agent Prevent loss of fluid via seals Viscosity Improver Reduce rate of change of viscosity Pour Point Depressant Improve low temperature fluidity Foam inhibitor Foam control Red dye Identification 33 Slide 34 Friction Modifier and Antiwear Additives • Friction modifier additives are put in some oils to reduce the lockup coefficient of friction. This allows for smooth shifts in a transmission or noise reduction in brakes. • There are a variety of types of additives on the market. In addition, oils can contain different amounts of the additives. • Some oils also contain additive packages that are designed to protect the gears at elevated temperatures. At elevated temperatures, the additives precipitate a protective coating on the gears for protection against wear. • Unfortunately, the additives also precipitate out on the friction surface at elevated temperatures. This can reduce the porosity of the material and result in glazing and friction fade. 34 Slide 35 N360 Paper Friction in Various Oils Wear and Friction Level 0.160 0.140 0.120 Friction Level 0.100 0.080 Dynamic Lockup 0.060 Wear 0.040 0.020 0.000 0 1 2 3 4 Citgo 80W90 Shell Donax TD J20‐C 5 6 TO‐4 TO‐4 Emerest Mobil DTE 150 7 Slide 36 Oil Categories • The main categories of oils are: – – – – – – – Engine oils Automatic Transmission fluids (Dexron III) Caterpillar TO-4 Transmission fluids Tractor Hydraulic fluids Gear lubes Synthetic fluids Biodegradable oils • Oils within each category usually have similar performance. • Each category of fluids is designed to give specific properties. 36 Slide 37 Oil Summary • There are a lot of different oil types in use with friction materials and gears. Each is designed to give properties to meet specific applications. • Differences in the oil include: – Viscosity – Base fluid – Additive type and amount 37 Slide 38 Brake Testing 38 Slide 39 Brake Testing in different oils • Brake noise is a common problem in wet brakes. It can be caused by a number of things: – Friction material type – Type of oil used – Brake design itself • We can evaluate noise using a full scale wheel end brake. Noise is sometimes audible and can be seen in the torque trace. • A negative sloping torque trace (as speed approaches zero) is desirable to eliminate noise. 39 Slide 40 Dynamometer 17 HDT-303 in Mobil 424 fluid Quiet Flat Torque trace 40 Slide 41 Dynamometer 17 HDT-303 in Elf C4 fluid Very noisy Positive slope 41 Slide 42 Dynamometer 17 N-653in Elf C4 fluid Quiet Negative slope 42 Slide 43 Dynamometer 17 N-653 in Mobil 424 fluid Quiet Negative slope 43 Slide 44 Dynamometer 17 N-670in Elf C4 fluid Slight noise Negative slope 44 Slide 45 Dynamometer 17 Carbon Cloth in Elf C4 fluid Very quiet Negative slope Smooth torque 45 Slide 46 Dynamometer 17 HDT-303 in Elf C4 fluid Very noisy No Sturaco 46 Slide 47 Dynamometer 17 HDT-303 in Elf C4 fluid with 2% Sturaco additive 2% Sturaco No noise 47 Slide 48 Dynamometer 17 N-670in Elf C4 fluid Slight noise No Sturaco 48 Slide 49 Dynamometer 17 N-670in Elf C4 fluid with 2% Sturaco additive 2% Sturaco Quiet, smooth 49 Slide 50 Brake Testing Summary • The shape of the torque curve is indicative to the amount of noise. Sloping down is quieter. • It remains very important to establish the proper friction material – oil combination for the application. • Individual brake designs may contribute more or less noise than what we test on the dynamometer. In general, noise is less of an issue in axle speed brakes than wheel speed brakes due to lower torque loads of axle speed brakes. • Top adds may be used as a temporary fix for noise problems. 50 Slide 51 • Vehicle Simulation Test testing • CASE STUDY : Case Study – Friction drag Slide 52 • Vehicle Simulation Test testing : Case Study –Friction drag • A customer had a condition in a forklift transmission with overall performance – One material had good frictional output but had high wear – One material had low wear but friction fade • After discussions with the customer, the following test plan was developed to simulate the inching conditions of the application Slide 53 • Vehicle Simulation Test : Inching Tests • • • • • • • • • • • • 10 second drags to simulate inching conditions. Test Conditions 133 mm OD ( 2 plates) 2400 rpm 620 J/cm² 52 W/cm² Pressure = 3.6 bar (u = 0.1) Slip time = 10 sec Oil flow variable to achieve temp. Critical opposing plate temp determined to be 245C 5,000 cycles Frequency = every 30 sec. Slide 54 • Inching Comparison (Cat TO-4 fluid) 245 C Center Plate temperature Problem at critical temp Slide 55 • Inching Comparison (Cat TO-4 fluid) Solution using N-670 245 C Center Plate temperature Slide 56 • Inching Comparison (Cat TO-4 fluid) 245 C Center Plate temperature Solution using N-670 Slide 57 Inching Test for Dana - Dynamometer 41 N-670-3 - Caterpillar TO-4 fluid 245 C (475 F) Rxn plate temp 290 C (550 F) Rxn plate temp A v g. Wear Midpoint A vg. Wear 0.20 0.20 0.20 0.15 0.15 0.15 0.15 0.10 0.10 0.10 0.10 0.05 0.05 0.05 0.05 0.00 0 1000 2000 3000 4000 0.00 5000 Coefficient of Friction 0.20 Cumulative Wear - mm Coefficient of Friction Midpoint System temp limit 0.00 0 1000 Engage m e nt No. Excessive high temperature will lead to poor performance 2000 3000 Engage m e nt No. 4000 0.00 5000 Cumulative Wear - mm • Slide 58 Inching Summary • Tests were run to simulate inching a vehicle. Friction fade and wear were analyzed. • Opposing plate temperature was determined to be key to eliminate fade and reduce wear. N-670-3 did not fade if plate temperature was kept at 245 C (475 F). Slide 59 • Vehicle Simulation Test : Case Study –Brakes • CASE STUDY Slide 60 Case Study – Brake Noise • • • • • A customer using a sump brake on a loader had field complaints of brake noise A visit to the work site revieled the use of a different oil being used in the brake system Carlisle agreed to evaluate this oil on our SAE#2 dyno under the J2490 µPVT test This procedure is recognized worldwide as a method to evaluate friction couples for noise We looked at our N611 friction paper in two oils • Mobil HD80W90 ‐ the recommended oil • China Gear oil ‐ being used at the site Slide 61 SAE J2490 Dyno results Slide 62 N-611 in Mobil HD 80W90 oil Slide 63 N-611 in China gear oil Slide 64 Case Study – Brake Noise Summary • The J2490 µPVT testing indicated the following; -The N611 operation in the Mobil HD80W-90 oil developed µm/µe ratios of less than 1 indicating no propensity for noise -The N611 operation in China Gear oil developed µm/µe ratios greater than 1 indication that noise can be generated • It was recommended the site switch back to the proper oil Slide 65 Wet Brake Guidelines • To properly size the brake some initial work must be done to determine energy going into the brake • Remember storing and/or removing the heat is key to success • Calculate the energy to dissipate during the duty cycle • Include level, uphill, downhill and any retarding • Result will be Energy/min/cycle • Determine the number of brakes on the vehicle • A material selection can be determined by filling out an application data sheet Slide 66 System Design Criteria 66 Slide 67 System Designs • Coefficient of friction (or Torque) is one requirement for a friction material system. Different systems will have different requirements as to which coefficient of friction is most important. – – – – Minimum Break Away static is most important in truck clutches Minimum dynamic friction is most important in aircraft brakes Ratio between lockup and dynamic is most important in nvh sensitive applications Stability of breakaway static is most important in overload clutches. • Other important parameters to consider are: – Unit energy – Unit power – Apply pressure – Oil flow and resulting system temperature • Friction materials have limits in which they can run so material recommendations are made considering the above parameters as well as performance requirements for each application. 67 Slide 68 Unit Energy • E = ½ m V2 , where: m = mass V = velocity • E = ½ I ω2 , where: I = inertia ω = rotational speed The number and size of the friction discs is designed to keep the unit energy reasonable. In general – – – • or Low energy is considered to be less than 80 J/cm2 (400 ft-lbs / in2) Moderate energy is between 80 -160 J/cm2 (400 – 800 ft-lbs / in2) High energy is above 160 J/cm2 (800 ft-lbs / in2) The higher the unit energy of a system, the more important sufficient oil flow, oil flow distribution, and low apply pressure becomes. Otherwise the system temperature and unit power become too severe for paper materials to survive. 68 Slide 69 Energy Capability 450 410 400 Unit Energy J / cm^2 350 280 300 230 250 200 150 115 100 85 50 0 Bronze N-266 Paper N-401 Paper N-653 Carbon Paper TC-120 Carbon Cloth 69 Slide 70 Apply Pressure • In brakes, apply pressure is calculated based on stopping distance requirements. • High apply pressure may result in high friction wear or fatigue. In general: – Low pressure is considered to be less than 2,000 kPa (300 psi) – Moderate pressure is between 2,000 – 4,000 kPa (300 – 600 psi) – High pressure is above 4,000 kPa (600 psi) • Apply pressure may dictate which materials can be used based on the materials chemistry and density. 70 Slide 71 Oil flow • Oil is introduced to the friction pack either by a force fed system or a sump. A sump is not as effective for cooling the friction pack as a force fed system during long stops. But for short duration stops it is more effective but at the expense of parasitic drag. • Oil flow can be critical for friction material life. The amount of oil required is largely dependent on the amount of energy for each stop. In general: – For low energy applications, .003 l/min/cm2 may be sufficient – For moderate energy applications, at least .009 l/min/cm2 is recommended – For high energy applications, .018 l/min/cm2 may be used • The surface temperature at the friction interface must be kept cool enough to not precipitate out additives causing friction fade. 71 Slide 72 Groove patterns • The grooves are put in the friction material to allow the oil to flow across the friction surface. The friction disc is generally considered worn out when the disc wears halfway through the groove depth. • A variety of groove patterns are used depending on the application. – – – – Waffle patterns with wide grooves are common in sump applications. Two pass multiple parallel patterns are common in force fed applications. Large parts (> 380 mm) often incorporate three pass groove patterns. Oil viscosity and oil flow determine groove width. Higher viscosity oils or sump type lubrication dictate wider grooves. – Sunburst and spiral radial patterns are more common in metallic and HDT parts. – Embossed grooves are better for parasitic drag and cleanliness vs cut grooves. However, they sacrifice groove depth. 72 Slide 73 Typical Groove Patterns 73 Slide 74 Failure Modes 74 Slide 75 Failure Modes • There are basically only 3 common causes of failure for paper friction materials: – Rough Opposing Surface – Papers require surface Ra < 0.5ųm – Excessive Heat – Excessive Pressure 75 Slide 76 Friction Wear vs. Separator Plate Finish Procedure R‐79‐398 TO‐4 Oil Incremental Wear (mm) Surface Finish N653‐4 N266‐4 Total 1k 25k 50k 75k 0‐75k 10‐11 uin (0.28 um) 0.053 0.074 0.106 0.129 0.362 39‐45 uin (1.14 um) 0.070 0.352 0.426 0.395 1.243 57‐60 uin (1.52 um) 0.088 0.225 0.537 0.302 1.152 11‐12 uin (0.30 um) 0.065 0.114 0.110 0.238 0.527 26‐32 uin (0.81 um) 0.077 0.441 0.317 0.291 1.126 Slide 77 Excessive Heat Failures • Three causes of excessive heat: – High Unit energy/power • The energy absorbed by the friction material system will dictate the amount of heat to be dissipated. – Low Oil Flow • The oil cools the friction pack, so insufficient oil flow across the entire pack will lead to overheating. – Not enough Heat sink • The thickness of the opposing plates and the fixture can allow for more heat absorption. 77 Slide 78 Excessive Heat Failures (cont’d) • High heat can cause several types of failures. – Hot spotting / Warping • Hot spots can be generated on the steel opposing plates due to excessive power stops. This can lead to distortion or erratic torque behavior. – Wear • Excessive heat can break down the binder or fibers in the friction material causing premature wear. – Friction fade • Heat can cause the additives in the oil to precipitate out onto the surface of the paper. This glazing can lead to loss of coefficient over time. 78 Slide 79 Reaction plate: Moderate discoloration and material transfer Discard reaction plate Slide 80 Reaction plate: Heavy discoloration and material transfer Discard reaction plate Slide 81 Excessive Pressure Failures • Excessive apply pressure can lead to failure for a variety of reasons: – Fatigue • Paper friction materials contain fibers which can fatigue and break with continuous high loading. – Compression / Wear • High pressure can lead to early compression and / or wear of paper friction materials due to their porous nature. – Increased Power • High apply pressure leads to shorter stop times, so the energy being absorbed is dissipated in a shorter time, causing high power stops. 81 Slide 82 Approximate Pressure Limits for Paper Materials (Can be affected by other system parameters) • Material psi MPa • • • • • • • • • N-360 N-401 N-420 N-414 N-452 N-611 N-266 N-670 N-653 350 400 400 400 550 600 800 1000 + 1000 + 2.5 2.8 2.8 2.8 3.8 4.2 5.6 6.9 6.9 82 Slide 83 Design Techniques to Maximize Clutch or Brake Energy Dissipation • High Thermal Conductivity of components • More conformable friction material • Reduce the difference between the outside and inside diameters of the friction couple • Higher pressures force conformable materials to have a larger effective surface area resulting in lower peak temperatures • Groove configuration fitting the application • Specify a high energy friction material 83 Slide 84 Careful – Accidents can happen 10/24/2012 84